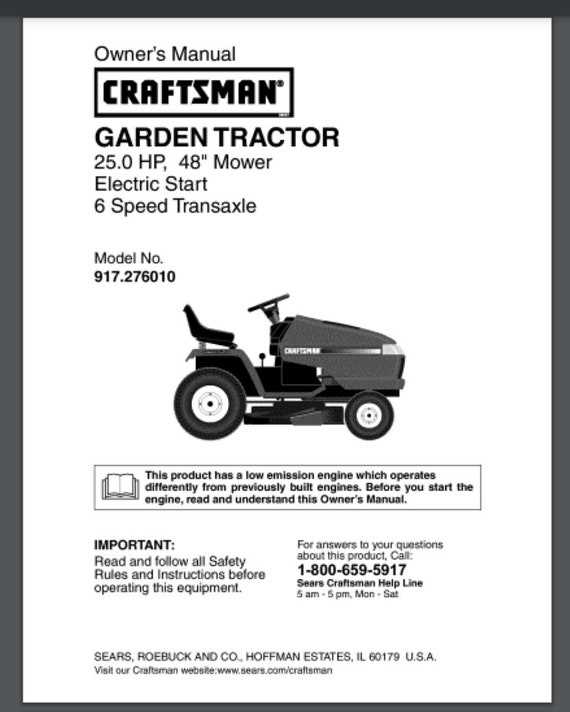

When maintaining your outdoor equipment, having a clear understanding of its structural elements is essential. This section delves into the various components that make up a specific model of riding mower, offering insights into their arrangement and function. By familiarizing yourself with these elements, you can enhance your maintenance skills and improve the overall performance of your machine.

Through a detailed exploration of the schematic, you’ll discover the significance of each segment and how they contribute to the mower’s operation. This information serves as a valuable resource for both novice and experienced users, enabling you to troubleshoot issues more effectively and make informed decisions during repairs.

Utilizing this knowledge can lead to better care for your equipment, ensuring it runs smoothly for years to come. Whether you’re looking to replace a worn-out component or simply wish to understand your machinery better, a comprehensive overview of the configuration will prove beneficial.

Understanding the Mower’s Cutting Assembly

The cutting assembly of this particular lawn tractor is a critical component that ensures efficient grass trimming and overall yard maintenance. It operates through a series of synchronized elements designed to work together seamlessly. For users aiming to maintain their lawns with precision, understanding the mechanism behind this assembly is key to achieving optimal performance.

Main Features of the Cutting System

The cutting system incorporates multiple blades that rotate at high speed to achieve a clean cut. These blades are mounted on a sturdy platform, supported by a series of brackets and pulleys that allow for smooth and controlled operation. Regular maintenance, such as sharpening the blades and ensuring the pulleys are properly lubricated, is essential to prolong the lifespan of the equipment.

Maintenance Tips for Longevity

Proper upkeep of the cutting assembly involves inspecting belts for wear, checking the alignment of the blades, and ensuring all connections are secure. Regular cleaning of the assembly will help prevent grass buildup, which can hinder performance. By keeping all components in good condition, users can avoid frequent repairs and ensure consistent cutting quality.

