The efficient operation of any robust fastening device relies on a clear comprehension of its individual components and their functions. By exploring these elements, users can enhance their ability to maintain and troubleshoot their equipment effectively.

Each segment plays a crucial role in ensuring smooth performance, from the mechanism that drives the fasteners to the housing that protects the internal workings. Understanding these roles allows users to maximize the lifespan of their tool and ensure optimal functionality.

In this exploration, we will delve into the intricate details of a specific model, breaking down its assembly into easily digestible parts. Whether for repair, maintenance, or simply gaining knowledge, grasping the nuances of each component will lead to the ultimate user experience.

Understanding Arrow T50 Stapler Mechanics

This section explores the inner workings of a popular fastening tool, emphasizing its mechanical components and how they interact to achieve efficient performance. A comprehensive understanding of these mechanisms can enhance usability and maintenance.

| Component | Function |

|---|---|

| Drive Mechanism | Propels the fasteners into materials. |

| Loading Chamber | Holds the fasteners for easy access. |

| Handle | Provides leverage for operation. |

| Spring | Returns the drive mechanism after use. |

| Safety Lock | Prevents accidental firing. |

Each element plays a crucial role, contributing to the ultimate efficiency and reliability of the tool, ensuring that tasks are completed seamlessly.

Key Components of the Arrow T50

Understanding the essential elements of this fastening tool is crucial for effective use and maintenance. Each component plays a significant role in its functionality, ensuring reliable performance for various tasks. This section will explore the main features that contribute to the tool’s efficiency and durability.

The housing serves as the main structure, providing stability and support. It is designed to withstand repeated use while protecting internal mechanisms. The trigger mechanism is vital for activating the device, offering both ease of use and precision during operation.

Another important element is the magazine, which holds the fasteners securely and allows for quick reloading. The anvil is essential for securing the fasteners in place, ensuring a strong bond with the materials being joined. Additionally, the depth adjustment feature allows users to customize the penetration of the fastener, catering to different materials and project requirements.

Finally, the handle is ergonomically designed for comfort, reducing hand fatigue during extended use. Together, these components create a reliable tool that meets the demands of various fastening applications.

