In the world of lawn maintenance, the efficiency of the equipment is largely determined by its internal mechanisms and how each element interacts with one another. A thorough understanding of how these systems function together ensures optimal performance and longevity of the machine. Various elements contribute to the smooth operation of the overall setup, each with a specific role that supports the whole mechanism.

Exploring the layout of these vital components is essential for anyone looking to troubleshoot, maintain, or replace worn-out sections. Knowing the configuration of each piece helps users identify potential issues before they become major problems. With clear knowledge of how everything fits together, maintaining and enhancing the functionality of your equipment becomes straightforward.

Proper maintenance can greatly extend the lifespan of your equipment and improve its reliability. Whether you’re a seasoned expert or a beginner, familiarizing yourself with the key sections will make handling repairs or upgrades easier. Understanding the relationship between each part allows for smarter choices and better care in the long run.

Having a reference to guide you through these components allows for a systematic approach to both understanding and managing the machine. As you move forward with maintenance tasks, you’ll find that a solid grasp of the system layout can make a world of difference in your overall experience.

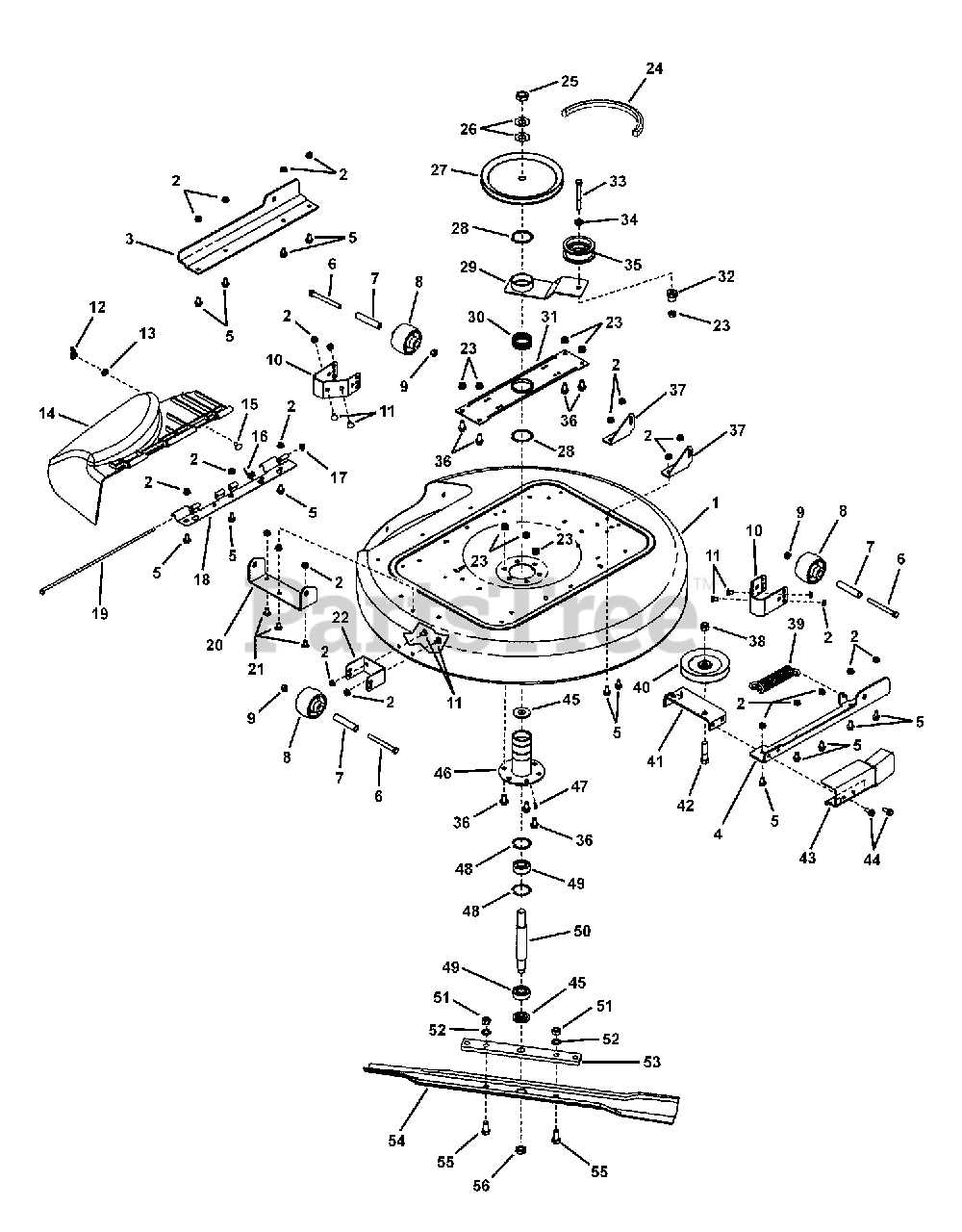

Understanding the Deck Components

To operate and maintain a grass-cutting machine effectively, it is crucial to understand the key elements that contribute to its cutting performance. These components work together to ensure smooth operation and precision in every pass across your lawn. Whether you’re replacing a worn part or conducting routine maintenance, knowing how each element functions will help you achieve optimal results.

