In the realm of heavy machinery, a comprehensive understanding of the various components that ensure operational efficiency is essential. Each section plays a crucial role in the overall functionality, contributing to both safety and performance. A detailed examination of these elements allows operators to maintain and troubleshoot equipment effectively.

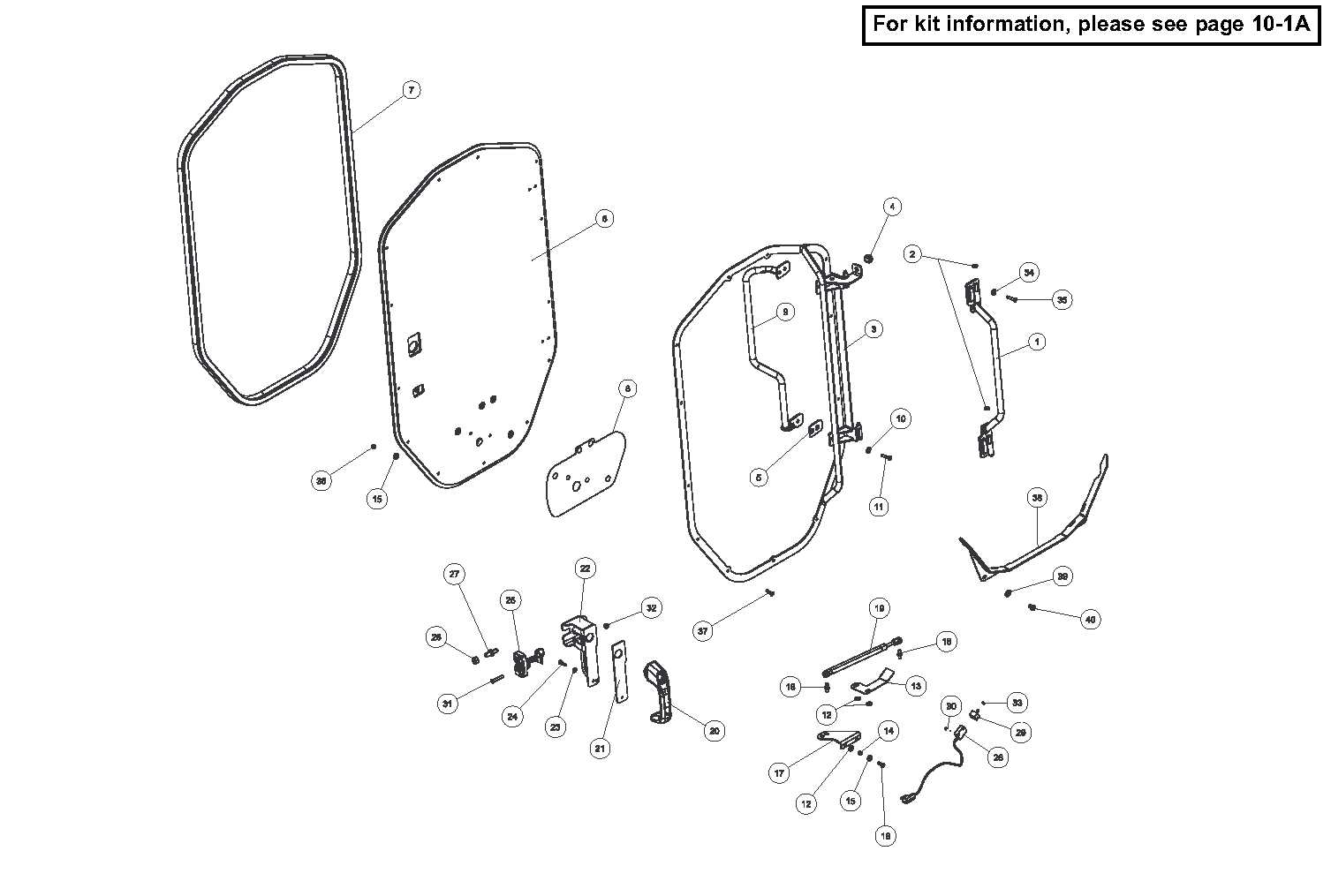

Visual aids such as schematics offer valuable insights into how these components interact. By breaking down each segment, operators can identify potential issues and make informed decisions regarding maintenance and repairs. This facilitates a deeper appreciation for the intricate design that underpins robust machinery.

