In the world of farming equipment, comprehending the intricacies of machinery is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring the overall efficiency and productivity of these powerful machines.

Exploring the layout of various elements allows operators and technicians to identify potential issues and facilitate repairs. This understanding not only enhances the lifespan of the equipment but also minimizes downtime, which is vital in the fast-paced agricultural sector.

By delving into the structure and organization of these vital parts, users can gain insights that lead to informed decisions regarding upkeep and upgrades. Ultimately, such knowledge fosters a deeper connection between the operator and their machinery, paving the way for greater success in the field.

Understanding John Deere 661R Components

Grasping the intricacies of machinery components is essential for optimal performance and maintenance. Each element plays a vital role in the overall functionality, contributing to efficiency and longevity. A thorough understanding of these components allows users to address issues promptly and enhance their operational capabilities.

In this section, we will explore various essential components that make up this specific model. The following table summarizes key elements, their functions, and significance in the overall system.

| Component | Function | Importance |

|---|---|---|

| Engine | Powers the machinery | Core of operation and performance |

| Transmission | Transfers power to the wheels | Critical for speed and control |

| Hydraulic System | Controls attachments and implements | Enhances versatility and productivity |

| Electrical System | Provides power to the control systems | Essential for functionality and safety |

| Chassis | Houses all components | Structural integrity and stability |

Each component interacts with others, forming a cohesive unit that ensures smooth operation. Regular maintenance and inspection of these parts can significantly affect performance, ultimately leading to improved productivity in various applications.

