When it comes to maintaining a utility vehicle, having a clear understanding of its component layout is essential for efficient servicing and repairs. This section provides a comprehensive overview of the various elements that make up these versatile machines. By familiarizing yourself with the configuration and organization of the components, you can ensure optimal performance and longevity.

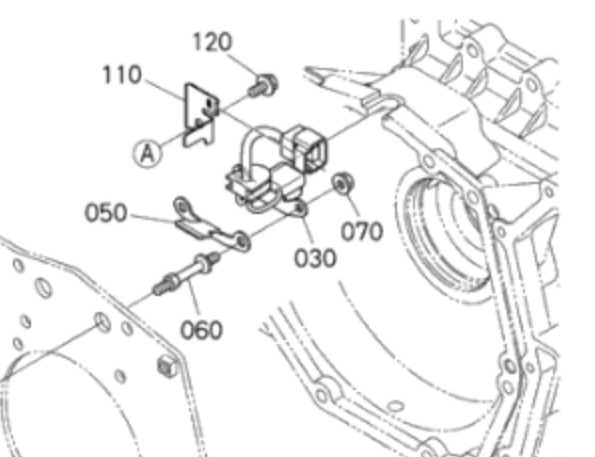

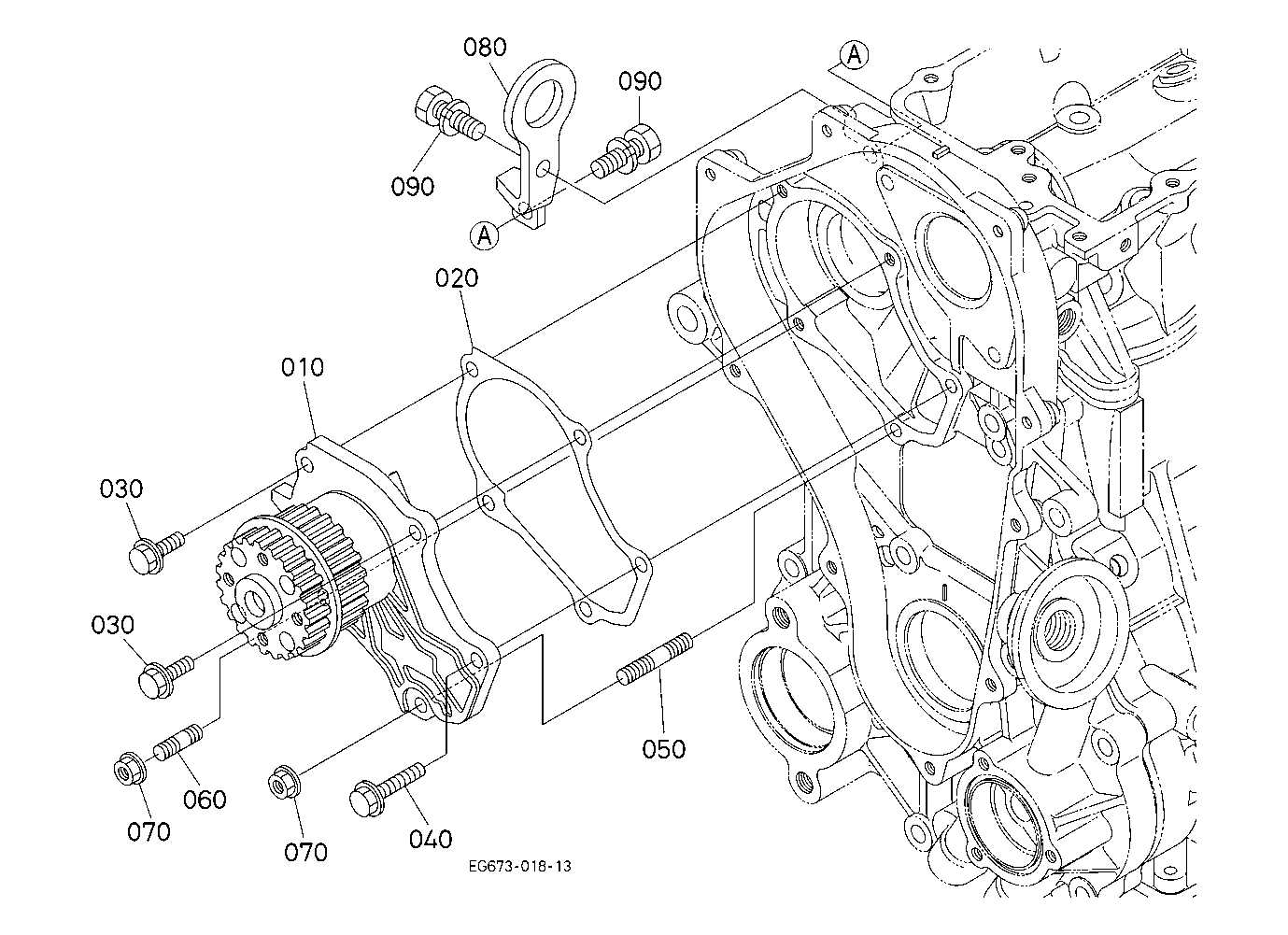

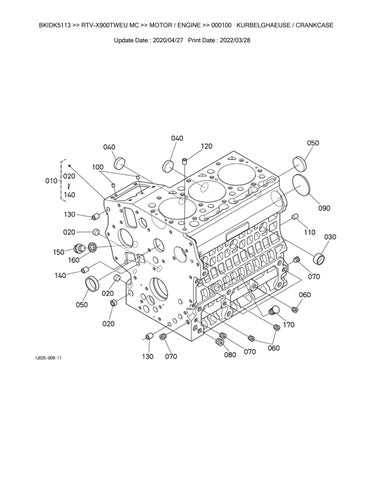

Visual representations of the assembly are invaluable resources for both seasoned technicians and DIY enthusiasts. They simplify the complex nature of machinery, allowing users to quickly identify and locate parts. This understanding can lead to more effective troubleshooting and maintenance practices, ultimately enhancing the vehicle’s functionality.

Furthermore, a detailed illustration can aid in the ordering process for replacements, ensuring you acquire the correct components without unnecessary delays. As you explore this visual guide, you will gain insights that not only facilitate repairs but also empower you to maximize the utility of your vehicle.

