Understanding the inner workings of any machine is key to ensuring its longevity and performance. By exploring the detailed layout of various mechanical elements, one can gain valuable insights into how these pieces come together to form a functional whole. This examination not only helps in routine maintenance but also assists in identifying potential issues before they escalate into larger problems.

Whether you’re performing regular upkeep or tackling repairs, having a clear view of how each component interacts is vital. With a well-organized layout of essential mechanical structures, you can easily navigate the complex network of interconnected parts. This guide aims to provide clarity and ease for those looking to ensure smooth and efficient operation.

In addition, by familiarizing yourself with these elements, you can

John Deere Z345R Parts Overview

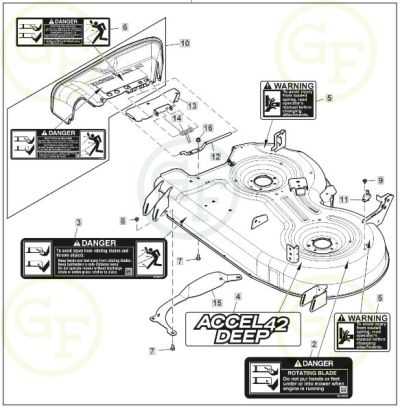

The overall structure of this lawn machine is built with a variety of essential components, each playing a critical role in its functionality. From the cutting mechanisms to the steering system, every element is designed to ensure smooth operation and reliable performance. Understanding the key features and how they interact will help users maintain and optimize their equipment.

Engine and Power System: At the core of the unit lies the motor, providing the necessary energy to power all the systems. Efficient fuel delivery and air intake keep this system running at peak performance, contributing to the overall efficiency of the machinery.

Blades and Cutting Deck: The rotating blades are the centerpiece of the cutting system. Designed for precision, they ensure a clean and consistent cut. The deck beneath them helps to channel grass clippings and ensures even distr

Key Components and Their Functions

This section covers the essential mechanical elements that ensure smooth and efficient operation of the equipment. Understanding these components will help users maintain performance and address any issues that may arise during usage.

- Engine: The power source responsible for driving the system, enabling movement and function.

- Transmission: Transfers power from the motor to the wheels, allowing speed and direction control.

- Cutting Deck: Houses the blades that trim the surface, ensuring an even and precise cut.

- Blades: Sharp components that rotate to slice through materials, ensuring effective operation.

- Steering Mechanism: Controls the direction of movement, providing accurate maneuvering around obstacles