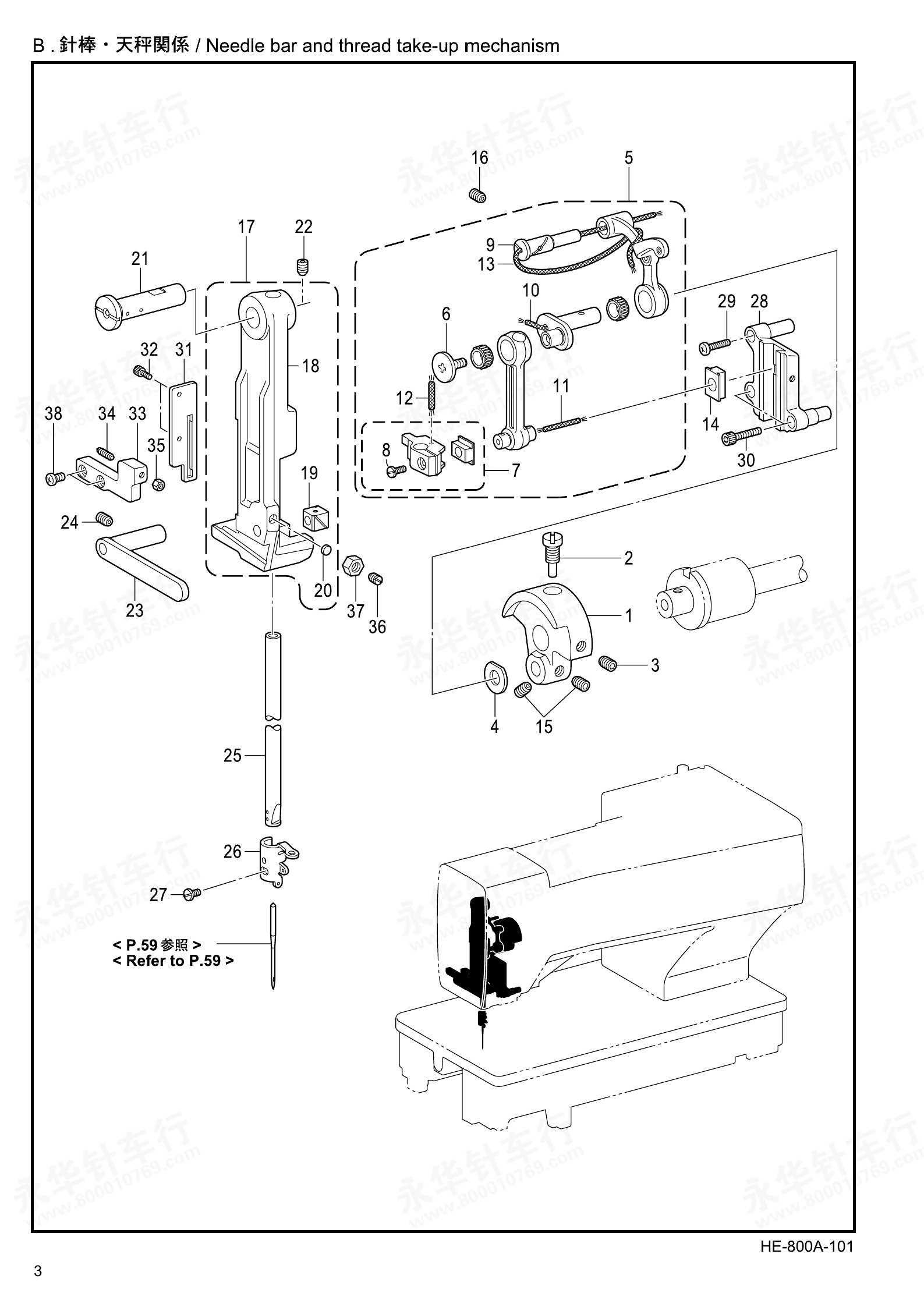

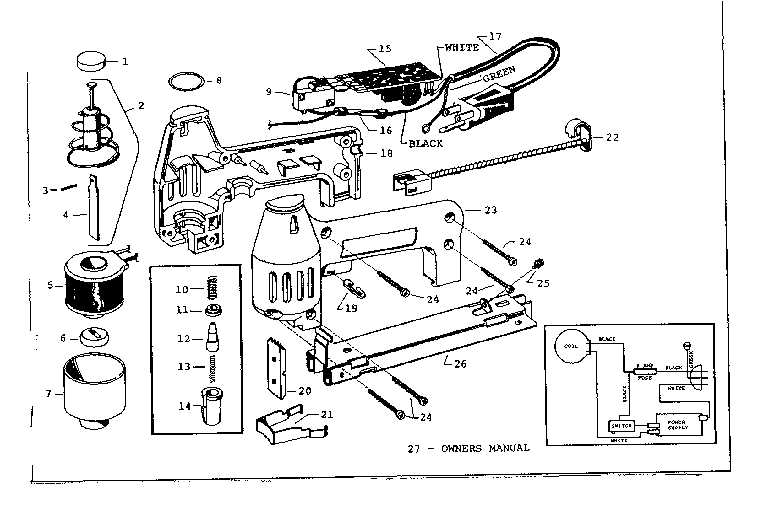

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide a clear overview of each element’s role and position within a device, enabling users to identify necessary replacements or adjustments easily.