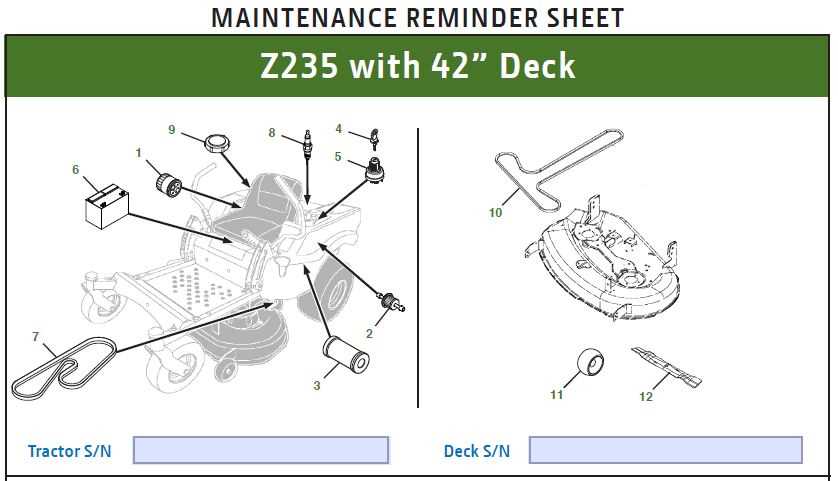

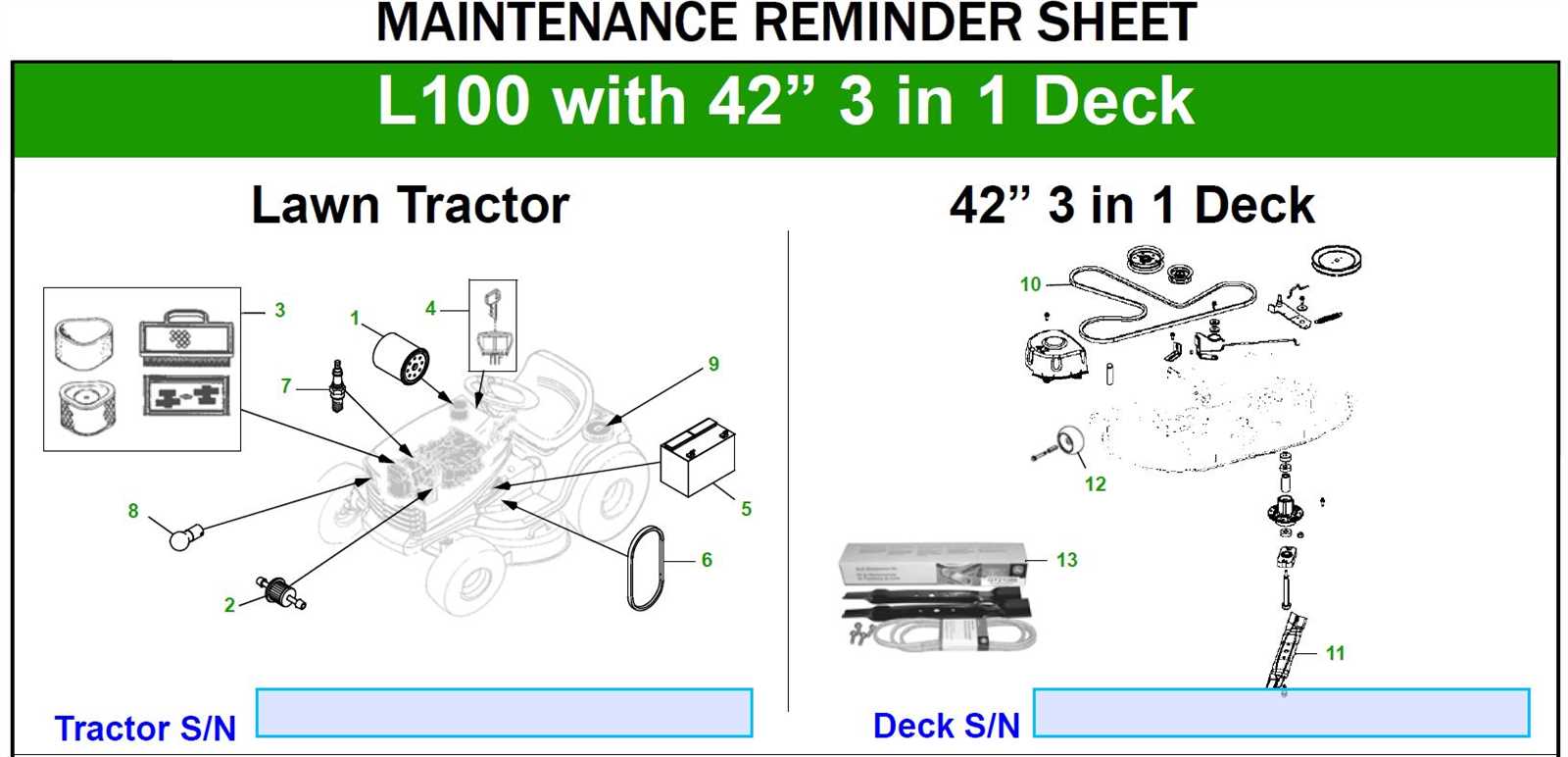

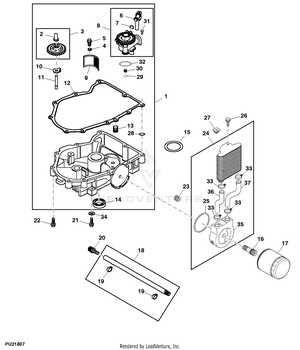

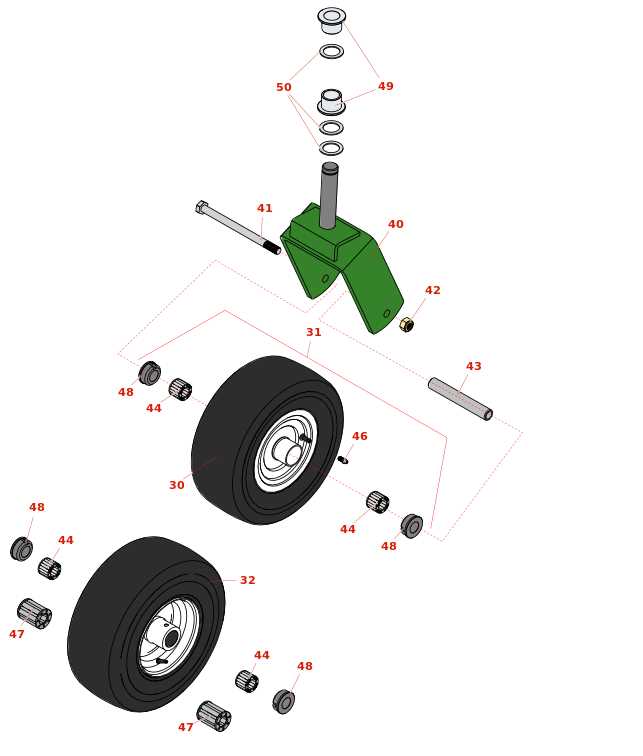

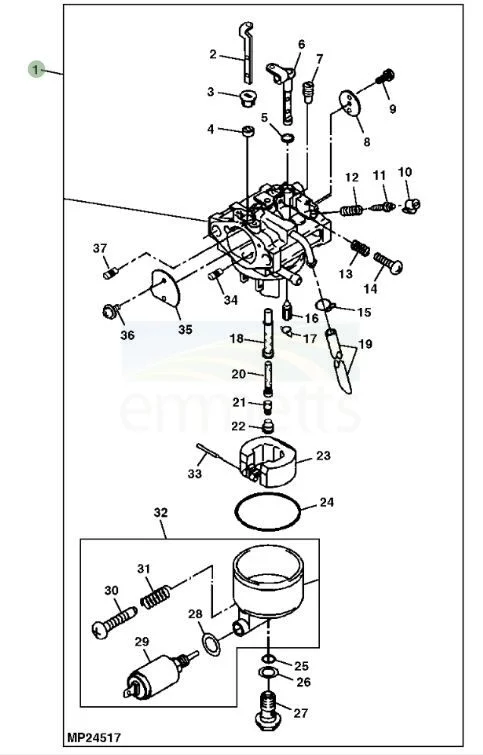

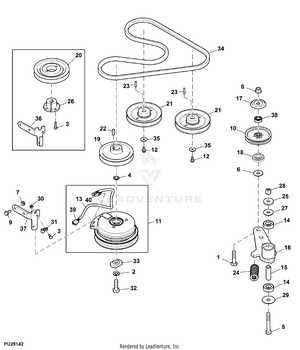

Importance of Parts Diagrams

Understanding the intricate components of machinery is essential for efficient maintenance and repair. Visual representations serve as crucial tools that allow technicians and operators to identify each element clearly, facilitating a smoother workflow. These illustrations provide not just a layout but also insights into how various sections interact, enabling informed decision-making during service tasks.

One significant advantage of utilizing these visual aids is the reduction of errors during repairs. When technicians can easily reference the configuration of each component, they are less likely to misplace or improperly install any parts. This accuracy ultimately leads to enhanced performance and longevity of the equipment.

Moreover, these visual guides foster a deeper understanding of the machinery. By studying the layout, users can grasp how systems operate collectively, which is invaluable for troubleshooting. This comprehension not only aids in immediate repairs but also promotes proactive maintenance, ensuring that issues are addressed before they escalate.

In summary, visual representations of machinery components are indispensable resources. They enhance efficiency, minimize mistakes, and promote a thorough understanding of the equipment, all of which contribute to its optimal functioning and durability.

Common Issues with John Deere 661R

Every piece of machinery comes with its own set of challenges. Users often encounter various operational difficulties that can affect performance and reliability. Understanding these common problems can help in preventive maintenance and enhance the lifespan of the equipment.

Electrical Problems

One frequent issue involves electrical components. Faulty wiring, blown fuses, or malfunctioning sensors can lead to unexpected shutdowns or erratic behavior. Regular inspections and prompt replacements of worn-out parts can mitigate these concerns.

Hydraulic System Failures

Another area of concern is the hydraulic system. Leaks, inadequate fluid levels, or failing pumps may result in reduced efficiency and power loss. Maintaining proper fluid levels and checking for leaks regularly are essential practices to ensure smooth operation.

Maintenance Tips for Longevity

Ensuring the long-term functionality of your machinery requires a proactive approach to upkeep. Regular maintenance not only enhances performance but also extends the lifespan of the equipment, ultimately saving time and resources. Here are some essential strategies to keep your machine in optimal condition.

