When dealing with appliances, it is essential to grasp the structure and arrangement of their internal elements. These components work in harmony to ensure the device operates efficiently, and understanding their placement can aid in maintenance and repairs. Whether you’re troubleshooting an issue or simply exploring the inner workings, knowing how the different parts connect can be a valuable skill.

Comprehending the layout of these internal mechanisms not only enhances your technical knowledge but also helps extend the lifespan of your equipment. Recognizing the correct connections and functions of various elements is critical for effective servicing. By taking a closer look at the arrangement, you gain insight into how the system operates as a whole.

Additionally, maintenance and troubleshooting become more manageable when you have a clear understanding of how each component fits within the larger framework. This knowledge can significantly reduce the complexity of repairs and prevent potential issues before they escalate.

Greystone CF-RV17 Parts Overview

The internal components of this device are essential for its efficient operation and durability. Each element is designed to perform specific functions, contributing to the overall performance and longevity of the system. Understanding the layout and interaction between these components can help ensure proper maintenance and avoid potential issues.

Key Elements and Their Roles

Among the various elements, some play a more critical role in ensuring functionality. These include the heating elements, control unit, and safety mechanisms, which work in harmony to maintain optimal performance. Regular inspections and cleaning of these parts can prolong the life of the unit.

Maintenance and Replacement Tips

To keep the system running smoothly, routine checks are vital. If any element shows signs of wear or damage, it’s essential to replace it promptly to avoid further complications. Always ensure compatibility when replacing components to maintain safety and efficiency.

Key Components and Their Functions

Understanding the essential elements and their roles is crucial for efficient maintenance and optimal performance. Each component contributes to the overall functionality, ensuring smooth operation and longevity. Below is a detailed breakdown of the primary elements and their respective purposes.

- Fan Motor – This component drives airflow through the system, maintaining consistent circulation and ensuring proper cooling or heating as needed.

- Thermostat – Responsible for regulating temperature, the thermostat ensures the system responds to changes in the environment, providing optimal comfort.

- Blades – The blades are designed to maximize air distribution, enhancing efficiency while minimizing energy consumption.

- Control Panel – This unit allows for adjustments and control of various settings, offering the ability to customize performance to meet specific needs.

- Filter – The filter helps remove impurities from the air, ensuring clean airflow and preventing damage to internal parts.

By familiarizing yourself with these core components, you can ensure better system upkeep and

