In the realm of small machinery, a comprehensive grasp of the various elements that contribute to performance is essential. For those who work with robust power sources, identifying the individual components is crucial for effective maintenance and repair. This section will explore the intricate relationships among these elements, ensuring a well-functioning apparatus.

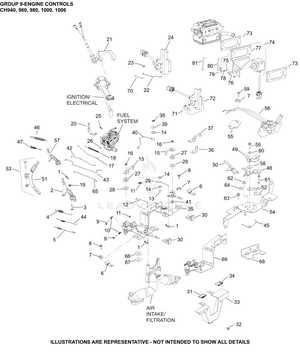

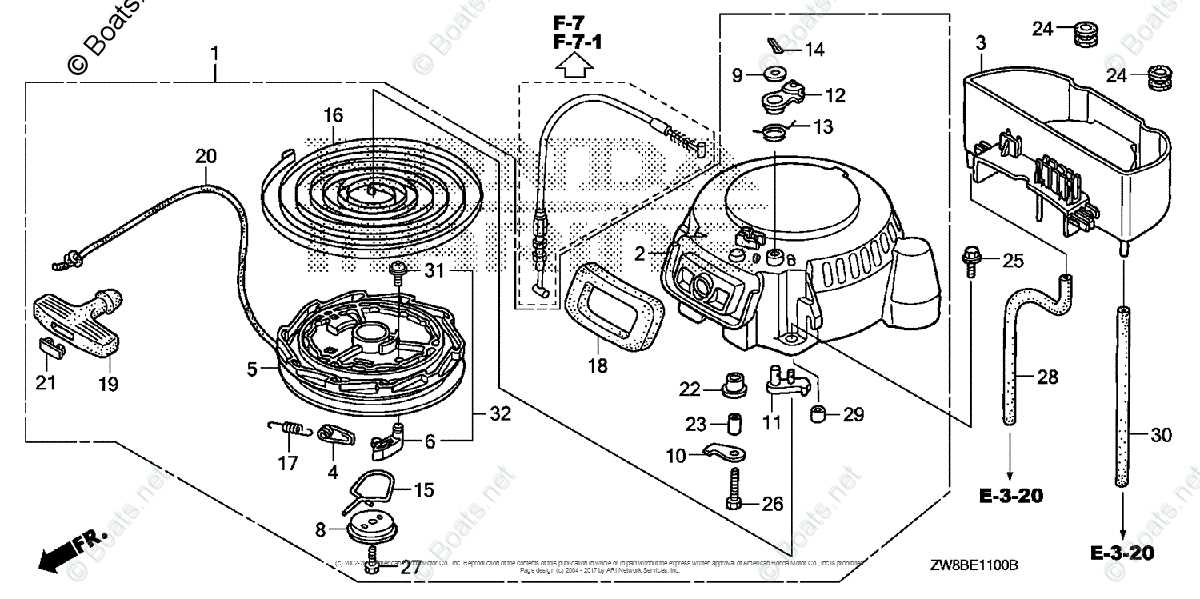

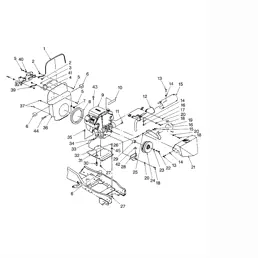

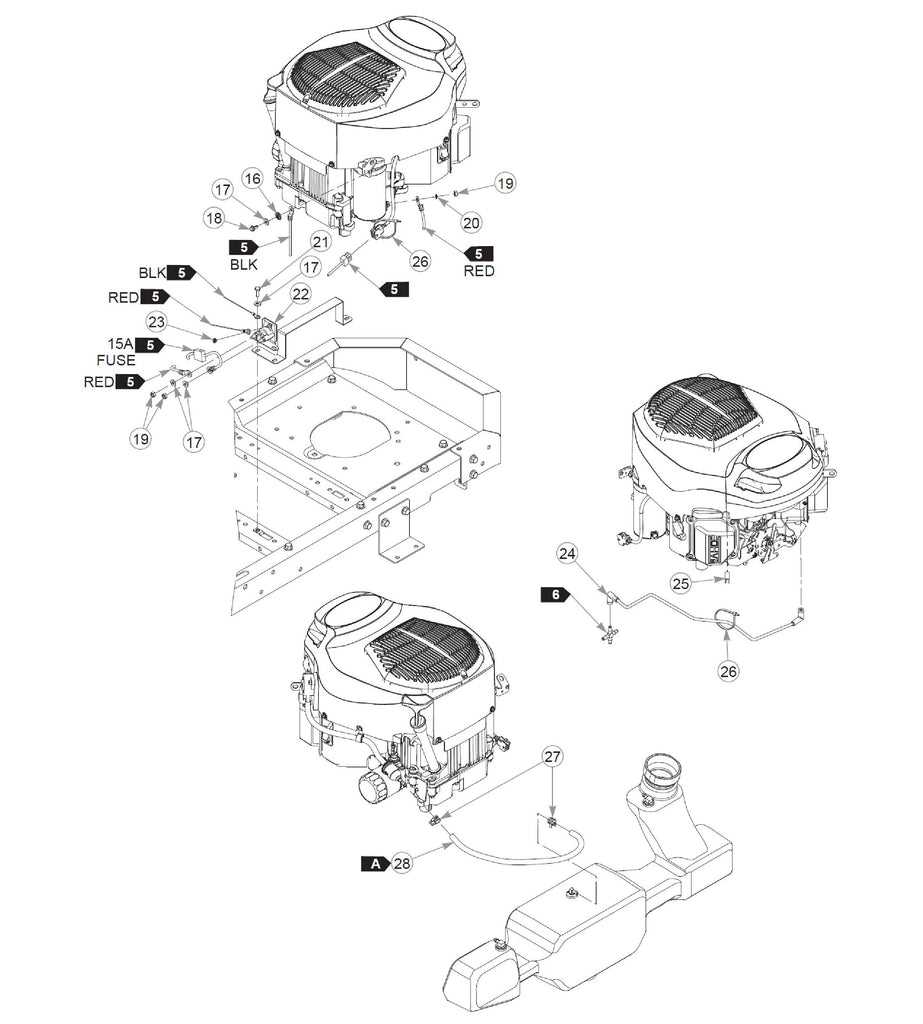

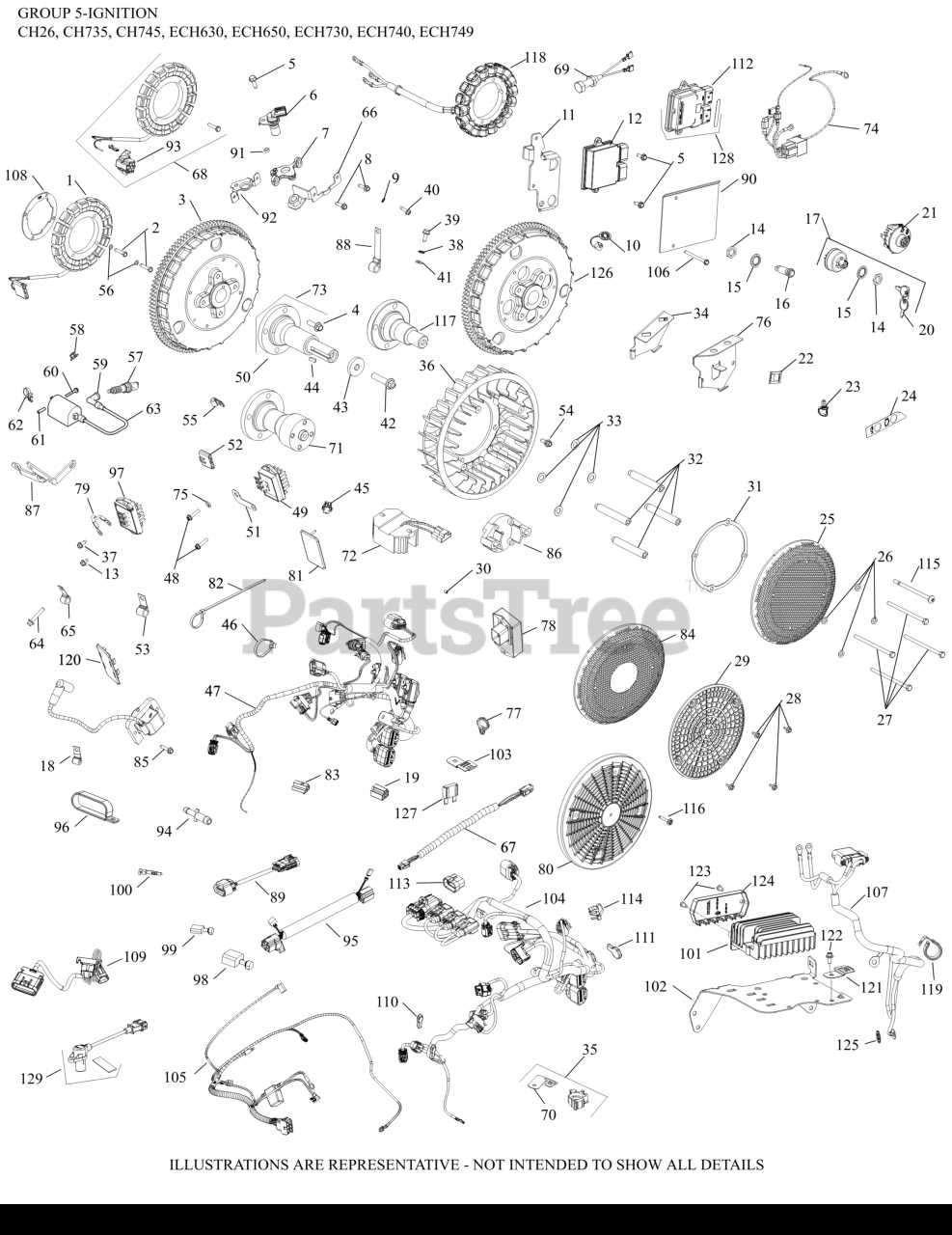

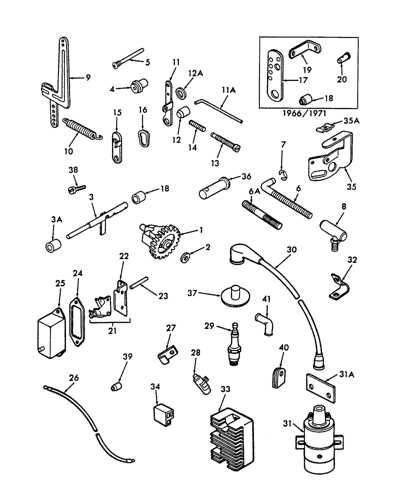

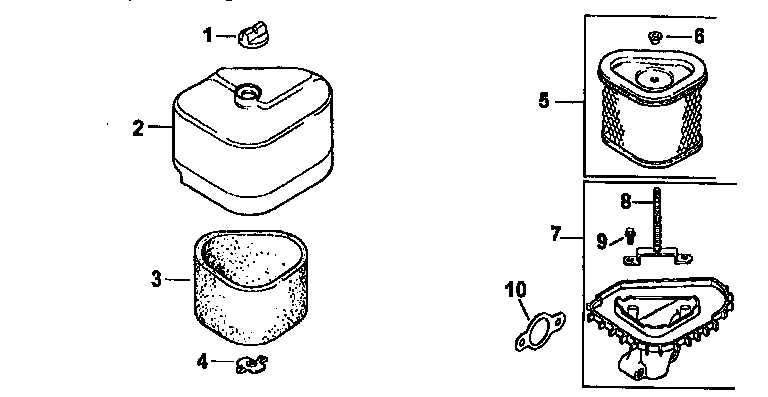

Every component plays a vital role in the overall efficiency and reliability of the power unit. From the ignition system to the fuel delivery mechanisms, understanding each part’s function can enhance the longevity and productivity of your machinery. This guide aims to provide a visual representation that will facilitate a deeper appreciation of how these elements interact.

