In the world of agriculture, machinery plays a vital role in enhancing efficiency and productivity. Understanding the various elements that comprise these machines is essential for effective operation and maintenance. This knowledge not only helps in troubleshooting but also ensures optimal performance during peak seasons.

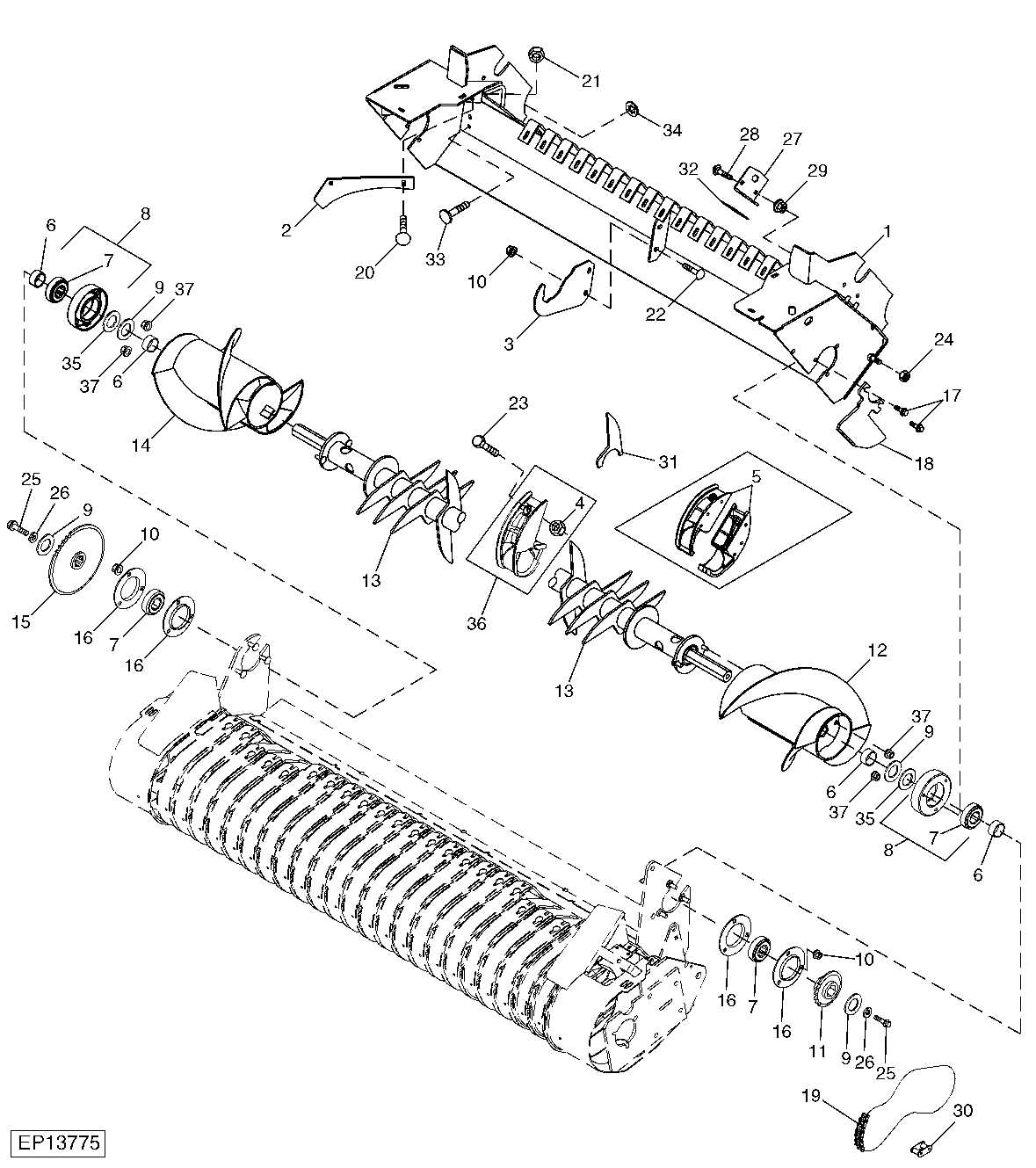

When dealing with complex machinery, visual representations of components can significantly aid in comprehending how each part interacts. A detailed illustration serves as a valuable resource for operators and technicians alike, enabling them to identify and address issues with precision. Recognizing the layout of the equipment can lead to improved functionality and prolonged lifespan.

