Maintaining your lawn care equipment is essential for ensuring optimal performance and longevity. A clear visualization of each individual piece plays a crucial role in effective repairs and replacements. By familiarizing yourself with the layout of various components, you can streamline the maintenance process and enhance the overall efficiency of your machinery.

In this guide, we will explore a detailed breakdown of essential elements found in a specific model of mower. Knowing how each part interacts can help you troubleshoot issues more effectively, enabling you to keep your device running smoothly. Whether you’re a seasoned professional or a weekend warrior, having this knowledge at your fingertips is invaluable.

Understanding the intricate relationships between various sections can empower you to make informed decisions during repairs. This resource aims to provide clarity and insight into the workings of your equipment, ensuring that you are well-equipped to handle any challenges that may arise.

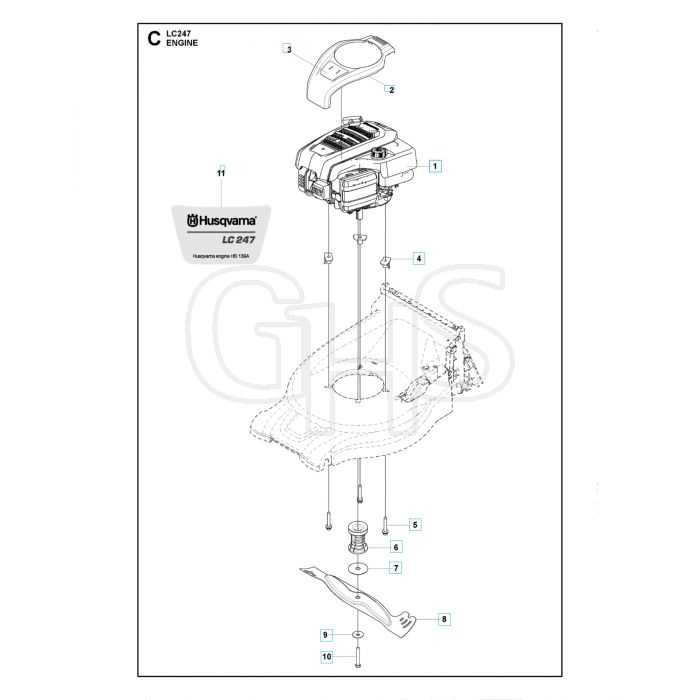

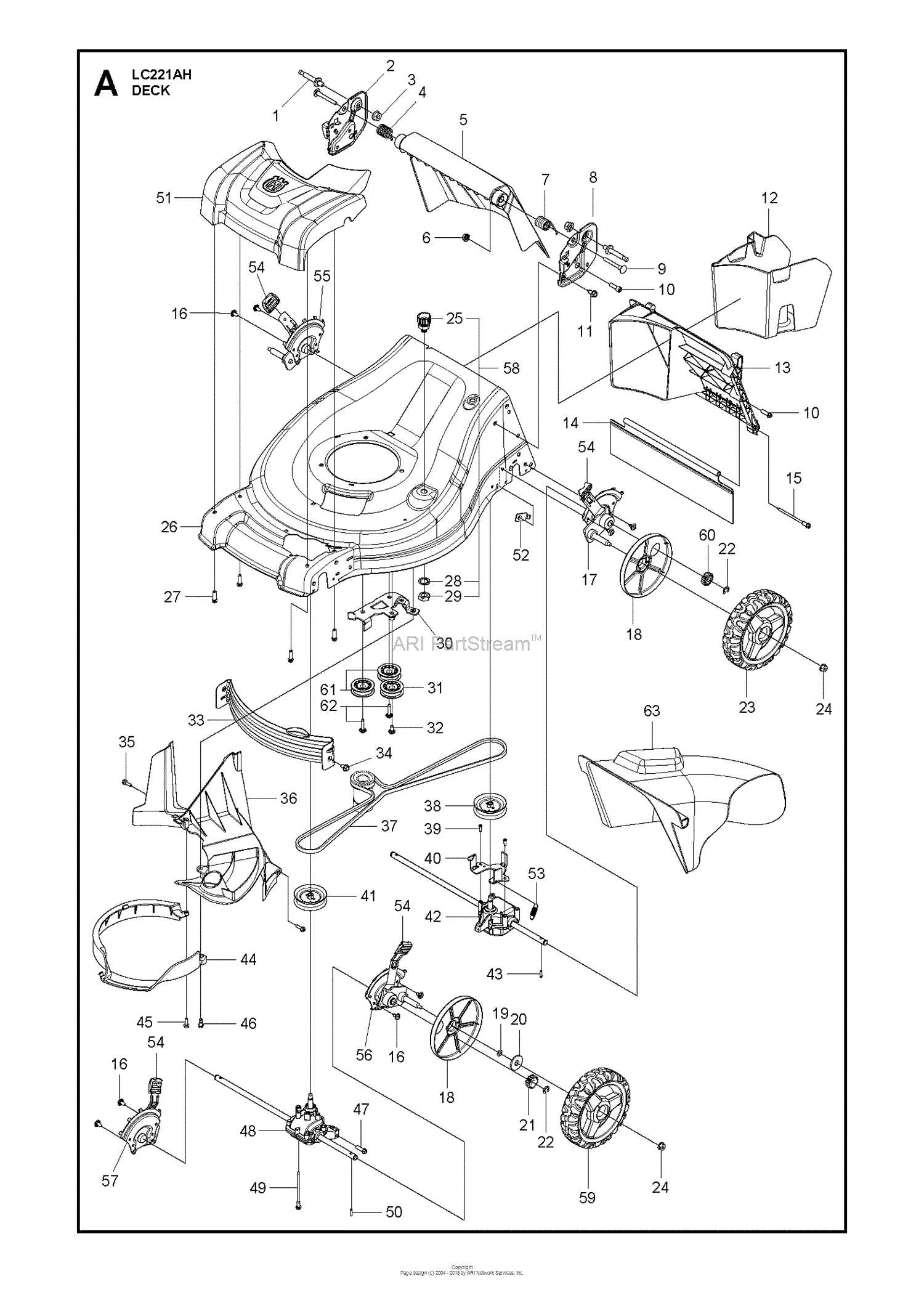

Understanding Husqvarna LC221A Components

Grasping the intricacies of a lawn maintenance machine requires an awareness of its various elements and how they function together. Each component plays a vital role in ensuring optimal performance and longevity. Below is a breakdown of the main components that contribute to the overall efficiency of these devices.

