Maintaining your gardening machinery is essential for optimal performance and longevity. By familiarizing yourself with the various elements that make up your tilling tool, you can ensure efficient operation and timely repairs. This knowledge empowers you to tackle any challenges that arise in your gardening endeavors.

In this section, we will explore the intricate design and functionality of the essential components involved in your gardening implement. Recognizing how these pieces interact with one another can greatly enhance your understanding of the machine’s overall operation.

Moreover, having access to a detailed overview of these elements will help you identify potential issues before they escalate. Armed with this information, you’ll be better prepared to keep your equipment running smoothly, allowing you to focus on what truly matters–creating a thriving garden.

Overview of RT 65

The RT 65 is a versatile garden tool designed to assist with soil preparation and cultivation tasks. This machine is engineered for efficiency, making it an essential addition for both amateur gardeners and professional landscapers. Its user-friendly features and robust construction ensure optimal performance in various soil conditions.

With a focus on enhancing productivity, the RT 65 is equipped with powerful components that facilitate ease of use and maneuverability. Its design emphasizes durability, ensuring it can withstand the rigors of regular use in diverse environments.

| Feature | Description |

|---|---|

| Engine Type | Powerful and reliable engine for efficient operation |

| Working Width | Generous width to cover large areas quickly |

| Weight | Stable and balanced for easy handling |

| Controls | Intuitive controls for effortless adjustments |

| Maintenance | Simple maintenance procedures to extend lifespan |

Key Features of RT 65 Tiller

The RT 65 model stands out due to its impressive capabilities and user-friendly design. Engineered for optimal performance in various soil conditions, it offers an array of features that enhance both efficiency and convenience for users. Below are some notable characteristics that make this model a reliable choice for gardening and landscaping tasks.

- Powerful Engine: Equipped with a robust engine that ensures consistent performance and reliability during operation.

- Adjustable Tilling Width: Features a customizable tilling width to accommodate different garden sizes and tasks.

- Ergonomic Handle: Designed with user comfort in mind, the adjustable handle reduces strain and improves maneuverability.

- Durable Construction: Made from high-quality materials, ensuring longevity and resistance to wear and tear.

- Easy Assembly: User-friendly setup process that allows quick readiness for immediate use.

- Transport Wheels: Integrated wheels facilitate easy movement across various terrains and storage options.

- Versatile Accessories: Compatible with a range of attachments that enhance functionality for diverse gardening needs.

Overall, the RT 65 model combines strength, versatility, and convenience, making it an ideal choice for anyone looking to cultivate their garden effectively.

Importance of Replacement Parts

Maintaining the efficiency and longevity of your equipment relies heavily on utilizing high-quality components. When any element becomes worn or damaged, replacing it promptly can prevent further issues, ensuring optimal performance and reducing downtime.

Benefits of Timely Replacements

- Improved Performance: New components restore functionality.

- Cost-Effectiveness: Prevents costly repairs by addressing small issues early.

- Increased Safety: Reduces the risk of accidents due to malfunctioning machinery.

Choosing Quality Components

- Research reputable suppliers for reliability.

- Verify compatibility with your equipment model.

- Consider warranties and customer reviews for assurance.

