The examination of intricate mechanisms is essential for understanding the functionality of various devices. This section delves into the organization and arrangement of elements within a specific machine, highlighting how each part contributes to the overall operation. By dissecting these components, users can gain insights into maintenance, troubleshooting, and enhancing efficiency.

Recognizing the individual elements and their interconnections allows for a clearer perspective on the system as a whole. This knowledge empowers users to identify potential issues and implement solutions effectively. Moreover, a comprehensive overview aids in the selection of suitable replacements or upgrades, ensuring optimal performance.

Ultimately, a thorough exploration of the layout serves as a valuable resource for both novice and experienced users. Whether for repair, modification, or simply increasing one’s understanding, this knowledge enhances one’s ability to interact with and utilize the device proficiently.

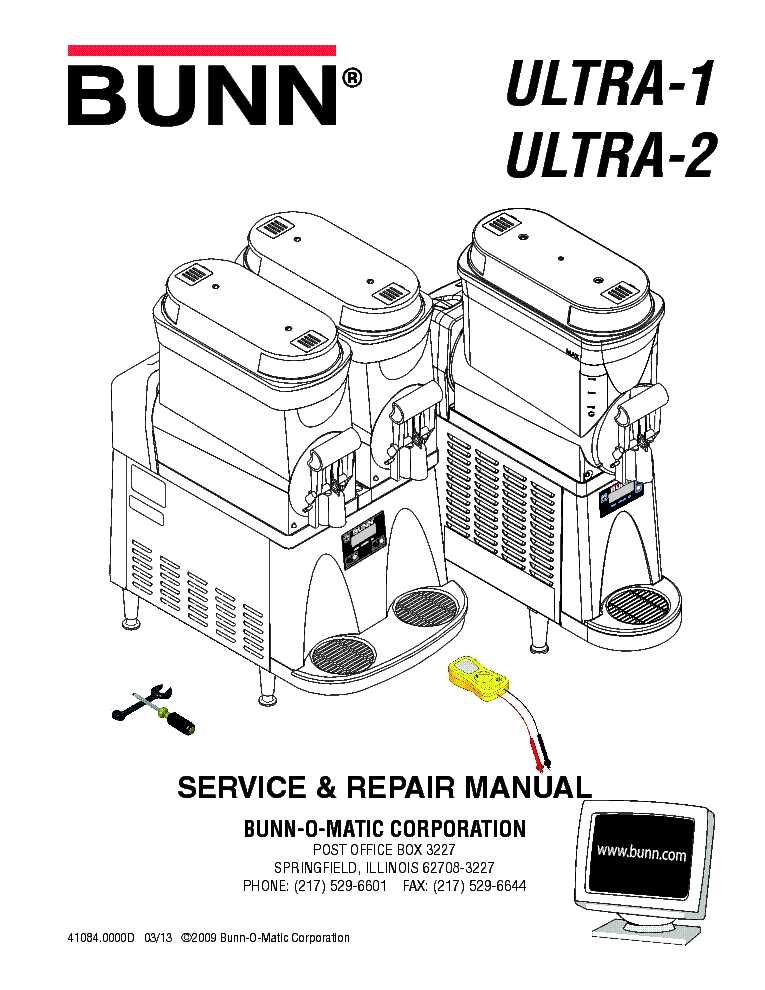

Essential Parts of Bunn Models

Understanding the fundamental components of coffee brewing machines is crucial for optimal performance and maintenance. Each model incorporates various elements that work together to ensure a consistent brewing experience. Recognizing these key components can enhance both usability and longevity.

One of the primary elements is the heating unit, which plays a vital role in regulating water temperature during the brewing process. Additionally, the water reservoir holds the liquid before it is heated, allowing for efficient brewing cycles. The filter basket is essential for holding coffee grounds, ensuring that the brewed beverage is free of sediment.

Another important component is the brew basket, which facilitates the flow of water through the coffee grounds, maximizing extraction. The carafe serves as the vessel for the finished product, designed to maintain temperature and flavor. Lastly, control panels provide users with the ability to adjust settings for customized brewing preferences.

