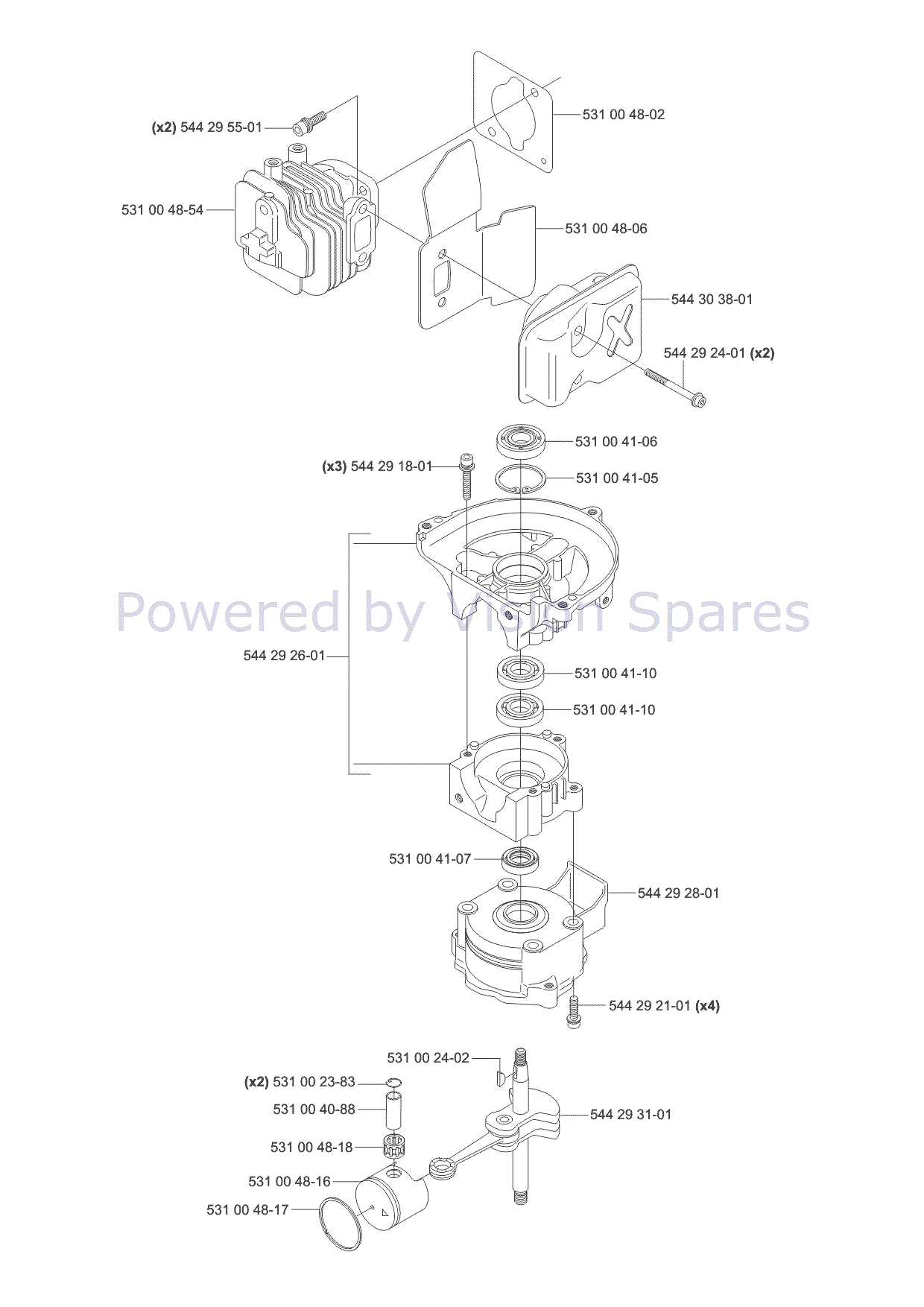

In the realm of internal combustion engines, the functionality of various elements is crucial for optimal performance. This section aims to explore the intricate assembly of specific mechanisms that play a vital role in fuel delivery and air mixture. By breaking down these components, we can gain insight into their importance and interaction.

Comprehending these assemblies not only enhances our knowledge but also aids in troubleshooting and maintenance. Each component serves a unique purpose, and recognizing how they fit together can lead to improved efficiency and reliability.

As we delve deeper into this subject, it becomes evident that understanding the layout and relationships of these mechanisms is the ultimate key to mastering engine performance. Engaging with this information will empower enthusiasts and professionals alike in their quest for excellence.