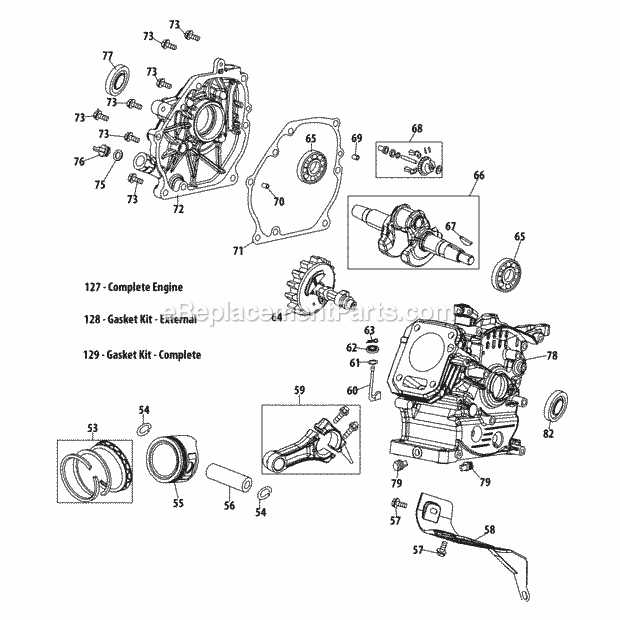

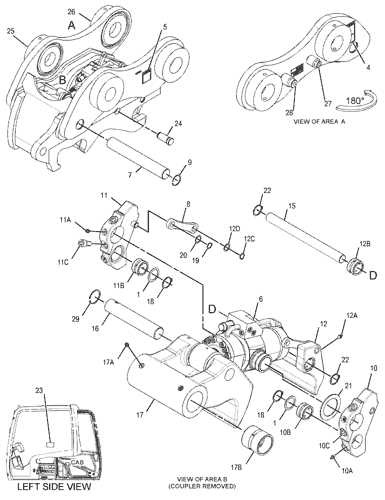

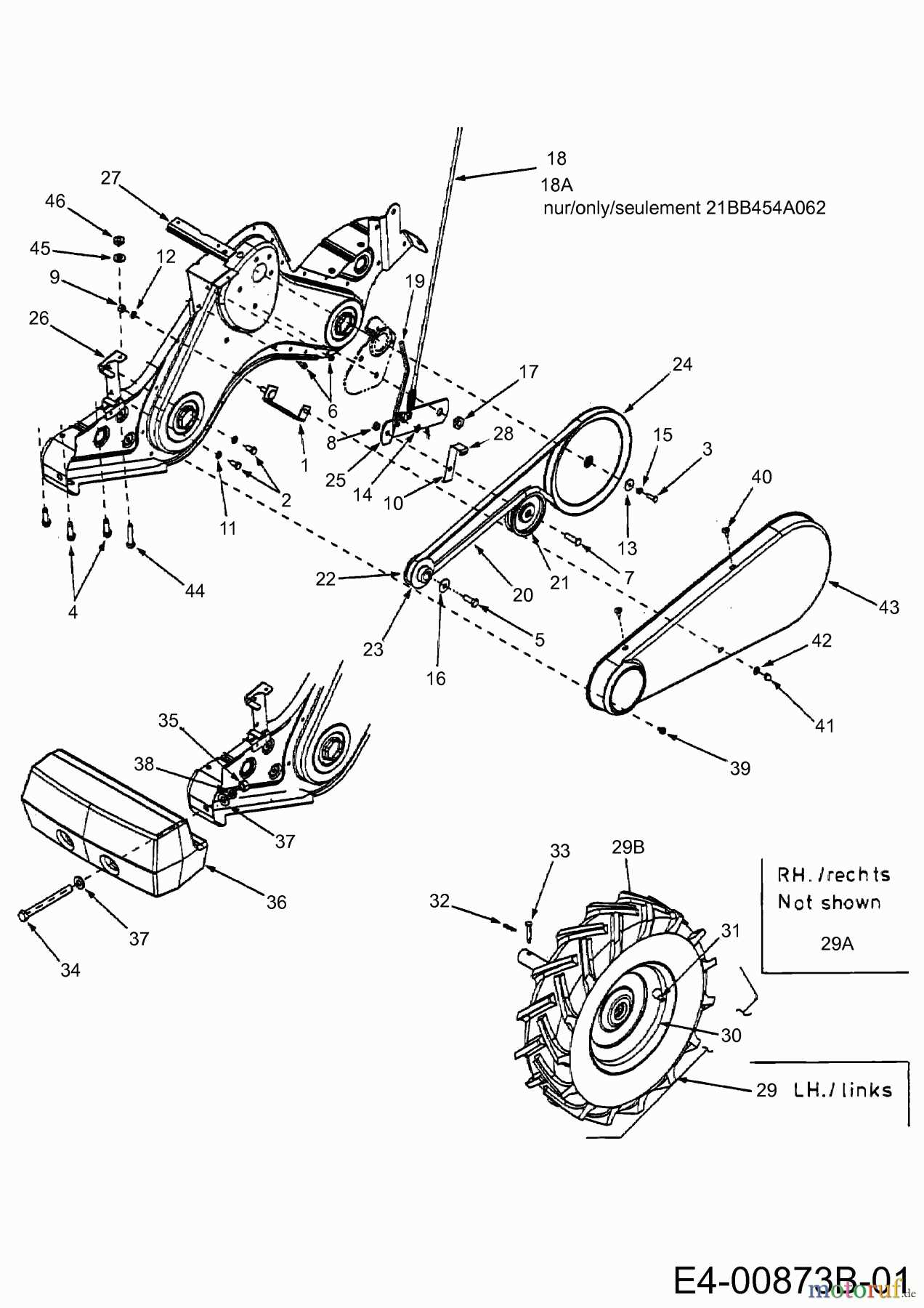

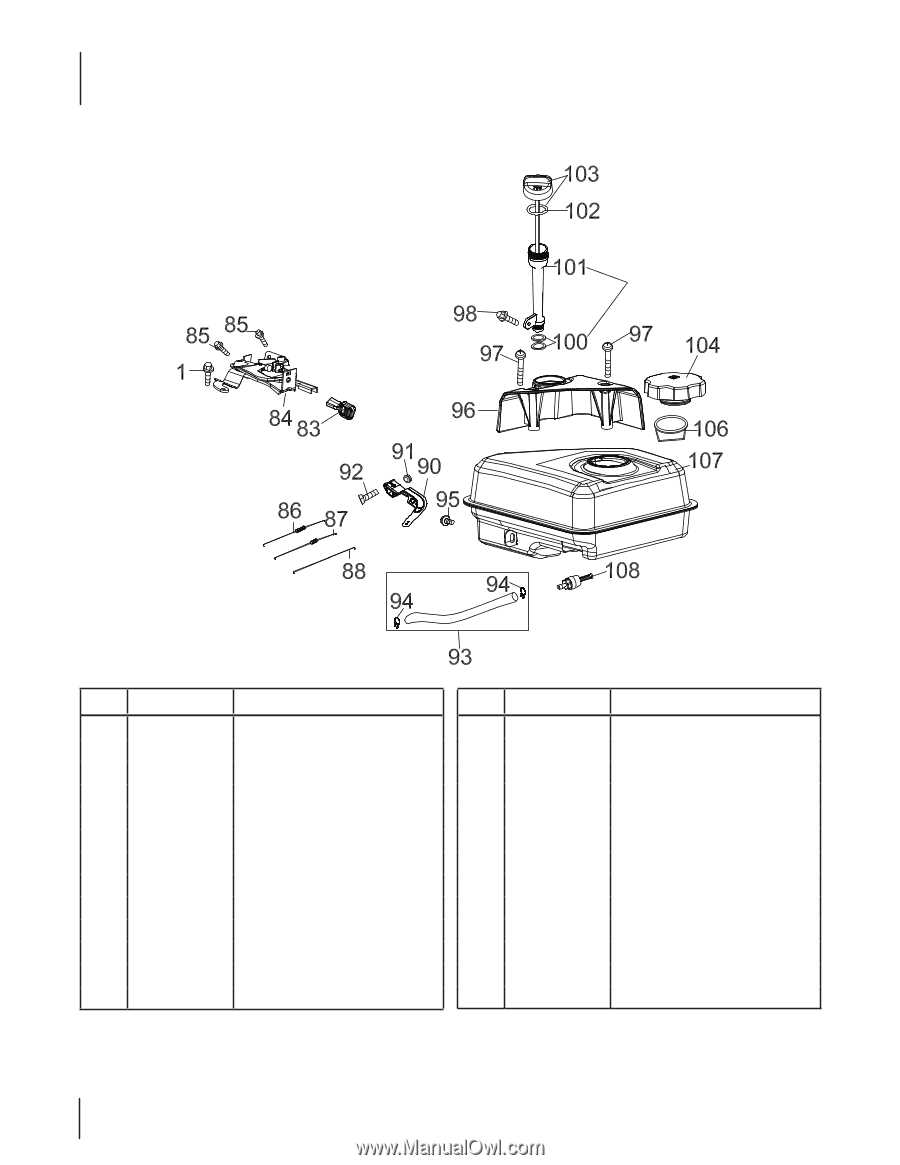

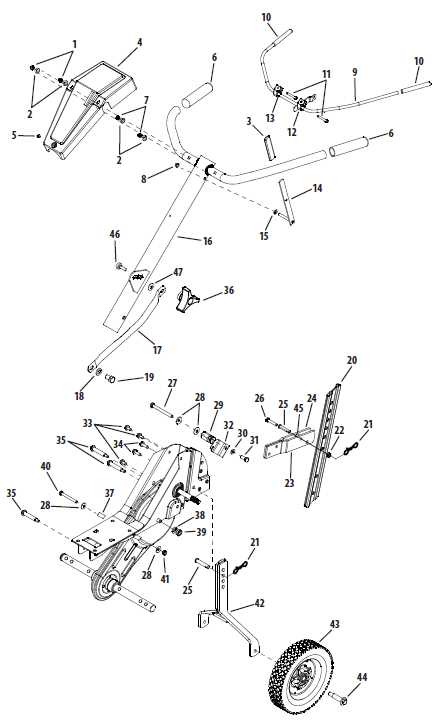

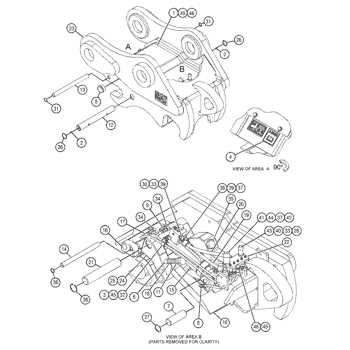

Understanding Tiller Parts Diagram

Gaining insight into the components of a garden cultivator is essential for effective maintenance and troubleshooting. Each element plays a crucial role in ensuring optimal performance, making it vital to familiarize oneself with their functions and interactions. By examining a visual representation of these components, users can better understand how each piece contributes to the overall operation of the equipment.

Focusing on the layout of these components allows users to identify potential issues, facilitating timely repairs and replacements. Recognizing how parts connect and work together ultimately enhances the longevity and efficiency of the machinery. Whether for routine checks or more complex fixes, understanding the structure can save both time and effort in maintaining a well-functioning cultivator.

Common Issues with RT 65

The RT 65 model often encounters several recurring problems that can affect its performance and efficiency. Understanding these issues can help users troubleshoot effectively and maintain their equipment in optimal condition.

Frequent Problems

- Engine starting difficulties

- Inconsistent power output

- Vibration during operation

- Clogs in the working components

Maintenance Tips

- Regularly check and clean the air filter.

- Inspect fuel lines for leaks or blockages.

