In the realm of mechanical devices, the intricate interplay of components forms the backbone of functionality and performance. Each piece serves a vital role, contributing to the overall efficiency and durability of the apparatus. Navigating through these intricate systems can often feel overwhelming, yet a comprehensive visual representation can significantly enhance understanding.

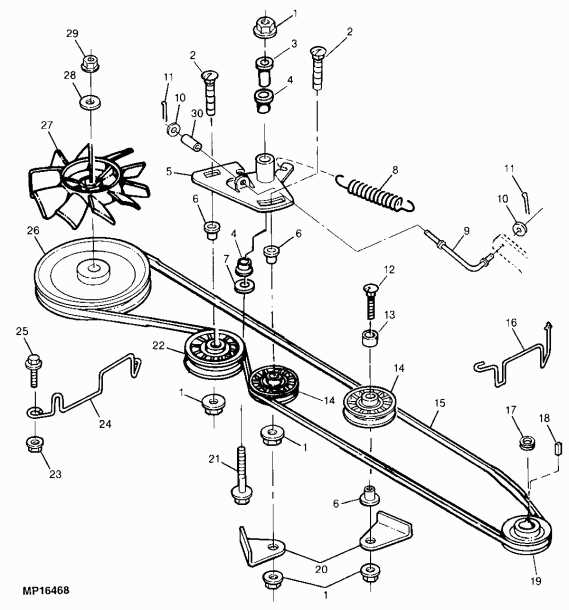

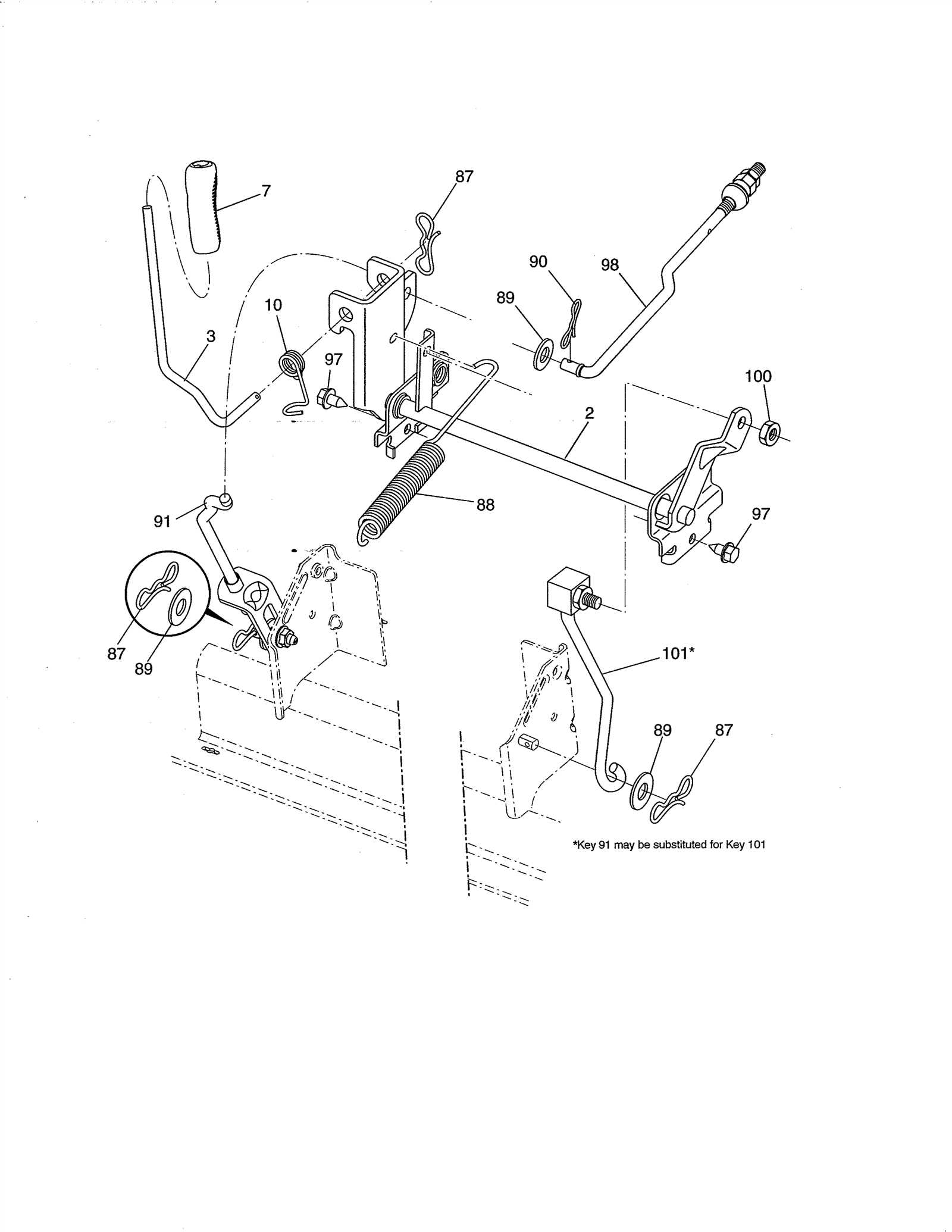

For those keen on maintenance or enhancement, familiarizing oneself with the specific elements that constitute the machinery