To navigate these visual guides, follow these key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout. Each visual typically has a legend or key that explains symbols and color coding used in the illustration. |

| 2 | Identify the main components. Look for larger parts first, as they often influence the functionality of smaller elements. |

| 3 | Trace connections. Pay attention to how different pieces are linked, as this can affect assembly and disassembly processes. |

| 4 | Check for annotations. Often, additional notes provide insights into specifications, such as dimensions or material types. |

| 5 | Refer to accompanying documentation. Manuals or guides can offer deeper explanations about the components and their functions. |

By mastering these techniques, users can effectively interpret visual representations and enhance their repair skills.

Common Issues with Stapler Parts

Understanding the frequent challenges encountered with fastening devices can enhance their longevity and performance. Many of these issues arise from wear, improper use, or lack of maintenance. Recognizing these problems early can prevent further complications and ensure efficient operation.

| Issue | Description |

|---|---|

| Jamming | Occurs when materials become stuck, preventing proper function. |

| Misalignment | Components may not line up correctly, leading to ineffective fastening. |

| Weak Pressure | Inadequate force applied can result in incomplete fastening. |

| Component Wear | Frequent use can lead to degradation of essential elements. |

| Spring Failure | Loss of tension in springs can hinder operation. |

Replacing Worn-Out Components

Maintaining the efficiency of your fastening device is essential for ensuring optimal performance. Over time, certain elements may degrade or become damaged, impacting functionality. Recognizing the signs of wear and understanding how to effectively replace these components can significantly enhance the longevity and reliability of your tool.

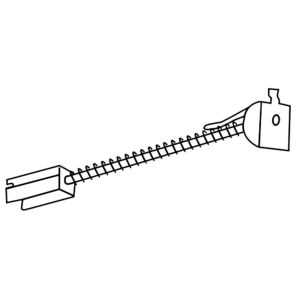

When addressing worn parts, it’s crucial to identify which components require attention. Commonly affected areas include the driving mechanism, spring tension, and loading features. Replacing these elements not only restores the tool’s performance but also prevents further damage that could lead to costly repairs or replacements.

To proceed with replacements, begin by disassembling the device carefully. Refer to the manufacturer’s guidelines for disassembly to avoid unnecessary damage. Once you have accessed the internal components, inspect each part for signs of wear or breakage. Choose high-quality replacements to ensure durability and compatibility with your device.

After installing new components, reassemble the device meticulously, checking that all parts are securely in place. Testing the tool after reassembly is vital to confirm that it operates smoothly and effectively. Regular maintenance and timely replacements can help you achieve the best results in your fastening tasks.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your fastening device requires regular upkeep. By implementing a few simple practices, you can significantly extend its lifespan and maintain optimal performance.

Regular Cleaning: Keep the mechanism free from dust and debris. Use a soft brush or cloth to remove any build-up that may affect functionality.

Lubrication: Apply a suitable lubricant to moving parts periodically. This reduces friction and prevents wear over time.

Correct Usage: Always follow the manufacturer’s guidelines regarding usage limits. Overloading can lead to damage and reduce efficiency.

Storage: Store your device in a cool, dry place when not in use. Avoid exposure to moisture, which can cause rust and corrosion.

Regular Inspections: Conduct routine checks for signs of wear or damage. Early detection can prevent more significant issues later.

Where to Buy Replacement Parts

Finding suitable components for your tool is essential for maintaining its functionality and longevity. Various retailers and online platforms offer a wide selection of these necessary items, ensuring you can easily restore your device to optimal performance.

Local Hardware Stores: Many neighborhood hardware stores carry essential supplies and can order specific items for you if they are not in stock.

Online Marketplaces: Websites like Amazon and eBay provide extensive inventories, allowing you to compare prices and read customer reviews before purchasing.

Manufacturer’s Website: Visiting the official site of the brand often yields authentic replacements, ensuring compatibility and quality.

Specialty Retailers: Consider shops that specialize in tools and equipment; they may have unique options that standard retailers do not offer.

Always ensure you verify the specifications and compatibility of the components to achieve the best results for your equipment.

Comparison with Other Stapler Models

This section explores the distinctions and similarities between various fastening devices, highlighting their features, usability, and design choices. By examining these aspects, users can make informed decisions based on their specific needs and preferences.