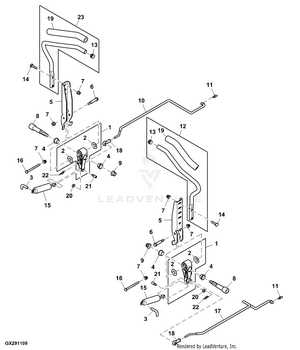

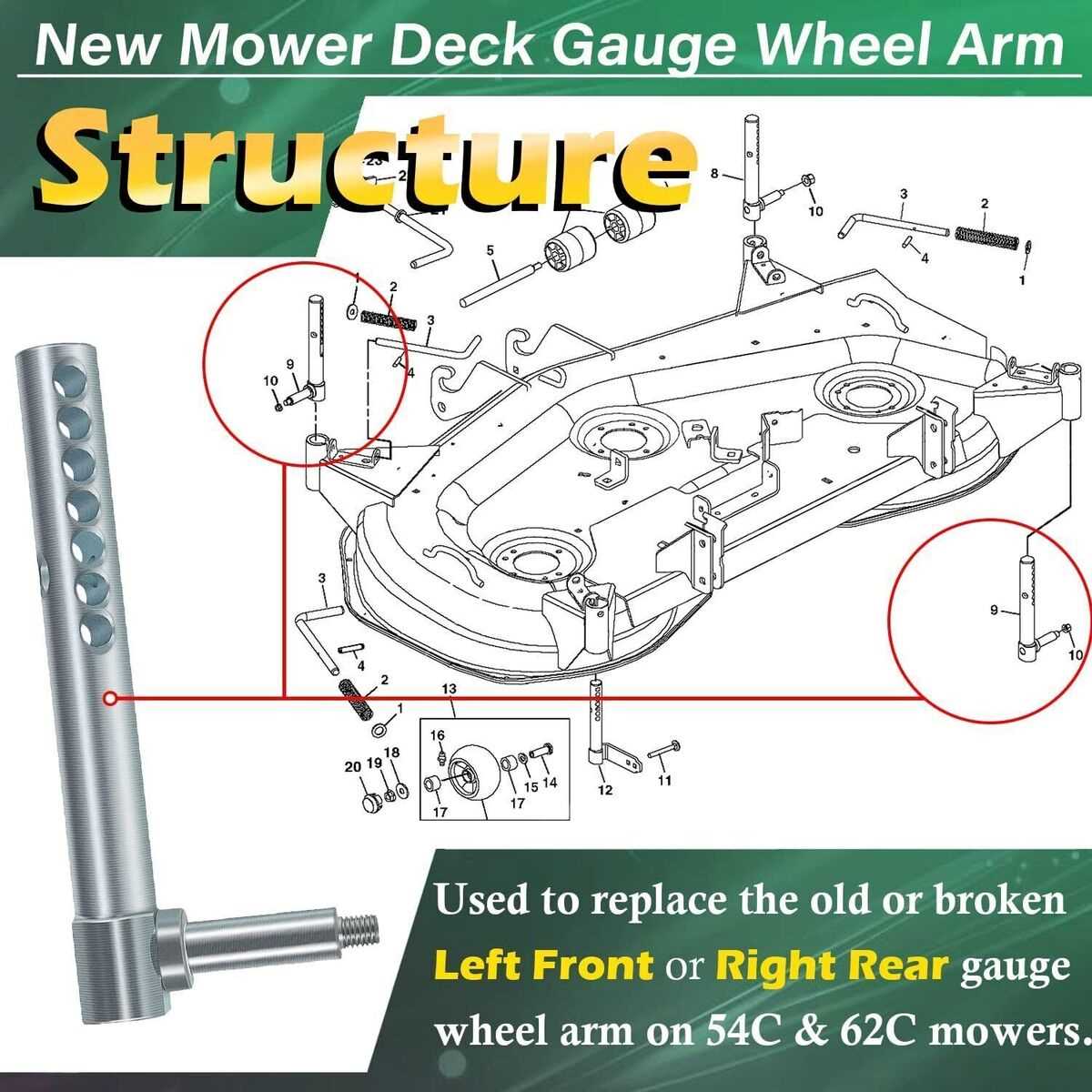

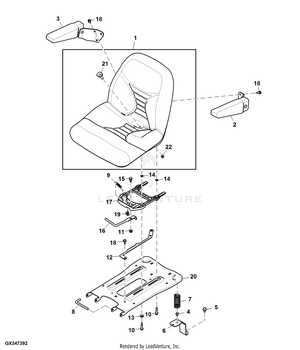

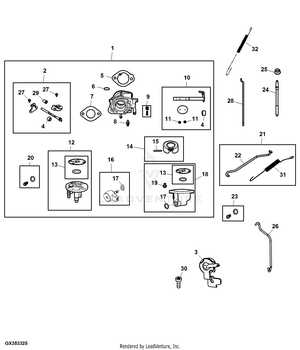

Deck Assembly Breakdown

The deck structure consists of various interconnected components that work together to ensure efficient operation. Understanding the different parts involved in this assembly is essential for both maintenance and optimal performance. Each element plays a specific role in supporting the cutting process, ensuring stability, and facilitating the smooth functioning of the entire system.

Main Components Overview

Key elements in the deck include blades, spindles, and pulleys. Blades are responsible for the precise cutting action, while spindles hold them in place and rotate to perform the cutting task. Pulleys manage the transfer of power, ensuring that the motion is distributed evenly to all working parts.