Whether you’re a seasoned farmer or new to the field, familiarizing yourself with the intricate design of your equipment is a key step towards success. Armed with this understanding, you can tackle repairs and maintenance tasks more effectively, ultimately contributing to the overall health of your agricultural operations.

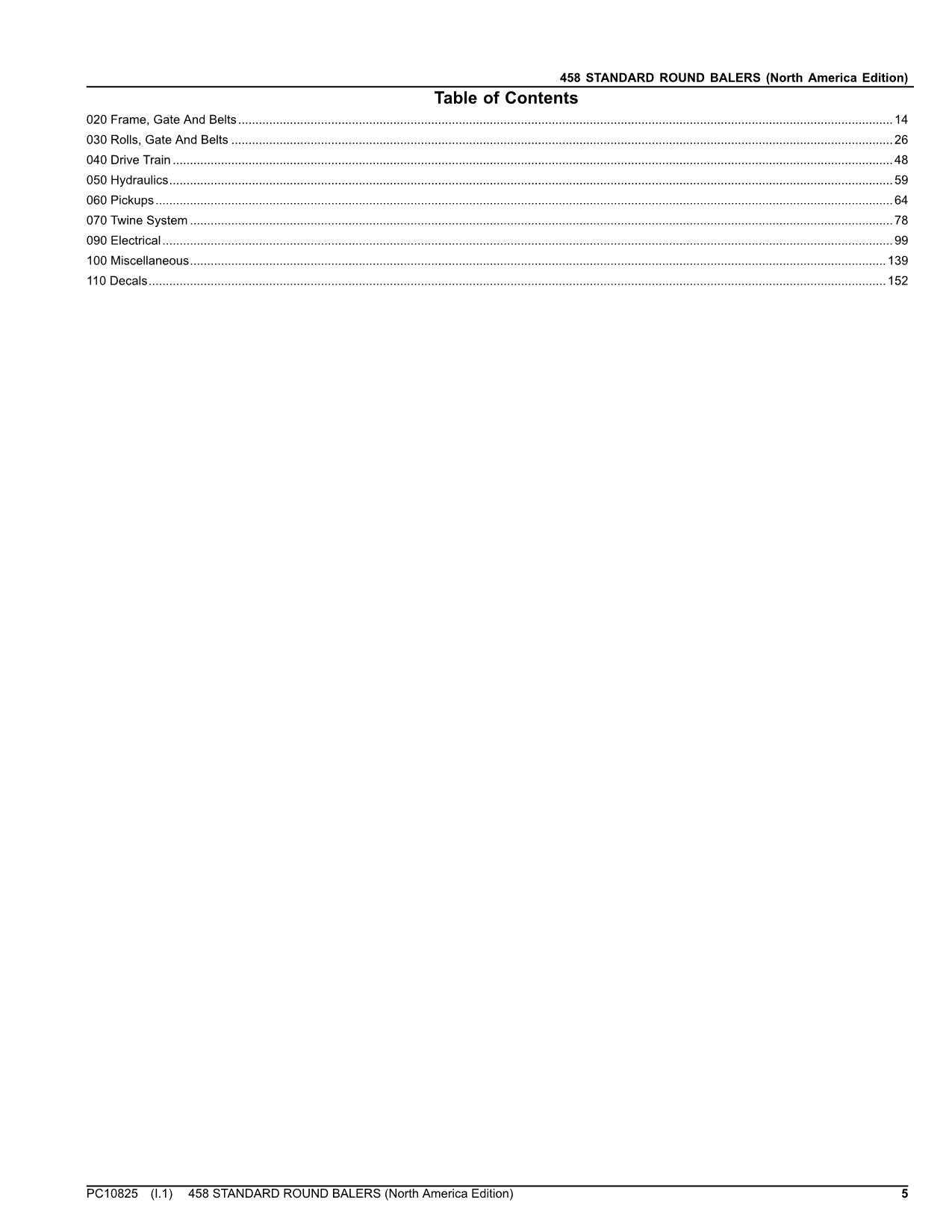

Understanding John Deere 458 Baler

The machine in question is a vital tool for agricultural operations, designed to efficiently bundle crops and manage waste. Its functionality relies on a series of interconnected components, each playing a crucial role in the overall performance. Familiarity with these elements can significantly enhance the efficiency and longevity of the equipment.