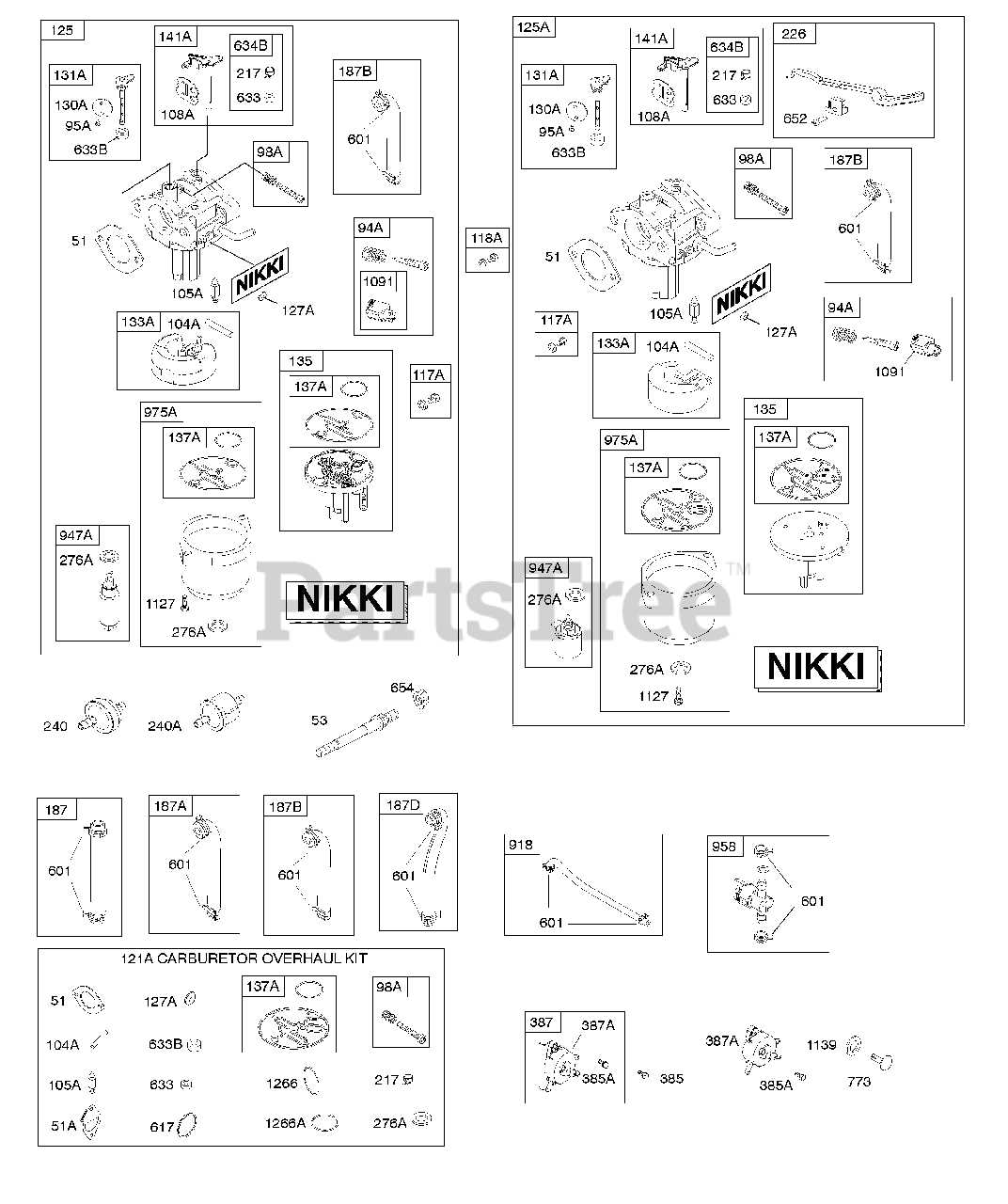

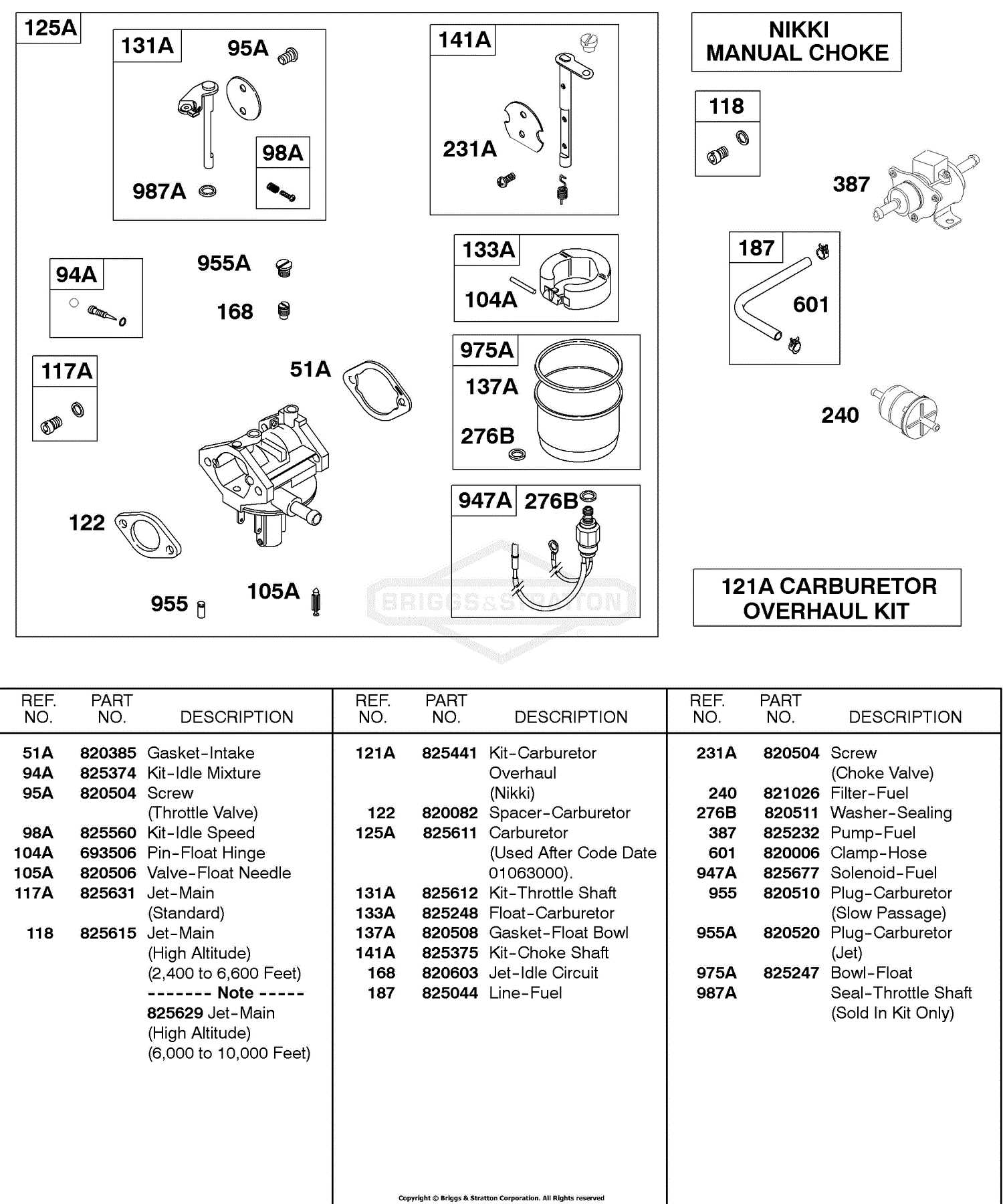

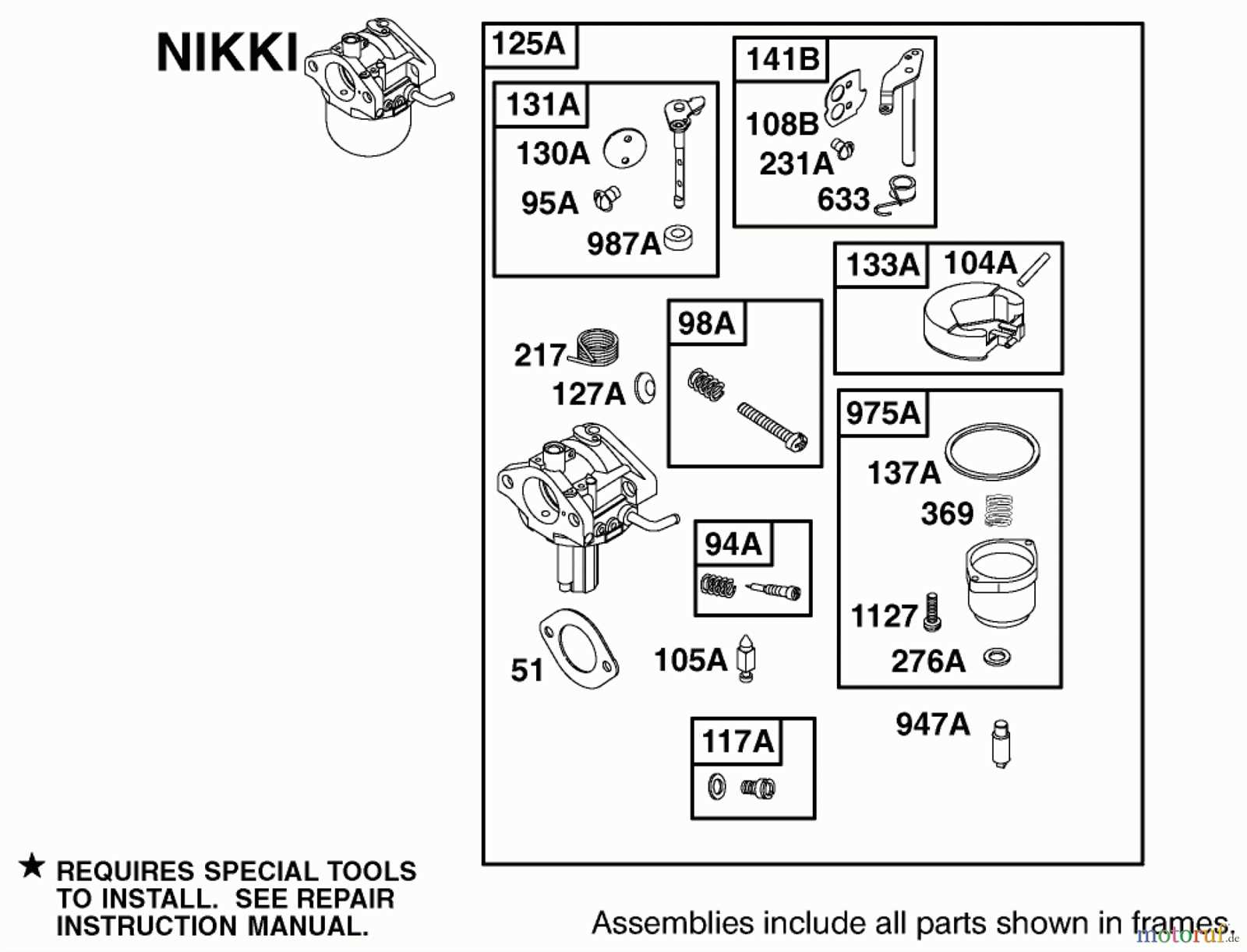

