When it comes to winter maintenance, having a thorough understanding of the machinery involved is essential for optimal performance. This section delves into the intricate details of various essential elements that contribute to efficient snow removal operations. By familiarizing oneself with these components, operators can ensure their equipment runs smoothly and effectively during harsh weather conditions.

Each element plays a vital role in the overall functionality of the apparatus. From the mechanisms that control movement to the attachments that enhance performance, recognizing how these parts interconnect is crucial. Proper maintenance and timely repairs not only prolong the lifespan of the equipment but also ensure safety and reliability on the job.

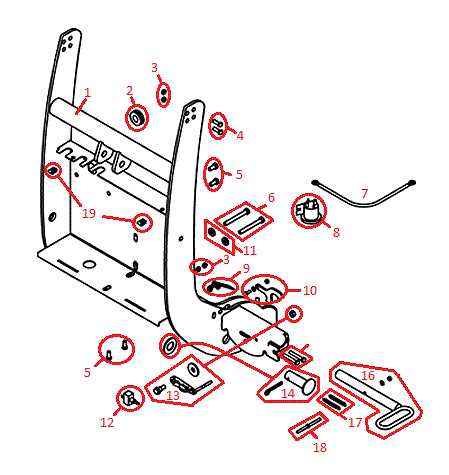

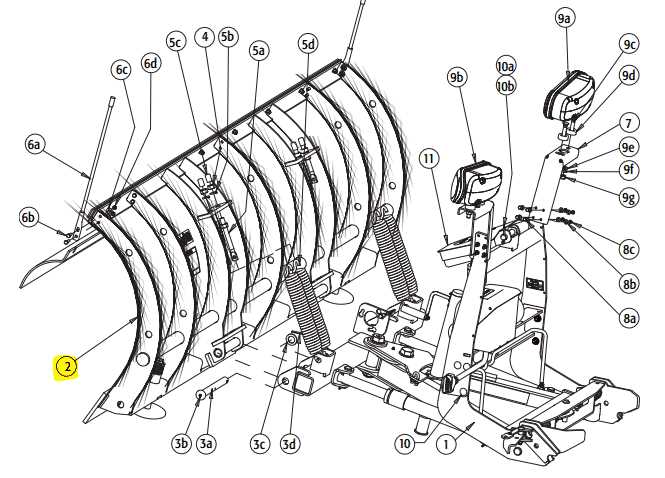

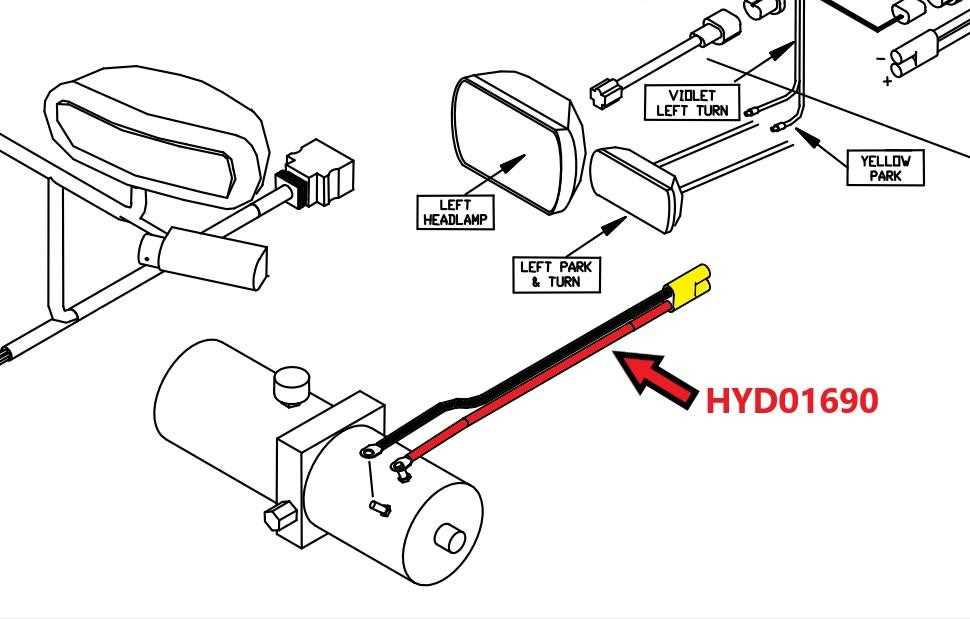

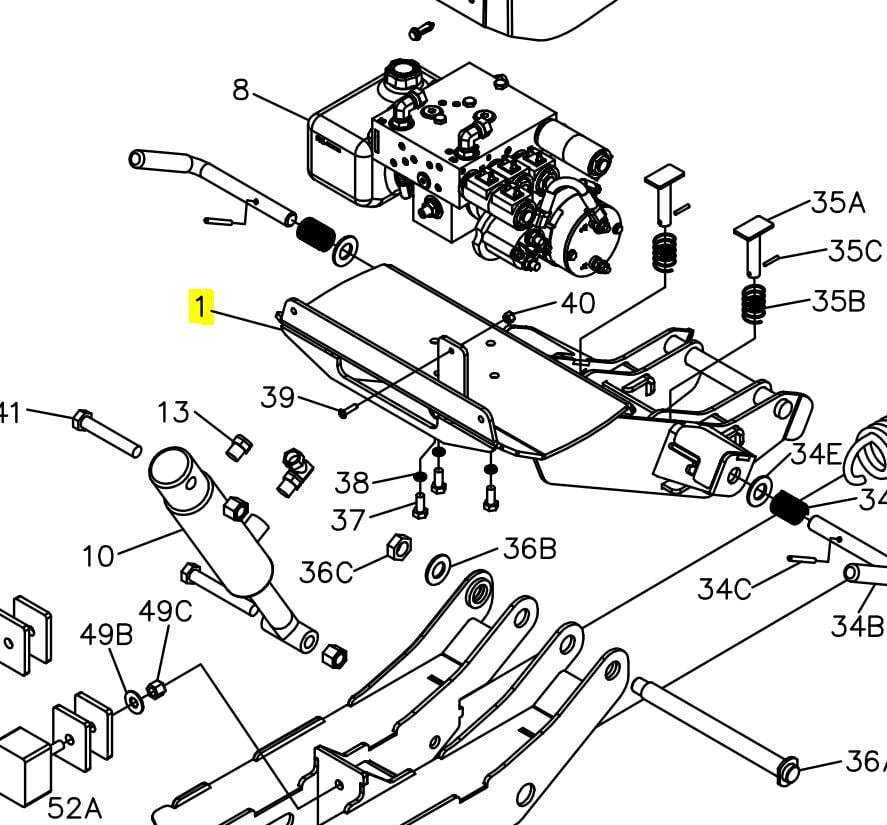

