When it comes to maintaining outdoor power equipment, having a clear understanding of the engine’s internal structure is essential. Familiarity with the arrangement of various elements can significantly enhance troubleshooting efforts and improve repair processes. This knowledge not only facilitates efficient maintenance but also extends the lifespan of the machinery.

Within the realm of small engines, the configuration of components plays a pivotal role in their functionality. Each piece, from the ignition system to the fuel delivery mechanism, serves a specific purpose that contributes to the overall performance. Recognizing how these elements interconnect allows for a more streamlined approach to repairs and upgrades.

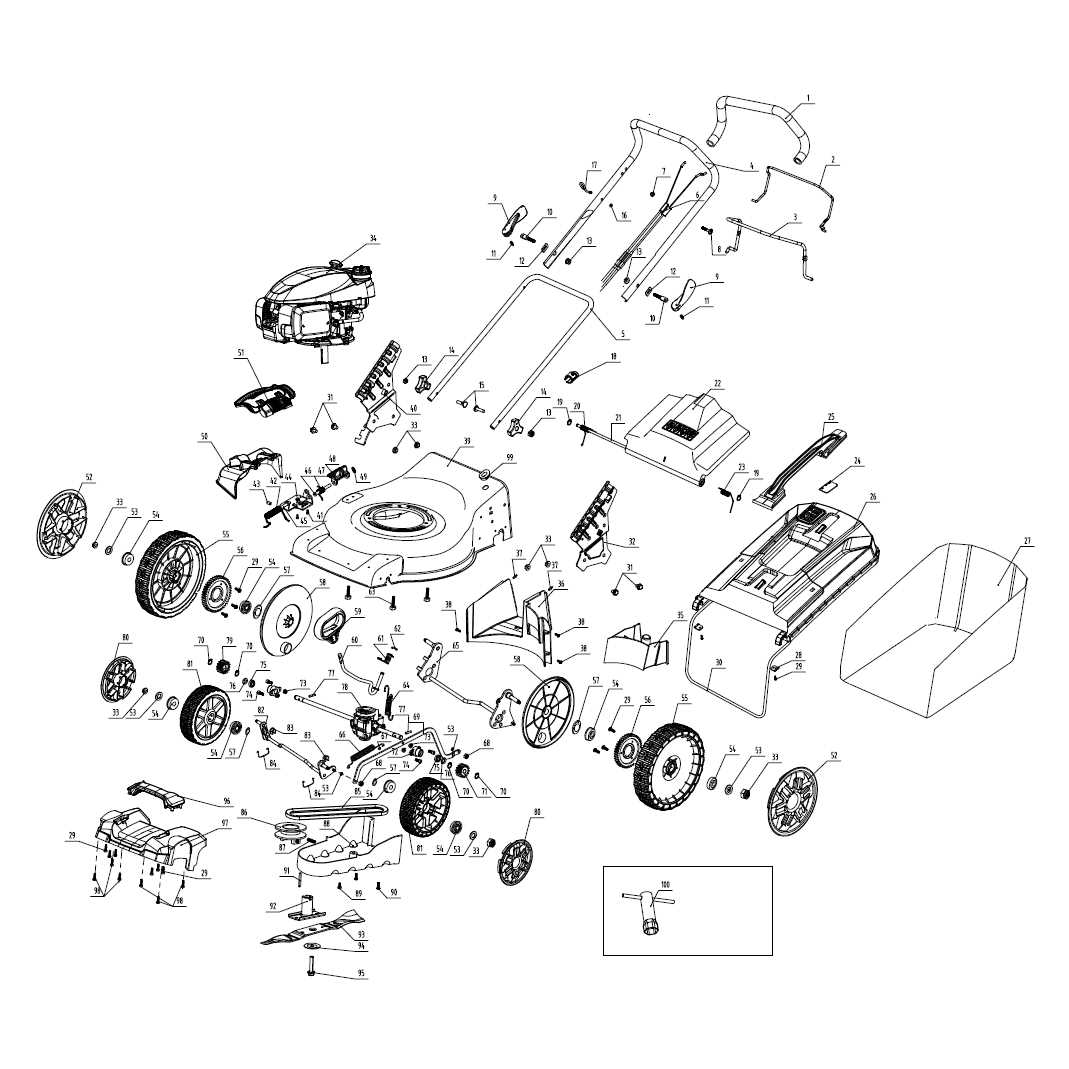

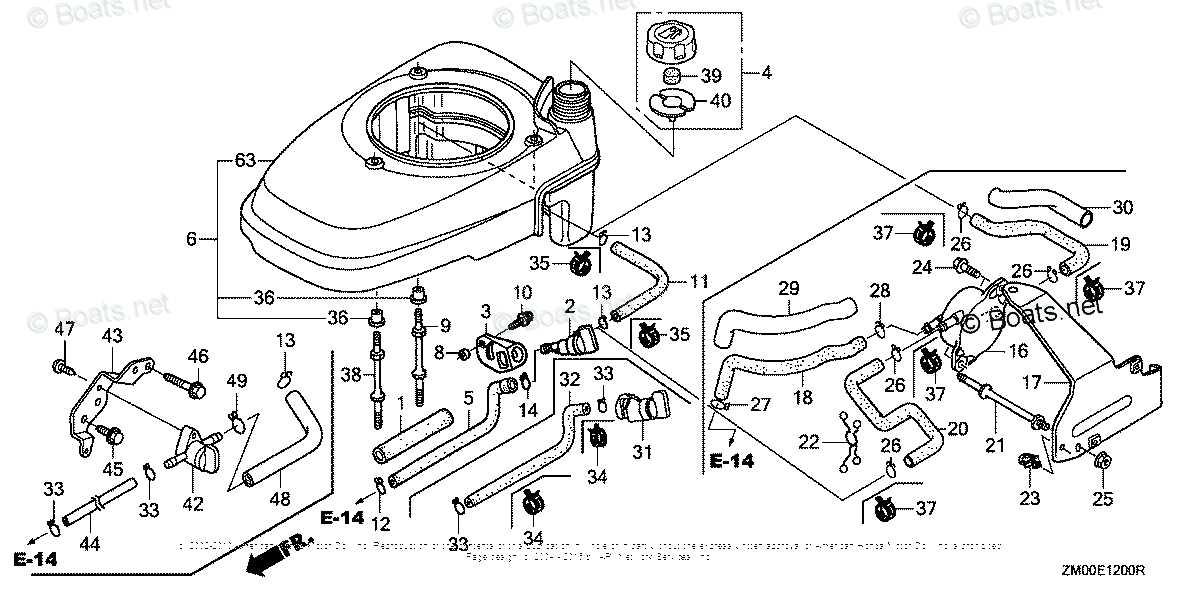

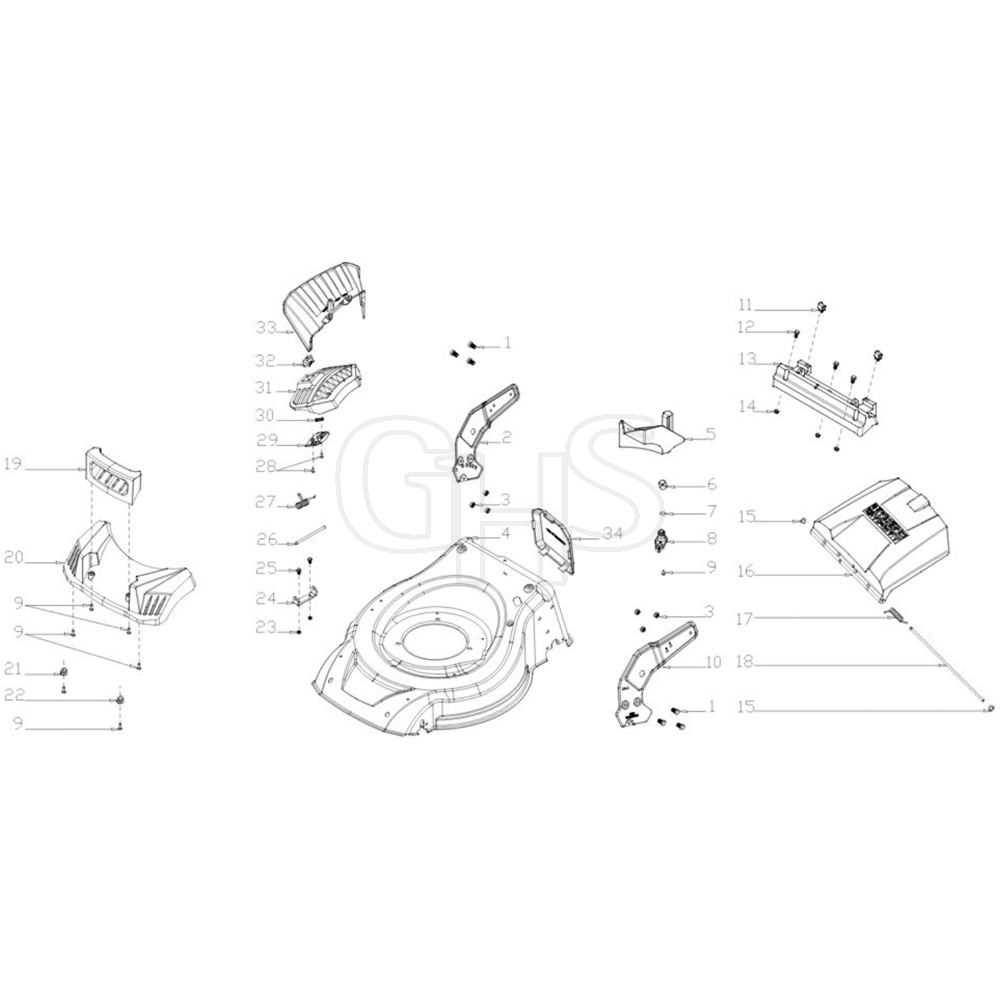

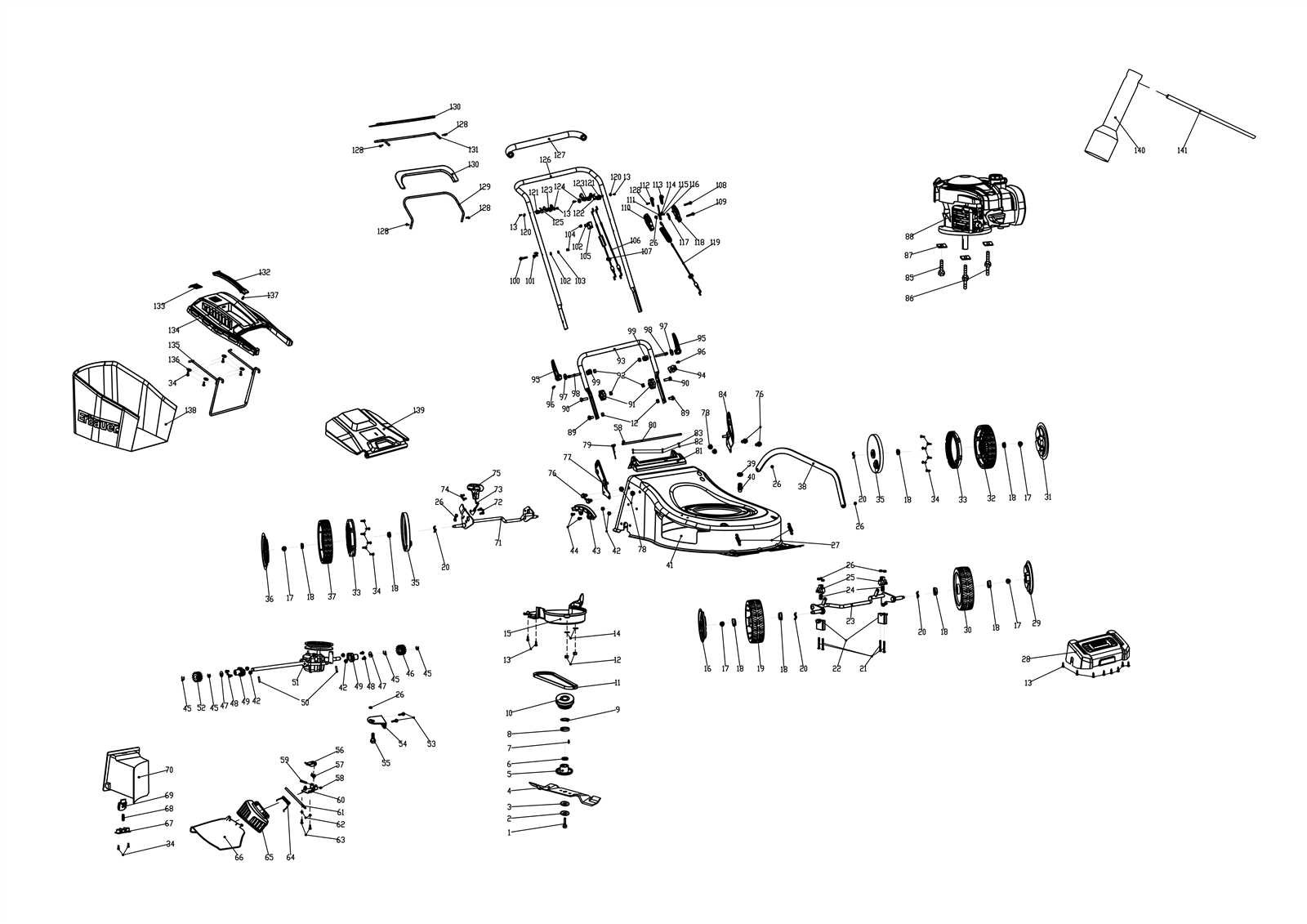

Visual representations of these layouts are invaluable tools for technicians and enthusiasts alike. They provide a detailed overview of each component’s placement and relationship to others, making it easier to identify issues and carry out effective solutions. Whether you’re a seasoned mechanic or a novice, having access to these illustrations can empower you to tackle any challenges that arise.

Understanding Honda GCV170 Engine Components

