In the realm of heavy machinery, comprehending the intricate network of elements that make up these powerful machines is essential. Each component plays a crucial role in ensuring optimal functionality and efficiency during operation.

By examining the various sections of an excavator, one can gain valuable insights into how these units operate as a cohesive whole. From the hydraulic systems that enable movement to the structural elements that provide stability, every piece contributes to the ultimate performance.

Delving into the specifics of each segment not only enhances maintenance practices but also aids in troubleshooting potential issues. This knowledge empowers operators and technicians alike to maximize the lifespan and productivity of their machinery.

Understanding Backhoe Parts

Exploring the essential components of excavation machinery is crucial for effective operation and maintenance. Each element plays a significant role in enhancing functionality and ensuring longevity. Grasping these elements will ultimately improve both efficiency and safety on the job site.

Key Components

- Loader Arm

- Dipper Stick

- Bucket

- Chassis

- Hydraulic System

Functions of Each Element

- Loader Arm: Responsible for lifting and moving materials.

- Dipper Stick: Extends the reach of the machinery for digging.

- Bucket: Used for scooping and transporting soil or debris.

- Chassis: Provides stability and support for the machine.

- Hydraulic System: Powers the movement and functions of all other components.

Essential Components of a Backhoe

Understanding the fundamental elements of this powerful machine is crucial for anyone involved in construction or excavation. These components work together seamlessly to enhance efficiency and performance, making the equipment indispensable for various tasks. Each segment plays a specific role in ensuring that the overall functionality is optimized for demanding environments.

Key Functional Elements

Among the most critical components are the digging mechanism and the lifting system. The digging tool, often characterized by its curved shape, is designed for breaking ground and moving material. The lifting apparatus, typically located at the rear, provides the ability to hoist heavy loads, showcasing the versatility of this machinery. Together, these elements allow for a range of applications, from trenching to lifting and moving materials.

Support Structures

Equally important are the support structures, which include the chassis and hydraulic systems. The chassis forms the backbone of the machine, providing stability and support during operation. Meanwhile, hydraulic systems are vital for powering movement and controlling the various attachments, ensuring that the equipment operates smoothly under different conditions. Understanding these crucial systems is essential for maintenance and effective usage.

Common Backhoe Attachments Explained

In the realm of excavation and construction, various tools enhance the versatility and efficiency of machinery. Understanding these essential implements is crucial for optimizing operations on the job site. Each attachment serves a distinct purpose, contributing to the overall functionality and adaptability of the equipment.

Bucket: The most recognizable accessory, the bucket is designed for digging, scooping, and transporting materials. Different sizes and shapes are available to accommodate various tasks, from trenching to loading.

Thumb: This attachment acts like an opposable digit, allowing for better grip on irregularly shaped objects. It’s invaluable for picking up and moving debris or rocks, providing added precision in handling.

Auger: Ideal for drilling holes in the ground, this tool is commonly used for installing fence posts or planting trees. Its spiral design facilitates efficient soil removal, making it easier to create deep, narrow holes.

Breaker: For tasks involving demolition, the breaker attachment delivers powerful impact energy to fracture concrete or asphalt. This makes it indispensable for renovation projects or road work.

Ripper: Designed to penetrate tough surfaces, the ripper is particularly useful in breaking up hard soil or asphalt. Its pointed design enables effective tearing through challenging materials.

Each of these tools enhances the capability of the machine, enabling operators to tackle a wide range of projects with increased efficiency and effectiveness. Understanding the roles of these attachments allows for better planning and execution of various tasks on site.

Importance of Maintenance for Backhoe Parts

Regular upkeep of machinery components is crucial for ensuring optimal performance and longevity. Neglecting this responsibility can lead to significant issues, impacting efficiency and increasing operational costs. By prioritizing maintenance, operators can prevent unexpected breakdowns and extend the lifespan of their equipment.

Timely inspections allow for early detection of wear and tear, which can be addressed before escalating into more serious problems. This proactive approach minimizes downtime and keeps projects on schedule. Moreover, maintaining critical components enhances safety for operators and those working in proximity to the equipment.

Implementing a consistent maintenance routine not only preserves functionality but also ensures compliance with industry standards. Investing in regular service can lead to substantial savings in the long run, as replacing malfunctioning elements is often more costly than routine checks and repairs. In conclusion, a commitment to upkeep fosters reliability and productivity in any operation relying on heavy machinery.