Functionality of Bunn Brewing Systems

Brewing equipment plays a crucial role in the preparation of quality beverages, ensuring consistent flavor and temperature. The efficiency of such systems is rooted in their design, which combines various components to optimize the brewing process. Understanding the functions of these elements helps users maximize their brewing experience.

The brewing process typically involves several key stages, each performed by specific components that work in harmony. Below is a summary of the primary functions of these systems:

| Component | Function |

|---|---|

| Water Reservoir | Stores water at the required temperature for brewing. |

| Brewing Chamber | Mixes hot water with ground coffee to extract flavors. |

| Drip Tray | Collects excess liquid during brewing to prevent spills. |

| Heating Element | Maintains optimal water temperature throughout the brewing cycle. |

| Control Panel | Allows users to adjust settings for brewing strength and time. |

Each element’s functionality is vital for delivering high-quality brewed beverages, making it essential for users to understand how they contribute to the overall operation of the equipment.

Common Issues with Bunn Parts

When it comes to brewing equipment, various complications can arise that affect performance and efficiency. Understanding these frequent problems can help in troubleshooting and maintaining optimal functionality. Issues often stem from wear and tear, improper usage, or inadequate maintenance, leading to undesirable outcomes in the brewing process.

Worn Seals and Gaskets

One of the prevalent concerns involves the degradation of seals and gaskets. Over time, these components may lose their integrity, resulting in leaks and a decline in brewing quality. Regular inspection and timely replacement are essential to ensure a consistent flow and prevent potential damage.

Heating Element Failures

Another common issue pertains to heating elements, which can malfunction due to electrical faults or mineral buildup. This can lead to insufficient heating or uneven temperatures, adversely affecting the flavor profile of the brewed beverage. Routine cleaning and periodic checks can help mitigate these risks and prolong the lifespan of the equipment.

Maintenance Tips for Bunn Machines

Regular upkeep of coffee brewing equipment is essential for ensuring optimal performance and longevity. Implementing effective maintenance strategies can help prevent common issues and enhance the quality of the beverage produced. Here are some helpful practices to consider for preserving the functionality of your brewing device.

Cleaning Procedures

Maintaining cleanliness is crucial in preserving the flavor and quality of your brews. Here are steps to follow:

| Task | Frequency | Description |

|---|---|---|

| Descaling | Every 1-3 months | Remove mineral buildup using a suitable descaling solution. |

| Wipe Exterior | Weekly | Clean the outer surfaces with a damp cloth to avoid dust accumulation. |

| Clean Brew Basket | After Each Use | Rinse and dry the brew basket to eliminate coffee residue. |

Routine Inspections

Conducting periodic assessments is vital for identifying potential problems before they escalate. Focus on the following areas:

| Component | Inspection Frequency | What to Look For |

|---|---|---|

| Heating Element | Monthly | Check for any signs of damage or corrosion. |

| Water Reservoir | Weekly | Ensure it’s clean and free from buildup or debris. |

| Electrical Connections | Monthly | Look for loose or frayed wires to ensure safety. |

Replacing Worn Out Components

Over time, various elements of your machine can experience wear and tear, affecting overall performance. Regular maintenance ensures that everything continues running smoothly. By identifying faulty or damaged pieces early, you can replace them to extend the lifespan of the equipment.

To successfully swap out deteriorated elements, follow these key steps:

- Unplug the machine and ensure it has cooled down completely.

- Identify the components that need replacing by checking for visible signs of damage or malfunction.