This section explores the essential elements that contribute to the performance and functionality of a specific small engine model. By examining these crucial components, users can gain insights into how they work together to ensure optimal operation.

| Component | Description |

|---|---|

| Air Filter | Traps dirt and debris, ensuring clean air enters the engine. |

| Spark Plug | Ignites the fuel-air mixture for combustion. |

| Fuel Tank | Stores the fuel necessary for engine operation. |

| Cylinder | Houses the piston and is essential for combustion. |

| Exhaust System | Releases combustion gases from the engine. |

Key Parts of the GCV170 Engine

Understanding the essential components of a small engine is crucial for maintenance and performance. Each element plays a vital role in ensuring efficient operation, contributing to overall functionality and durability.

The power source is the heart of the engine, providing the necessary energy for operation. Complementing it is the ignition system, which sparks the combustion process, while the fuel delivery system ensures the right mix of air and fuel reaches the combustion chamber. Additionally, the cooling mechanism prevents overheating, preserving the integrity of all components.

Moreover, the exhaust system is responsible for directing harmful gases away, maintaining optimal performance. The lubrication system is equally important, reducing friction and wear between moving parts. Finally, the chassis housing contains and protects these vital components, ensuring everything works seamlessly together.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a detailed view of the various elements and their relationships within a system, helping users identify what they need to address or replace.

Familiarize yourself with the symbols and notations used in the visuals. Each element typically has a unique identifier, which is crucial for locating the correct item in lists or catalogs. Pay attention to the numbering system as it often correlates with part references.

Next, focus on the layout. Components are usually arranged logically, reflecting how they fit together in the machinery. This organization aids in visualizing the assembly process and pinpointing any potential issues.

Lastly, consult accompanying documentation. Detailed descriptions and specifications usually accompany these illustrations, offering essential insights and guidance. This combination enhances your ability to tackle repairs efficiently and effectively.

Common Issues with GCV170 Parts

When dealing with outdoor power equipment, various components may encounter common problems that can affect performance and efficiency. Understanding these issues is essential for maintaining optimal functionality.

-

Fuel System Problems:

- Clogs in fuel lines can lead to insufficient fuel flow.

- Old or contaminated fuel can cause starting issues.

-

Air Filter Issues:

- A dirty or clogged air filter restricts airflow, impacting engine performance.

- Regular cleaning or replacement is crucial to avoid overheating.

-

Starter Malfunctions:

- Worn pull cords can make starting difficult.

- Defective recoil mechanisms may require complete replacement.

-

Electrical Component Failures:

- Battery issues can lead to starting failures or erratic performance.

- Corroded terminals may disrupt power supply.

-

Lubrication Problems:

- Inadequate oil levels can result in increased friction and overheating.

- Old oil can lose its effectiveness, requiring timely changes.

Addressing these common challenges promptly can enhance the longevity and reliability of your equipment, ensuring it operates efficiently throughout its lifespan.

Replacing Parts: A Step-by-Step Guide

Maintaining equipment in optimal condition requires a clear understanding of the replacement process. This section will provide a comprehensive overview of how to effectively swap out components, ensuring your machinery runs smoothly and efficiently.

Preparation for Replacement

Before beginning the replacement procedure, it’s essential to gather the necessary tools and familiarize yourself with the components involved. Follow these steps:

- Identify the specific component that needs replacement.

