For those who take pride in maintaining their outdoor spaces, having a clear visual reference for machinery components can be invaluable. A comprehensive illustration serves as a guide, aiding in both the upkeep and repair of your equipment. With the right information, even complex systems can be tackled with confidence.

Visual aids simplify the process of identifying individual elements, making it easier to understand how everything fits together. Whether you’re a seasoned user or a novice, this knowledge empowers you to perform maintenance tasks efficiently.

By delving into the intricacies of your tools, you can ensure optimal performance and longevity. Discovering the ultimate layout of each section not only enhances your understanding but also equips you with the ability to address any issues that may arise.

Understanding the Craftsman Model 917

This section delves into the intricate design and functionality of a popular lawn care machine. By exploring its components and their interactions, users can gain insights into maintenance and optimization for enhanced performance. A thorough comprehension of the system is essential for anyone looking to maximize efficiency and prolong the lifespan of their equipment.

Many users find that familiarizing themselves with the inner workings of this tool not only simplifies repairs but also fosters a greater appreciation for its engineering. Each element plays a crucial role in ensuring the overall effectiveness of the machine. Understanding these aspects allows for informed decisions regarding upgrades or replacements.

Moreover, recognizing how different parts relate to one another can prevent common issues that arise from misuse or neglect. With proper knowledge, operators can troubleshoot problems swiftly, ensuring that their equipment remains in peak condition throughout its lifespan.

In conclusion, gaining a solid grasp of the features and functions inherent in this lawn care device equips users with the skills necessary for effective management and upkeep. Embracing this understanding can lead to a more rewarding experience with lawn maintenance.