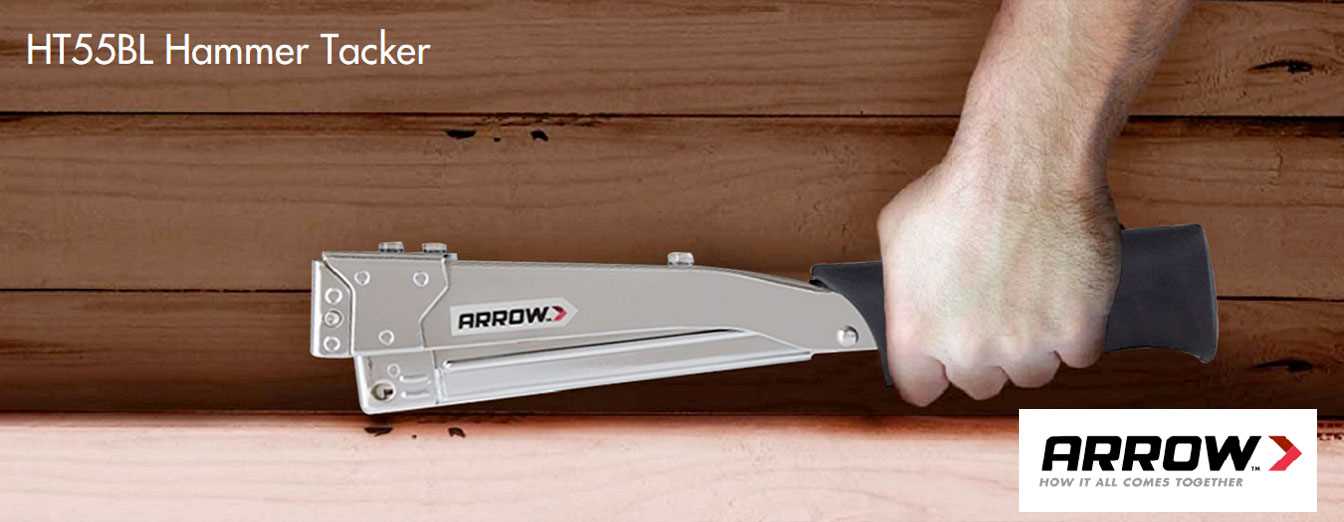

Design and Ergonomics

When comparing fastening devices, design plays a crucial role in user experience. Some models prioritize compactness, making them portable, while others emphasize ergonomic grips for prolonged use. Comfort can significantly influence efficiency during tasks.

Performance and Reliability

Performance metrics such as stapling capacity and durability vary among different models. Certain devices excel in heavy-duty applications, while others are tailored for light use. Reliability is a key factor, as consistent functionality can enhance productivity in various settings.

DIY Repairs: Tools Needed

When tackling home repairs, having the right equipment is essential for a successful outcome. Whether you’re fixing a mechanical device or addressing wear and tear on a utility tool, a well-equipped workspace can make all the difference. Here’s a guide to the fundamental tools you’ll want to have on hand for effective do-it-yourself projects.

Essential Hand Tools

- Screwdrivers: A set of various sizes and types (flathead and Phillips) is crucial for loosening and tightening fasteners.

- Pliers: Needle-nose and slip-joint pliers are handy for gripping and manipulating small parts.

- Wrenches: Both adjustable and fixed wrenches will help you handle nuts and bolts effectively.

- Hammer: A reliable hammer is necessary for driving in nails and other fasteners.

Additional Tools

- Utility Knife: For cutting materials like paper, plastic, or light wood.

- Measuring Tape: Precision is key; having a measuring tape ensures accuracy in your repairs.

- Safety Gear: Protective eyewear and gloves are essential to keep you safe while you work.

- Lubricants: Oils and sprays can help maintain moving parts and prevent rust.