In the realm of culinary equipment, a well-functioning device for slicing ingredients is essential for both professional kitchens and home cooking. This section aims to provide an in-depth overview of the various components that contribute to the efficient operation of such machinery. By familiarizing oneself with these elements, users can enhance their understanding of maintenance and repair processes.

Every slicing apparatus consists of multiple key elements that work together to ensure optimal performance. Recognizing how each part interacts not only aids in troubleshooting but also promotes better care of the equipment. A thorough grasp of these components can significantly extend the lifespan of the device, allowing for consistent results in food preparation.

Moreover, understanding the arrangement of these elements is crucial for anyone looking to disassemble, clean, or replace specific sections of the machine. By gaining insight into the internal layout, users can navigate their way through any issues that may arise, ensuring that their slicing tasks remain seamless and efficient. Knowledge of these intricacies empowers users to make informed decisions regarding their culinary tools.

Understanding Hobart Meat Slicer Components

Grasping the various elements of a commercial cutting device is essential for efficient operation and maintenance. Each component plays a critical role in ensuring smooth functionality, contributing to the overall performance of the machine. This section delves into the key features of such devices, offering insights into their design and importance.

Key Components Overview

Every machine consists of multiple essential parts that work in harmony. These include the cutting mechanism, support structure, and control systems. Understanding how each part interacts can enhance operational efficiency and prolong the lifespan of the equipment.

Maintenance and Care

Proper upkeep of the device is vital for optimal performance. Regular inspection of critical components, such as blades and gears, ensures that the equipment functions effectively. Keeping these elements clean and well-lubricated minimizes wear and tear, promoting longevity and reliability.

In summary, a comprehensive understanding of the various components is crucial for anyone working with such cutting devices. This knowledge not only aids in effective operation but also in preventive maintenance, ensuring that the equipment remains in top condition.