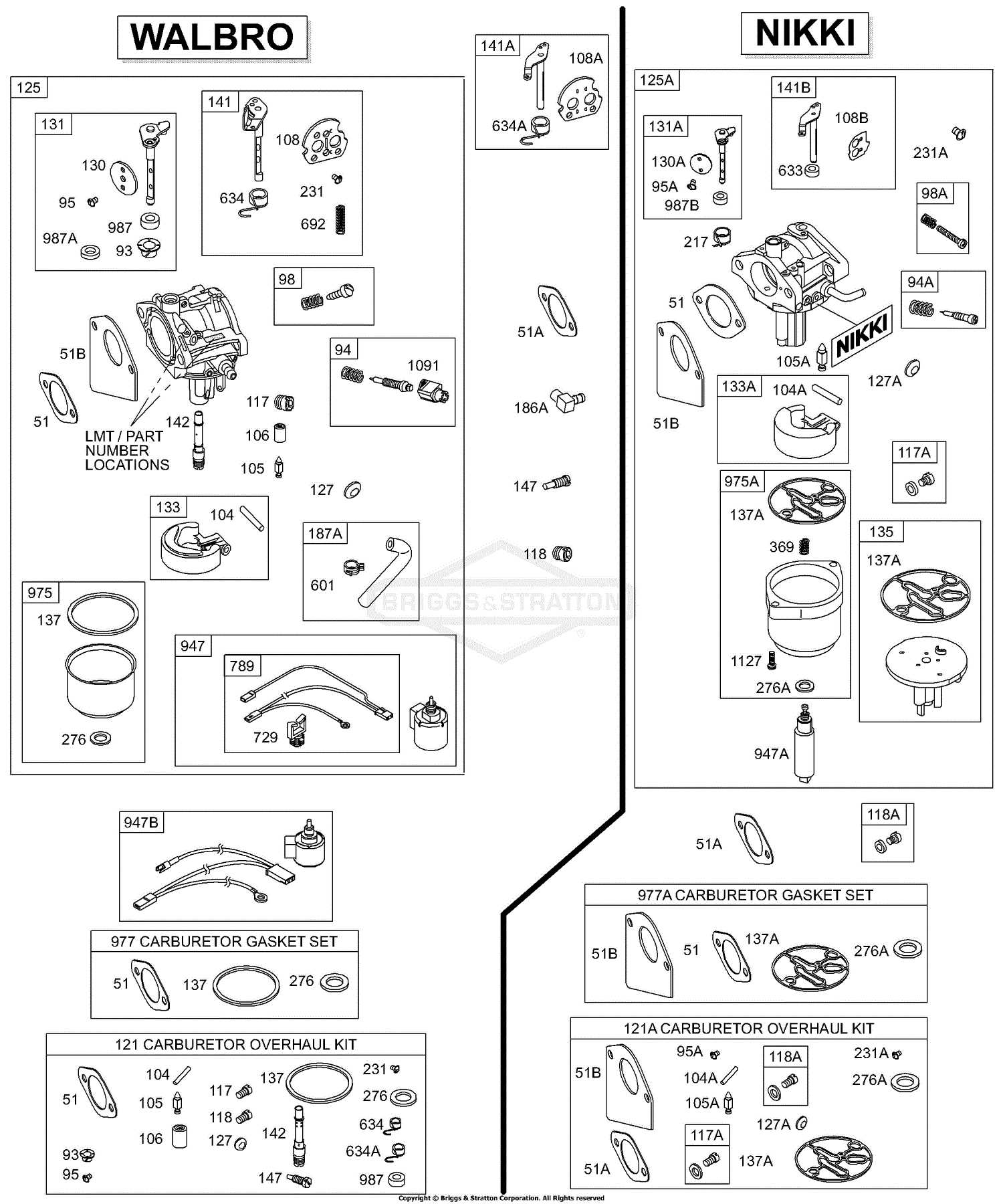

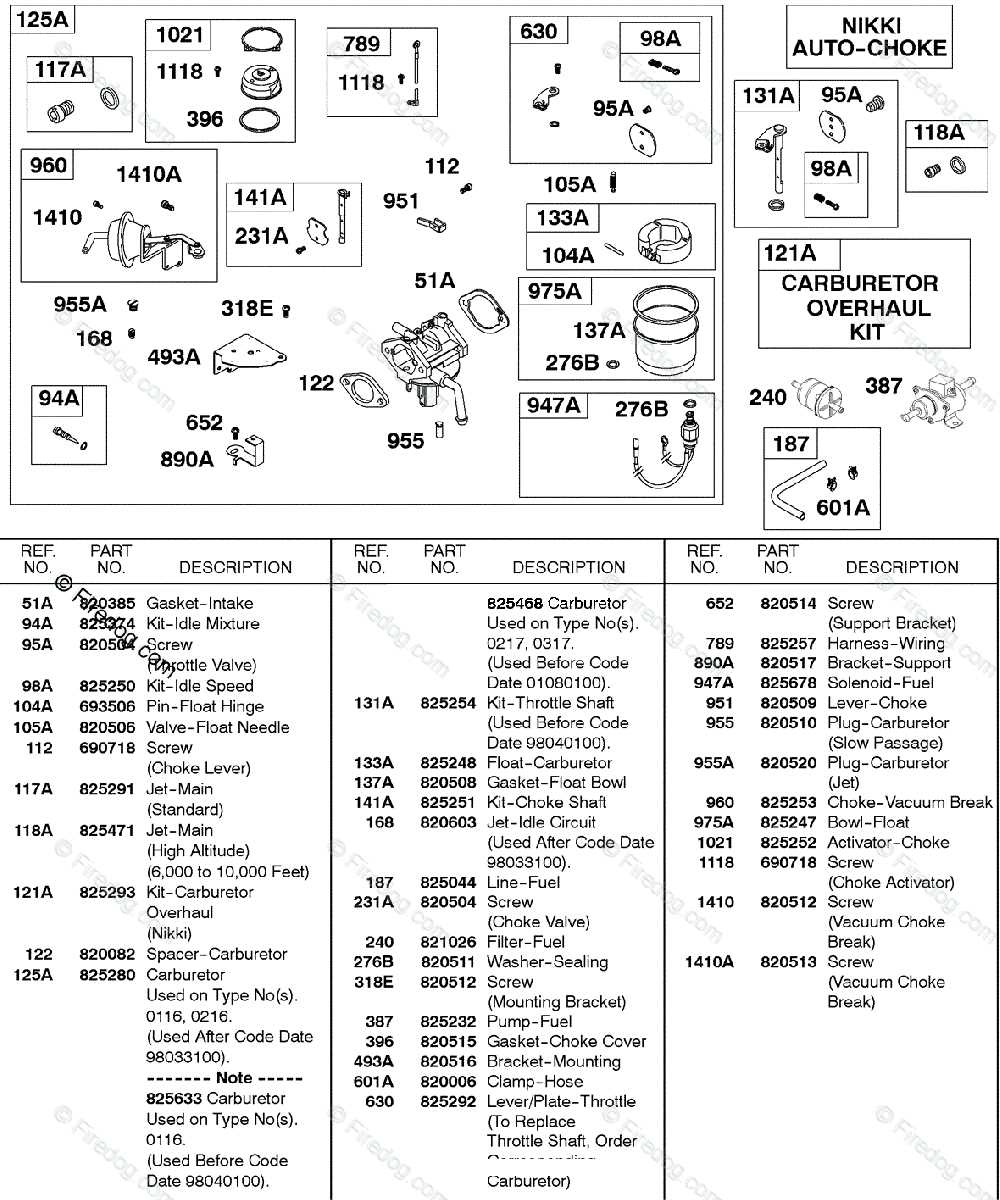

Nikki Carburetor Overview

This section provides a comprehensive look at a specific fuel delivery mechanism widely used in various engines. Understanding its components and functionality is crucial for optimal performance and maintenance.