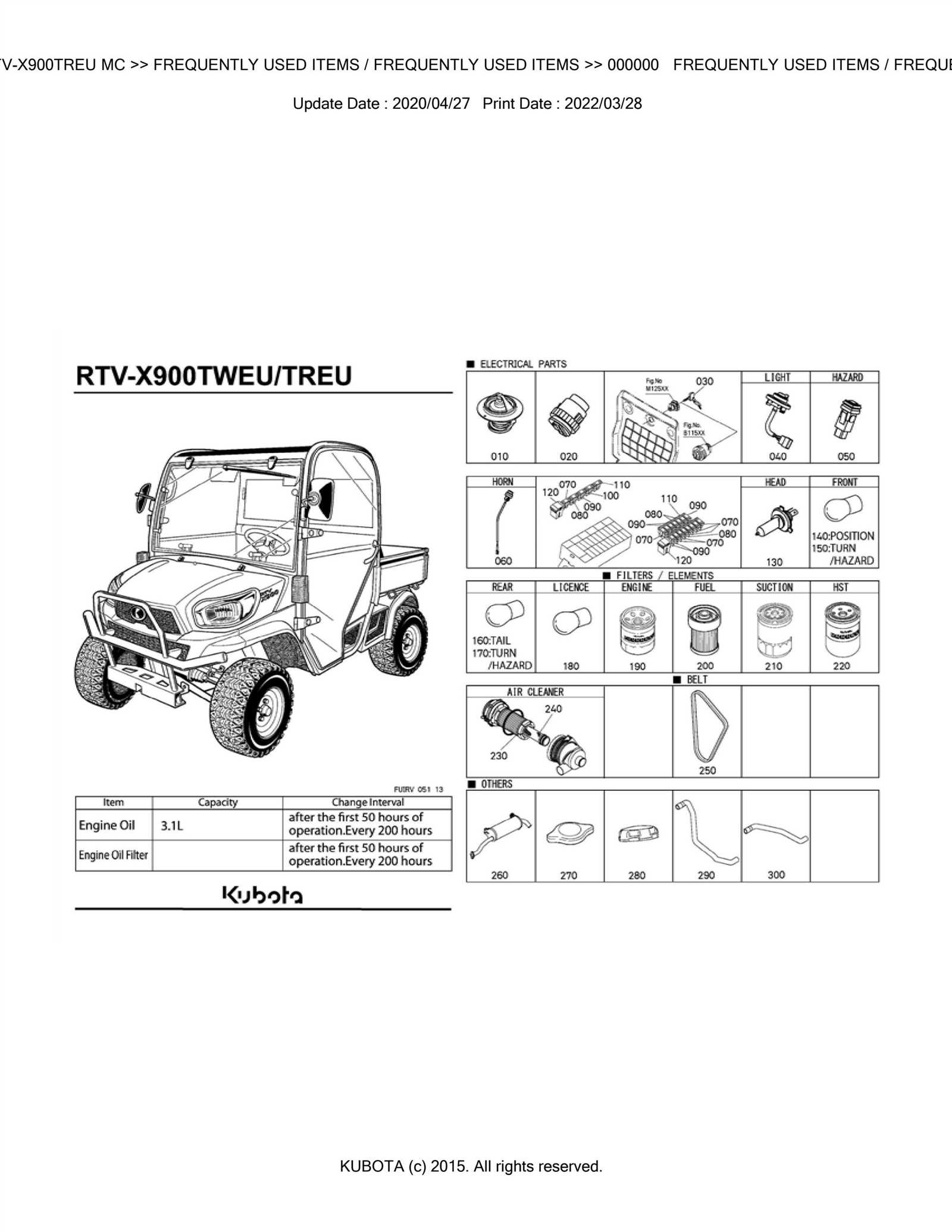

This section provides an insightful overview of a versatile utility vehicle known for its ruggedness and efficiency in various applications. Understanding the components and their arrangement is crucial for maintenance and repair. By breaking down the key elements of the vehicle, users can ensure optimal performance and longevity.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the vehicle, providing the necessary torque and horsepower for various tasks. |

| Transmission | The system that transfers power from the engine to the wheels, allowing for smooth acceleration and deceleration. |

