In the realm of lawn maintenance, the efficient functioning of machinery relies heavily on the intricate interplay of various elements. Each component serves a distinct purpose, ensuring that the overall system operates smoothly and effectively. A comprehensive exploration of these vital parts is essential for optimal performance and longevity.

When examining the assembly of a specific mowing machine, it becomes crucial to identify how each segment contributes to the whole. Knowing the arrangement and role of individual elements can lead to better maintenance practices and enhance operational efficiency. Diving into the specifics allows users to grasp not only functionality but also potential areas for improvement.

Whether you are a seasoned technician or a novice user, having access to detailed illustrations and explanations of these crucial components can provide invaluable insights. Such resources empower individuals to troubleshoot issues effectively and make informed decisions regarding repairs and upgrades.

Cub Cadet LT1042 Overview

This section provides a detailed look at a popular model of a residential lawn tractor, focusing on its key features, functionality, and design elements. It is engineered to offer exceptional mowing performance for medium to large-sized lawns. The machine boasts a durable construction and user-friendly features, making it a go-to choice for homeowners who seek efficient lawn maintenance solutions. Its innovative mechanics ensure reliability, while the overall build provides ease of use for various outdoor tasks.

Key Features

This model comes equipped with a powerful engine and a well-constructed cutting system that delivers precise results. The intuitive design of the controls ensures a seamless mowing experience, while the robust frame offers long-lasting durability. Key components are designed to withstand regular use, ensuring that this lawn tractor remains a reliable tool throughout its lifespan.

Specifications

| Feature | Description |

|---|---|

| Engine Type | Single-cylinder, air-cooled |

| Engine Power | 17.5 HP |

| Transmission | Automatic |

| Cutting Width | 42 inches |

| Fuel Capacity | 3.0 gallons |

| Turning Radius | 18 inches |

Designed to meet the needs of homeowners, this model is known for its efficiency and ease of maintenance. The mower’s features allow it to tackle various tasks such as mowing, mulching, and side discharging, making it a versatile tool in maintaining a well-kept lawn.

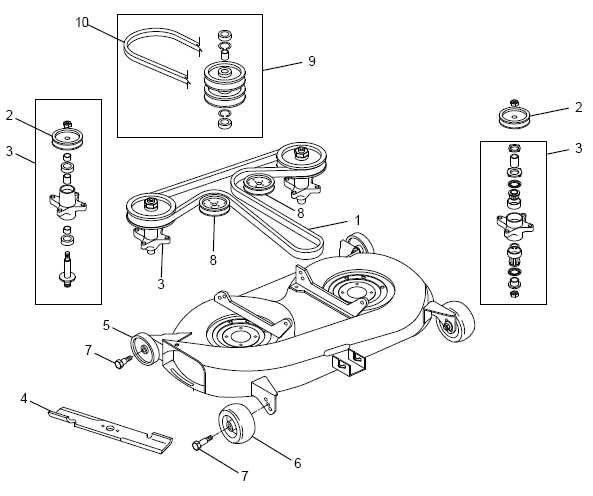

Understanding Deck Components

Maintaining a well-functioning lawn care machine requires a solid grasp of its various elements. Each component plays a vital role in ensuring optimal performance and longevity. This section will delve into the essential elements that contribute to the effective operation of the mowing mechanism.

- Blades: The sharp edges responsible for cutting grass efficiently. Their condition directly affects the quality of the cut.

- Spindles: The rotating assemblies that support and drive the blades. They must be well-lubricated for smooth operation.

- Belt System: Transfers power from the engine to the blades. Regular inspection is necessary to prevent slippage and wear.

- Chassis: The frame that holds all components in place. It must be sturdy to withstand various conditions.

- Adjustable Height Mechanism: Allows users to change the cutting height for different grass types and conditions.

Understanding these key elements is crucial for effective maintenance and troubleshooting. Regular checks can enhance performance and extend the life of your equipment.

Parts Diagram Explanation

Understanding the layout and components of machinery is crucial for effective maintenance and repair. A visual representation serves as a guide, highlighting the relationships between various elements and simplifying the identification process. This section delves into the intricacies of such illustrations, offering clarity on their significance and utility.