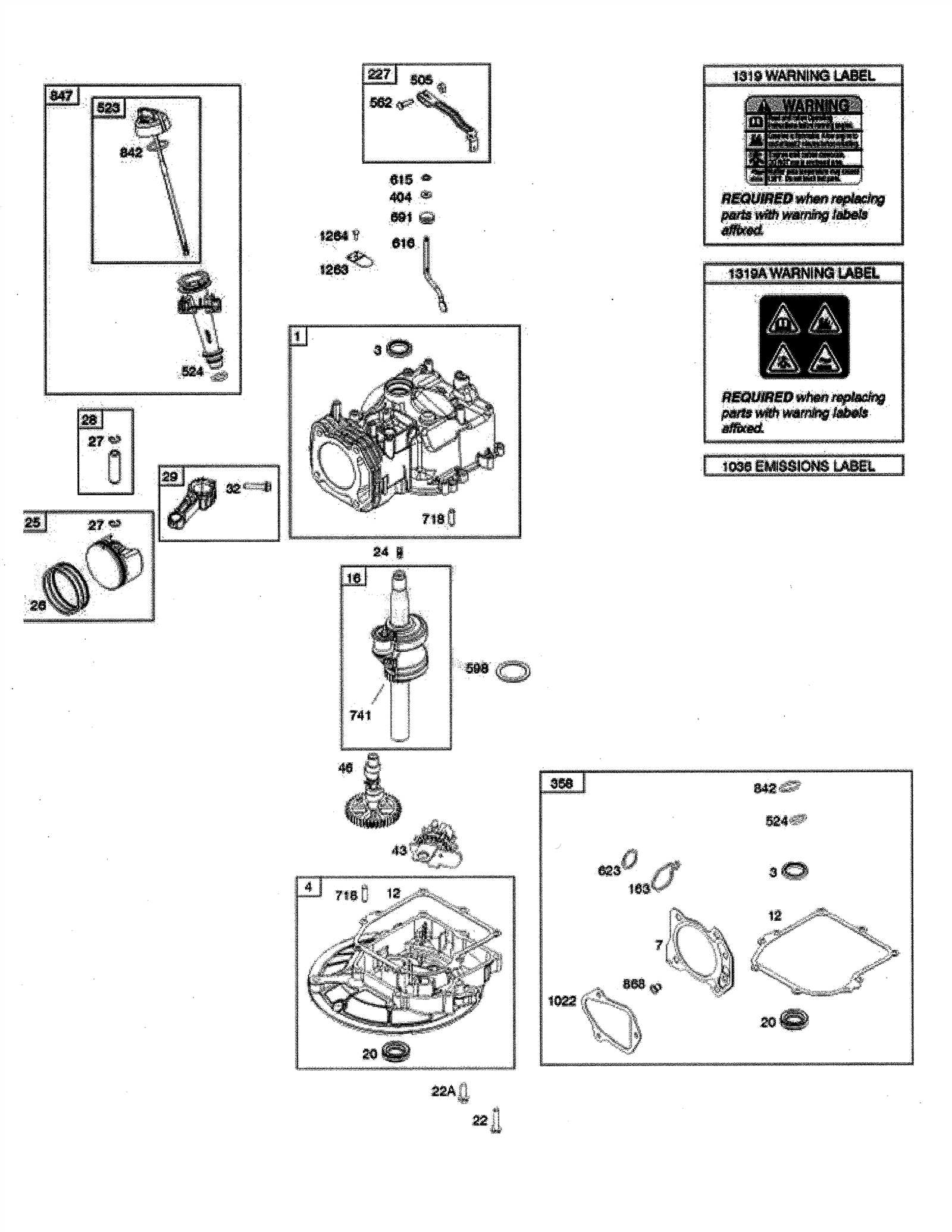

- Engine: The powerhouse of the machine, responsible for driving the entire system. Understanding its specifications can help in maintenance and troubleshooting.

- Cutting Deck: This is where the magic happens. The deck houses the blades and is crucial for achieving a clean cut. Its design influences the machine’s maneuverability.

- Blades: Sharp and durable, these elements are essential for effective grass trimming. Regular sharpening and replacement are necessary for peak performance.

- Wheels: The wheels determine how easily the machine can navigate different terrains. Their size and material impact the overall handling.