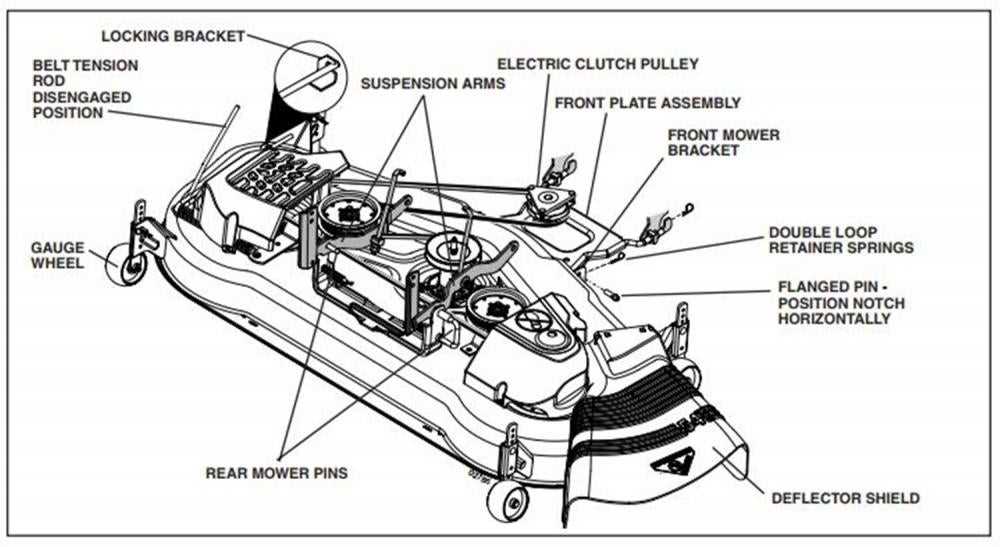

Key Components of the 48” Mower Deck

The cutting assembly of this lawn care machine is comprised of several vital elements that work in unison to provide a clean and even trim. Understanding the essential parts of the cutting system helps ensure smooth operation and makes maintenance easier.

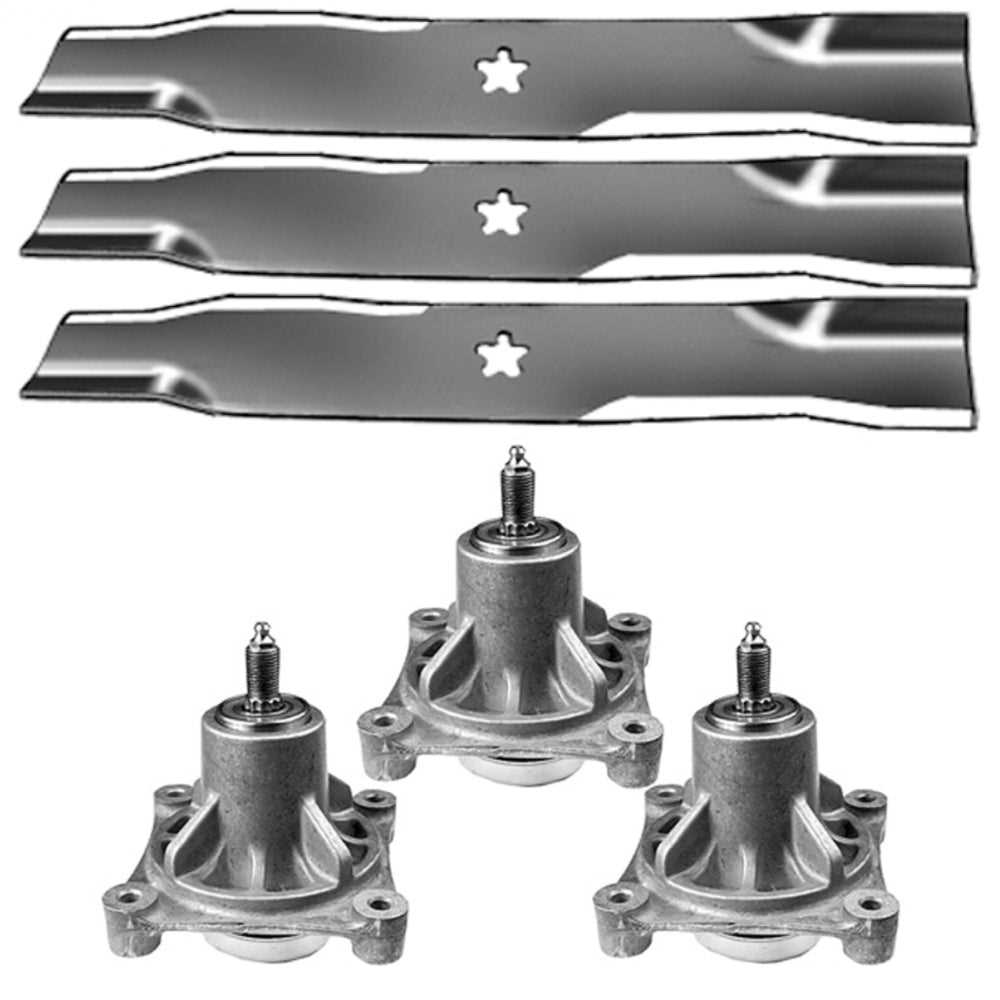

Blades and Spindles

The blades are central to the cutting process, slicing through grass with precision. They are mounted on spindles, which rotate at high speed, powered by the drive mechanism. Proper blade sharpening and spindle maintenance are critical for optimal cutting performance.