| Chassis | The frame that supports all vehicle components and ensures structural integrity while navigating tough terrains. |

| Suspension | This system absorbs shocks and maintains stability, enhancing ride comfort over uneven surfaces. |

| Wheels | Robust wheels designed for traction and durability, essential for off-road capabilities. |

Importance of Parts Diagrams

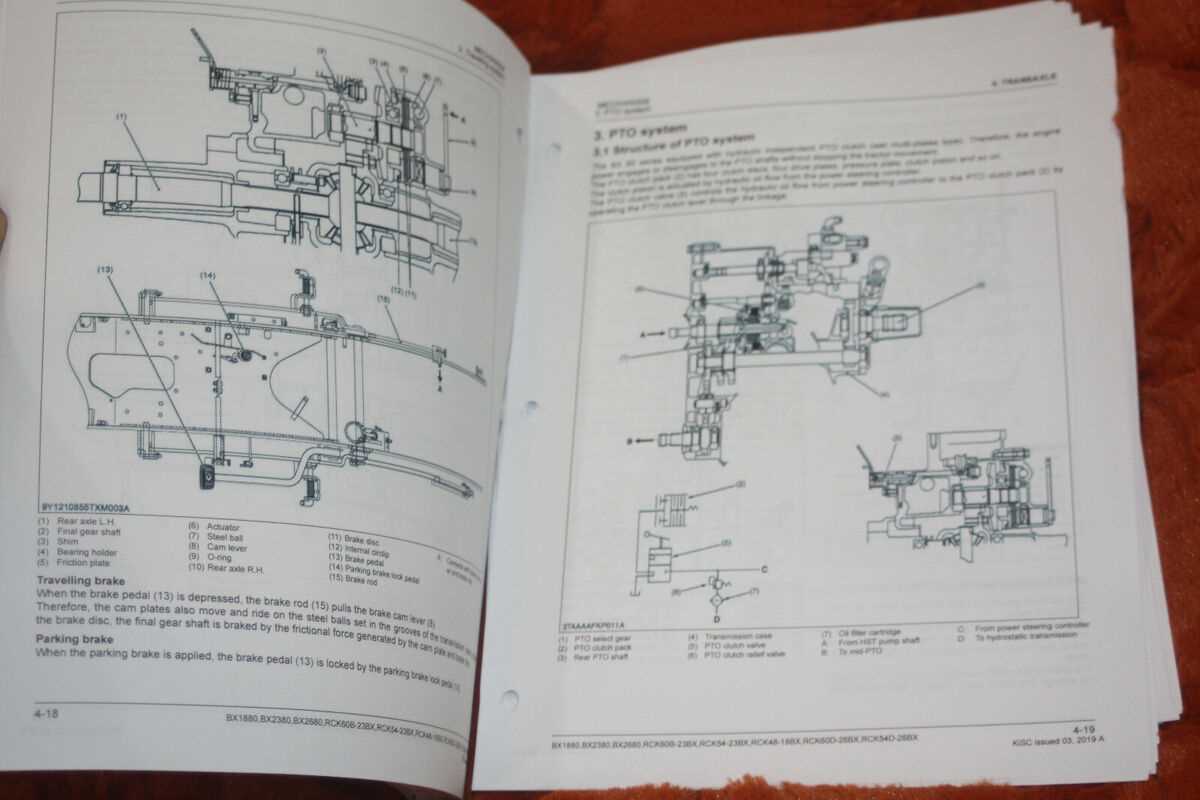

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of assemblies not only facilitate the identification of individual elements but also enhance the efficiency of troubleshooting processes. By providing a clear overview, these illustrations serve as essential tools for both novices and experienced technicians alike.