Key Components

- Fuel inlet

- Throttle valve

- Float chamber

- Jet assembly

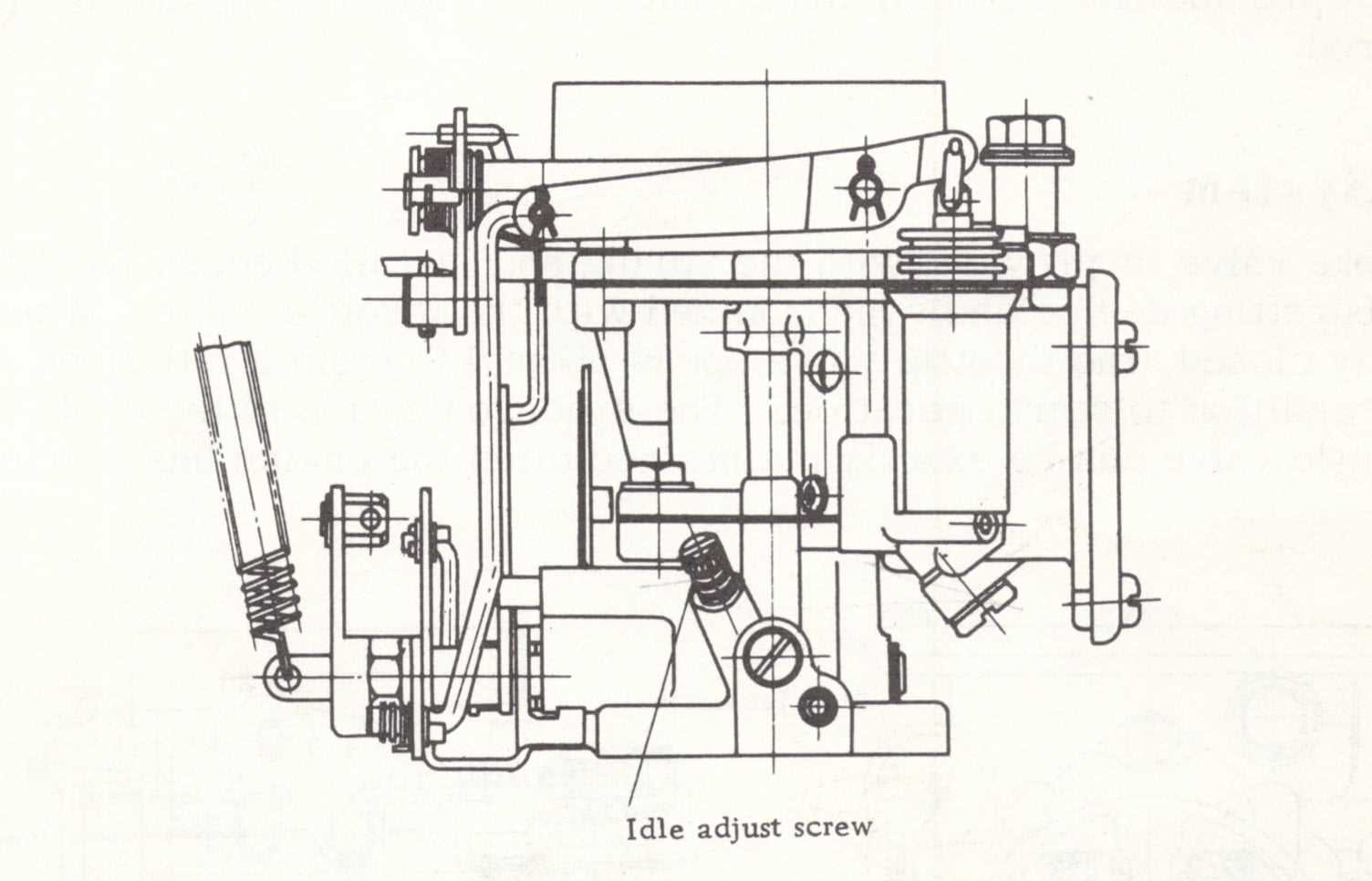

Functionality

The operation of this device involves a careful balance of air and fuel, ensuring efficient combustion. Here are the essential steps:

- Air enters through the intake.

- Fuel is drawn into the airstream.

- The mixture is adjusted for optimal performance.

Components of Nikki Carburetors

This section explores the essential elements that make up a particular fuel delivery system, emphasizing their functionality and significance. Understanding these components is crucial for anyone looking to optimize performance and ensure longevity.

Key Elements

- Float Chamber

- Jet System

- Throttle Valve

- Venturi

- Fuel Inlet

Functionality Overview

- The float chamber regulates fuel supply.

- The jet system controls the mixture of air and fuel.

- The throttle valve manages airflow and engine speed.

- The venturi creates a pressure drop to facilitate mixing.

- The fuel inlet provides the necessary supply from the tank.

Importance of Proper Maintenance

Regular upkeep is crucial for ensuring optimal performance and longevity of any mechanical system. By attending to these needs, one can prevent minor issues from escalating into major problems.

Neglecting maintenance can lead to decreased efficiency, increased wear and tear, and ultimately costly repairs. Consistent attention not only preserves functionality but also enhances reliability, providing peace of mind to users.

Moreover, maintaining components in top condition supports smoother operation and can even improve fuel efficiency. Emphasizing routine checks and timely replacements fosters a more sustainable approach, benefiting both the user and the environment.