is essential. This not only aids in troubleshooting but also empowers users to undertake modifications or repairs with confidence. Clarity in the arrangement and function of each component is crucial for effective operation.

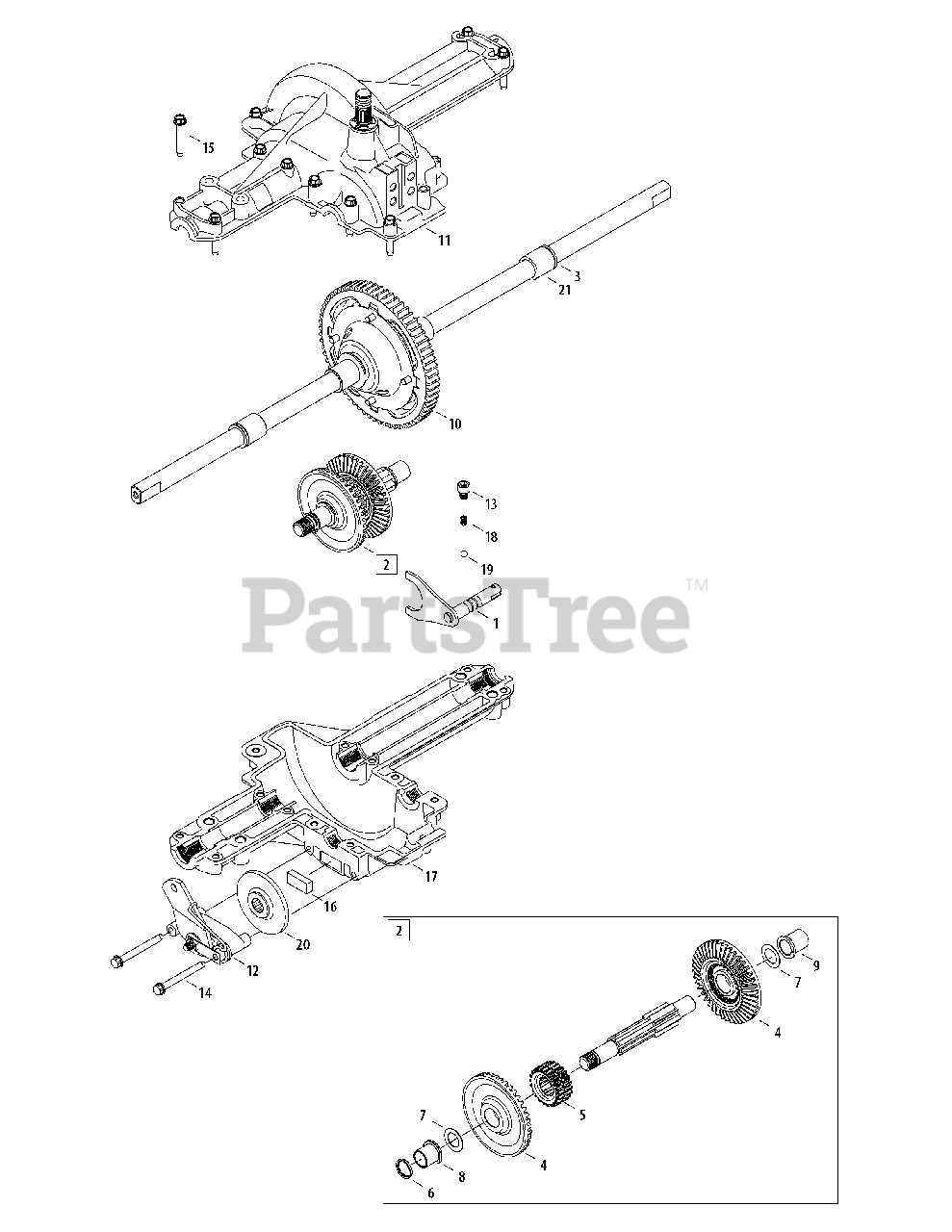

This resource provides a detailed illustration of the various elements involved, offering insights into their connections and individual purposes. By exploring this visual guide, users can gain a deeper appreciation for the craftsmanship involved in these devices and ensure their longevity through informed care and attention.