Utilizing schematic representations can significantly streamline the workflow during repairs or replacements. When mechanics can easily reference how components fit together, they can reduce downtime and improve the accuracy of their work. This practice not only helps in preserving the integrity of the machine but also promotes longevity and optimal performance.

| Benefit | Description |

|---|---|

| Efficiency | Visual aids help technicians locate and identify parts quickly, reducing the time spent on repairs. |

| Accuracy | Clear illustrations minimize the risk of errors during assembly or disassembly, ensuring proper installation. |

| Knowledge Transfer | New users can learn from these visuals, gaining a better understanding of how various components interact. |

| Maintenance Planning | By referencing component layouts, users can anticipate potential issues and plan maintenance schedules effectively. |

Key Components of the RTV 500

This section explores the essential elements that make up the functionality and efficiency of this versatile utility vehicle. Understanding these components is crucial for maintenance and optimal performance, ensuring a reliable experience in various applications.

- Engine: The heart of the vehicle, providing the necessary power to drive and operate other systems effectively.

- Transmission: This system is responsible for transferring power from the engine to the wheels, allowing for smooth acceleration and deceleration.

- Suspension: Designed to absorb shocks and provide stability, enhancing comfort during movement over rough terrain.

- Steering System: Facilitates maneuverability, enabling precise control during operation, especially in tight spaces.

- Braking System: Ensures safety by providing reliable stopping power under various conditions.

- Frame: The structural foundation that supports all other components, contributing to the overall durability and stability of the vehicle.

Each of these key components plays a vital role in the overall functionality of the vehicle, ensuring it meets the demands of various tasks effectively.

How to Read the Diagram

Understanding the visual representation of components and their relationships is essential for effective maintenance and repair tasks. This guide will help you navigate the intricate illustrations that depict the various elements and their functions within a vehicle. Mastering this skill allows you to identify parts quickly and ensure accurate replacements and repairs.

Identifying Key Components

The first step in interpreting the illustration is to familiarize yourself with the symbols and labels used. Each element will typically have a specific notation that indicates its function, location, and connection to other components. Look for legends or keys that explain these symbols, as they provide crucial context for understanding how everything fits together.

Following Connections and Relationships

Next, focus on the lines and arrows that connect different elements. These lines often represent physical connections, such as hoses, wires, or brackets, indicating how parts interact with one another. Pay attention to any directional arrows, which can signify flow or movement, helping you grasp the overall operation of the system more clearly.

Common Replacement Parts

Regular maintenance of utility vehicles is essential to ensure optimal performance and longevity. Over time, certain components may require replacement due to wear and tear, enhancing both functionality and safety. Understanding which elements are commonly replaced can aid owners in planning for maintenance effectively.

- Filters: Air and oil filters are crucial for maintaining engine efficiency. Regular replacement prevents contaminants from damaging internal components.

- Batteries: A reliable power source is essential for starting the engine and operating electrical systems. Replacement may be needed if the battery shows signs of failure.

- Tires: Worn tires can affect traction and handling. Regular inspection and timely replacement are vital for safe operation.

- Brake Components: Brake pads and discs may wear down over time, necessitating replacement to ensure effective stopping power.

- Belts and Hoses: These components can deteriorate with age and usage. Regular checks can help identify cracks or fraying that require replacement.

- Fluids: Engine oil, coolant, and transmission fluid should be replaced according to maintenance schedules to ensure proper operation.

Identifying and replacing these common components can greatly enhance the reliability and safety of utility vehicles, allowing for a smooth and efficient performance in various tasks.

Maintenance Tips for RTV 500

Regular upkeep is essential for ensuring the longevity and optimal performance of your utility vehicle. Proper care not only enhances functionality but also prevents costly repairs and downtime. Adhering to a systematic maintenance routine will keep your machine running smoothly and efficiently.