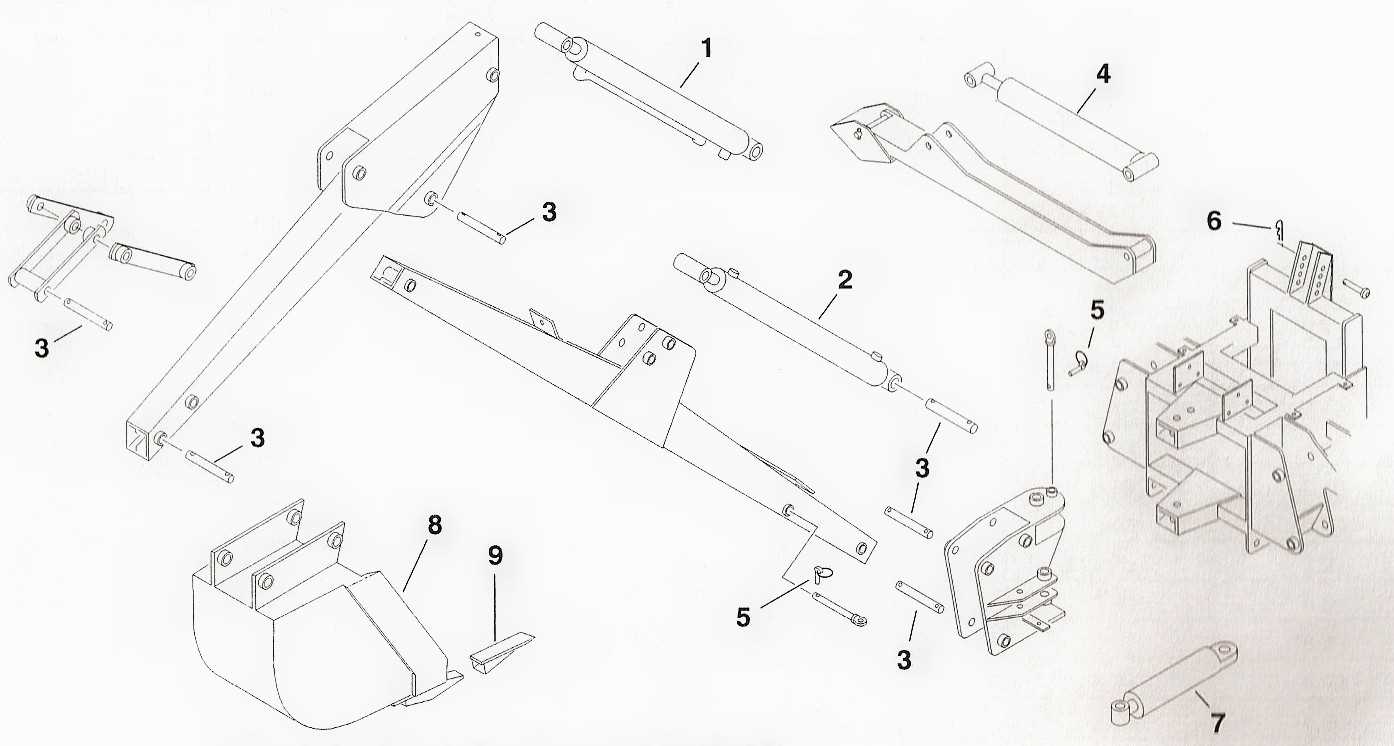

How to Read Backhoe Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to work with heavy machinery. These visual guides provide essential information about components and their relationships, allowing for better maintenance and repair practices. By familiarizing yourself with the layout and symbols used in these representations, you can improve your troubleshooting skills and efficiency.

Identifying Components

The first step in interpreting these illustrations is to identify individual elements. Each part is typically labeled with a reference number, which corresponds to a list in the manual. Take the time to match these numbers with their descriptions to gain a clearer understanding of each component’s function.

Understanding Connections

Another crucial aspect is recognizing how different components are interconnected. Lines often represent hydraulic or electrical connections, while arrows may indicate the direction of movement or flow. Pay attention to these details as they reveal how the entire system operates together.

In summary, becoming proficient at reading these technical visuals not only facilitates repairs but also enhances overall operational knowledge, ensuring your equipment runs smoothly and efficiently.