Understanding Craftsman T2200 Components

Grasping the intricacies of mechanical assemblies is crucial for effective maintenance and operation. Each element within a system plays a pivotal role, contributing to the overall functionality and performance. Familiarity with these components enhances troubleshooting and repair efforts, ensuring longevity and reliability.

Key Elements of the System

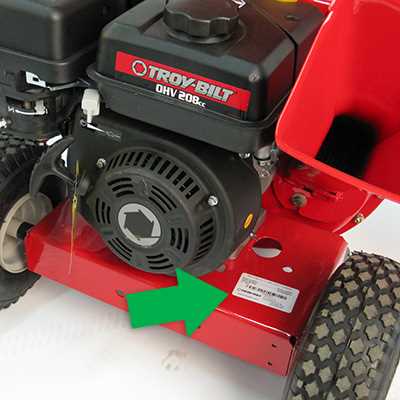

- Engine: The powerhouse responsible for converting fuel into mechanical energy.

- Transmission: This component facilitates the transfer of power from the engine to the wheels, affecting speed and torque.

- Chassis: The framework that supports various parts, providing structural integrity and stability.

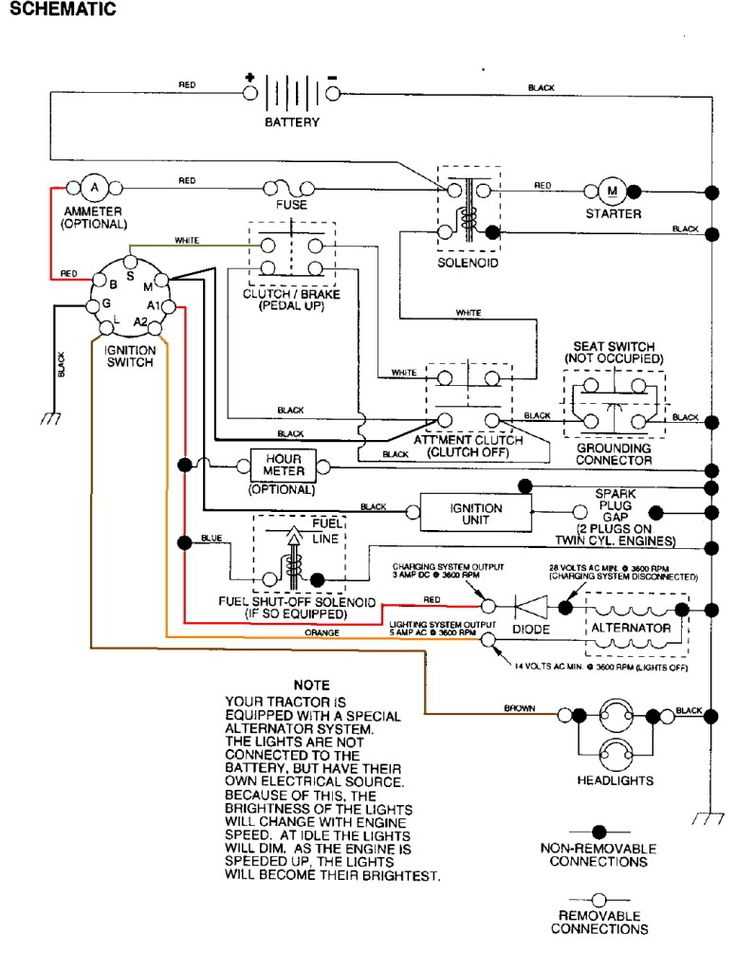

- Electrical System: Comprising wiring, batteries, and other components, this system ensures proper functionality of electronic features.

Common Maintenance Considerations

- Regularly check and replace fluids to prevent overheating and wear.

- Inspect belts and hoses for signs of wear or damage.

- Keep electrical connections clean and free from corrosion.

- Schedule routine inspections to identify potential issues before they escalate.

Understanding the fundamental components of any mechanical system is essential for efficient operation and maintenance. By knowing what each part does, operators can ensure their equipment runs smoothly and efficiently.

Importance of Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and repair. Visual representations serve as invaluable resources, offering clarity on how various elements interact within a system. These illustrations not only simplify complex assemblies but also enhance the efficiency of troubleshooting processes.