Support Mechanisms and Adjustments

Beyond the core components, the deck relies on support

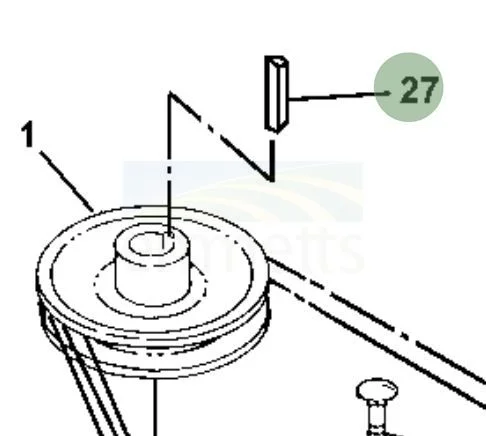

Engine and Transmission Diagram

The engine and transmission are crucial components that work together to ensure the smooth operation of the vehicle. In this section, we will explore how these systems interact and provide a visual representation of their internal structure. Understanding their layout is essential for proper maintenance and troubleshooting.

Engine Layout and Components

The engine consists of several key parts, including the combustion chamber, valves, and pistons. These elements work in unison to convert fuel into mechanical energy. The arrangement of these parts plays a vital role in the engine’s efficiency and power output.

Transmission Mechanism

The transmission transfers the engine’s power to the wheels, allowing for speed adjustments and smooth shifting between gears. It includes gears, shafts, and a clutch system that synchronize the movement of the vehicle. Proper care of the transmission ensures long-term performance and reliability.

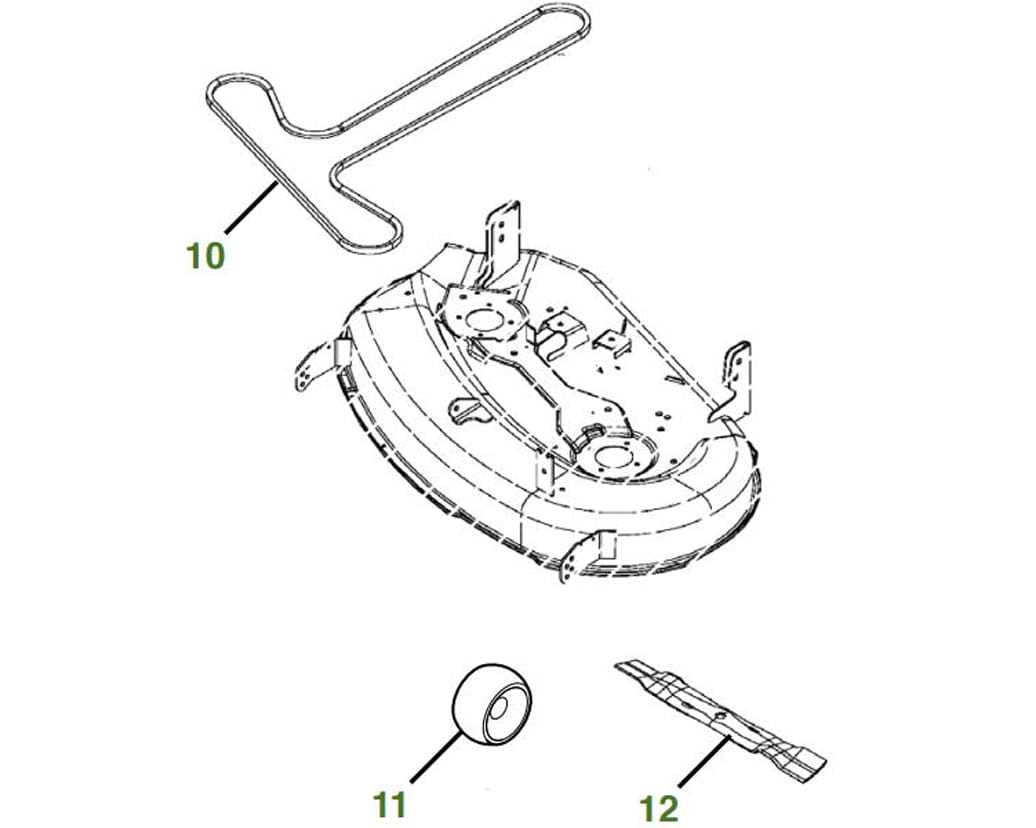

Blades and Cutting Mechanism

The cutting system is crucial for achieving a precise and efficient lawn trim. A well-maintained set of blades ensures an even cut, contributing to the overall performance of the machine. The mechanism that supports the cutting function must work seamlessly for optimal results.