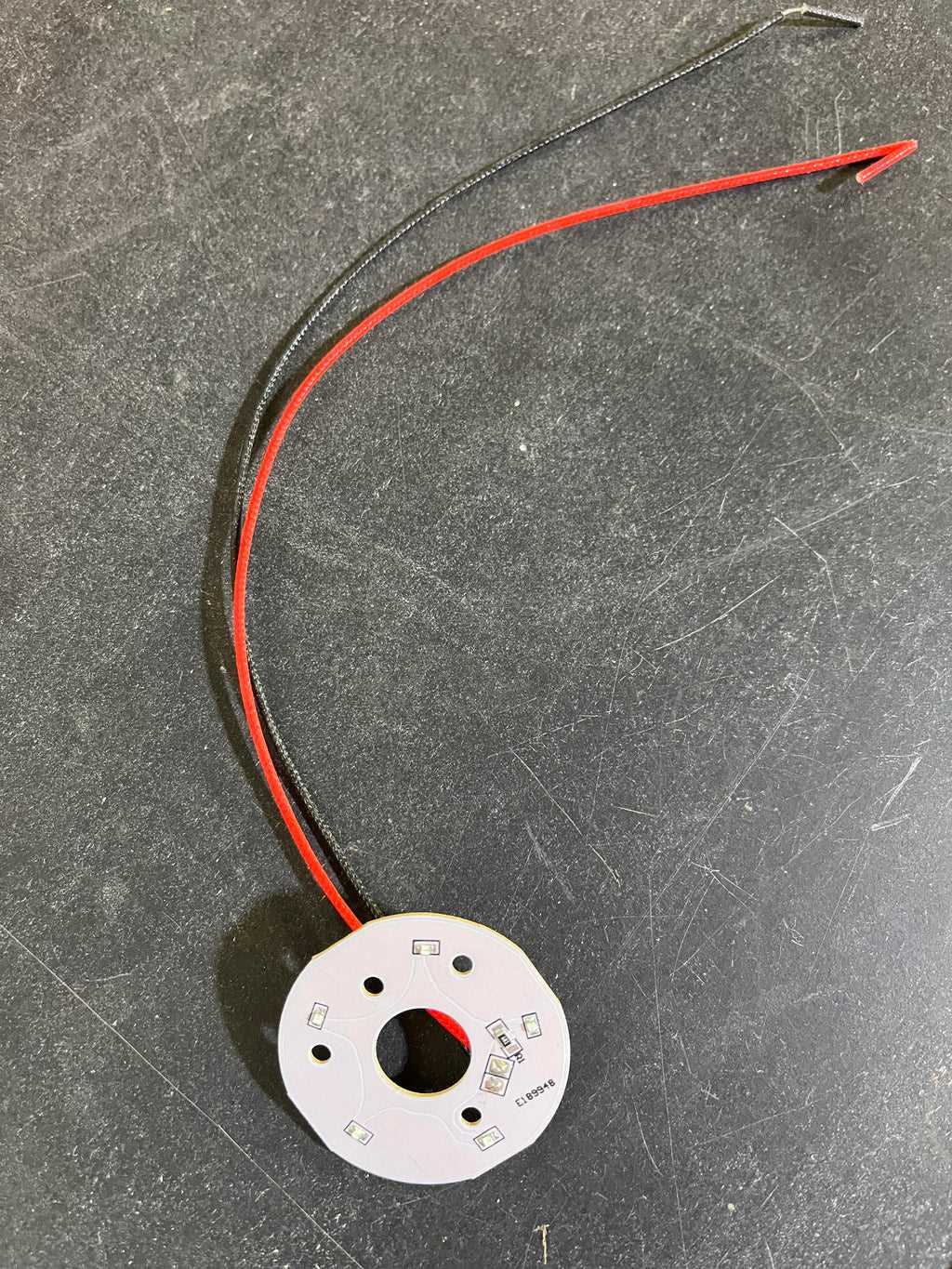

Understanding the Electrical System Layout

The electrical configuration in any unit is crucial for ensuring smooth operation and safety. A clear understanding of the wiring and connections helps users maintain and troubleshoot the system effectively, preventing potential malfunctions. This section explores the essential elements of the electrical network, focusing on its layout and functionality.

Below is a simplified overview of the key components and their connections:

| Component | Function |

|---|---|

| Main Power Supply | Provides energy to the entire system, powering all connected elements. |

| Fuse Box | Protects the circuit by cutting off power in case of overload or short circuits. |

| Wiring Harness | Links all electrical components, ensuring consistent energy flow and control. |

| Control Panel | Allows users to monitor and manage electrical settings, enhancing operational efficiency. |

| Grounding System | Ensures safety by directing excess electricity into the ground, reducing the risk of shock or fire. |

Familiarizing yourself with these elements will allow for better maintenance and quicker identification of potential issues

Maintenance Tips for Key Mechanisms

Ensuring the longevity and smooth operation of crucial mechanisms requires regular upkeep and attention to specific components. Regular maintenance can prevent common issues and prolong the lifespan of the entire system, enhancing overall performance.

Lubrication of Moving Parts

One of the most essential steps in maintaining key mechanisms is proper lubrication. Without adequate lubrication, moving elements can experience friction, leading to wear and tear. Apply suitable lubricants to all joints, rotating components, and hinges to keep the system functioning smoothly.

- Use a high-quality lubricant that matches the material of the parts.

- Avoid over-lubrication, as it may attract dust and debris.

- Inspect the parts regularly and reapply lubricant as necessary.

Inspect for Wear and Tear

Regular inspections can help identify worn or damaged components before they lead to more serious problems. Examine all critical areas, looking for signs of rust

Replacing Worn or Damaged Parts

Over time, various components of appliances may begin to show signs of wear, potentially affecting their performance. Identifying these worn-out elements early and replacing them promptly can help extend the overall lifespan of your device while ensuring it continues to function efficiently.