One significant benefit of these visual guides is their ability to streamline repairs. By providing a clear overview of the structure, they allow users to quickly identify the necessary components, reducing the time spent searching for specific pieces. This efficiency is particularly beneficial for those unfamiliar with the inner workings of a device.

Moreover, these resources facilitate better communication among technicians and customers. When everyone can reference the same visual aid, misunderstandings are minimized, leading to more accurate descriptions of issues and more effective solutions. This shared understanding fosters a collaborative environment, ultimately enhancing overall service quality.

In summary, visual representations of components play a pivotal role in the repair and maintenance landscape. They not only aid in understanding and efficiency but also promote clear communication, making them indispensable tools for anyone working with complex machinery.

Identifying Key T2200 Parts

Understanding the essential components of a specific model can significantly enhance maintenance and repair efforts. Familiarity with each element not only aids in troubleshooting but also ensures optimal performance. Below are crucial sections to consider for effective identification.

- Engine Assembly: The powerhouse that drives the entire mechanism, crucial for performance.

- Transmission System: Responsible for power transfer, it plays a vital role in the overall functionality.

- Fuel System: Essential for delivering energy, this system includes the tank, lines, and filters.

- Electrical Components: These parts facilitate the starting process and control various functions.

- Chassis Structure: The frame supports all components, providing stability and durability.

- Cutting Deck: An integral feature for tasks requiring precision, it directly influences the quality of work.

Recognizing these fundamental sections can simplify the process of finding the correct replacements and ensure your equipment operates smoothly.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for efficient repairs and maintenance. This guide will provide you with the fundamental concepts to interpret these illustrations effectively, enabling you to identify each element and its function.

Familiarize Yourself with the Key

Most illustrations come with a legend or key that explains the symbols used. Familiarize yourself with these indicators to decode the specific parts and their corresponding numbers or letters.

Analyze the Layout

The arrangement of elements often reflects their physical positioning in the assembly. By examining the layout, you can determine how different components interact and relate to one another.

| Symbol | Description |

|---|---|

| A | Main component |

| B | Supporting part |

| C | Fastening element |

Common Issues with Craftsman T2200

When working with lawn care equipment, users often encounter various challenges that can affect performance and efficiency. Understanding these common problems can lead to more effective maintenance and troubleshooting.

- Engine Difficulties: Issues such as difficulty starting or stalling can arise due to fuel or ignition problems.

- Blade Malfunctions: Dull or damaged blades may hinder cutting performance, requiring regular inspection and sharpening.

- Transmission Problems: Slipping or failure to engage can result from wear and tear or improper maintenance.

- Electrical Failures: Issues with wiring or battery connections may lead to operational failures or inconsistent power supply.

Addressing these issues promptly can enhance longevity and overall effectiveness, ensuring a smoother operation during use.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often feel like a daunting task. However, understanding where to search and how to identify what you need can streamline the process significantly. Whether you’re looking for specific elements to enhance functionality or simply seeking to replace worn-out items, there are effective strategies to simplify your search.

First, consider exploring online resources that specialize in components for various models. Websites that offer comprehensive catalogs often include detailed descriptions, specifications, and compatibility information. Utilizing these tools can save you time and help you find exactly what you need.

Additionally, reaching out to local suppliers or service centers can provide valuable insights. They often have extensive knowledge of available options and can assist you in locating hard-to-find items. Don’t hesitate to ask for recommendations based on your equipment’s model and requirements.

Lastly, forums and community groups focused on equipment maintenance can be invaluable. Engaging with other users can lead to tips and tricks that may not be widely known, including suggestions for alternative components that work just as well.

Maintenance Tips for T2200 Owners

Proper upkeep is essential for ensuring longevity and optimal performance of your equipment. Regular attention to maintenance tasks can prevent potential issues and enhance overall efficiency.

- Check and replace the oil regularly to maintain engine health.

- Inspect air filters and clean or replace them as needed to ensure proper airflow.

- Sharpen blades to enhance cutting performance and reduce strain on the motor.

- Examine belts and cables for wear or damage, replacing them promptly.

- Clean the exterior and undercarriage to prevent rust and debris buildup.

By following these essential practices, you can ensure that your equipment operates smoothly and efficiently for years to come.

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial for maintaining its performance and longevity. Several reliable sources offer high-quality replacements to ensure your tools run smoothly and efficiently.

| Source | Website | Notes |

|---|---|---|

| Official Manufacturer | manufacturer.com | Guaranteed authenticity and warranty support. |

| Authorized Dealers | dealers.com | Wide selection with expert advice. |

| Online Retailers | online-retailers.com | Convenient shopping with customer reviews. |

| Local Hardware Stores | localstores.com | Immediate availability and local support. |