At the core of this machinery lies a robust mechanism that enables the compression of materials into compact units. This process is essential for easy handling and storage. Understanding how these elements work together provides insight into maintenance practices that can prevent downtime and ensure optimal productivity.

Additionally, recognizing the importance of specific features, such as the feeding system and tensioning apparatus, contributes to better operational decisions. Regular inspections and timely replacements of worn-out components are key to sustaining performance levels and minimizing the risk of operational failures.

Furthermore, knowing the layout of the internal systems aids in troubleshooting issues that may arise during use. This knowledge empowers operators to address minor problems before they escalate, thereby enhancing the reliability of the machine.

Key Components of the Baler

Understanding the essential elements of this agricultural machinery is crucial for optimal performance and maintenance. Each component plays a significant role in the efficient operation and longevity of the equipment.

Primary Elements

- Feeding Mechanism: This part ensures that the material is evenly fed into the machine, enhancing the compacting process.

- Compression Chamber: Here, the gathered material is compacted into bales, ensuring consistent density.

- Tie System: This mechanism secures the bales, often using twine or wire to hold them together firmly.

Auxiliary Components

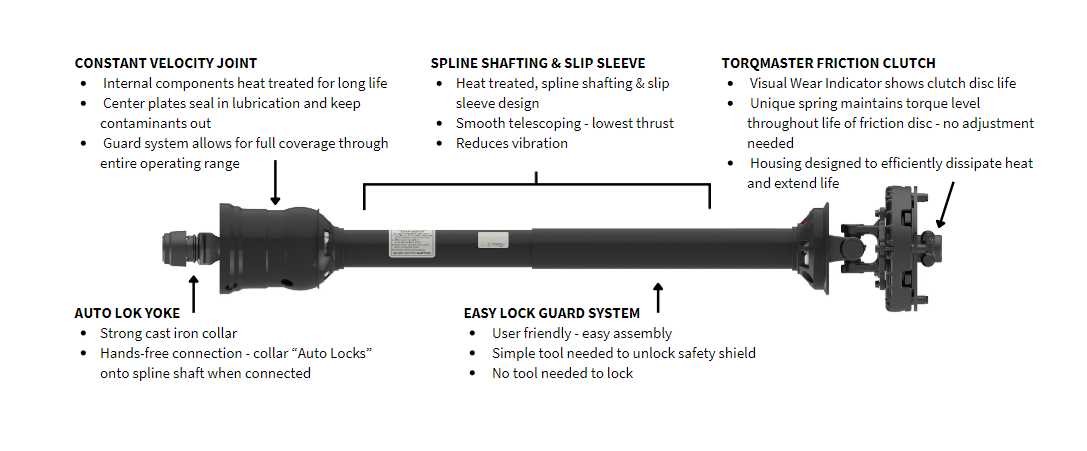

- Pickup Assembly: This component gathers material from the ground, facilitating the initial intake.

- Power Transmission: Involves gears and belts that transfer energy from the tractor to the machine.

- Control Systems: Allow the operator to adjust settings for different materials and bale sizes.

Importance of Regular Maintenance

Consistent upkeep of agricultural machinery plays a crucial role in ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns, ultimately leading to increased productivity and reduced operational costs.

Benefits of Routine Upkeep

- Enhanced Performance: Well-maintained equipment operates smoothly, leading to improved output.

- Prolonged Lifespan: Regular checks and servicing can significantly extend the life of your machinery.

- Cost Savings: Preventative maintenance often reduces the need for costly repairs down the line.

- Safety Assurance: Keeping machines in top condition helps ensure a safe working environment.

Key Maintenance Practices

- Conduct regular inspections to identify wear and tear.

- Clean components regularly to prevent build-up and corrosion.

- Replace worn parts promptly to avoid further damage.

- Follow manufacturer guidelines for servicing intervals.

Common Issues with Baler Parts

In the world of agricultural machinery, various components can encounter challenges that affect their performance and efficiency. Understanding these common issues can help in maintaining optimal operation and prolonging the lifespan of the equipment.