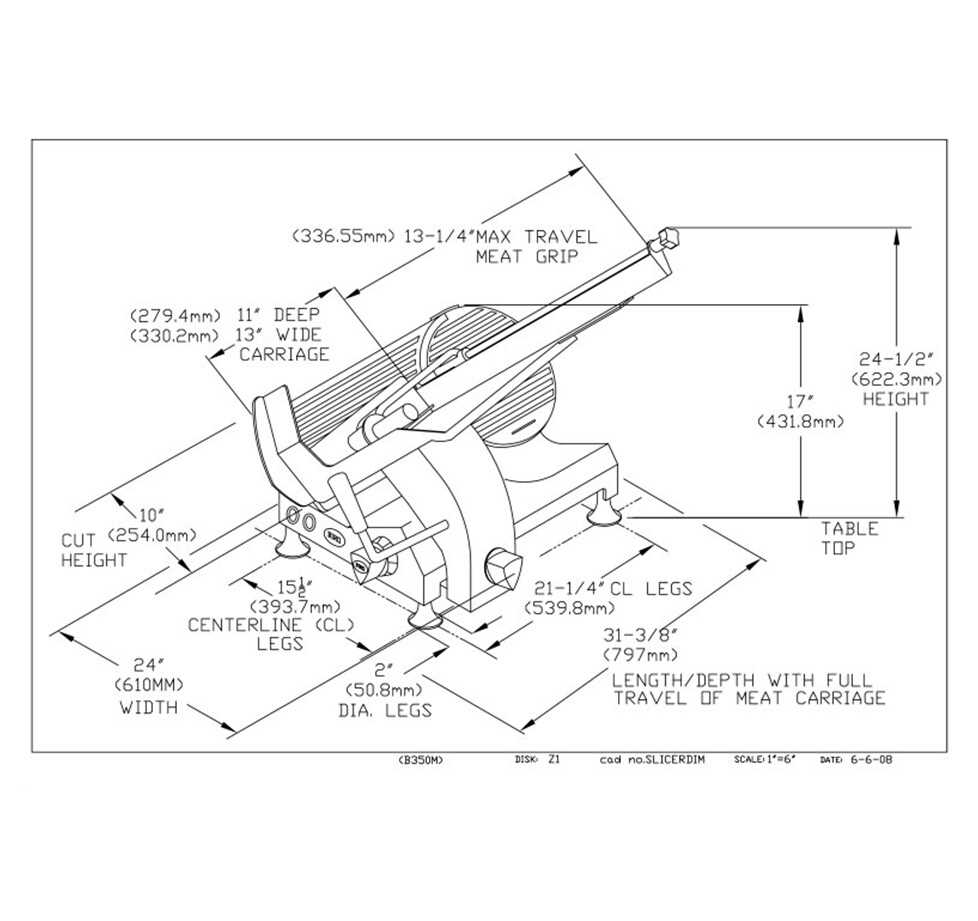

Identifying Key Components of the Slicing Machine

In this section, we will explore the essential components that make up the slicing apparatus. Understanding these integral parts is crucial for operating and maintaining the equipment effectively.

- Main Blade Assembly: This vital component is responsible for the primary cutting function.

- Carriage and Feed Tray: These parts facilitate the movement of the food item through the slicer during operation.

- Adjustment Knobs: Used to regulate the thickness of the slices, these knobs ensure precision in slicing.

- Safety Guard: A protective feature that shields the operator from the blade during use.

- Power Switch: Controls the machine’s on/off function, ensuring safe operation.

Each of these elements plays a critical role in the functionality and safety of the slicing machine. Familiarizing yourself with these components will enhance your ability to operate and maintain the equipment efficiently.

Maintenance Tips for Slicing Equipment Components

In order to ensure optimal performance and longevity of your slicing equipment, regular maintenance of its components is essential. This section provides practical advice on how to effectively care for and maintain the various parts that contribute to the smooth operation of your slicing apparatus.

1. Cleaning: Proper cleaning of the slicing machine components is crucial to prevent buildup of residues that can affect performance. Use gentle cleaning agents and follow manufacturer guidelines for the appropriate cleaning frequency.

2. Lubrication: Components such as bearings and gears benefit from regular lubrication to reduce friction and wear. Use recommended lubricants and follow the lubrication schedule outlined in the equipment manual.

3. Inspection: Regular inspection of parts like blades, belts, and seals helps detect early signs of wear or damage. Prompt replacement of worn-out components can prevent costly repairs and downtime.

4. Adjustment: Ensure all parts are correctly aligned and adjusted according to manufacturer specifications. Misalignment can lead to inefficiencies and potential safety hazards during operation.

5. Storage: When not in use, store slicing equipment in a clean and dry environment to prevent dust accumulation and corrosion. Covering the equipment can further protect it from environmental factors.

6. Training: Properly train personnel responsible for equipment maintenance to ensure they understand the importance of each maintenance task and can perform them effectively.

By following these maintenance tips, you can extend the lifespan of your slicing equipment and maintain consistent performance, ensuring efficient operation in your kitchen or food service establishment.

Common Challenges with Slicing Equipment Components

In the operation of slicing devices, users may encounter various common issues related to the functionality and performance of the machine’s key parts. Understanding these challenges is crucial for efficient maintenance and troubleshooting.

One frequent concern involves the blades, where dullness or misalignment can lead to uneven cutting and reduced efficiency. Another critical component is the motor, susceptible to overheating or electrical issues, affecting the slicer’s overall performance.

Furthermore, problems with the carriage system, such as sticking or improper movement, can hinder smooth slicing operations. Additionally, issues with the safety features, like malfunctioning guards or switches, pose risks to users.

Regular inspection and proper maintenance help mitigate these challenges, ensuring the slicer operates smoothly and safely, maintaining high standards in food preparation environments.

How to Replace Slicer Blades

Replacing the cutting components of your food preparation machine is essential for maintaining its efficiency and performance. Over time, these elements can become dull or damaged, affecting the quality of the slices produced. This guide will walk you through the steps to safely and effectively change the blades, ensuring your device operates at its best.

- Gather Necessary Tools:

- New cutting blades

- Screwdriver

- Protective gloves

- Cleaning cloth

- Ensure Safety:

Before starting, make sure the machine is unplugged to prevent any accidental activation. Wear protective gloves to safeguard your hands during the process.

- Remove the Existing Blades:

Locate the screws or fasteners holding the blades in place. Using the screwdriver, carefully remove them, and gently detach the old blades from the machine.

- Clean the Area:

Before installing the new blades, clean the surrounding area to remove any debris or food particles that may have accumulated. Use a damp cloth for effective cleaning.