The following table outlines the major components found in the cutting system, detailing their roles and importance for the overall performance:

| Component | Description |

|---|---|

| Spindle Assembly | The central mechanism that drives the blades, ensuring they rotate efficiently for clean cuts. |

| Blades | The sharp cutting elements that trim the grass. Regular sharpening is essential to maintain their performance. |

| Pulley System | Transmits power from the engine to the spindle assembly, enabling the blades to rotate. |

| Anti-Scalp Wheels | These wheels prevent the cutting blades from coming into contact with the ground, helping to maintain an even cut. |

| Blade Drive Belt | A critical component that connects the engine to the pulley system, transmitting power to the blades. |

Key Parts of a Mower Deck

Understanding the essential components of the cutting mechanism can help you maintain and troubleshoot effectively. These elements work together to ensure that the blades operate smoothly and efficiently, providing a clean and consistent cut. Familiarity with each section allows for proper upkeep and swift repairs when necessary.

- Cutting Blades: The primary elements responsible for the actual trimming action, rotating at high speed to create an even cut.

- Blade Spindles: These shafts connect the cutting blades to the engine’s power source, enabling their rotation.

- Drive Belt: A critical component that transfers power from the engine to the spindles, ensuring that the blades spin properly.

- Chassis: The frame supports the entire system, providing a solid base for mounting the engine, blades, and other components.

- Anti-Scalp Rollers: These help prevent the blades from scalping the ground by ensuring consistent cutting height, particularly on uneven terrain.

Each of these elements plays a specific role in achieving the desired results. Regular maintenance ensures their longevity and functionality.

Common Issues with Mower Decks

When working with cutting systems, several common problems can arise that affect performance. These issues are typically related to the core components involved in the cutting process, leading to inefficient operation and potential damage to the equipment.

Here are some of the most frequent challenges users may encounter:

- Uneven Cutting – This occurs when the blades fail to cut evenly, often due to misalignment or dullness. Regular maintenance and proper calibration are key to avoiding this issue.

- Clogging – Grass buildup can restrict airflow and hinder the cutting process. Clearing debris regularly is essential to prevent this problem.

- Excessive Vibration – If components are loose or the blades are unbalanced, excessive shaking can occur. Tightening screws and ensuring proper blade alignment helps eliminate this issue.

- Power Loss – A decrease in cutting performance can be a result of engine trouble, inadequate fuel, or a blockage in the system. Routine checks and cleaning are crucial to maintaining consistent power output.

- Rust and Corrosion – Metal parts exposed to moisture can develop rust, which weakens the equipment. Storing the system in a dry location and using rust-resistant materials can help prevent this damage.