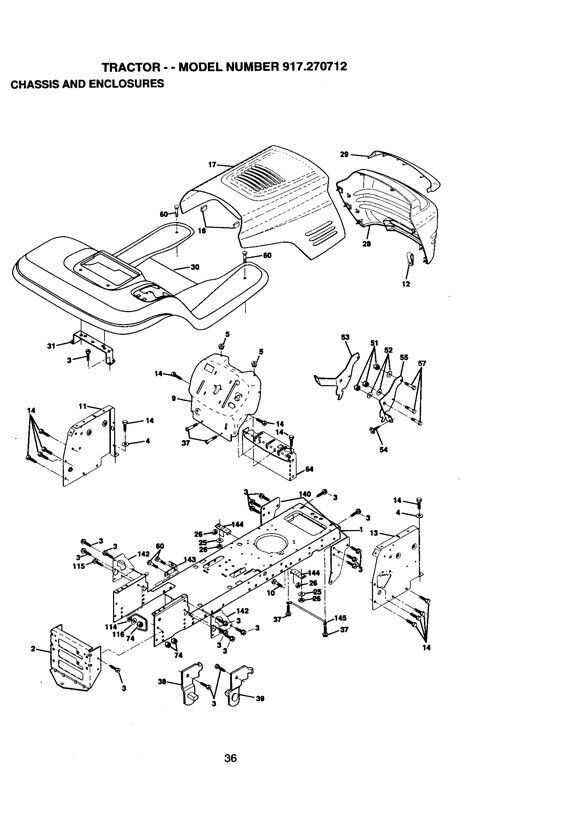

Importance of Parts Diagrams

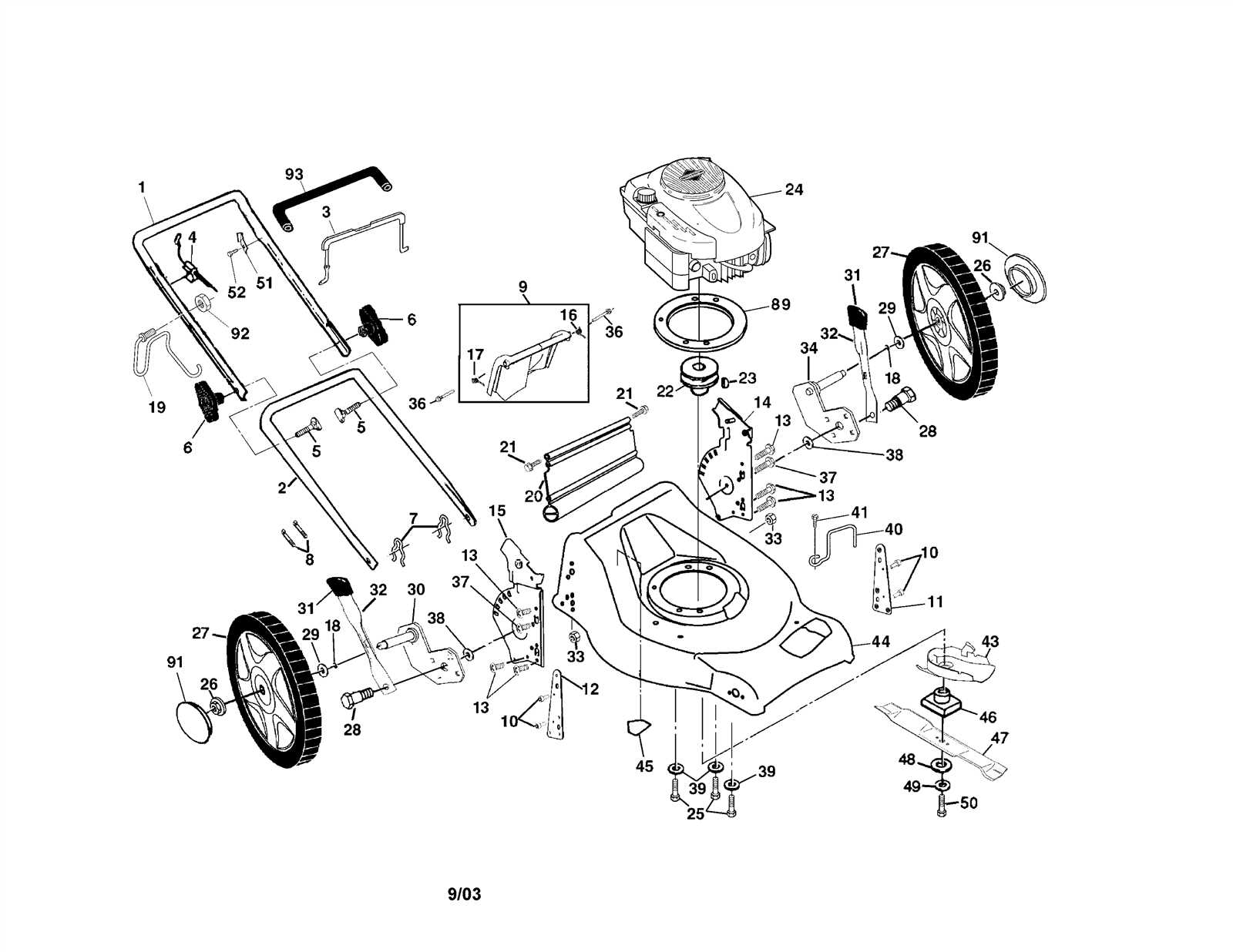

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. They provide a clear layout, allowing users to identify individual elements and their interconnections. This clarity is essential for efficient maintenance, repair, and upgrades.

Furthermore, such illustrations aid in troubleshooting by highlighting potential areas of concern. Users can quickly locate specific items, reducing time spent searching and enhancing overall productivity. Accurate depictions also minimize the risk of errors during reassembly, ensuring that all parts are correctly fitted and aligned.

Ultimately, these visual tools serve as invaluable resources for both seasoned professionals and beginners alike, fostering a deeper comprehension of mechanical systems and improving operational efficiency.

Common Issues with Model 917

Many users encounter similar challenges with this lawn equipment, leading to frustration and performance issues. Understanding these common problems can help in troubleshooting and maintaining optimal functionality.

1. Engine Difficulties: A frequent concern is the engine’s inability to start or run smoothly. This could stem from fuel delivery issues, spark plug problems, or a clogged air filter. Regular checks and maintenance can mitigate these issues.

2. Cutting Performance: Another common issue involves uneven cutting or difficulty in maneuvering. This may be related to dull blades, improper deck height adjustment, or tire pressure imbalances. Ensuring sharp blades and proper adjustments can enhance cutting quality.

3. Transmission Problems: Users often report issues with gear shifting or movement. These can arise from low transmission fluid, worn belts, or damaged linkages. Regular inspections and timely replacements can prevent more serious complications.

4. Electrical Failures: Issues with the electrical system, such as battery drainage or malfunctioning lights, are also prevalent. Checking connections and ensuring proper battery maintenance can help avoid these setbacks.

5. Vibration and Noise: Excessive vibration or unusual sounds can indicate mechanical wear or loose components. Regular tightening and inspection of parts can significantly reduce these disturbances.

Addressing these issues promptly can lead to improved performance and longevity, making your experience more enjoyable.

Where to Find Replacement Parts

Locating components for your equipment can be crucial for maintaining its performance and longevity. Various resources are available to assist you in acquiring the necessary items, whether through local retailers, online platforms, or specialized shops dedicated to repairs and accessories.