By diving into the specifics, users will be equipped to tackle common issues and optimize performance. Whether you are a seasoned technician or a novice, having access to a clear representation of these crucial components will prove invaluable. Let us delve into the details that define the ultimate functionality of this power source.

Understanding Kohler 26 HP Engines

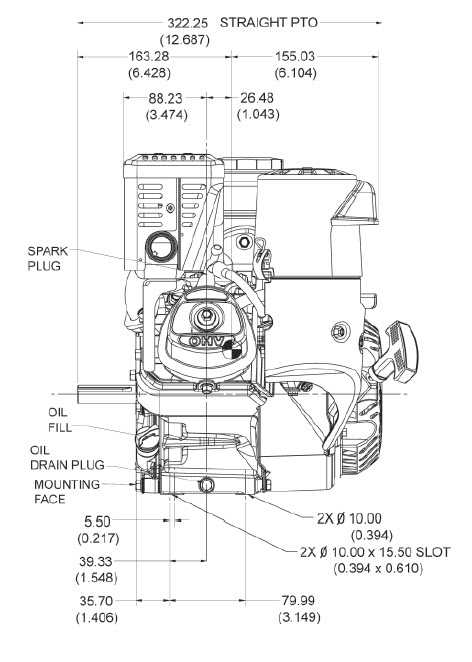

In exploring the intricacies of the robust 26 horsepower Kohler motor, we delve into its inner workings and design principles. This section unveils the core elements that define the performance and reliability of this powerful machinery.

Performance Dynamics

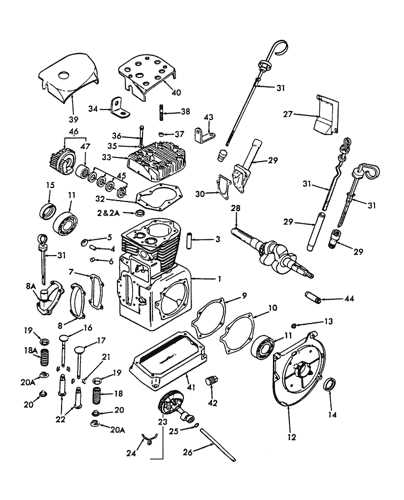

At the heart of these engines lies a synergy of components that harmoniously convert fuel into mechanical power. This synergy propels various applications, showcasing a blend of efficiency and endurance.

Structural Insights

Examining the architecture, we uncover the blueprint that integrates precision-crafted elements. These components orchestrate a symphony of combustion and movement, engineered for sustained operation under diverse conditions.

Key Components of Kohler Engines

Understanding the essential elements that contribute to the performance of a power unit is crucial for maintenance and efficiency. Each component plays a significant role, working in harmony to ensure smooth operation and longevity. This section delves into the vital sections that make up these machines, highlighting their functions and importance.

Power Generation Mechanisms

At the core of any unit lies the power generation mechanism, responsible for converting fuel into usable energy. This includes the combustion chamber and associated systems that facilitate the ignition process. Proper functioning of these components directly influences the overall output and reliability of the equipment.

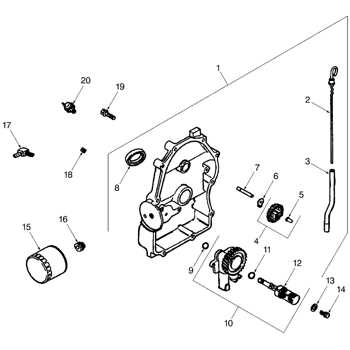

Cooling and Lubrication Systems

Effective cooling and lubrication are essential for preventing overheating and ensuring smooth operation. These systems work together to maintain optimal temperatures and reduce friction among moving parts. Regular inspection and maintenance of these elements are vital to prolong the lifespan of the machinery.

Importance of Engine Diagrams

Visual representations of mechanical assemblies serve a crucial role in understanding and maintaining complex machinery. These illustrations provide clarity and insight into the intricate relationships between components, making them invaluable for both professionals and enthusiasts alike.