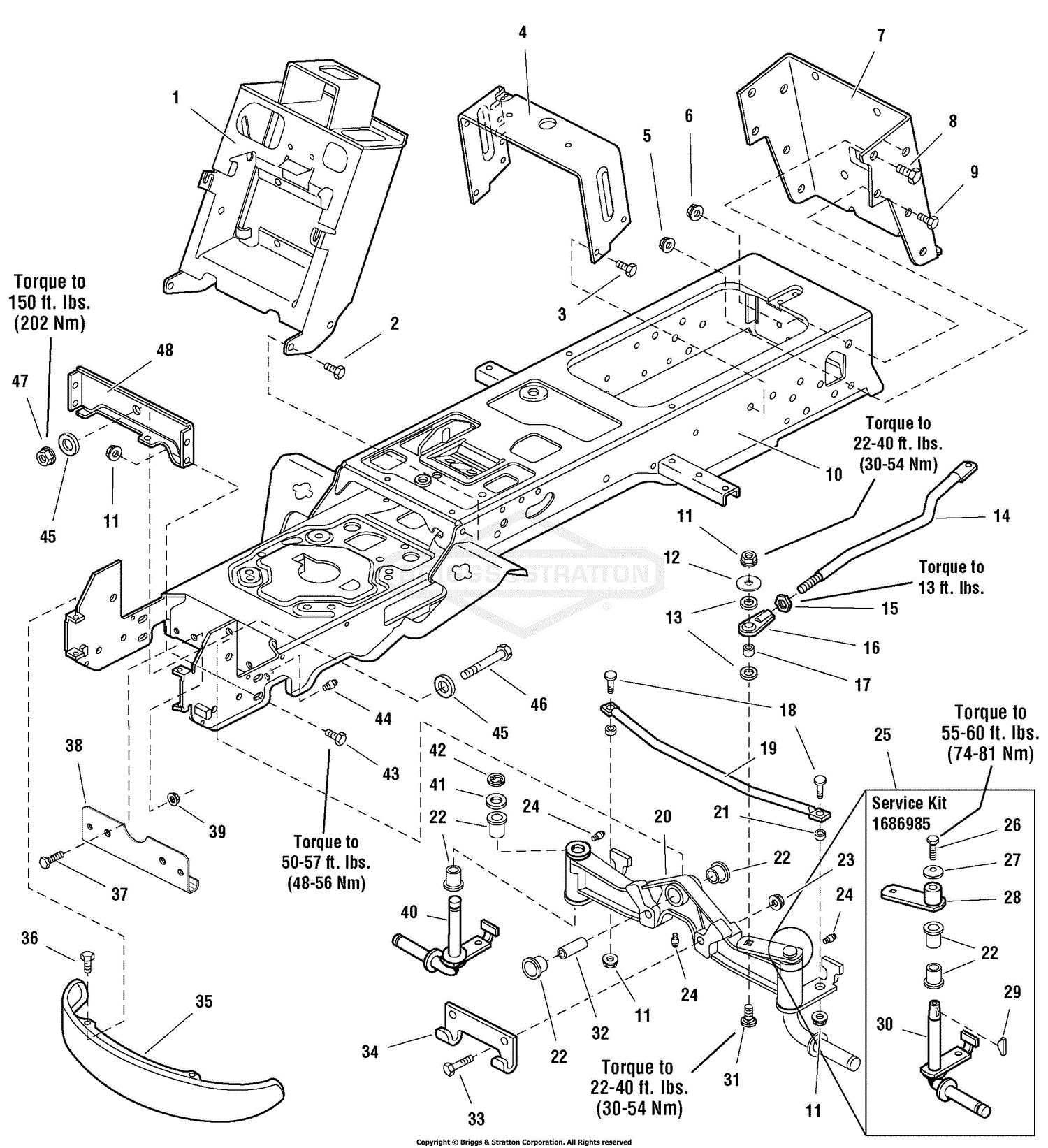

Assembly Instructions for Mower Decks

Proper assembly of lawn equipment components is essential for ensuring optimal performance and longevity. This guide provides step-by-step instructions for assembling key elements, helping to ensure all parts are correctly positioned and securely fastened. Following these procedures will allow the machine to operate smoothly and efficiently.

Step 1: Preparing the Workspace

Begin by clearing the area where you will be working. Ensure there is ample space and all necessary tools are within reach. Organizing the components beforehand will simplify the process and help avoid confusion during assembly.

Step 2: Connecting the Main Frame

Start by attaching the central framework to the base structure. Ensure that all bolts and screws are aligned properly and tightened securely. Double-check that the connections are stable before moving on to the next step.

Step 3: Attaching the Cutting Mechanism

Align the cutting blades with their designated slots. Carefully secure each blade to its corresponding mount, making sure they are fastened tightly to prevent any wobbling during operation.

Step 4: Installing Additional Components

Next, install any additional components such as belts, pulleys, or guards. Pay close attention to the orientation of each part and follow the recommended placement guidelines. This step is crucial for ensuring everything functions as intended.

Step 5: Final Inspection

After assembling all parts, perform a final inspection. Check that all connections are secure and there are no loose fasteners. Test the movement and alignment of all mechanical components before the unit is ready for use.

How to Maintain Your Mower Deck

Proper upkeep of your lawn cutting system is essential for ensuring optimal performance and longevity. Regular maintenance helps prevent common issues, keeps everything running smoothly, and guarantees a clean and efficient operation each time you work on your lawn. By following a few key steps, you can easily extend the life of your equipment and enhance its functionality.

1. Keep the Blades Sharp

A dull blade can tear grass rather than cutting it cleanly, leading to an uneven appearance. Sharpening your blades regularly will ensure they remain effective and prevent damage to the grass. If the edges are worn down or chipped, consider replacing them to maintain a professional finish.

2. Clean After Every Use

Grass clippings, dirt, and debris can quickly build up, affecting both the performance and appearance of your system. After each session, take the time to clean off any residue. This simple action prevents rusting and helps components stay in good working condition.