Drive System

The drive system is what powers the cutting mechanism, transferring energy from the engine to the rotating blades. This includes belts and pulleys, which must be aligned and tensioned correctly for smooth functioning. Regular checks of the belt condition prevent issues during operation.

How the Belt System Operates

The belt system plays a critical role in ensuring the efficient transmission of power throughout the machine. By connecting key components, it enables synchronized motion and precise functioning of various mechanical parts. Understanding how this system works can help maintain performance and prevent potential issues during operation.

- Power Transfer: The belt acts as a medium to transfer energy from the engine to other moving parts, ensuring smooth and continuous motion.

- Tension and Alignment: Maintaining proper tension and alignment is essential for reducing wear and preventing slippage, which could lead to inefficient performance.

- Pulleys and Idlers: The belt runs over a series of pulleys

Blade Assembly and Maintenance Tips

Proper blade installation and upkeep are essential for maintaining the efficiency and longevity of your cutting equipment. Regular inspection and adjustments ensure optimal performance, preventing potential damage and promoting clean, even cuts. Following a consistent maintenance routine helps avoid wear and tear on both the blades and the machinery.

Installation Guidelines

When assembling blades, it’s crucial to align them correctly to avoid imbalances that can lead to vibrations or uneven cutting. Ensure that the mounting bolts are securely fastened but avoid overtightening, which could damage the components. Double-check that the blades are positioned at the correct angle for optimal cutting efficiency.

Maintenance Best Practices

Routine sharpening of the blades is vital to maintain sharpness and ensure smooth operation. Dull blades can cause the machine to strain and produce uneven results.

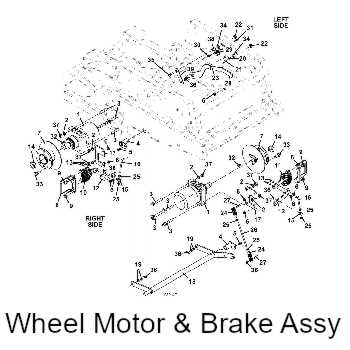

Common Issues with Spindles

Spindles play a crucial role in the functionality of mowing equipment, and understanding potential problems can enhance maintenance and performance. Regularly inspecting these components is essential to ensure a smooth operation and to avoid costly repairs.

Typical Problems Encountered

- Wear and Tear: Over time, spindles can wear down, leading to reduced efficiency and uneven cutting.

- Bearing Failure: Bearings within the spindles may become damaged or corroded, resulting in increased friction and noise.

- Misalignment: Improper installation or wear can cause misalignment, affecting the overall performance of the equipment.

Signs of Malfunction

- Unusual vibrations during operation.

- Increased noise levels, particularly grinding sounds.

- Uneven cutting patterns on the lawn.

Pulley System: Function and Replacement

The pulley system is a crucial component in the functioning of lawn care machinery, responsible for transferring power from the engine to various moving parts. This mechanism ensures smooth operation by utilizing a series of pulleys, belts, and springs to manage the rotational force. Over time, these elements may wear out or become damaged, requiring timely attention and replacement to maintain optimal performance.

Understanding the role of each component in the pulley system is essential for troubleshooting and repair. Pulley wheels are designed to guide the belts, while springs provide tension to keep the system taut. Regular maintenance and replacement of worn-out parts help prevent issues such as slippage, overheating, and uneven operation.

Component Function Signs of Wear Replacement Tips Drive Pulley Transfers engine power to the belt Cracks, warping, or missing teeth Ensure proper alignment and secure fit during installation Idler Pulley Helps maintain belt tension Worn bearings, rough spinning Lubricate before replacing; check for rust Spring Provides tension to keep the pulley system tight Stretching or breakage Choose a spring with appropriate tension strength for the system V-belt Connects pulleys and transfers power Fraying, cracking, or slipping Measure correctly and replace with the manufacturer’s specified length When it becomes necessary to replace a pulley component, it is critical to use compatible replacements that meet the required specifications. Incorrect parts may compromise the system’s efficiency and could lead to more significant mechanical failures.