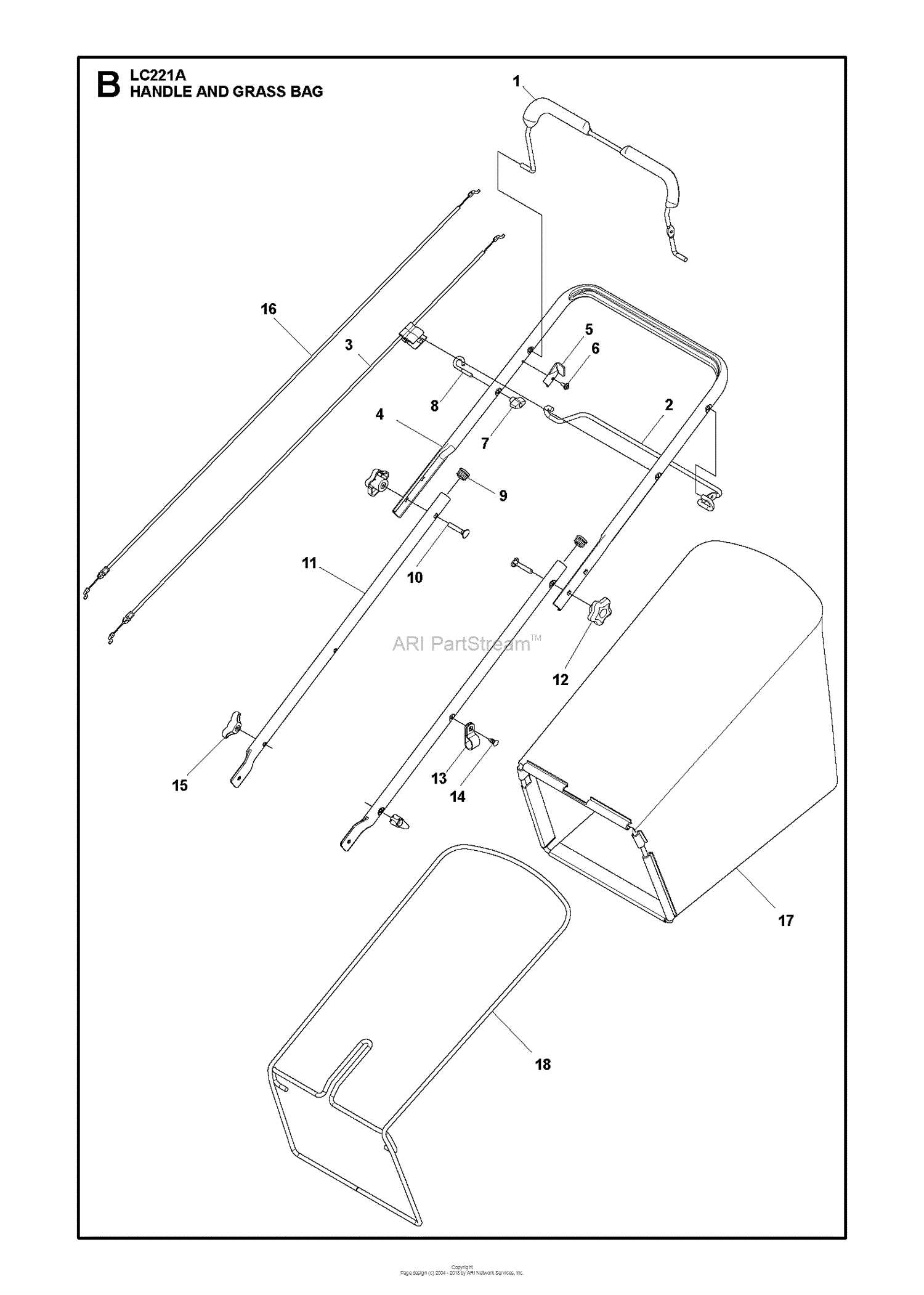

- Handle: A comfortable and adjustable handle allows for better control and reduces user fatigue during operation.

- Fuel System: Essential for the engine’s operation, this system includes the tank, filter, and lines, ensuring a steady fuel supply.

- Safety Features: Components like the kill switch and blade brake are critical for user safety, preventing accidents during operation.

Familiarity with these parts not only aids in proper maintenance but also enhances the user experience. Recognizing when a component needs attention can lead to more efficient and effective lawn care practices.

Importance of Parts Diagrams

Understanding the intricacies of mechanical systems is crucial for effective maintenance and repair. Visual representations serve as essential tools for identifying components and their relationships within a machine.

These illustrations offer numerous benefits:

- Facilitate quick identification of necessary components.

- Enhance comprehension of assembly and disassembly processes.

- Assist in troubleshooting and diagnosing issues efficiently.

By providing a clear overview, these resources ultimately improve the reliability and longevity of equipment.

Key Features of Husqvarna LC221A

This model offers a blend of advanced engineering and user-friendly design, ensuring efficient lawn maintenance. Its construction emphasizes durability and ease of use, making it a top choice for homeowners seeking reliable performance.

Performance

- Powerful engine for effective cutting.