Identifying Backhoe Problems via Diagrams

Understanding mechanical issues can be challenging, but visual representations provide valuable insights into potential malfunctions. By studying these illustrations, operators and technicians can effectively pinpoint problems and streamline the repair process.

When analyzing visual aids, consider the following key areas:

- Component Relationships: Recognizing how various elements interact helps identify where failures may occur.

- Common Failure Points: Certain areas are prone to wear and tear; visual guides often highlight these hotspots.

- Assembly Instructions: Understanding how parts fit together can reveal misalignments or improper installations.

To diagnose issues effectively, follow these steps:

- Review the Visuals: Begin by examining the schematic for a comprehensive overview of the machinery.

- Identify Symptoms: Note any unusual sounds or performance issues that correlate with specific components.

- Trace the Problem: Use the illustration to follow connections and locate the source of the problem.

- Consult Manuals: Refer to technical manuals for additional details on each component’s function and potential failure modes.

By leveraging these visual tools, operators can enhance their diagnostic skills, leading to more efficient maintenance and repair strategies.

Best Practices for Parts Replacement

Ensuring the longevity and efficiency of machinery involves careful consideration when it comes to component swaps. Adhering to established guidelines not only enhances performance but also minimizes the risk of future breakdowns. Understanding the optimal approaches to substitutions can significantly impact overall operational success.

1. Assess Compatibility: Before proceeding with any exchange, it is crucial to verify that the new component aligns perfectly with existing systems. Checking specifications and compatibility will prevent malfunctions and ensure seamless integration.

2. Prioritize Quality: Always opt for high-quality replacements, even if they come at a higher cost. Durable and reliable components often lead to fewer issues in the long run, enhancing the overall efficiency of the machinery.

3. Follow Manufacturer Guidelines: Adhering to the recommendations provided by the original equipment manufacturer is essential. These instructions are designed to ensure proper fit and function, as well as to maintain warranty coverage.

4. Document the Process: Keeping detailed records of all substitutions made can prove invaluable for future maintenance. Documentation aids in tracking performance and identifying recurring issues over time.

5. Regular Maintenance Checks: After replacing any component, conduct routine inspections to ensure everything operates smoothly. Regular checks help detect potential problems early, preventing costly repairs and downtime.

6. Consult Professionals: If uncertain about any aspect of the replacement process, seek advice from experts. Their experience can provide insights that enhance both safety and effectiveness.

By following these best practices, individuals can ensure that their machinery remains in optimal condition, thereby maximizing productivity and minimizing the likelihood of unexpected failures.

Tools Needed for Backhoe Repair

Ensuring the longevity and efficiency of heavy machinery requires a comprehensive set of instruments. Having the right tools at your disposal not only facilitates repairs but also enhances overall performance. From specialized equipment to basic hand tools, each plays a crucial role in maintenance and restoration.

Essential Instruments: Start with a wrench set to handle various bolt sizes, and include screwdrivers for precision tasks. A socket set is vital for accessing hard-to-reach fasteners. Don’t forget a hammer and pry bar for additional leverage when necessary.

Diagnostic Tools: To diagnose issues effectively, a multimeter for electrical systems and pressure gauges for hydraulic evaluations are indispensable. These instruments help pinpoint problems before they escalate.

Safety Gear: Equipping yourself with safety glasses, gloves, and a hard hat ensures protection while performing repairs. Prioritizing safety is paramount in any maintenance environment.

Ultimately, having a well-organized toolkit tailored for repair tasks not only saves time but also leads to successful outcomes. Investing in quality tools enhances both the repair process and the machinery’s lifespan.

Resources for Backhoe Parts Information

Finding reliable information about machinery components is crucial for maintenance and repairs. Access to comprehensive resources can help users identify necessary items, understand their functionality, and ensure optimal performance of their equipment. A variety of platforms and publications provide detailed insights and technical data to assist both professionals and enthusiasts alike.

Online Platforms

Numerous websites specialize in offering extensive catalogs, technical manuals, and user forums. These platforms often feature search functionalities that allow users to locate specific components easily. Many sites also provide diagrams and illustrations that clarify assembly and disassembly processes, aiding in accurate identification and replacement of items.

Manufacturer Resources

Official manufacturer websites frequently publish detailed specifications, service bulletins, and user guides. These documents are invaluable for obtaining precise information about each component, including compatibility and maintenance schedules. Additionally, contacting customer support can yield personalized assistance and expert advice tailored to individual needs.