- Gather appropriate tools such as wrenches, screwdrivers, and pliers.

- Ensure you have the correct replacement part on hand.

- Read the equipment manual for specific instructions related to the task.

Step-by-Step Replacement Process

Follow these steps to effectively replace the component:

- Disconnect the equipment from the power source to ensure safety.

- Remove any protective covers or guards to access the part.

- Carefully detach the old component, taking note of how it is installed.

- Install the new part, ensuring it is aligned correctly.

- Reassemble any covers or guards that were removed.

- Reconnect the power source and conduct a test run to ensure everything is functioning properly.

Maintaining Your Honda GCV170

Regular upkeep of your outdoor equipment ensures optimal performance and longevity. By following a systematic maintenance routine, you can prevent common issues and enhance the efficiency of your machine. This guide will cover essential practices to keep your engine running smoothly.

Routine Checks

Start with frequent inspections of vital components. Check the air filter to ensure it is clean and free from debris. A clogged filter can restrict airflow, impacting performance. Additionally, examine the oil level and quality; changing the oil at recommended intervals is crucial for engine health.

Seasonal Maintenance

As seasons change, so do maintenance needs. Before winter storage, drain any residual fuel to prevent degradation and clogging. In spring, inspect the spark plug for wear; replacing it can significantly improve starting and efficiency. Always ensure that the blades are sharp for effective cutting.

Staying proactive with maintenance not only saves time and money but also ensures your equipment operates at its best for years to come. Embrace these practices to enjoy a hassle-free experience!

Where to Find Replacement Parts

Locating suitable components for your outdoor equipment can significantly enhance its performance and longevity. Whether you’re in need of a specific element or looking to stock up on essentials, understanding where to search can save both time and effort.

Online Retailers: Numerous e-commerce platforms specialize in offering a wide range of components for various machinery. These sites often provide detailed descriptions, compatibility information, and customer reviews to help you make informed choices.

Local Dealers: Authorized dealers are a reliable source for genuine components. Visiting a nearby store allows you to consult with knowledgeable staff who can guide you to the right items and answer any questions.

Salvage Yards: For those seeking budget-friendly options, salvage yards can be a treasure trove of usable components. While the inventory may vary, you might find exactly what you need at a fraction of the cost.

Manufacturer Websites: Many manufacturers maintain official websites that feature a section for ordering components directly. This ensures you receive high-quality, compatible items specifically designed for your equipment.

Forums and Community Groups: Engaging with online communities can be beneficial for discovering where to purchase components. Members often share their experiences, recommend sources, and sometimes offer to sell or trade items.

By exploring these avenues, you can effectively locate the necessary components to keep your equipment running smoothly and efficiently.

Comparing GCV170 with Other Models

When evaluating small engines, it is essential to understand the unique features and performance capabilities of various models. This analysis provides insights into how one specific engine stacks up against its competitors in terms of efficiency, reliability, and ease of maintenance. By comparing these characteristics, users can make informed decisions tailored to their specific needs.

Performance: In terms of power output, some models may excel in delivering higher torque, making them suitable for heavier tasks. Conversely, others prioritize fuel efficiency, allowing for longer operational periods without frequent refueling. Understanding these differences can significantly impact user experience.

Durability: Construction materials and design play a critical role in longevity. Certain engines are built with advanced materials that resist wear and tear, while others may require more frequent repairs. Assessing durability helps users gauge the long-term investment of their chosen engine.

Maintenance: User-friendliness is another aspect where models diverge. Some require regular servicing that can be cumbersome, whereas others are designed for easy access to components, facilitating straightforward upkeep. This factor can influence the overall satisfaction of ownership.

Ultimately, comparing various engines allows potential buyers to select the best option based on their specific requirements, whether they seek power, efficiency, or ease of care.

Tips for DIY Repairs and Maintenance

Maintaining your equipment can save time and money, ensuring longevity and optimal performance. With a little knowledge and the right tools, you can tackle various tasks confidently. Here are some essential strategies to guide you through the process.

Understand Your Equipment

Before beginning any repairs, take the time to familiarize yourself with the machine’s components. Referencing a reliable guide can provide insights into the various parts and their functions, allowing for a more effective approach. Knowledge is key to successful maintenance.

Gather Necessary Tools

Having the right tools on hand is crucial for efficient repairs. Ensure you possess basic equipment such as wrenches, screwdrivers, and safety gear. Investing in quality tools will enhance your ability to perform tasks effectively and safely.