1. Check Fluid Levels

Monitoring fluid levels is crucial for the vehicle’s health. Regularly inspect and top off engine oil, coolant, and transmission fluid. Clean, fresh fluids help prevent overheating and ensure smooth operation.

2. Inspect Tires

Maintaining proper tire pressure is vital for traction and stability. Check for wear and tear, and rotate tires periodically to promote even wear. Replace tires when tread depth becomes insufficient to ensure safety.

3. Clean Air Filter

A clean air filter is essential for optimal engine performance. Inspect the air intake system regularly and replace the filter when it becomes dirty. This will enhance air circulation and improve fuel efficiency.

4. Examine Belts and Hoses

Check belts and hoses for signs of wear, such as cracks or fraying. Replacing damaged components promptly can prevent breakdowns and maintain reliable performance during use.

5. Lubricate Moving Parts

Ensure that all moving parts are adequately lubricated to reduce friction and wear. Use appropriate lubricants for different components, and pay special attention to joints and pivot points.

6. Regular Cleaning

Keep the exterior and undercarriage clean to prevent corrosion and damage. Regular washing helps remove dirt and debris, which can lead to rust and mechanical issues over time.

7. Follow Manufacturer’s Guidelines

Always refer to the manufacturer’s maintenance schedule and recommendations. Adhering to these guidelines will help you stay on track with inspections and replacements, ensuring your vehicle remains in peak condition.

Where to Find Genuine Parts

Acquiring authentic components for your vehicle is crucial for maintaining its performance and longevity. Whether you are looking for replacements or upgrades, sourcing original items ensures compatibility and quality. Numerous avenues are available for obtaining these essential elements.

Authorized Dealers are among the best sources for genuine components. These outlets are recognized by manufacturers and typically offer a comprehensive range of items that meet the required standards. Shopping at authorized dealers guarantees that you receive authentic and reliable components.

Online Retailers also present a convenient option. Many reputable websites specialize in offering original items, providing detailed descriptions and specifications. Be sure to select well-reviewed platforms that emphasize customer satisfaction and offer secure payment methods.

Local Repair Shops can be invaluable resources. Establishments with a solid reputation often have connections to suppliers of original components. They can assist you in locating the necessary items while also providing installation services if needed.

Lastly, consider Manufacturer’s Websites, which frequently feature catalogs of their offerings. These platforms provide direct access to original products, allowing for easy ordering and sometimes even discounts or promotions.

Understanding Assembly and Disassembly

Grasping the process of putting together and taking apart machinery is essential for effective maintenance and repair. This section delves into the methods and best practices involved in both assembling and disassembling components of a vehicle, ensuring that operators and technicians can perform these tasks safely and efficiently.

Assembly involves aligning and connecting various elements to create a fully operational unit. It is crucial to follow the correct sequence and utilize the right tools to avoid damaging parts. Thoroughly understanding the manufacturer’s guidelines can help in achieving a seamless assembly process.

Disassembly, on the other hand, requires careful removal of components without causing harm. Knowing the right order to detach pieces is vital to prevent issues during reassembly. It is advisable to organize removed parts systematically, perhaps using labeled containers, to streamline the process when putting everything back together.

Both assembly and disassembly are critical skills that contribute to the longevity and performance of the vehicle. Mastering these techniques not only enhances operational efficiency but also promotes a deeper understanding of the machinery as a whole.

Benefits of Using Diagrams

Visual representations play a crucial role in understanding complex systems and enhancing communication. They simplify intricate information, allowing individuals to grasp concepts quickly and efficiently. This clarity is especially valuable in technical fields where detailed knowledge is essential.

One of the primary advantages of employing visual aids is their ability to provide a clear overview of components and their relationships. By illustrating connections, these representations facilitate better comprehension and retention of information. Users can easily identify key elements and their functions, which can significantly improve problem-solving capabilities.

Additionally, visual aids can serve as effective tools for collaboration. They enable teams to share insights and ideas in a coherent manner, promoting discussion and ensuring that everyone is on the same page. This collaborative approach can lead to enhanced productivity and innovative solutions, as different perspectives are considered and integrated.

Moreover, utilizing visual representations can save time and reduce errors. When individuals can refer to clear illustrations rather than lengthy texts, they are less likely to misinterpret instructions or overlook critical details. This efficiency not only streamlines workflows but also enhances overall accuracy in task execution.

In conclusion, integrating visual aids into various processes can significantly improve understanding, collaboration, and efficiency. Their ability to simplify information while fostering communication makes them invaluable in both individual and team settings.