Identifying and Fixing Deck Misalignment

When the cutting mechanism of your mower fails to deliver consistent results, it is often a sign that adjustments are needed to restore proper alignment. Misalignment can occur due to a variety of factors, such as wear and tear or improper handling, affecting the quality of the mowing job. Recognizing and addressing these issues early can help ensure a smooth and efficient operation while preventing further damage.

Signs of Misalignment

One of the first indicators that something is wrong is uneven grass cutting. If one side of your mower leaves taller grass or causes an inconsistent appearance, it’s a clear signal that alignment adjustments are necessary. Another telltale sign is if the unit seems to pull or tilt in one direction while operating. These symptoms point to misalignment within the cutting assembly that needs to be corrected.

Steps to Correct Misalignment

Begin by ensuring the cutting mechanism is securely attached and free from any obstructions or damage. After verifying that all components are intact, inspect the positioning of the cutting blades. Use a measuring tool to check their height and alignment relative to the ground. Adjust the supports or brackets as necessary to achieve an even level. In some cases, it may be necessary to replace worn or damaged parts to restore optimal performance.

Important: Regular maintenance, including periodic checks of all related components, can prevent misalignment and extend the lifespan of the machine.

Proper Lubrication for Smooth Deck Operation

To ensure optimal performance and longevity of your mower’s cutting system, regular maintenance, including proper lubrication, is essential. Without adequate lubrication, the moving components may experience increased friction, leading to wear and tear that can reduce efficiency and shorten the life of the equipment. This section will guide you through the correct lubrication practices to maintain smooth and reliable operation.

Choosing the Right Lubricant

The type of lubricant used in your mower’s cutting mechanism is crucial for reducing friction and protecting the metal surfaces from corrosion. Be sure to use a high-quality grease or oil that is recommended by the manufacturer, designed specifically for the conditions in which you operate your equipment. The right lubricant not only prevents rust but also keeps moving parts functioning seamlessly.

Application Areas

Pay close attention to the key components that require lubrication, such as the spindle bearings, pulleys, and wheels. These areas are exposed to constant movement and should be lubricated regularly. It’s important to apply lubricant in the correct spots to avoid excess buildup, which could attract dirt and debris, negatively affecting performance. Using a grease gun or applying oil with a brush to these areas ensures that each component operates smoothly.

In addition, periodically check the condition of the lubricant and replace it when necessary to maintain efficiency. A well-maintained system with proper lubrication ensures the machine runs with less noise and vibration, providing a more enjoyable and effective mowing experience.

Tips for Extending Deck Lifespan

Maintaining your lawn mower’s cutting mechanism is essential for ensuring its long-term performance and reliability. Regular upkeep can prevent unnecessary wear and tear, saving you from costly repairs down the road. Proper care not only keeps the mower working efficiently but also prolongs the life of its various components.

One of the key practices is regular cleaning after each use. Grass clippings, dirt, and debris can accumulate, causing rust and reducing the effectiveness of the cutting system. By removing these materials, you prevent buildup that could lead to corrosion or damage. Pay attention to areas where moisture might collect and dry them thoroughly to avoid deterioration.

Another important aspect is lubrication. Keeping moving parts well-lubricated reduces friction, which helps prevent premature wear. Check for lubrication points regularly and apply the appropriate grease or oil as specified in the manual. This simple step can significantly improve the efficiency and lifespan of the mower’s mechanical components.

Additionally, inspect the condition of the blades regularly. Dull or damaged blades can strain the engine and cause uneven cuts. Sharpening the blades as needed ensures smooth performance and prevents unnecessary stress on the entire machine.

Lastly, proper storage is essential. When the equipment is not in use, store it in a dry, sheltered area to protect it from the elements. Exposure to extreme temperatures or moisture can accelerate wear and cause parts to degrade more quickly. Ensuring that the equipment is stored properly will help maintain its functionality over time.