- Adjustable cutting height for versatility.

- Lightweight design for easy maneuverability.

Convenience

- Ergonomic handle for comfortable operation.

- Easy-start feature for quick readiness.

- Compact size for efficient storage.

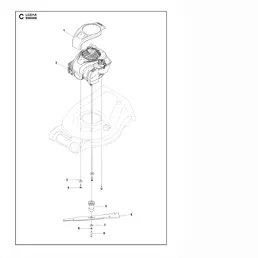

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide a clear layout of various elements, enabling users to identify and locate specific pieces with ease. Familiarizing oneself with the structure and notations used in these visuals can greatly enhance troubleshooting and assembly processes.

Key Elements to Look For

- Labels: Each component is typically labeled with a unique identifier. This helps in cross-referencing with the accompanying list of items.

- Numbering System: A consistent numbering system is often employed to indicate the order or importance of parts.

- Lines and Arrows: Lines connect related elements, while arrows can show movement or the direction of assembly.

- Groupings: Components may be grouped based on their function, making it easier to locate assemblies.

Steps for Effective Interpretation

- Begin by reviewing the entire illustration to get a sense of its layout and structure.

- Identify key labels and note their corresponding numbers or identifiers.

- Follow the connections indicated by lines to understand how components interact with each other.

- Use the list of items to find detailed descriptions and specifications for each part.

- Refer to any additional notes or legends provided, as they may offer crucial insights.