3. Check for Wear and Tear

Over time, components may begin to wear out. Inspect for any loose parts, cracks, or signs of damage. Tightening bolts and replacing worn-out elements will prevent bigger problems and keep everything operating safely.

4. Lubricate Moving Parts

Friction between moving components can cause unnecessary wear and tear. Applying lubricant to the necessary points helps reduce resistance and ensures smoother operation. Be sure to follow the manufacturer’s recommendations for the best types of lubricants to use.

5. Store Properly

When the season ends, proper storage is vital. Make sure the unit is stored in a dry, sheltered area to prevent rust and degradation from exposure to the elements. Before storing, perform a final inspection and cleaning to ensure it’s ready for the next use.

Tools Needed for Deck Repairs

When performing maintenance on a lawn equipment’s cutting mechanism, having the right tools can make the process faster and more efficient. The necessary tools range from basic hand tools to specialized equipment, depending on the complexity of the repair task. Ensuring you have everything at hand can save both time and effort.

- Wrenches: Adjustable and socket wrenches are essential for loosening and tightening bolts and nuts.

- Screwdrivers: A variety of screwdrivers, both flathead and Phillips, will help in removing screws holding various components.

- Pliers: Needle nose and standard pliers can assist in gripping and manipulating small parts.

- Jack or Lift: Lifting equipment may be necessary to safely elevate the unit, allowing access to the underside.

- Lubrication Tools: A grease gun or spray lubricant is useful for keeping moving parts well-oiled to prevent wear.

- Measuring Tools: A tape measure and ruler will ensure that parts are aligned and adjusted to the correct specifications.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s recommended torque specifications, preventing damage or loosening over time.

Having these tools ready before starting the repair can help avoid delays and ensure that each task is performed properly, prolonging the life of the equipment.

Identifying Wear and Tear on Parts

Regular inspection is essential for maintaining the longevity and efficiency of your equipment. Over time, certain components may experience gradual damage due to constant use, environmental factors, and exposure to various elements. Detecting early signs of deterioration helps prevent further damage and ensures smooth operation during tasks.

Common Signs of Damage

Look for cracks, discoloration, or signs of rust that indicate parts have been exposed to excessive wear. These symptoms often occur after prolonged use or under harsh conditions. Additionally, any unusual noise or vibrations during operation may be a sign that components are beginning to lose their functionality.

Proper Evaluation and Maintenance

To properly assess damage, visually inspect each element closely. Rotate or move adjustable parts to check for loose connections or irregular movements. Replacing worn-out components at the earliest stage can save both time and money, ensuring that the equipment continues to function at its best.

Upgrading Mower Deck Performance

Enhancing the efficiency and output of your lawn care equipment involves a series of targeted modifications. By focusing on key components and their interactions, you can significantly improve the machine’s cutting precision, longevity, and overall function. Simple upgrades can make a noticeable difference, leading to a smoother, more efficient operation with better results each time.

Optimizing Blade Efficiency

The primary factor affecting cutting quality is the sharpness and balance of the rotating elements. Regularly sharpening blades and ensuring they are properly aligned can drastically improve performance. Additionally, choosing blades designed for specific grass types or terrains can provide better results and extend the lifespan of your equipment.

Improving Airflow and Ventilation

Proper airflow is essential for the effective operation of the equipment. Enhancing ventilation systems can prevent overheating and improve the discharge of clippings. Upgrading components that facilitate airflow, such as ventilation covers or enhanced chute designs, can lead to smoother operation and fewer clogging issues.

Troubleshooting Mower Deck Problems

When dealing with performance issues in your equipment’s cutting system, it’s important to first identify the symptoms. These may include uneven cutting, strange noises, or difficulty in operation. Addressing these problems efficiently requires a methodical approach to pinpoint the root cause.

1. Uneven Cutting

If the cutting results are inconsistent, it could be due to worn-out components or misalignment. Inspect the blades for any signs of damage or dullness. Uneven height adjustments or improper leveling can also contribute to an irregular cut. Ensure that all settings are calibrated according to the manufacturer’s recommendations.

2. Strange Noises

Unusual sounds, such as grinding or squealing, often indicate that something is obstructing the moving parts. Check for debris or buildup around the spindles and pulleys. Additionally, ensure that all bolts and nuts are tightly secured to prevent any loose parts from creating friction or noise.

3. Difficulty in Operation

If the equipment is hard to maneuver or feels sluggish, examine the belts for wear or misalignment. A slipping or loose belt can reduce efficiency and make operation cumbersome. Regular maintenance, including lubrication of moving parts, is essential to maintaining smooth functionality.