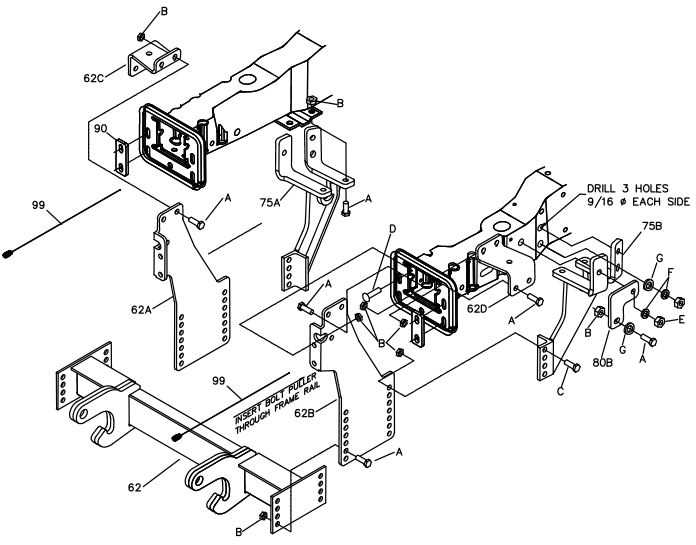

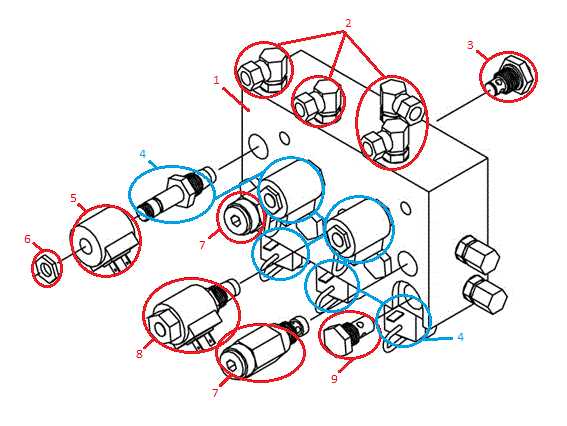

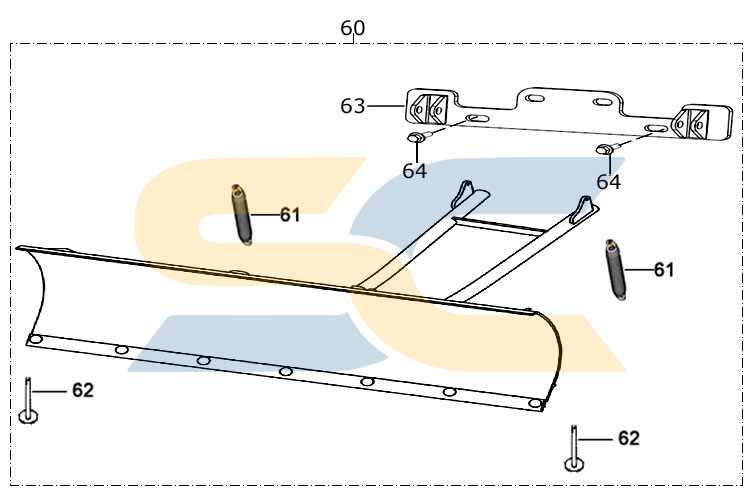

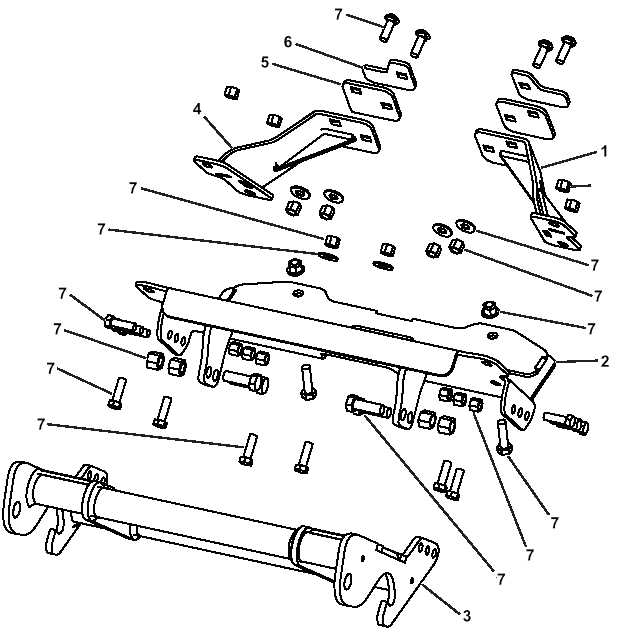

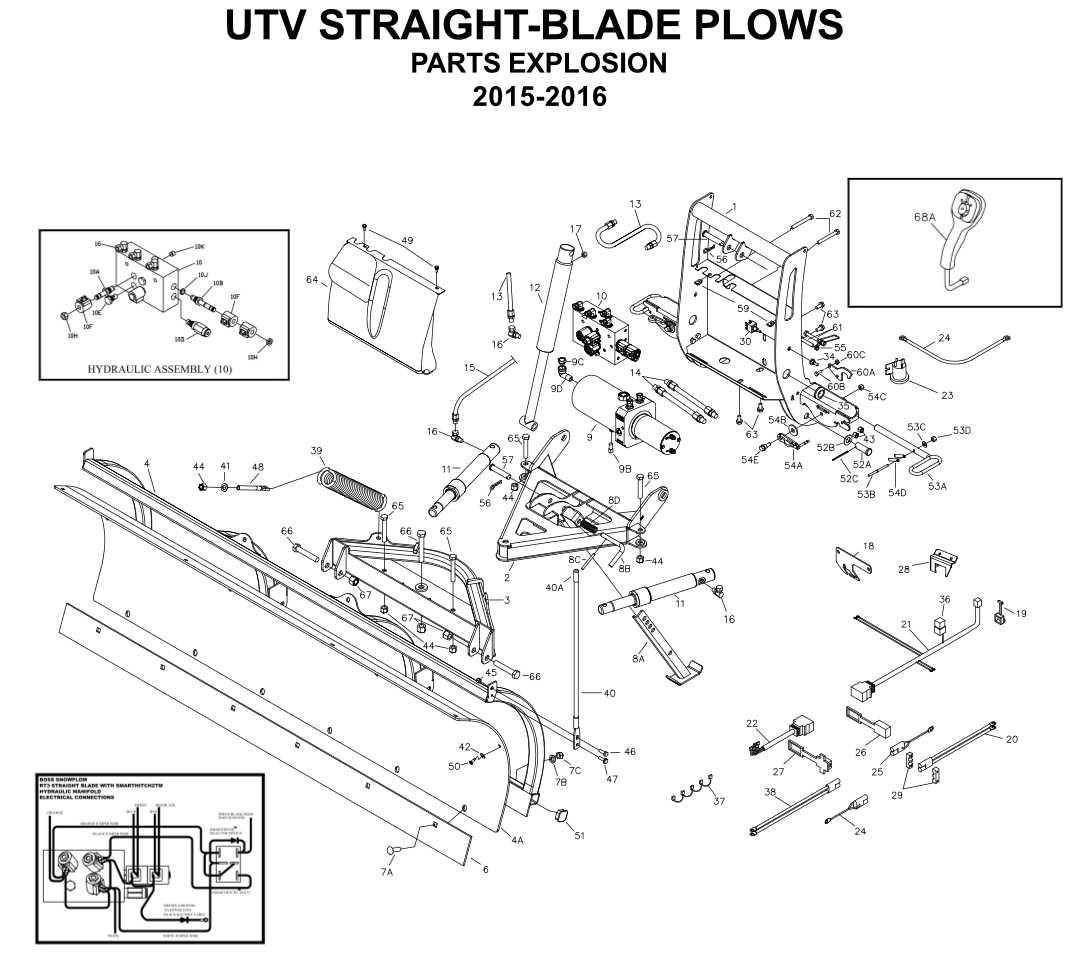

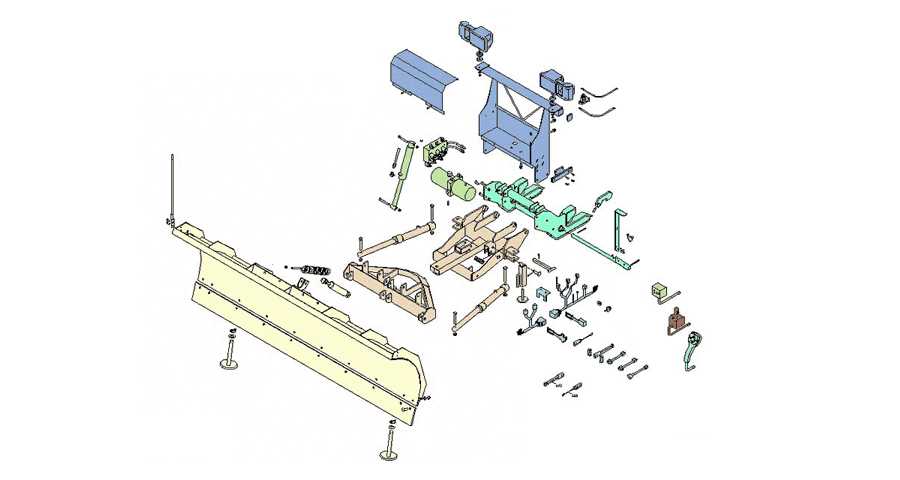

In this exploration, visual representations serve as valuable tools for understanding the layout and assembly of these critical components. Such illustrations can simplify complex systems, enabling users to quickly identify and address any issues that may arise. Whether you are a seasoned operator or a newcomer to the field, grasping these concepts will empower you to make informed decisions regarding maintenance and repairs.

Understanding Boss Plow Components

This section delves into the essential elements that constitute a snow removal system, exploring their functions and interactions. A comprehensive grasp of these components enhances operational efficiency and maintenance practices.