Step-by-Step Guide to Replacement

The process of replacing old or malfunctioning elements typically begins with carefully disassembling the relevant sections. Always ensure that the device is powered off and disconnected before proceeding. Next, remove the faulty component, taking note of how it was installed, and replace it with a new one. Use compatible replacement elements and follow the manufacturer’s guidelines for proper installation.

Maintenance Tips for Longevity

Regular maintenance can prevent premature wear. Clean the equipment regularly, inspect it for any signs of deterioration, and address minor issues before they worsen. Simple care practices can greatly extend the operational life of your appliance, minimizing the need for frequent replacements.

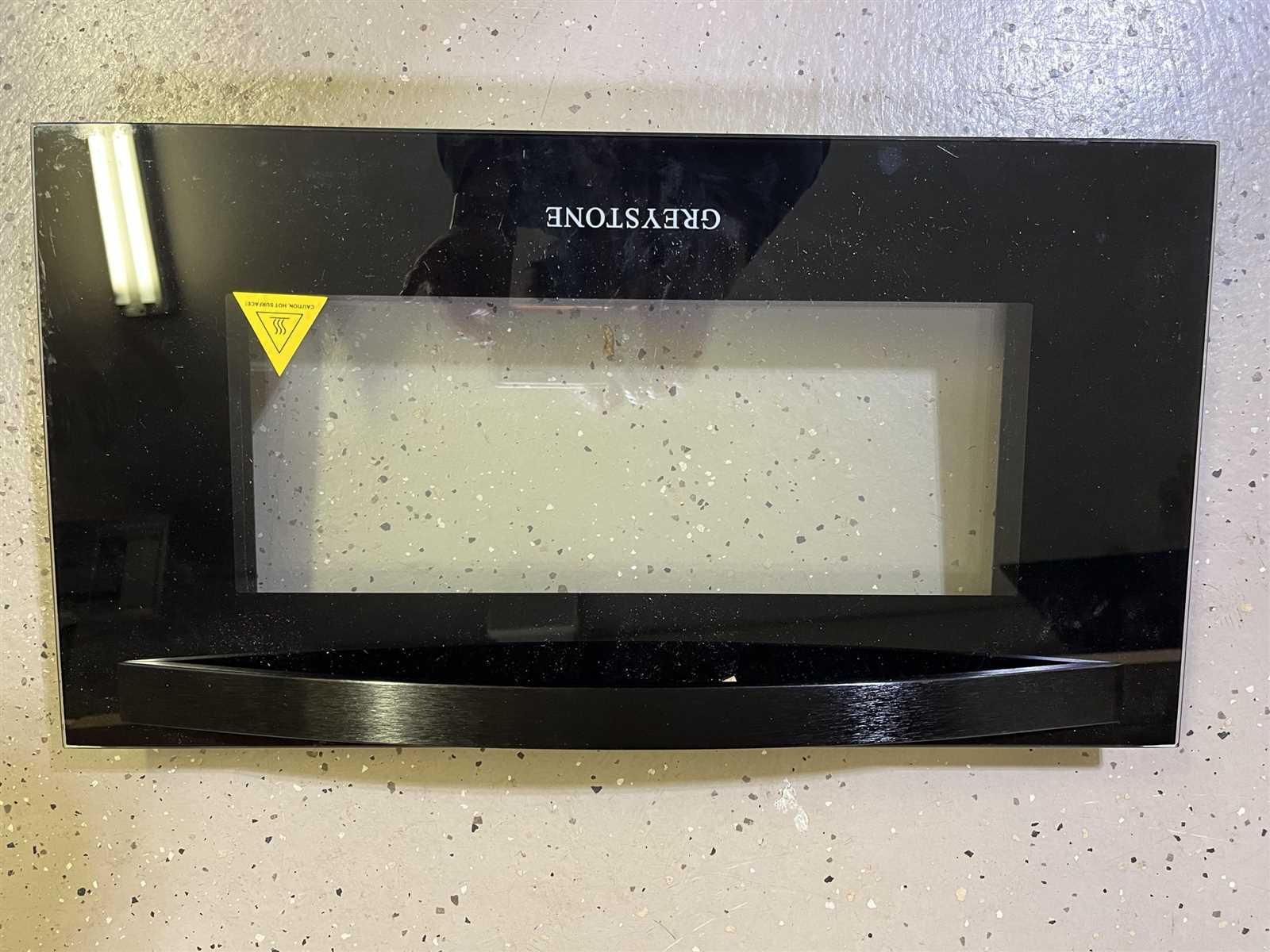

Installation Guide for New Components

This section provides essential instructions for effectively integrating new elements into your system. Proper installation is crucial for optimal performance and longevity. By following these guidelines, users can ensure a smooth transition and reliable functionality of their equipment.

Preparation Steps

Before commencing the installation, gather all necessary tools and components. Review the specifications of the new parts to ensure compatibility. It’s advisable to disconnect the power supply to avoid any electrical hazards during the process. Additionally, create a clean and organized workspace to facilitate efficient assembly.

Step-by-Step Installation

Begin by removing the old components carefully, taking note of their arrangement for reference. Install the new elements by following the reverse order of removal. Ensure all connections are secure and double-check that no loose wires are present. Once the installation is complete, restore the power and conduct a functionality test to confirm that everything operates as intended.

Identifying Common Issues and Solutions

In any mechanical system, recognizing frequent problems and their corresponding remedies is crucial for maintaining optimal functionality. Users may encounter various malfunctions that can impede performance, leading to inefficiencies. This section aims to highlight some typical challenges along with practical solutions to ensure smooth operation.

Frequent Problems

| Issue | Description | Possible Solution |

|---|---|---|

| Poor Performance | Insufficient output or efficiency, often caused by blockages or wear. | Regularly inspect components for debris and replace worn parts as necessary. |

| Noisy Operation | Unusual sounds indicating potential mechanical failure or misalignment. | Examine for loose components and realign or tighten as needed. |