- Keep blades sharp for better performance.

- Perform routine oil changes.

Identifying Parts for Repair

When undertaking maintenance or repairs on garden equipment, recognizing the components involved is crucial for effective troubleshooting. A thorough understanding of each element not only simplifies the repair process but also ensures that any replacements are accurately matched to the original specifications.

Start by examining the overall structure of the machine, as this will help in locating key features and individual sections. Referencing a schematic can provide insight into how the components interact and where potential issues might arise.

Labeling each section can facilitate organization during the repair process. As you identify each part, take note of any visible wear or damage, as these can be indicators of what needs replacement. Having a comprehensive list of the elements will streamline your shopping process for new components.

In addition, familiarize yourself with common terminology used in the industry. This knowledge will not only aid in identifying what you need but will also improve communication when seeking assistance or ordering replacements.

By systematically assessing and documenting the components, you can approach repairs with confidence and efficiency, ensuring your equipment is restored to optimal working condition.

Where to Find OEM Parts

When seeking original equipment components, it’s essential to know the best sources to ensure quality and compatibility. Various avenues exist, each offering unique advantages for enthusiasts and professionals alike.

Authorized Dealers: Visiting certified retailers guarantees access to genuine items tailored specifically for your equipment. They often provide expert advice and support.

Manufacturer Websites: The official site can be a valuable resource for locating authentic components. Many manufacturers feature an online catalog for easy navigation.

Online Marketplaces: Reputable e-commerce platforms frequently host a wide array of original components. It’s advisable to check seller ratings and reviews for reliability.

Local Repair Shops: Establishments specializing in equipment repair may stock OEM items or assist in ordering them, providing a personal touch to the purchasing experience.

Forums and Communities: Engaging with fellow enthusiasts in online forums can yield recommendations and insights on where to procure authentic parts effectively.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the lifespan of any garden machinery. Implementing a consistent maintenance routine can enhance performance and ensure reliability over time. By focusing on specific areas of care, users can enjoy their equipment for many seasons.

Routine Inspection

Check components regularly to identify wear and tear. Look for signs of damage or rust, especially in moving parts. Ensuring everything is in good condition prevents larger issues down the line.

Proper Storage

When not in use, store equipment in a dry, sheltered area. Avoid exposing machinery to extreme weather conditions. Proper storage protects against corrosion and prolongs usability.