Moreover, grasping the layout of these components enhances one’s ability to optimize the use of the equipment. As operators delve into the specifics, they can leverage this knowledge to ensure longevity and peak performance, ultimately leading to improved productivity and reduced downtime.

Understanding Cat Skid Steer Doors

In the realm of compact machinery, the entrance components play a pivotal role in ensuring safety and accessibility. These structures not only provide protection to the operator but also facilitate ease of entry and exit. Grasping the intricacies of these elements can significantly enhance the overall functionality and maintenance of the equipment.

Various features contribute to their design, including durability and ease of use. The mechanisms involved often incorporate advanced technology, allowing for seamless operation under various conditions. Familiarity with these components can ultimately lead to improved performance and longevity of the machinery.

Regular maintenance and understanding of the operational aspects are essential for optimal functionality. Recognizing wear and tear signs ensures timely interventions, preventing potential hazards. This awareness can also aid in selecting suitable replacements or upgrades when necessary.

Key Components of Skid Steer Doors

The functionality and durability of an operator’s enclosure rely on various essential elements. Understanding these components can enhance maintenance and ensure longevity, contributing to overall efficiency during operation. Each part plays a critical role in safeguarding the operator while allowing ease of access and visibility.

| Component | Description |

|---|---|

| Frame | The structural support that provides stability and houses other elements, often made of robust materials for added durability. |

| Seals | Gaskets or weather stripping that prevent dust, debris, and moisture from entering, ensuring a comfortable work environment. |

| Hinges | Mechanisms that allow the entryway to pivot open and closed, facilitating easy access while ensuring secure closure. |

| Glass Panels | Transparent sections that provide visibility, often made from tempered or laminated materials for safety. |

| Locking Mechanism | A system designed to secure the entryway, providing protection against unauthorized access and ensuring safety. |

Importance of Proper Door Functionality

Ensuring that entry and exit mechanisms operate smoothly is crucial for the overall safety and efficiency of any machinery. Proper functionality not only enhances accessibility but also significantly impacts operational effectiveness. When these mechanisms are well-maintained, they contribute to a seamless workflow and reduce the risk of accidents.

Safety Considerations

A malfunctioning entry system can lead to serious safety hazards. If an operator is unable to access the interior quickly during an emergency, the consequences could be dire. Regular maintenance and timely repairs of these mechanisms are essential to prevent such risks and ensure that operators can exit swiftly if needed.

Operational Efficiency

When mechanisms operate as intended, they facilitate quicker transitions between tasks. This efficiency can translate to increased productivity and reduced downtime. An effective entry system ensures that operators can focus on their work without unnecessary interruptions caused by mechanical failures.

In conclusion, maintaining optimal functionality of these access mechanisms is vital for both safety and productivity. Regular inspections and prompt interventions are key to achieving this goal.

Common Issues with Cat Door Parts

When operating heavy machinery, maintaining functionality is essential. Various components can experience wear and tear, leading to performance issues. Identifying and addressing these problems early can prevent costly repairs and ensure safety during use.

Frequent Problems

One of the most prevalent challenges involves the misalignment of components, which can hinder proper closure or secure locking mechanisms. Over time, environmental factors and constant movement can exacerbate this issue, leading to gaps that compromise security.

Wear and Tear

Another significant concern is the deterioration of seals and hinges. These parts are exposed to dust, debris, and moisture, which can cause them to break down. Regular inspection and maintenance can mitigate these effects, extending the lifespan of these essential components. Staying proactive in addressing these common issues can enhance overall machine reliability.

How to Identify Door Components

Understanding the various elements of an entryway enclosure is essential for maintenance and repairs. Recognizing each component allows for effective troubleshooting and ensures that replacements are accurate and efficient. This section will guide you through the identification process.

1. Framework: The skeleton of the entry system provides structural integrity. Look for metal or composite materials that form the edges and support the overall assembly.