One frequent problem is wear and tear on essential components due to prolonged use. This can lead to reduced functionality and increased downtime. Additionally, improper adjustments can result in misalignment, causing further complications. It’s crucial for operators to be aware of these potential pitfalls to mitigate risks.

| Issue | Description | Possible Solutions |

|---|---|---|

| Wear and Tear | Components may degrade over time, affecting efficiency. | Regular inspections and timely replacements. |

| Misalignment | Incorrect adjustments can lead to mechanical failures. | Routine calibrations and adjustments are essential. |

| Jamming | Debris or foreign objects can obstruct movement. | Frequent cleaning and maintenance checks. |

| Hydraulic Issues | Fluid leaks or pressure drops can impair operation. | Regular fluid checks and leak repairs. |

Finding Replacement Parts Efficiently

Locating suitable components for agricultural machinery can often be a challenging task. Understanding the intricacies of the equipment and knowing where to search can streamline the process significantly. Utilizing the right resources and strategies is essential for ensuring minimal downtime and optimal performance.

Start by consulting the operator’s manual, which typically contains essential information about the specific components needed for your machinery. This document often includes part numbers, specifications, and diagrams that illustrate where each piece fits within the system.

Online platforms and marketplaces are invaluable for sourcing replacements. Websites dedicated to agricultural equipment offer extensive catalogs, complete with customer reviews and ratings. These resources can help you compare prices and availability across different suppliers, ensuring you make an informed decision.

Consider joining forums or community groups focused on farming and machinery. These platforms allow you to connect with other users who may have faced similar challenges. Sharing experiences can lead to recommendations for reliable sources and advice on the best practices for maintaining equipment.

Lastly, establish a good relationship with local dealers and distributors. They can provide not only the necessary components but also expert advice on maintenance and troubleshooting. Regular communication ensures you are kept updated on the latest products and innovations in the industry.