- Install New Blades:

Align the new blades with the mounting area and secure them in place using the screws or fasteners. Ensure they are tightened properly to avoid any movement during operation.

- Test the Machine:

Once the new blades are installed, plug the machine back in and perform a test run. Check for proper operation and listen for any unusual sounds that may indicate a problem.

Regularly replacing the cutting components will not only improve the performance of your device but also enhance the quality of your food preparation tasks.

Cleaning Procedures for Slicer Parts

Maintaining the functionality and hygiene of slicing equipment is essential for optimal performance and safety. Regular cleaning routines help prevent contamination and extend the lifespan of the machine. This section outlines effective methods for cleaning various components of the equipment.

Recommended Cleaning Steps

Follow these steps to ensure thorough cleaning:

- Disconnect the equipment from the power source.

- Disassemble removable components according to the manufacturer’s guidelines.

- Wash the parts using warm, soapy water and a soft brush to remove residues.

- Rinse thoroughly with clean water to eliminate any soap traces.

- Dry all components completely with a clean towel or let air dry before reassembling.

- Wipe down the main unit with a damp cloth to remove any spills or dirt.

Cleaning Frequency

Regular cleaning is crucial for maintaining hygiene standards. The frequency should be based on usage and specific operational conditions:

| Usage Level | Cleaning Frequency |

|---|---|

| Heavy (daily use) | After each use |

| Moderate (several times a week) | At least once a day |

| Light (occasional use) | At least once a week |

Choosing the Right Replacement Parts

Selecting appropriate components for your equipment is essential to maintain its performance and longevity. Properly matching elements ensures that your device operates efficiently and reduces the likelihood of future issues. When considering replacements, it’s crucial to understand the specifications and compatibility of each component.

Firstly, always refer to the manufacturer’s guidelines for the specific characteristics required for your device. These details often include dimensions, materials, and functionality. Utilizing original components can offer peace of mind, as they are designed to fit seamlessly and work effectively within the system.

In addition, examining customer reviews and product ratings can provide insight into the reliability of alternative options. Many users share their experiences, highlighting potential concerns or advantages associated with various components. It’s beneficial to consider both the quality and the price, ensuring that you make a sound investment without compromising performance.

Finally, consulting with professionals or industry experts can further assist in making informed decisions. Their expertise can guide you toward suitable choices that will enhance the efficiency and durability of your equipment. Making educated selections will ultimately lead to improved functionality and satisfaction with your device.

Safety Precautions for Meat Slicers

Ensuring a secure environment when using cutting equipment is crucial for preventing accidents and injuries. Adhering to safety measures helps protect operators and those nearby while enhancing the overall efficiency of the task. Proper understanding and implementation of these guidelines can significantly reduce risks associated with the use of sharp instruments.

- Read the Manual: Always familiarize yourself with the manufacturer’s guidelines before operating the device.

- Wear Appropriate Gear: Use cut-resistant gloves and non-slip footwear to enhance personal protection.

- Keep the Area Clean: Ensure that the workspace is free of clutter and debris to prevent slips and falls.

- Inspect Equipment Regularly: Check for any wear or damage to components before each use, ensuring everything functions correctly.

- Use Safety Features: Make sure all safety guards are in place and operational before starting the machine.

- Never Override Safety Mechanisms: Avoid disabling any safety features, as they are designed to protect users.

Implementing these precautions can create a safer working environment and minimize the likelihood of accidents. Regular training and awareness programs can further enhance safety standards and promote responsible usage among operators.

Benefits of Regular Parts Inspection

Conducting routine examinations of essential components in equipment is vital for maintaining optimal performance and extending the lifespan of machinery. This practice helps to identify potential issues before they escalate, ensuring that devices operate smoothly and efficiently.

Enhanced Performance

Regular assessments contribute significantly to the overall effectiveness of machinery. By identifying worn-out or damaged components, operators can replace them promptly, leading to:

- Improved operational efficiency

- Minimized downtime

- Consistent quality in output

Cost Savings

Investing time in systematic evaluations can lead to substantial cost reductions. Early detection of problems allows for:

- Lower repair costs by addressing issues before they worsen

- Reduced need for emergency replacements

- Extended service life of equipment

Ultimately, regular inspections play a crucial role in maintaining machinery, enhancing productivity, and ensuring long-term financial savings.