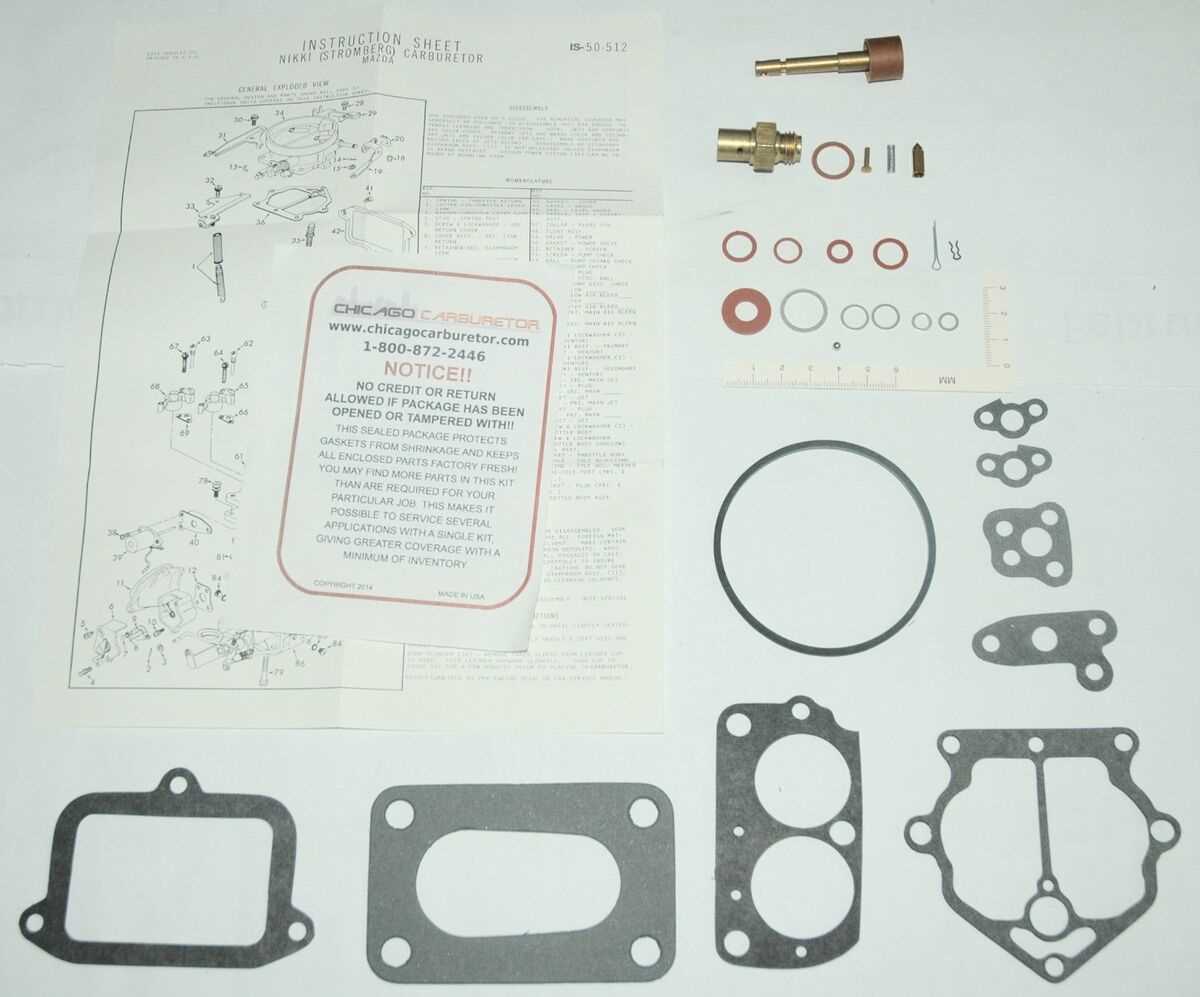

Common Issues with Carburetors

When dealing with fuel delivery systems, various challenges can arise that affect performance and efficiency. Understanding these common problems is crucial for maintaining optimal function and longevity of the system.

One frequent issue is improper fuel mixture, which can lead to poor combustion and reduced power output. This can occur due to clogged passages or incorrect adjustments. Additionally, leakage can be a significant concern, often caused by worn seals or gaskets, leading to fuel wastage and potential hazards.

Another common challenge is the buildup of deposits, which can impede airflow and disrupt the delicate balance necessary for effective operation. Regular cleaning and maintenance are essential to prevent this from becoming a serious problem.

Lastly, environmental factors such as temperature fluctuations and humidity can impact functionality, making it important to monitor performance regularly and address any anomalies promptly.

Understanding Fuel Mixture Ratios

Fuel mixture ratios play a crucial role in the performance and efficiency of any internal combustion engine. These ratios determine how much fuel is combined with air, influencing the combustion process and overall engine functionality. Achieving the right balance is essential for optimal operation, reducing emissions, and preventing engine damage.

The ideal ratio typically varies depending on the engine type and specific requirements. A mixture that is too rich can lead to incomplete combustion, resulting in wasted fuel and increased emissions, while a mixture that is too lean can cause overheating and potential engine failure. Therefore, understanding these dynamics is vital for anyone involved in engine maintenance or tuning.

Adjustments to the fuel mixture can be made through various methods, including changing jet sizes or altering air intake. Monitoring performance and making precise adjustments are key steps in ensuring the engine runs efficiently and effectively. Ultimately, mastering the nuances of fuel mixture ratios is essential for achieving peak performance and longevity of the engine.