Key Elements of the System

- Blade: The primary tool for pushing snow, typically adjustable for various conditions.

- Mounting Frame: Connects the blade to the vehicle, ensuring stability and support during operation.

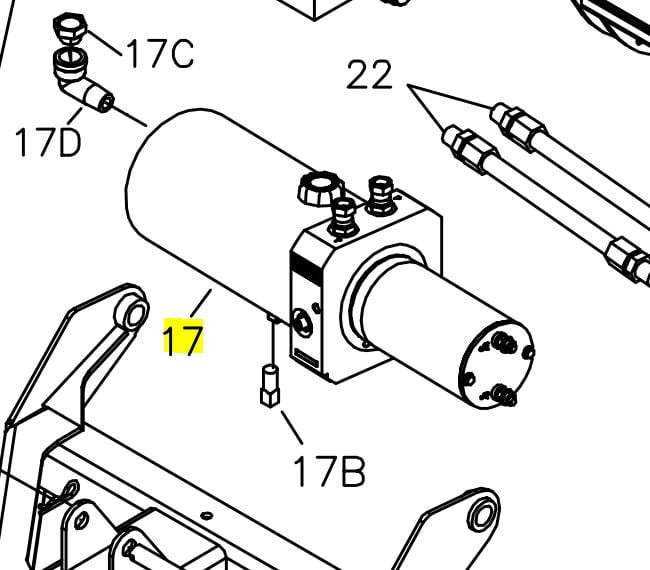

- Hydraulic System: Facilitates movement and adjustments of the blade, allowing for precise control.

- Control Mechanism: The interface for the operator to manage blade functions effectively.

- Lights: Enhance visibility during nighttime or low-light conditions, ensuring safety.

Maintenance and Care

- Regularly inspect each element for signs of wear and tear.

- Clean components to prevent corrosion and buildup from snow and ice.

- Lubricate moving parts to ensure smooth operation.

- Check hydraulic fluid levels and connections to maintain optimal performance.

- Replace any damaged elements promptly to avoid further issues.

By understanding these vital components and their upkeep, users can ensure a reliable and effective snow management experience.

Importance of Accurate Diagrams

Precise representations are essential in various fields, serving as a visual aid that enhances understanding and facilitates communication. Accurate visuals not only help in identifying components but also in grasping their interrelations and functions within a system. This clarity is vital for effective maintenance and troubleshooting, ensuring that operations run smoothly and efficiently.

Enhancing Efficiency

When individuals work with clear and detailed visuals, they can quickly locate the necessary elements, reducing the time spent on searches and minimizing errors. This efficiency translates to better productivity and less frustration, allowing teams to focus on critical tasks rather than deciphering complex layouts.

Improving Safety

Well-crafted illustrations significantly contribute to safety by providing precise instructions on assembly and disassembly. Understanding the correct order of operations reduces the risk of accidents and damage, ultimately protecting both personnel and equipment. Emphasizing clarity in these representations fosters a safer working environment.

Identifying Key Plow Parts

Understanding the essential components of a snow management tool is crucial for effective operation and maintenance. Each element plays a significant role in the overall functionality, ensuring optimal performance in winter conditions. Familiarity with these critical sections helps users troubleshoot issues and make informed decisions regarding repairs or upgrades.

The following table outlines the primary components, their functions, and common materials used in their construction:

| Component | Function | Common Materials |

|---|---|---|

| Blade | Clears snow from surfaces | Steel, poly |

| Mounting Frame | Supports attachment to the vehicle | Steel |

| Hydraulic System | Controls lifting and angling | Hydraulic fluid, metal |

| Trip Edge | Prevents damage by allowing the blade to pivot | Steel |

| Skid Shoes | Regulates blade height and protects surfaces | Plastic, metal |

By recognizing these elements, operators can enhance their efficiency and ensure that their equipment is well-maintained and ready for challenging weather conditions.

Common Issues with Plow Systems

When it comes to snow removal equipment, various challenges can arise that affect performance and efficiency. Understanding these common problems is essential for maintaining optimal operation and ensuring that the equipment can tackle harsh winter conditions effectively.