Blade Design and Function

The sharpness and balance of the blades play a key role in maintaining an efficient cut. Regular inspection is important to ensure that the edges remain sharp, preventing uneven grass length and damage to the turf.

- Blades must be sharpened periodically to maintain cutting precision.

- Proper balancing of the blades reduces wear and tear on the mechanism.

- A clean cut minimizes stress on the grass, promoting healthier lawn growth.

Cutting Mechanism Maintenance

To ensure

Steering and Control System

The steering and control mechanism is essential for achieving precision and agility while operating the machine. This system is designed to provide smooth maneuverability, allowing users to navigate through various terrains with ease. A well-functioning control setup ensures optimal performance and enhances the overall user experience.

Components of the steering and control system typically include the steering wheel, linkage, and hydraulic elements. Each component plays a crucial role in translating the operator’s input into responsive movements, ensuring the machine reacts accurately to directional changes.

Maintaining the steering and control system involves regular checks and adjustments. It is important to inspect the hydraulic fluid levels, ensure that all linkages are free from wear, and confirm that the steering wheel responds appropriately. By addressing any issues promptly, operators can prolong the lifespan of the system and enhance safety during operation.

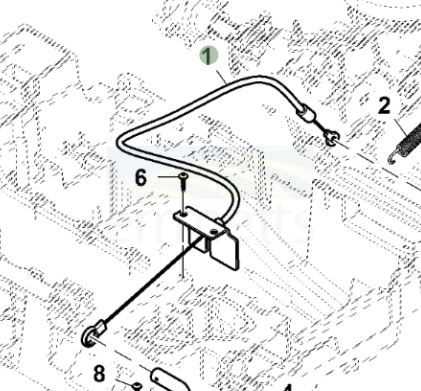

Electrical Parts and Wiring

This section delves into the essential components and connections that constitute the electrical system of the machinery. Understanding the layout and function of these elements is crucial for effective maintenance and troubleshooting. Each component plays a significant role in ensuring the equipment operates smoothly and efficiently.

Key Electrical Components

Among the vital elements of the electrical assembly are the battery, ignition switch, and various sensors. The battery serves as the primary power source, while the ignition switch facilitates the starting process. Sensors monitor critical parameters, relaying information to the control systems, which enhances operational performance.

Wiring and Connections

The wiring harness connects all electrical parts, ensuring proper communication and power distribution. Each wire must be inspected regularly for wear and damage to prevent electrical failures. Secure connections are paramount, as loose or corroded terminals can lead to operational issues. Regular maintenance of the wiring system contributes significantly to the longevity and reliability of the equipment.

Maintenance Tips for Z345R

Proper upkeep of your lawn equipment is essential for ensuring optimal performance and longevity. Regular maintenance can prevent breakdowns and enhance the efficiency of your machine, allowing you to achieve a well-manicured lawn with ease. Adhering to a consistent maintenance schedule is key to keeping your equipment running smoothly.

Routine Checks and Cleaning

Conducting routine inspections is vital to identify any wear or damage early. Check the blades for sharpness and clean them after each use to avoid grass buildup. Additionally, inspect the air filter regularly and replace it when it appears dirty to ensure proper airflow and engine performance.

Fluid Maintenance

Monitoring and changing fluids is crucial for the health of your machine. Regularly check the oil level and change the oil according to the manufacturer’s guidelines to maintain engine efficiency. Ensure that the fuel system is clean and filled with fresh fuel to prevent starting issues and enhance overall performance.

Where to Find Replacement Parts

Locating suitable components for your outdoor equipment can significantly enhance its performance and longevity. Understanding where to source these items ensures that you maintain the optimal functioning of your machinery.

Online Retailers

Many online platforms specialize in providing a wide range of components for outdoor machinery. These sites often feature user-friendly interfaces that allow for easy navigation and search options. Here are some notable retailers:

- Major e-commerce websites that carry a vast inventory.

- Specialized online shops dedicated to machinery supplies.

- Manufacturer websites offering original equipment.

Local Dealers and Stores