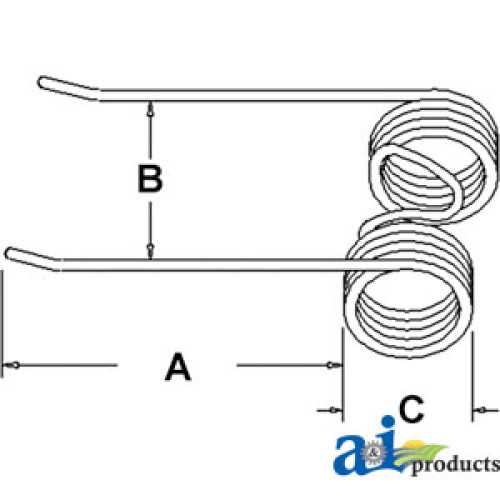

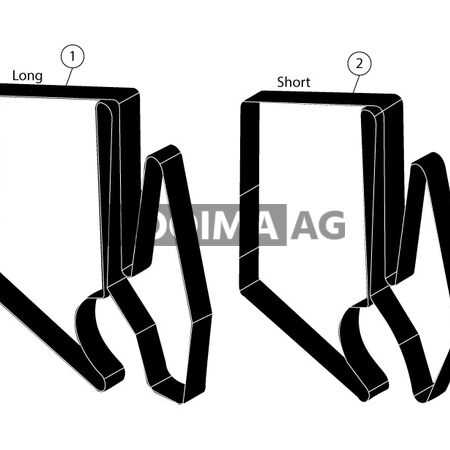

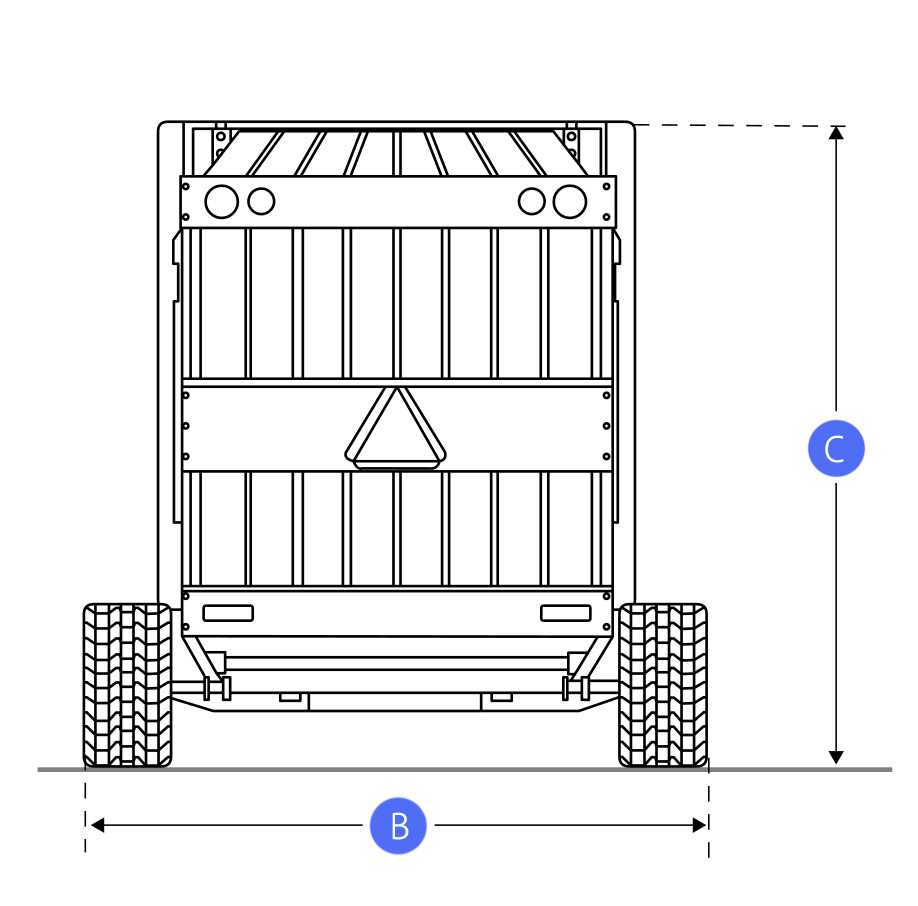

How to Interpret the Parts Diagram

Understanding a machinery schematic is essential for effective maintenance and repair. Such visual representations provide a clear overview of components and their relationships, making it easier to identify specific elements within the system. By familiarizing yourself with these illustrations, you can enhance your ability to troubleshoot and address issues that may arise.

Begin by examining the legend or key, which typically explains the symbols and notations used throughout the schematic. This information is crucial for interpreting the layout accurately. Pay attention to the numbering or labeling of each component, as it often correlates with a list or catalog that details specifications and replacement options.

Next, follow the flow indicated by the diagram. Many schematics are designed to show the sequence of operation, so tracing lines or arrows can reveal how parts interact during function. This insight is invaluable when diagnosing performance problems or planning maintenance tasks.

Lastly, compare the schematic with the physical equipment. Identifying where each element is located in relation to the illustration can aid in understanding the system as a whole. Regular practice with these visual aids will build your confidence in managing machinery effectively.

Tools Needed for Repairs

When it comes to maintaining and fixing agricultural machinery, having the right tools is essential for achieving effective and efficient results. Proper equipment not only ensures the repair process goes smoothly but also enhances safety and durability in operations. Below are key tools that are commonly required for such tasks.

Essential Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Socket set

- Hammer

- Measuring tape

Specialized Equipment

- Torque wrench

- Grease gun

- Diagnostic tools

- Cutting tools (saw, utility knife)

- Safety gear (gloves, goggles)

Having these tools on hand will facilitate effective repairs, ensuring your equipment remains in optimal working condition for the demands of agricultural activities.

Best Practices for Baler Operation

Effective management of equipment used for forage compression is essential for optimizing productivity and ensuring longevity. Adopting certain strategies can significantly enhance performance and minimize downtime. This section outlines key practices to consider during operation.

Preparation Before Operation

- Inspect machinery regularly to ensure all components are functioning correctly.

- Lubricate moving parts as per the manufacturer’s recommendations to reduce wear and tear.

- Ensure proper tensioning of belts and chains to prevent slippage and damage.

- Check hydraulic systems for leaks or malfunctions before use.

During Operation

- Maintain a consistent feeding speed to achieve uniform density in the final product.

- Monitor moisture levels in the material being processed to avoid spoilage.

- Adjust settings based on crop type and conditions for optimal results.

- Stay alert to any unusual sounds or vibrations, which may indicate potential issues.

By implementing these best practices, operators can enhance the efficiency and reliability of their equipment, leading to better results and reduced operational costs.