Common Replacement Parts Needed

Maintaining outdoor power equipment often requires replacing certain components to ensure optimal performance and longevity. Various elements may wear down over time due to regular usage, environmental factors, and age. Identifying these crucial items can help keep your machine running smoothly and efficiently.

Blades are among the most frequently replaced components. Dull or damaged blades can hinder cutting efficiency and lead to uneven results. Regular sharpening and timely replacement are essential for maintaining a clean cut.

Air filters play a vital role in engine health by preventing debris from entering the combustion chamber. A clogged filter can reduce performance and increase fuel consumption. It’s advisable to check and replace them regularly to ensure proper airflow.

Fuel filters are equally important, as they keep contaminants from reaching the engine. A blocked fuel filter can lead to starting issues and reduced power. Replacing this component periodically can prevent costly repairs down the line.

Spark plugs are essential for ignition and overall engine performance. Worn or fouled spark plugs can result in hard starting and misfires. Regular inspections and replacements can significantly enhance engine efficiency.

Belts, particularly drive belts, are crucial for transferring power from the engine to the cutting mechanism. Over time, they may wear out or become frayed, leading to performance issues. Regular monitoring and timely replacement can ensure smooth operation.

By staying aware of these common components and their maintenance needs, you can prolong the life of your equipment and enhance its performance, ensuring that it remains reliable for years to come.

Maintaining Your Lawn Mower

Proper upkeep of your grass-cutting equipment is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns, allowing you to enjoy a pristine lawn season after season.

Regular Inspection

Conducting routine checks on your machine can prevent larger issues down the line. Look for wear on the blades, inspect the air filter, and ensure all moving parts are functioning smoothly. A well-maintained mower will operate more effectively, making your lawn care tasks easier.

Cleaning and Care

Keeping your equipment clean is crucial. Remove grass clippings and debris after each use to avoid corrosion and clogs. Additionally, consider sharpening the blades regularly; a sharp edge makes cleaner cuts, promoting healthy grass growth. Investing time in these practices will lead to the ultimate performance of your mower.

Troubleshooting Common Issues

Addressing frequent problems with lawn maintenance equipment is essential for ensuring optimal performance. Understanding the typical symptoms and their causes can significantly aid in restoring functionality. This section will guide you through identifying and resolving various concerns that may arise during operation.

Engine Won’t Start: If the motor fails to ignite, check the fuel supply first. Ensure there is enough clean fuel in the tank, as stale or contaminated fuel can lead to starting issues. Additionally, inspect the spark plug for wear or carbon buildup, which can hinder ignition.

Uneven Cutting: When the cutting results are inconsistent, it may indicate a dull blade or improper height adjustment. Regularly sharpen the blade and ensure it is correctly aligned. Also, inspect the wheels for any obstructions that could affect mobility.

Excessive Vibration: If you experience unusual shaking during operation, this could be a sign of an imbalanced blade or loose components. Examine all mounting hardware and tighten any loose screws. Checking the blade for damage or misalignment is also recommended.

Overheating: Overheating can lead to severe damage if not addressed. Ensure that air filters are clean and unobstructed, allowing for adequate airflow. Additionally, check the oil level, as low oil can cause overheating due to increased friction.

By systematically addressing these common issues, you can enhance the efficiency and lifespan of your equipment, ensuring a well-maintained lawn throughout the season.

Where to Find Genuine Parts

When maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Genuine items ensure compatibility and reliability, helping you avoid potential issues from inferior alternatives.

Authorized Dealers

- Locate official retailers in your area.

- Visit their websites for online purchases.

- Check for service centers that provide genuine components.

Online Marketplaces

- Search trusted e-commerce sites specializing in machinery.

- Look for vendor ratings and customer reviews to ensure authenticity.

- Utilize forums and community groups for recommendations on reliable sources.

Benefits of Regular Maintenance

Consistent upkeep of machinery ensures optimal performance and longevity. By dedicating time to routine checks, users can prevent minor issues from escalating into major problems, ultimately saving time and resources.

Enhanced Efficiency

Regular servicing leads to improved operational efficiency. Clean components and well-lubricated parts reduce friction, allowing devices to function smoothly and effectively. This results in better output and lower energy consumption.

Cost Savings

Investing in periodic maintenance can lead to significant financial savings. Early detection of wear and tear minimizes the likelihood of costly repairs or replacements. Furthermore, maintaining peak condition often extends the lifespan of the equipment.