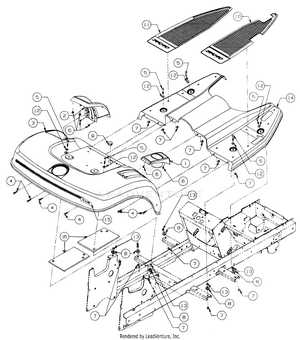

Understanding the structure and functionality of mechanical equipment is crucial for proper maintenance and long-term performance. Identifying individual elements and their roles ensures that any required adjustments or repairs are performed accurately and efficiently. Whether addressing minor tune-ups or major overhauls, a clear view of each component is essential for effective troubleshooting.

In this section, we will explore the main mechanical elements, focusing on their interactions and how they contribute to the overall efficiency of the machine. By breaking down the specific features and connections, users can gain a deeper understanding of how to approach both routine maintenance and more complex repairs.

With a thorough review of the system’s core elements, you will be better equipped to manage maintenance tasks, ensuring the longevity and reliable performance of your equipment. Regular inspections and an informed approach will significantly reduce the risk of unexpected breakdowns.

Key Components Overview of Cub Cadet 2185

Understanding the main elements of this lawn tractor model is essential for ensuring its optimal performance and long-term durability. Each part plays a crucial role in the machine’s overall functionality, contributing to both the power system and the user’s control over the vehicle. Regular maintenance and knowledge of how these elements interact will help keep the machine running efficiently.

The engine is the powerhouse, providing the necessary force to operate. The transmission system ensures smooth transitions between speeds, while the cutting deck allows for precision grass trimming. Additionally, the steering mechanism and wheels offer stability and maneuverability, which are vital for handling various terrains.

Each of these key components must be regularly inspected and maintained to avoid breakdowns. This overview highlights the importance of familiarizing yourself with the core systems to extend the machine’s lifespan and maintain its efficiency.

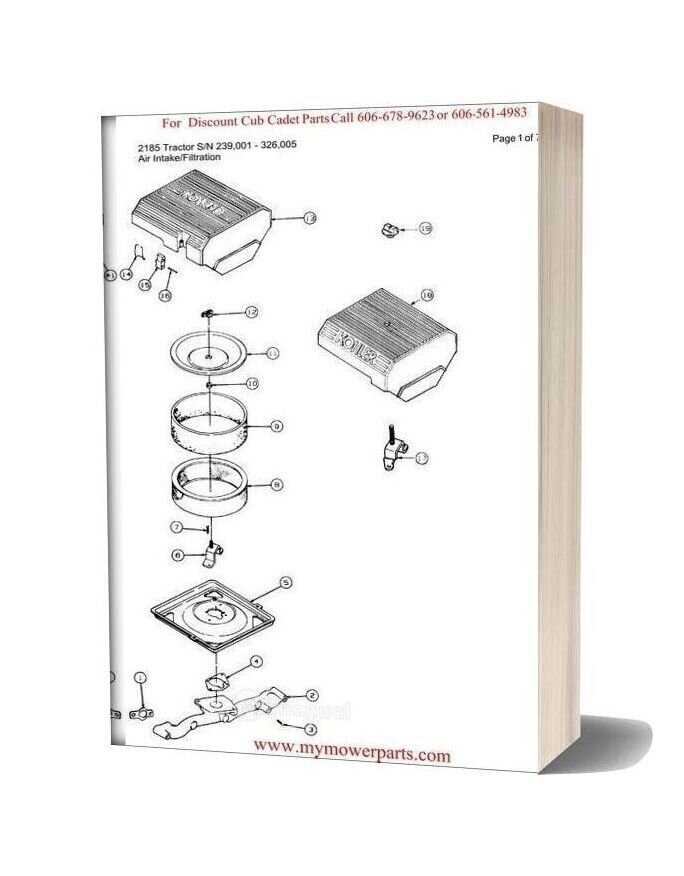

Engine Parts and Their Functions

The engine is a complex system composed of various components that work together to convert fuel into mechanical energy. Each element plays a critical role in ensuring the smooth and efficient operation of the engine. Below is a closer look at some of the essential components and their primary roles in this process.