2. Fasteners: These are crucial for securing different sections together. Identify screws, bolts, or clips that hold components in place, ensuring everything remains stable.

3. Sealants: Often found around the perimeter, these materials prevent air and water infiltration. Check for rubber gaskets or adhesive strips that maintain the enclosure’s efficiency.

4. Handles and Latches: Essential for functionality, these elements enable opening and closing. Examine various styles, from simple knobs to complex locking mechanisms.

5. Panels: The surfaces that make up the entryway can be made of glass, metal, or composite materials. Identifying the type will help in selecting appropriate cleaning or replacement solutions.

By familiarizing yourself with these components, you can ensure that any work performed on the entryway is done with precision and care, prolonging its lifespan and functionality.

Maintenance Tips for Skid Steer Doors

Proper upkeep of the entry mechanisms on your equipment is essential for optimal performance and longevity. Regular attention to these components not only enhances functionality but also ensures safety during operation. Here are some key practices to keep in mind for maintaining these vital features.

Regular Inspection

Frequent assessments of the closing mechanisms are crucial. Look for any signs of wear or damage, such as cracks or misalignments. Early detection of issues can prevent more significant problems and costly repairs down the line. Make it a habit to check hinges and seals for proper operation.

Lubrication and Cleaning

Keeping the moving parts well-lubricated will facilitate smooth operation. Use appropriate lubricants designed for heavy machinery. Additionally, ensure that all surfaces are clean from debris and grime, which can hinder movement and cause premature wear. Regular cleaning paired with lubrication will significantly extend the lifespan of these components.

By following these maintenance tips, you can ensure that your equipment remains functional and safe for years to come.

Replacing Damaged Door Parts

When components of your equipment’s entryway become worn or broken, it is essential to address these issues promptly to ensure functionality and safety. Neglecting repairs can lead to further damage and increased costs down the line. This section will guide you through the steps to efficiently replace these crucial elements, restoring optimal performance.

Begin by assessing the extent of the damage. Identify which components need replacement and gather the necessary tools for the job. It’s advisable to consult a manual or resource for specific instructions related to your equipment model. Once you have the right replacement items, remove the damaged components carefully, ensuring not to disturb adjacent elements.

Next, install the new items by following the reverse steps of removal, making sure each piece is securely fitted. After installation, test the mechanism to confirm everything operates smoothly. Regular maintenance checks will help prevent future issues and extend the lifespan of your equipment.

Where to Find Replacement Parts

When it comes to sourcing components for your machinery, understanding where to look can save both time and money. Various avenues exist to obtain the necessary items, whether you prefer online shopping or visiting local suppliers. Knowing the right places can ensure you find high-quality replacements that meet your equipment’s specifications.

One of the most convenient options is online marketplaces, where numerous retailers offer a vast selection of components. Websites dedicated to heavy machinery often provide detailed catalogs, allowing you to search by model and category. Additionally, manufacturer websites can be a reliable source, ensuring that you get original components designed for your machine.

Local dealerships and authorized distributors also play a vital role in the supply chain. They typically stock essential items and can provide expert advice on compatibility and installation. If you need parts quickly, visiting a nearby store can expedite the process, minimizing downtime.

For those seeking cost-effective solutions, consider exploring salvage yards or second-hand markets. These places often have a range of usable components at reduced prices. However, it’s crucial to verify the condition and compatibility of these items before purchase.

Lastly, online forums and communities dedicated to machinery enthusiasts can offer valuable insights. Members often share tips on where to find quality components and may even offer leads on hard-to-find items. Engaging with these groups can enhance your knowledge and help you connect with trustworthy suppliers.

Using Diagrams for Assembly Guidance

Visual representations serve as invaluable tools for facilitating the assembly process of complex machinery. They break down intricate procedures into manageable steps, ensuring accuracy and efficiency.

- Enhances understanding of components.

- Clarifies the order of assembly.

- Reduces the likelihood of errors.

- Facilitates quicker troubleshooting.

By utilizing these visual aids, individuals can navigate the assembly process with greater confidence and precision, ultimately leading to a more successful outcome.