Importance of Visual Aids

Visual aids play a pivotal role in assisting users to comprehend complex systems. By providing an organized view, these representations allow individuals to easily locate specific elements, ensuring efficient troubleshooting and part replacement. The clarity offered by these visuals can significantly reduce errors during repair tasks.

Components Breakdown

Each section of the illustration typically showcases individual components, marked with labels and reference numbers. This breakdown helps users not only recognize the parts but also understand their function within the larger assembly. Familiarity with these components enhances the ability to diagnose issues and implement solutions effectively.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. Regular attention ensures optimal performance and prevents costly repairs. Following a structured maintenance routine can significantly enhance durability and reliability.

Firstly, always clean the machinery after use to remove dirt and debris. This helps prevent corrosion and mechanical issues. Regularly inspect the components for wear and replace any damaged parts promptly to avoid further complications.

Additionally, keep all moving parts well-lubricated. This reduces friction and wear, enhancing efficiency. Changing the oil and filters at recommended intervals is also crucial to ensure a smooth operation and to protect internal mechanisms.

Lastly, store the equipment in a dry, sheltered area when not in use. This protects it from harsh weather conditions and prolongs its functional life. Implementing these simple practices can lead to significant improvements in performance and longevity.

Common Issues and Solutions

When maintaining a lawn mower, it’s important to be aware of typical challenges that may arise with its cutting assembly. Proper troubleshooting can help avoid unnecessary repairs and ensure smooth operation. Below are some frequent issues that users may encounter, along with practical solutions to address them.

- Uneven Cutting

One of the most common problems is uneven cutting, which often results in an unsatisfactory lawn appearance. This can be caused by various factors such as dull blades, uneven tire pressure, or a misaligned cutting mechanism. To resolve this issue, consider the following:

- Inspect and sharpen the blades regularly.

- Check and adjust tire pressure to ensure even height across all wheels.

- Ensure the cutting mechanism is properly aligned and balanced.

- Excessive Vibration

Excessive vibrations during operation are a sign that something is wrong with the cutting assembly. This may be due to loose parts, worn-out bearings, or damaged blades. To fix this problem:

- Tighten any loose bolts or fasteners.

- Inspect bearings for wear and replace if necessary.

- Check the blades for damage or imbalance, and replace if needed.

- Clogging

Clogging is another common issue that often occurs when mowing thick or wet grass. This can slow down operation and affect cutting efficiency. To prevent clogging:

- Ensure the cutting assembly is clean and free of debris.

- Avoid mowing when grass is wet or overly thick.

- Inspect for any blockages in the chute or air flow system.

- Unresponsive Blades

If the blades do not engage or spin as expected, it could be a sign of an issue with the drive belt, pulley system, or engagement mechanism. To address this:

- Examine the drive belt for wear or breakage and replace it if needed.

- Check the pulleys for any damage or misalignment.

- Inspect the blade engagement system for proper function and make necessary adjustments.

By regularly maintaining and checking these components, many of these issues can be easily resolved, ensuring longer-lasting performance and efficient operation.

Where to Find Replacement Parts

When it comes to maintaining your lawn equipment, finding reliable components is essential for ensuring optimal performance and longevity. If your machine needs a replacement for a worn-out or damaged part, there are several trusted sources where you can find what you need.

Authorized Dealers are often the best place to start. They carry genuine replacements that match the exact specifications of your equipment, ensuring compatibility and quality. These dealers can also offer expert advice and assistance in selecting the right item for your needs.

Another option is online marketplaces. Websites like Amazon, eBay, and specialized lawn equipment retailers provide a wide range of items, often at competitive prices. Be sure to check the seller’s reputation and reviews before purchasing to avoid counterfeit or subpar products.

Finally, local hardware stores or repair shops may have a selection of compatible components. While their inventory may not be as extensive as online retailers, these stores can provide immediate availability and personalized customer service.

Comparing Deck Options Available

When selecting a mowing system for your lawn tractor, it’s important to understand the various choices available for the cutting mechanism. Different designs offer unique benefits in terms of performance, durability, and maintenance. By examining the different configurations and features, you can find the best fit for your yard care needs. In this section, we will explore the primary variations and help you compare them to make an informed decision.