- Consult your user manual to ensure you

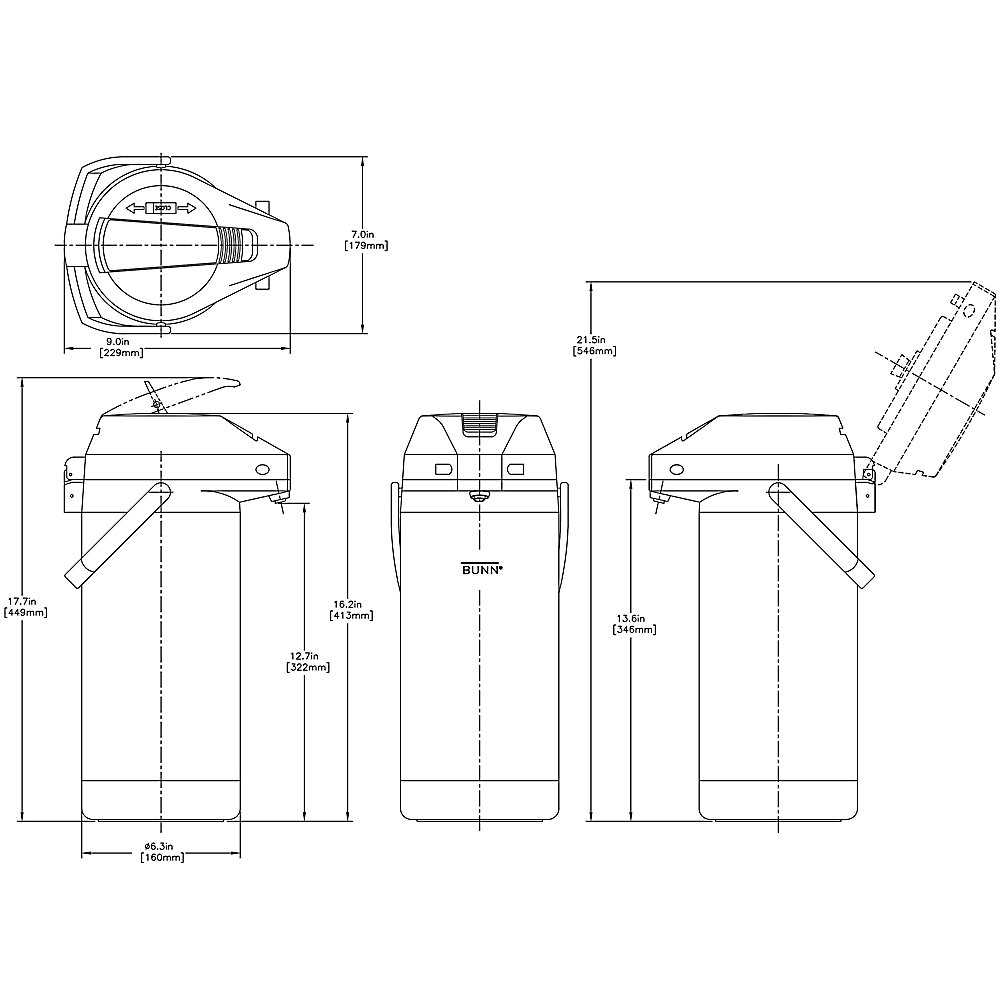

Identifying Components by Model

When working with various models, it is essential to recognize how specific elements fit within the overall machine structure. Understanding the design of each unit allows for easier identification of necessary components and ensures compatibility during maintenance or replacement.

Model-Specific Features

Each model may have distinct characteristics that influence the type and arrangement of its internal mechanisms. By familiarizing yourself with these details, you can quickly pinpoint the correct component. Looking at the configuration can give clues to the functionality and purpose of each part.