Mechanical Failures

One of the most frequent issues involves mechanical failures, such as malfunctioning lift systems or hydraulic components. These failures can lead to inadequate lifting capabilities or inconsistent blade positioning, making it difficult to clear snow effectively. Regular maintenance checks can help identify wear and tear before it becomes a significant problem.

Electrical Problems

Electrical issues, including faulty connections or dead batteries, can disrupt the functionality of control systems. If the operator is unable to activate or adjust the equipment as needed, it can result in inefficient operations. Ensuring that electrical components are in good condition and properly connected is crucial for reliable performance.

Maintenance Tips for Longevity

Ensuring the durability and performance of your equipment requires regular care and attention. By following a few essential practices, you can significantly extend its lifespan and enhance its efficiency. This section outlines key maintenance strategies to keep your machinery in top condition.

- Regular Inspections: Perform frequent checks to identify any signs of wear or damage.

- Cleanliness: Keep all surfaces free of dirt, debris, and corrosive materials to prevent deterioration.

- Lubrication: Apply appropriate lubricants to moving components to reduce friction and wear.

- Fastener Tightness: Ensure that all bolts and screws are tightened to the manufacturer’s specifications.

- Storage Practices: Store equipment in a dry, sheltered location to protect it from environmental factors.

Implementing a consistent maintenance schedule is crucial. Consider the following:

- Develop a maintenance calendar to track routine tasks.

- Document any repairs or replacements made to monitor patterns over time.

- Train operators on proper handling techniques to minimize misuse.

By adhering to these guidelines, you can maximize the performance and lifespan of your machinery, ensuring it remains reliable for years to come.

How to Replace Worn Parts

Maintaining the functionality of your equipment is essential for optimal performance. When components begin to show signs of wear, timely replacement is crucial to avoid more significant issues down the line. This section provides a straightforward guide to identifying and substituting these worn elements effectively.

Before starting, ensure you have the necessary tools and a suitable workspace. Always refer to your equipment manual for specific instructions related to your model. Here’s a general approach to replacing worn components:

| Step | Description |

|---|---|

| 1 | Inspect the Equipment: Examine all elements for signs of damage or excessive wear. |

| 2 | Gather Tools: Collect the required tools, including wrenches, screwdrivers, and any specialized equipment. |

| 3 | Disconnect Power: Ensure the machinery is powered down and disconnected to prevent accidents. |

| 4 | Remove Old Components: Carefully take out the worn parts, noting their arrangement for proper reinstallation. |

| 5 | Install New Components: Place the new elements in the same configuration as the old ones, ensuring a secure fit. |

| 6 | Reconnect Power: Once everything is reassembled, reconnect the power source and conduct a test run. |

Regular maintenance and timely replacements will ensure your equipment remains reliable and efficient. Always keep an eye out for early signs of wear to minimize downtime and enhance longevity.

Comparing Different Plow Models

This section delves into the nuances of various snow-clearing systems, highlighting their unique features and capabilities. By examining the strengths and weaknesses of each model, users can make informed decisions based on their specific needs and conditions. Understanding these distinctions is crucial for optimizing performance and ensuring efficiency in winter operations.

Performance and Efficiency

When evaluating different systems, performance is a key factor. Some models excel in deep snow, while others are designed for rapid clearing on paved surfaces. Efficiency can vary based on design, with certain configurations minimizing fuel consumption and maintenance costs, making them more appealing for long-term use.

Durability and Build Quality

The construction and materials used in each model significantly influence longevity and resistance to wear. Heavy-duty options may provide better performance in harsh conditions, while lighter systems can be more versatile. Assessing the build quality helps ensure that the chosen solution can withstand the demands of frequent use.

Where to Find Quality Diagrams

Finding reliable illustrations for machinery components is essential for effective maintenance and repair. These resources can guide you through assembly, disassembly, and troubleshooting processes. Quality visuals enhance understanding and efficiency, ensuring that tasks are completed with precision.

Online Resources

The internet offers a plethora of websites dedicated to technical resources. Reputable manufacturers often provide downloadable visuals on their official sites. Additionally, forums and community platforms may feature user-generated content that can be both insightful and practical.

Print Manuals and Guides

Printed manuals are another excellent source of detailed illustrations. Many suppliers distribute comprehensive guides that include not only diagrams but also maintenance tips and troubleshooting advice. Ensure that the manuals are up-to-date for the best results.