Start by checking local hardware stores, which often carry a range of supplies for common brands. Additionally, online marketplaces provide a vast selection, allowing you to compare prices and find the exact match for your needs. Manufacturer websites also offer official components, ensuring compatibility and reliability.

For more specialized items, consider forums and communities focused on equipment repair. Members often share links to suppliers or even offer second-hand options. By exploring these avenues, you can efficiently secure the components required to keep your machinery running smoothly.

Benefits of Using Original Components

Utilizing authentic components in maintenance and repairs ensures optimal performance and longevity of your equipment. Original parts are designed to meet specific standards, guaranteeing compatibility and reliability. This choice leads to fewer issues over time and enhances overall efficiency.

Quality Assurance

Original components are manufactured to high standards, ensuring:

- Consistent performance

- Durability and resistance to wear

- Safety compliance

Cost-Effectiveness

While it may be tempting to opt for cheaper alternatives, original components often prove to be more economical in the long run due to:

- Reduced frequency of replacements

- Lower maintenance costs

- Enhanced resale value of the equipment

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent upkeep and attention to detail. By implementing a few key practices, you can significantly extend the lifespan of your tools and machinery, while also enhancing their efficiency.

Regular Cleaning: Dirt and debris can accumulate over time, leading to wear and tear. Make it a habit to clean surfaces and components after each use, preventing grime buildup that could hinder functionality.

Routine Inspections: Conducting periodic checks allows you to identify potential issues before they escalate. Examine belts, filters, and other essential parts for signs of damage or excessive wear.

Lubrication: Proper lubrication is vital for moving parts. Use the appropriate type of lubricant to reduce friction and prevent overheating, which can lead to premature failure.

Follow Manufacturer Guidelines: Adhering to the recommended maintenance schedule can ensure that all necessary tasks are performed at the right intervals. This includes changing oils, replacing filters, and other crucial actions.

Store Properly: When not in use, keep your equipment in a dry, sheltered space. This protects against environmental factors that could cause corrosion or degradation.

By integrating these maintenance practices into your routine, you can help ensure that your tools remain in peak condition for years to come.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These illustrations provide a visual guide, helping users identify and locate individual elements, ensuring that tasks are carried out smoothly and efficiently.

To navigate these visual aids effectively, consider the following steps:

- Familiarize Yourself with the Layout: Start by observing the overall arrangement of the components. Each section is typically labeled, offering insight into the assembly.

- Identify Key Components: Look for symbols or markers that denote crucial parts. This will help you locate specific items you may need to replace or inspect.

- Refer to the Legend: Many schematics include a legend or key. This section explains symbols and designations, aiding in the interpretation of the visual elements.

- Trace Connections: Follow lines or arrows that indicate how parts interact with one another. This can reveal the relationship between components and how they function as a whole.

- Take Notes: Jot down any observations or queries. Having a reference will assist you during repairs or when sourcing replacements.

By applying these strategies, you can enhance your understanding of component illustrations, making repair tasks more manageable and effective.

Upgrading Components for Better Performance

Enhancing the efficiency and functionality of your equipment can significantly impact its overall performance. By focusing on key elements and integrating superior parts, you can achieve a smoother operation and increased reliability. This section explores various upgrade options that can optimize your machine’s capabilities.

Essential Upgrades

Consider investing in high-quality components such as engines, blades, and drive belts. Each upgrade contributes to improved performance and longevity.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | High-performance model | Increased power and efficiency |

| Blades | Premium steel | Sharper cut and durability |

| Drive Belt | Reinforced type | Better traction and reduced wear |

Final Considerations

Upgrading components is an investment that pays off in enhanced performance and durability. Assess your needs and select parts that align with your goals for optimal results.

Resources for DIY Repairs

Engaging in do-it-yourself repairs can be a rewarding experience, allowing individuals to save money while gaining hands-on skills. Access to the right tools and information is crucial for successfully tackling various tasks. This section aims to provide valuable resources that empower enthusiasts to confidently address their repair needs.

Online Communities and Forums

Joining online communities can be an excellent way to connect with others who share similar interests. Forums dedicated to home improvement and repair often feature discussions, tips, and troubleshooting advice. Engaging with these platforms can provide insights into common issues and solutions, fostering a collaborative environment where knowledge is shared.

Instructional Videos and Tutorials

Visual learning can significantly enhance the repair process. Numerous platforms offer instructional videos that guide users step-by-step through various projects. From basic maintenance to complex repairs, these resources often break down tasks into manageable segments, making it easier to follow along and achieve successful outcomes.

In conclusion, harnessing the power of online resources can greatly improve one’s ability to perform repairs. Whether through community engagement or visual aids, individuals can enhance their skills and confidence in tackling home projects.