Benefits of Visual Guides

- Enhanced Understanding: Diagrams simplify the complexity of machinery by breaking down systems into understandable sections.

- Accurate Maintenance: With clear visuals, technicians can more easily identify parts that require servicing or replacement.

- Improved Communication: These visuals facilitate better collaboration among team members by providing a common reference point.

- Efficiency in Repairs: Knowing the layout of a system allows for quicker troubleshooting and less time spent searching for components.

Applications in Various Fields

- Automotive: Detailed illustrations assist mechanics in performing repairs accurately and efficiently.

- Aerospace: Complex systems are mapped out to ensure precise assembly and maintenance procedures.

- Manufacturing: Visual aids help workers understand assembly lines and equipment setups.

In summary, these visual tools are indispensable for ensuring the longevity and functionality of intricate systems. They foster understanding, communication, and efficiency across various applications, making them a vital resource in the field of mechanics.

Common Issues with Kohler 26 HP

Understanding the frequent problems associated with this particular power unit can greatly enhance maintenance and performance. Users often encounter several challenges that can affect reliability and efficiency, leading to potential operational downtime.

Fuel System Troubles: Inadequate fuel delivery can result from clogged filters or faulty injectors, causing poor performance and difficulty starting.

Cooling System Failures: Overheating is a common issue, often stemming from blocked cooling passages or a malfunctioning radiator, which can lead to severe damage if not addressed.

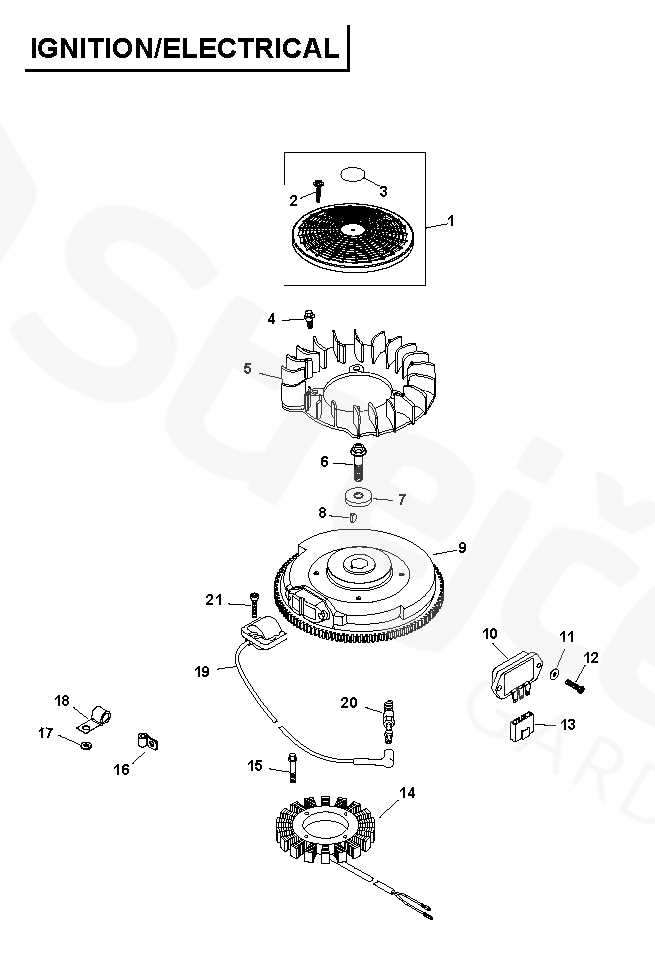

Electrical Component Issues: Battery failures, faulty wiring, or bad connections can lead to starting problems or intermittent performance, requiring careful inspection.

Oil Leaks: Seals and gaskets may wear out over time, leading to leaks that can affect lubrication and overall functionality.

Regular maintenance and prompt attention to these issues can ultimately prevent more severe complications and ensure optimal operation.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires regular upkeep and attention to detail. Implementing a few key practices can significantly extend the lifespan and efficiency of your equipment.

- Regularly check and change lubricants to prevent wear and tear.

- Keep air filters clean to promote optimal airflow and performance.