| Component | Function |

|---|---|

| Piston | Moves within the cylinder to compress fuel and air mixture, enabling combustion. |

| Cylinder | Houses the piston and allows the combustion process to occur within a confined space. |

| Transmission and Drivetrain Diagram

The transmission and drivetrain system plays a crucial role in the overall performance of lawn tractors. It is responsible for transferring power from the engine to the wheels, ensuring smooth operation and optimal control. Understanding the layout and components of this system is essential for maintenance and repair. Main Components of the DrivetrainThe drivetrain consists of several key elements, such as the gearbox, drive belts, and axles. These parts work together to ensure that the vehicle can handle various terrains efficiently. Each component must be regularly inspected to avoid wear and tear, which could lead to performance issues. Maintaining the Transmission SystemThe transmission is responsible for adjusting speed Cutting Deck Parts and MaintenanceThe functionality and upkeep of the cutting mechanism are critical for ensuring smooth operation and prolonging its lifespan. Regular attention to key components can prevent breakdowns and keep the equipment running efficiently. Key Components: The cutting system consists of multiple essential elements that work together to provide an even and precise trim. Blades, belts, and pulleys are among the main elements, each requiring individual care and inspection. Maintenance Tips: Regular sharpening of blades, checking belt tension, and lubricating moving parts are important for maintaining peak performance. Always inspect these elements after each use to catch wear and tear early. By following these guidelines, you ensure that the trimming system remains reliable and efficient, providing consistent results during every operation. Steering and Suspension System BreakdownThe steering and suspension systems are key components in ensuring smooth control and handling. Their proper functioning is essential for maintaining stability and comfort during operation. Understanding the layout and interaction between these systems can help diagnose potential issues and ensure long-term reliability. Steering MechanismThe steering mechanism plays a crucial role in guiding the movement of the equipment. It includes several interconnected elements that work together to translate the driver’s input into directional control. Regular inspection and maintenance of these parts can help avoid premature wear and ensure precise maneuverability. Suspension ComponentsThe suspension system is designed to absorb shocks and maintain balance on uneven surfaces. Key components such as springs, shock absorbers, and linkages ensure a smooth ride by minimizing Electrical Components and Wiring LayoutThe electrical system of any machinery is vital for its functionality and performance. This section explores the essential electrical elements and the arrangement of wiring, providing insights into how these components interact to ensure optimal operation. Key Electrical Elements

Understanding the primary electrical components is crucial for troubleshooting and maintenance. Components such as the battery, ignition system, and various sensors play a significant role in the overall functionality. Each part serves a specific purpose, contributing to the effective operation of the machinery. Wiring ConfigurationThe layout of the wiring is equally important, as it dictates how power is distributed throughout the system. Proper configuration ensures that electrical signals travel efficiently between components. Regular inspection of the wiring can prevent potential issues, enhancing the longevity of the machine. Fuel System Parts OverviewThe fuel system is crucial for the efficient operation of any machinery, ensuring that the engine receives the necessary fuel for combustion. Understanding the various components involved in this system can help with troubleshooting and maintenance, contributing to the longevity and performance of the equipment. Key ComponentsEssential elements of the fuel system include the tank, pump, filter, and injectors. Each component plays a specific role in the transportation and delivery of fuel, making their proper functioning vital for optimal performance. Maintenance and Troubleshooting

Regular maintenance of the fuel system is important to prevent issues such as clogs and leaks. Inspecting and replacing worn-out parts can significantly enhance the efficiency and reliability of the machinery. Cooling System Components ExplainedThe efficiency of any engine relies significantly on its cooling system. This system is essential for maintaining optimal operating temperatures, preventing overheating, and ensuring longevity. Understanding its key components helps in troubleshooting and maintaining the overall health of the machine.

Regular maintenance of these components is crucial for the effective performance of the cooling system. Checking fluid levels, inspecting for leaks, and ensuring the proper functioning of each part can prevent potential overheating issues and extend the life of the engine. Exhaust System and Emission ControlsThe exhaust mechanism plays a crucial role in the effective operation of an engine, ensuring that harmful gases are safely channeled away from the power unit. Properly functioning emission controls are essential for reducing the environmental impact and enhancing the overall efficiency of the equipment. Key components of the exhaust assembly typically include:

To maintain optimal performance and comply with environmental regulations, it is important to regularly inspect and service these components. Common maintenance practices include:

By prioritizing the upkeep of the exhaust system and emission controls, operators can enhance the lifespan of their machinery while minimizing their ecological footprint. |