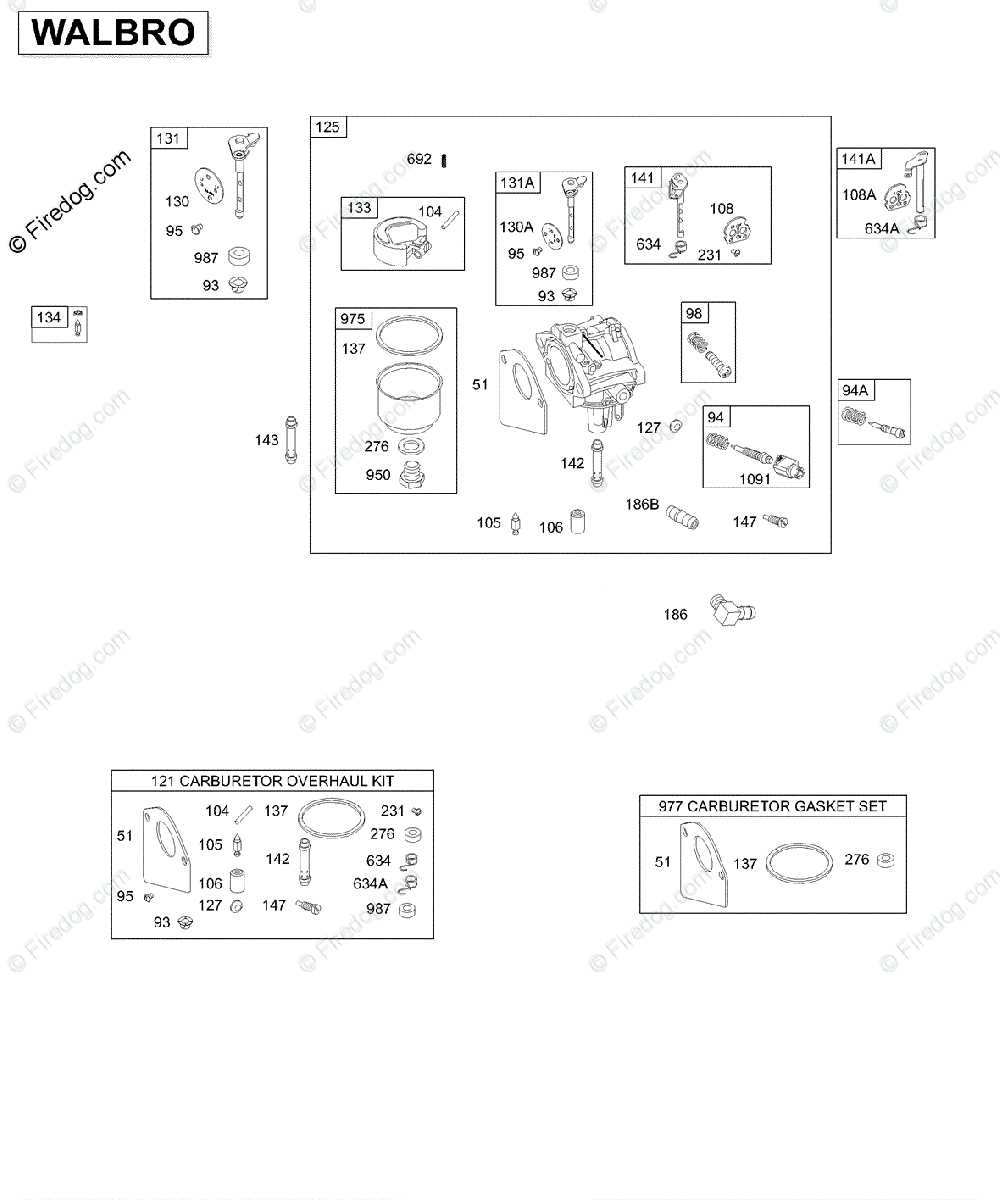

How to Identify Parts in Diagrams

Understanding the components depicted in technical illustrations is crucial for effective maintenance and troubleshooting. These visuals serve as guides, enabling users to pinpoint specific elements and their functions within a system. By familiarizing yourself with common symbols and layouts, you can enhance your comprehension and ability to work with complex machinery.

1. Familiarize with Symbols: Each illustration typically employs standardized icons to represent various elements. Investing time in learning these symbols will streamline the identification process and reduce confusion during assembly or repair tasks.

2. Reference Key Descriptions: Most visual aids come with accompanying legends or keys that explain the representations used. Consulting these descriptions allows for a clearer understanding of what each symbol signifies, ensuring accurate interpretation.

3. Follow the Flow: Pay attention to the layout and how components are interconnected. Observing the flow can provide insights into functionality and the relationship between different sections, aiding in quicker identification.

4. Use Color Coding: Many illustrations utilize color to differentiate parts or indicate specific functions. Recognizing these color schemes can be an effective strategy to enhance your ability to locate and understand various components.

5. Practice with Examples: Engaging with various visuals will help reinforce your skills. The more examples you examine, the more intuitive the identification process will become. Regular practice builds familiarity and confidence.

Tuning Tips for Optimal Performance

Achieving the best efficiency from your engine requires a fine balance between various components. Proper adjustments can significantly enhance power output, fuel efficiency, and overall responsiveness. Understanding the nuances of tuning will lead you to discover the ultimate performance enhancements.

Start with the Basics: Ensure that the foundational elements, such as air intake and fuel delivery, are clean and functioning optimally. This creates a solid platform for further adjustments.

Adjust Fuel Mixture: Experimenting with the fuel-air ratio can yield noticeable improvements. A richer mixture can enhance power but may lead to inefficiency, while a leaner mix might boost mileage but reduce power. Aim for the perfect blend.

Fine-Tune Idle Speed: Setting the idle speed correctly can improve throttle response and overall engine stability. Test different speeds to find the sweet spot that provides smooth operation without stalling.

Regular Maintenance: Keeping components in top condition is vital. Regularly check and replace worn elements to prevent performance loss and ensure longevity.

Seek Professional Help: If you’re unsure, consulting with an expert can provide insights and adjustments tailored to your specific setup, helping you achieve optimal results.

Repair vs. Replacement Considerations

When faced with the dilemma of fixing a malfunctioning component or opting for a new one, several factors come into play. Each choice has its own advantages and drawbacks, influencing both functionality and budget. Understanding these aspects can guide you in making an informed decision tailored to your specific needs.

Key considerations include the extent of the damage, the cost of repairs compared to a new unit, and the availability of replacement options. Additionally, the long-term reliability and performance of each option should be evaluated.

| Aspect | Repair | Replacement |

|---|---|---|

| Cost | Generally lower upfront costs | Potentially higher initial expense |

| Time | May require more time for troubleshooting and fixing | Quick solution if a new item is readily available |

| Longevity | Depends on quality of repair | New items often come with warranties |

| Performance | Could restore to original functionality | New units may offer improved performance |

Ultimately, the choice between repairing and replacing depends on individual circumstances and priorities. Assessing these factors will lead to a more satisfactory outcome, ensuring the best performance for your equipment.

Resources for Further Learning

Expanding your knowledge about engine tuning and maintenance can greatly enhance your skills and understanding. Various resources are available to help you delve deeper into the intricacies of these essential components, providing both theoretical background and practical insights.

Books and Manuals

- Automotive Repair Manuals: Comprehensive guides covering various engine systems.

- Technical Handbooks: Detailed texts focusing on tuning and optimization techniques.

- Reference Books: Explore topics on fuel delivery systems and their functionalities.

Online Resources

- Forums and Communities: Engage with experienced enthusiasts and professionals for tips and troubleshooting advice.

- Video Tutorials: Visual demonstrations that break down complex concepts into manageable steps.

- Educational Websites: Websites offering articles, guides, and FAQs on engine systems.

Utilizing these resources will enhance your expertise and empower you to tackle various challenges in engine performance and maintenance.