- Inspect all components for signs of damage or corrosion.

- Maintain proper fuel quality to enhance operation and reliability.

- Schedule routine cleaning to eliminate dirt and debris buildup.

By following these suggestions, you can help ensure that your machinery remains in peak condition for years to come.

Where to Find Replacement Parts

Locating suitable components for your machinery can be a daunting task, especially when seeking quality and compatibility. Fortunately, several avenues are available to help streamline the process and ensure you obtain what you need efficiently.

Authorized Dealers and Distributors

One of the most reliable sources for obtaining components is through authorized dealers and distributors. These establishments often carry a comprehensive selection of items that are specifically designed for your equipment, ensuring a perfect fit and optimal performance. Additionally, they typically offer expert advice and support, making it easier to navigate your options.

Online Marketplaces and Specialty Stores

The internet offers a plethora of options for sourcing replacement components. Numerous online marketplaces feature a wide array of offerings, allowing you to compare prices and reviews effortlessly. Specialty stores focused on equipment maintenance often provide detailed information about the products they sell, helping you make informed decisions. Remember to check for customer feedback to gauge the reliability of both the supplier and the items.

Diagram Interpretation for DIY Repairs

Understanding visual schematics is essential for anyone looking to tackle maintenance and repair tasks independently. These illustrations serve as a guide, detailing the layout and relationship of components within a system. Familiarity with these visuals can simplify complex procedures, enabling more efficient troubleshooting and restoration.

Key Elements to Consider

- Symbols: Each icon represents a specific component or function. Recognizing these is crucial for accurate interpretation.

- Labels: Pay attention to annotations that provide essential information regarding size, specifications, and material.

- Connections: Understanding how elements are linked can help identify potential issues and guide replacement strategies.

Steps for Effective Interpretation

- Study the Layout: Begin by examining the overall arrangement of the components. Note any groups or clusters that indicate related parts.

- Identify Symbols: Refer to a legend if available, to clarify what each symbol represents.

- Follow Flow: Trace the pathways indicated for fluids or electrical currents to comprehend functionality.

- Cross-reference: If possible, compare the schematic with real-life components to solidify your understanding.

Comparative Analysis with Other Brands

In the competitive landscape of small power units, evaluating the offerings of various manufacturers is essential for discerning users. This analysis will highlight key attributes, performance metrics, and reliability factors, providing a clearer understanding of how one brand stands against its competitors.

Performance and Efficiency

When comparing performance metrics, it’s vital to assess not just the raw power output but also fuel efficiency and operational smoothness. Many alternatives boast impressive horsepower, yet they may fall short in terms of fuel consumption or vibration levels. A thorough examination reveals that while some brands excel in torque delivery, others may offer more refined operation at lower speeds.

Durability and Maintenance

Durability is another critical factor in this comparison. Some manufacturers emphasize robust construction and longer service intervals, which can significantly reduce downtime. Conversely, others may require more frequent maintenance, impacting overall usability. Users often find that brands with a reputation for sturdiness and ease of upkeep tend to offer greater long-term value, even if their initial cost is higher.

Ultimately, making an informed choice involves considering these diverse aspects and determining which attributes align best with individual needs and preferences.

Expert Recommendations for Owners

For those who possess a powerful machine, understanding its upkeep and maintenance is essential for longevity and performance. Here are some expert insights that can enhance your ownership experience and ensure your device operates at its best.

Regular Maintenance Schedule

Establishing a consistent maintenance routine is crucial. Owners should perform periodic checks to identify any potential issues before they escalate. Regular tasks include oil changes, air filter replacements, and spark plug inspections.

Using Quality Components

Investing in high-quality components can significantly affect performance. It’s advisable to choose reputable brands known for their durability and reliability. This choice not only enhances functionality but also extends the lifespan of the machinery.

| Maintenance Task | Frequency | Recommended Action |

|---|---|---|

| Oil Change | Every 50 hours | Use high-grade oil suitable for your machine |

| Air Filter Check | Every 25 hours | Clean or replace as necessary |

| Spark Plug Inspection | Every 100 hours | Replace if worn or damaged |