Types of Cutting Mechanisms

There are several types of cutting systems available for lawn tractors, each with specific advantages depending on the user’s requirements. Some are designed for efficiency in cutting, while others focus on durability or ease of maintenance. Below, we provide a comparison table to showcase key characteristics of the most common options.

| Type | Cutting Width | Material Quality | Maintenance Frequency | Best Use Case |

|---|---|---|---|---|

| Standard Steel | 42″-50″ | Durable, rust-resistant | Low | Ideal for regular, moderate grass cutting |

| High-Performance Blades | 44″-54″ | Enhanced strength, extra protection against wear | Medium | Best for tough grass, uneven terrain |

| Multi-Deck System | 48″-60″ | Heavy-duty | High | Recommended for professional landscapers, commercial use |

Factors to Consider When Choosing

Choosing the right option depends on several factors such as the size of the area to be mowed, the type of grass, and your long-term maintenance preferences. For example, a wide-cut system might be beneficial for larger lawns, while a heavy-duty option would be more suitable for tough terrain or high-use conditions. Additionally, materials such as reinforced steel can extend the lifespan of the equipment but may require more frequent upkeep.

Assembly Instructions for DIY Repairs

Repairing outdoor equipment can be an empowering and cost-effective solution, especially when you can handle the maintenance yourself. Whether you are restoring a lawn care machine or addressing any minor malfunction, understanding how to assemble or reassemble specific components is crucial. With the right guidance, tools, and a step-by-step approach, the process becomes manageable and efficient.

Step-by-Step Assembly Process

Before beginning any reassembly, ensure you have all the necessary tools and components. Take your time to review the manual or reference images to identify each piece accurately. This helps to avoid confusion during the assembly. Below is a general outline of the steps for assembling essential parts back into place.

| Step | Description |

|---|---|

| 1 | Inspect all parts for wear and damage before starting the assembly. Replace any broken or worn-out pieces if necessary. |

| 2 | Position the components according to the assembly plan, ensuring correct orientation for proper fitting. |

| 3 | Secure the parts using appropriate fasteners, checking alignment as you proceed to avoid unnecessary adjustments later. |

| 4 | Test the assembled unit by gently operating it. If necessary, make minor adjustments to ensure smooth operation. |

Common Troubleshooting Tips

If the assembly process does not go as planned, double-check the following:

- Ensure all fasteners are tightened properly.

- Check for any misplaced components that could hinder movement or cause imbalances.

- If the item is not functioning properly, review the manual once more to confirm that no steps were skipped.

With careful attention to detail and patience, completing DIY repairs can be a straightforward and rewarding experience. By following these assembly instructions, you can extend the lifespan of your equipment and ensure it performs optimally for years to come.

Enhancing Performance with Upgrades

Improving the efficiency and functionality of your lawn care equipment can significantly boost performance. By upgrading various components, you can ensure a smoother, more effective operation while extending the lifespan of the machine. Upgrades provide both practical benefits and the potential for a more enjoyable user experience, especially when dealing with tough outdoor conditions. Whether it’s enhancing cutting quality, reducing maintenance time, or increasing overall durability, selecting the right improvements can make a noticeable difference.

Key Areas for Upgrades

- Cutting Blades: Upgrading the blades can result in cleaner cuts and a more even lawn appearance. Consider opting for high-quality materials or sharpened edges that last longer and resist wear.

- Spindle Assembly: A more durable spindle assembly can reduce the risk of mechanical failure and ensure smooth operation over extended periods.

- Belts: Replacing old, worn-out belts with high-performance versions ensures that the machine operates efficiently, preventing slipping and enhancing power transmission.

- Wheels and Bearings: High-quality wheels and smooth bearings can make your equipment more maneuverable, minimizing strain on the engine and increasing overall efficiency.

Choosing the Right Upgrades

When selecting upgrades, it’s important to consider both compatibility and performance enhancement. Not every component will provide the same level of improvement, so understanding the specific needs of your equipment and how each part interacts will help you make informed decisions. Look for high-quality, trusted brands that offer parts designed to work in harmony with your machinery for the best results.

- Check user reviews and professional recommendations to ensure you’re getting top-performing upgrades.

- Focus on parts that can help reduce maintenance frequency, such as more durable belts or rust-resistant components.

- Consider eco-friendly options that help reduce fuel consumption and emissions while improving cutting precision.