Locating Essential Mechanisms

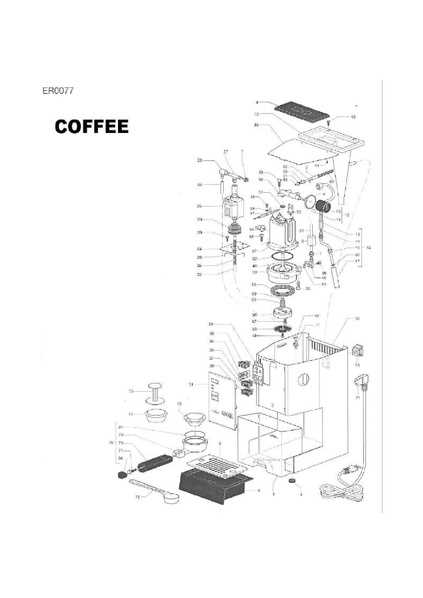

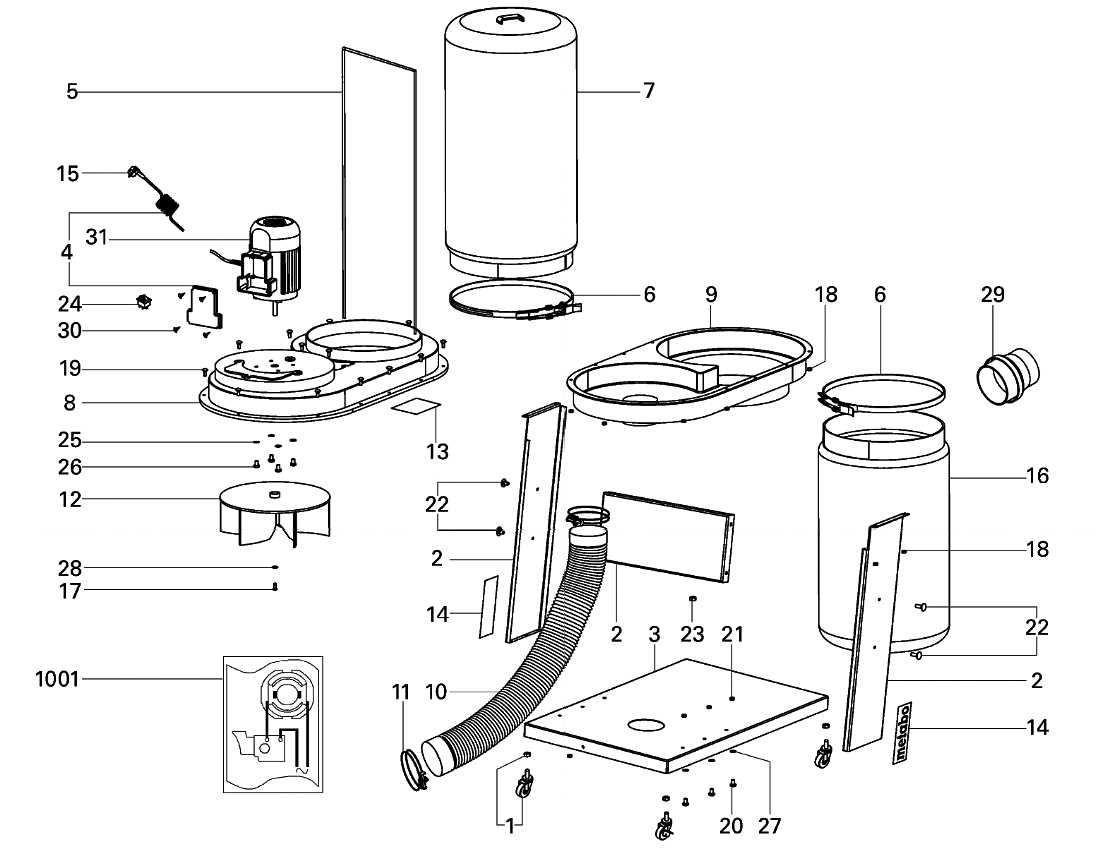

Visual Guide to Bunn Diagrams

This section offers a detailed overview of how to navigate various component layouts for coffee machines. By understanding the visual representations, users can easily identify key elements and streamline troubleshooting or maintenance tasks. The structured illustrations provide clarity in distinguishing different mechanisms, ensuring smoother assembly or repair processes.

Key Elements in Machine Layouts

When working with appliance blueprints, it’s important to recognize the different symbols and placements of mechanisms. These visuals help in understanding the role of each section, making it easier to follow instructions for replacements or repairs.

Understanding Connections and Flow

Connection points and fluid paths within these schematics highlight how the system operates. This visual aid simplifies identifying issues related to misalignments or blockages.

Component Function Heating Element Provides heat to the system Benefits of Using Authentic Parts

When maintaining any equipment, choosing original components offers a range of advantages that contribute to the overall performance and longevity of the device. These genuine elements are specifically designed to meet the standards required for optimal functionality, ensuring compatibility and reliability.

Improved Durability: Original replacements are built with high-quality materials, enhancing the lifespan of the equipment and reducing the frequency of repairs. This leads to a smoother operation over a prolonged period.

Enhanced Efficiency: By using manufacturer-approved components, the device functions at its best, minimizing energy consumption and preventing potential malfunctions that can arise from incompatible or substandard alternatives.

Safety Assurance: Authentic pieces are tested for safety and adhere to strict guidelines, helping to protect users from hazards that could occur with unverified substitutes. This ensures safe operation in both commercial and home environments.