Regular Inspections

Conducting routine assessments can help identify potential issues before they escalate. Focus on the following areas during inspections:

| Component | Inspection Frequency | Key Checks |

|---|---|---|

| Engine | Every 50 hours | Oil level, filters, leaks |

| Hydraulic System | Every 100 hours | Fluid levels, hoses, connections |

| Blades | Every 25 hours | Sharpness, damage, wear |

Lubrication and Cleaning

Maintaining proper lubrication and cleanliness is vital for smooth operation. Regularly grease moving parts and clean debris from components to prevent wear. Additionally, using the appropriate lubricants enhances efficiency and reduces friction.

Where to Find Replacement Parts

Locating suitable components for machinery can be a straightforward process with the right approach. Understanding where to search can save both time and money while ensuring that your equipment remains in top condition.

Online Retailers: Numerous e-commerce platforms specialize in equipment components. These sites often provide detailed descriptions and images to help you identify the correct item.

Local Dealers: Visiting authorized dealerships can be beneficial. They usually carry a wide range of original components and can offer expert advice.

Salvage Yards: Consider exploring salvage yards that focus on agricultural equipment. They may have used components at a fraction of the original price.

Manufacturer Websites: Many manufacturers have official websites featuring catalogs of available items. This resource can be invaluable for ensuring compatibility.

Online Forums and Communities: Engaging with fellow machinery enthusiasts can provide insights on where to find specific components, as well as recommendations for reliable sources.

How to Interpret Diagrams Effectively

Understanding visual representations is crucial for grasping complex information quickly. By breaking down these illustrations, you can uncover essential details and connections that enhance your overall comprehension.

Here are some key strategies to help you interpret visual aids:

- Identify the Components: Look for labels and symbols that indicate various elements.

- Follow the Flow: Trace pathways and relationships to understand how parts interact.

- Use a Legend: Refer to accompanying legends to clarify meanings of specific symbols.

- Take Notes: Jot down insights or questions as you analyze the representation.

- Practice: Regularly engaging with different types of visuals will improve your skills over time.

By employing these techniques, you can delve deeper into the material and extract the ultimate insights necessary for effective understanding.

Comparing Models: 661R vs. Others

When evaluating different models within the same category, it’s essential to assess their features, performance, and suitability for various tasks. Each model presents unique advantages, making it crucial to consider what best aligns with specific needs and applications.

| Feature | 661R | Model A | Model B |

|---|---|---|---|

| Power | 25 HP | 22 HP | 28 HP |

| Weight | 1500 lbs | 1400 lbs | 1600 lbs |

| Transmission | Hydrostatic | Manual | Automatic |

| Fuel Efficiency | 20 MPG | 22 MPG | 18 MPG |

By examining these attributes, potential users can make informed choices tailored to their operational requirements, ensuring optimal performance and efficiency across different applications.

Cost Analysis of Replacement Parts

Understanding the financial implications of substituting components is crucial for effective maintenance and budget management. This analysis helps in evaluating the potential expenses associated with procuring new items, ensuring that operators can make informed decisions that align with their operational needs.

Replacement expenses can vary significantly based on several factors, including brand reputation, availability, and material quality. It is essential to consider not just the upfront costs, but also long-term value and performance to ensure that investments lead to greater efficiency and reduced downtime.

Moreover, conducting a thorough comparison of different suppliers can reveal hidden savings. Often, opting for generic alternatives may lower initial expenditures, yet it is important to assess the impact on durability and reliability.

Ultimately, a well-rounded cost analysis empowers decision-makers to balance quality and expense, facilitating a strategic approach to maintaining equipment longevity.

Expert Reviews and Recommendations

This section aims to provide insightful evaluations and suggestions regarding various components for a popular agricultural machine. Expert opinions can help users make informed decisions when selecting the best accessories or replacements for optimal performance.

Key Factors to Consider

- Durability: Look for parts that withstand heavy use and adverse conditions.

- Compatibility: Ensure the components fit perfectly with your equipment to avoid functionality issues.

- Manufacturer Reputation: Choose trusted brands known for quality and reliability.

- Cost-Effectiveness: Evaluate the balance between price and performance.

Top Recommended Components

- High-Performance Filters: Essential for maintaining engine efficiency and longevity.

- Heavy-Duty Blades: Crucial for effective cutting and productivity in various terrains.

- Robust Belts: Vital for reliable operation and minimizing downtime.

- Advanced Electronics: Enhance control and monitoring of the machinery for improved results.