| Inconsistent Functionality | Intermittent issues affecting reliable operation. | Check electrical connections and replace any faulty wiring or components. |

Preventive Measures

To mitigate the occurrence of these issues, regular maintenance is essential. Establishing a routine inspection schedule and promptly addressing minor problems can significantly extend the lifespan of the system and enhance overall performance.

Compatible Accessories for Upgrading

Enhancing functionality and performance often involves selecting appropriate add-ons and enhancements. Upgrading your appliance can lead to improved efficiency, increased versatility, and a better overall user experience. Below are some accessory options to consider for a significant upgrade.

Essential Add-ons

- Temperature Control Sensors: Improve precision in temperature regulation, ensuring optimal performance.

- Advanced Shelving Units: Customize storage space to accommodate various food items effectively.

- Smart Connectivity Modules: Enable remote monitoring and control through mobile devices for enhanced convenience.

Performance Enhancements

- Upgraded Ventilation Fans: Enhance airflow, improving cooling efficiency.

- Energy-Saving LED Lighting: Reduce energy consumption while providing better illumination.

- High-Quality Insulation Kits: Improve energy retention, leading to cost savings on utility bills.

Safety Considerations During Assembly

Ensuring a safe assembly process is crucial for maintaining the integrity of the unit and preventing potential hazards. Proper precautions should be taken to minimize risks and ensure the well-being of all individuals involved in the assembly procedure.

- Personal Protective Equipment (PPE): Always wear appropriate safety gear, including gloves, goggles, and protective clothing, to guard against injuries.

- Work Area Organization: Maintain a clean and organized workspace to prevent accidents. Remove any unnecessary tools or materials that could create hazards.

- Read Instructions Thoroughly: Before starting the assembly, carefully review all provided instructions to understand the steps and safety warnings.

- Tool Safety: Use tools correctly and ensure they are in good working condition. Familiarize yourself with each tool’s specific safety requirements.

- Team Communication: Communicate clearly with team members during the assembly process. Use hand signals or verbal cues to enhance coordination.

- Check for Damage: Inspect all components before assembly for any signs of damage. Do not use damaged parts, as they could compromise safety and functionality.

By adhering to these safety guidelines, individuals can significantly reduce the likelihood of accidents and ensure a smoother assembly experience.