Maintaining outdoor machinery is essential for optimal performance and longevity. Whether you’re tackling large landscapes or simply ensuring your garden looks its best, having a grasp of your equipment’s components can significantly enhance your efficiency. This section aims to unravel the complexities of machine maintenance by providing a clear understanding of the various elements that make up your machinery.

Each piece of equipment is composed of numerous intricate parts that work in harmony to deliver excellent results. Knowing how these components fit together not only aids in troubleshooting but also assists in identifying the right replacement pieces when necessary. By exploring the intricacies of your machine’s assembly, you can empower yourself to tackle repairs and maintenance with confidence.

Additionally, this guide will help demystify the relationships between different parts, illustrating how each contributes to the overall functionality of the unit. With the right knowledge, you’ll be better equipped to make informed decisions, ensuring your lawn equipment operates at peak efficiency throughout the seasons.

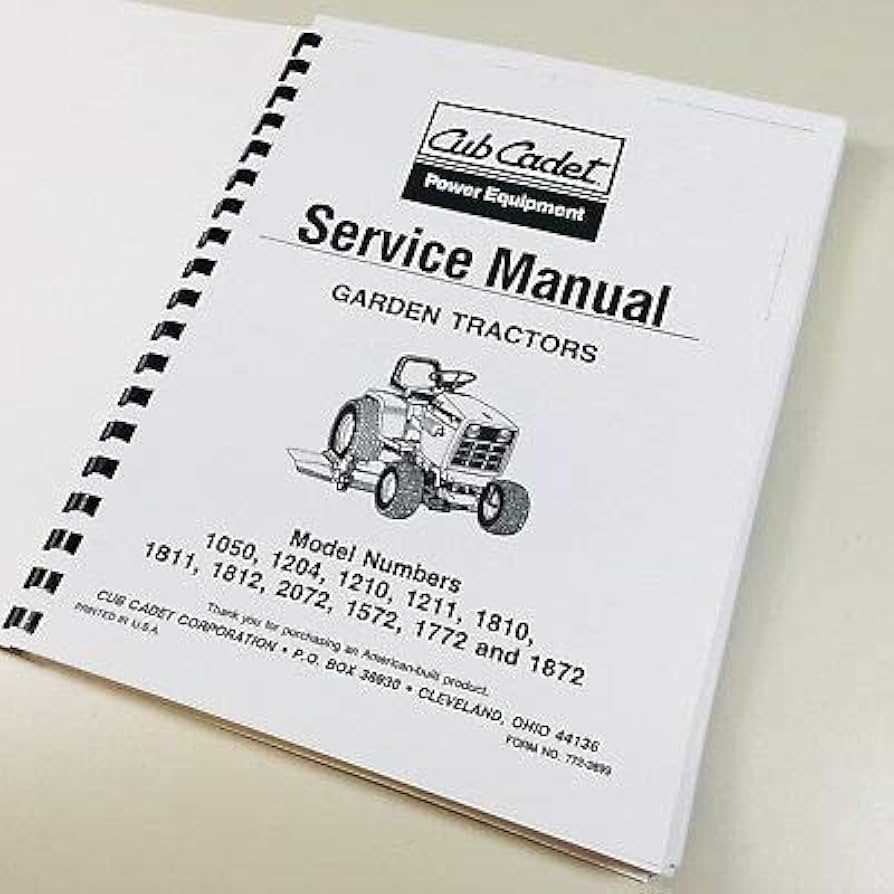

Cub Cadet SLTX 1050 Overview

This section provides a comprehensive look at a popular lawn care machine known for its efficiency and reliability. Designed for both residential and commercial use, this model stands out due to its robust construction and user-friendly features.

Performance: Equipped with a powerful engine, it ensures a smooth operation and can handle various terrains with ease. Users appreciate its ability to tackle tough grass and uneven landscapes.

Design: The design focuses on ergonomics and functionality. With comfortable seating and intuitive controls, it enhances the overall mowing experience.

Maintenance: Regular upkeep is straightforward, allowing owners to keep their equipment in peak condition without excessive effort. Accessing essential components is simplified, which is a significant advantage.

Overall, this machine embodies a blend of power, comfort, and durability, making it an ideal choice for anyone seeking reliable lawn care solutions.

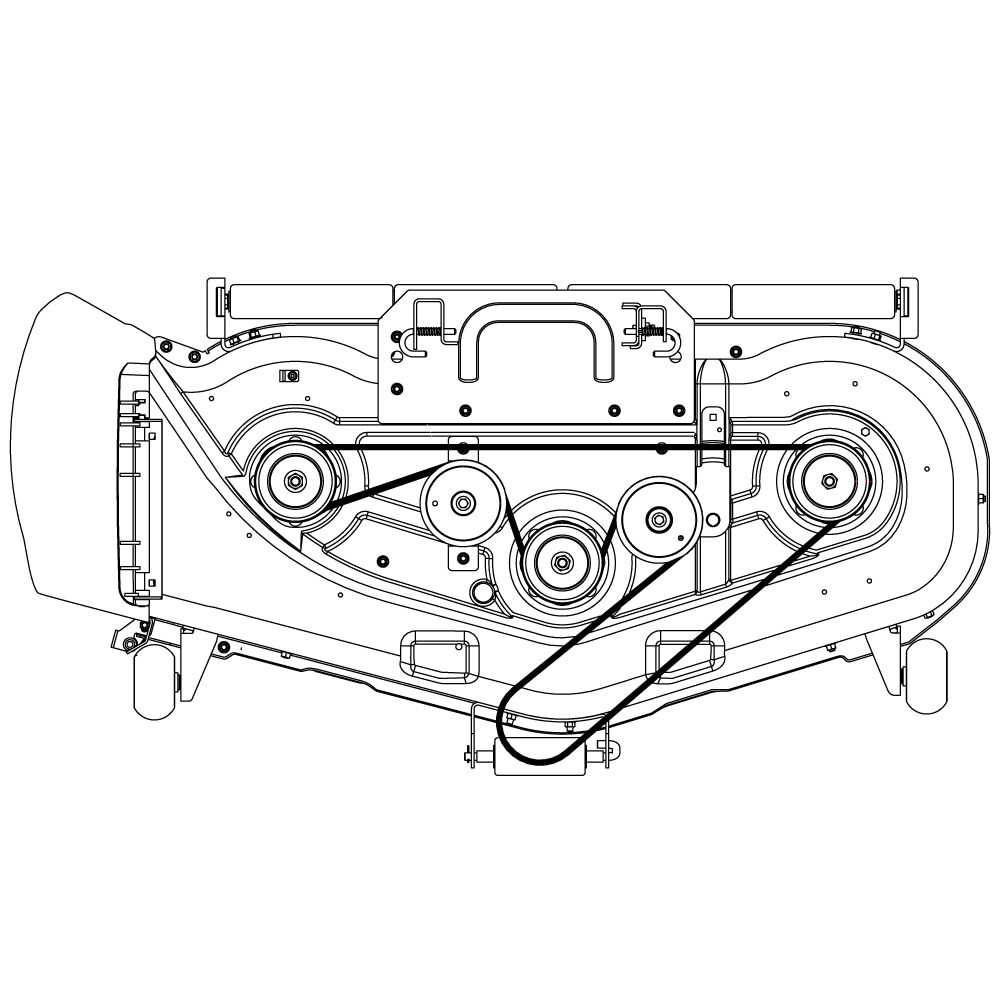

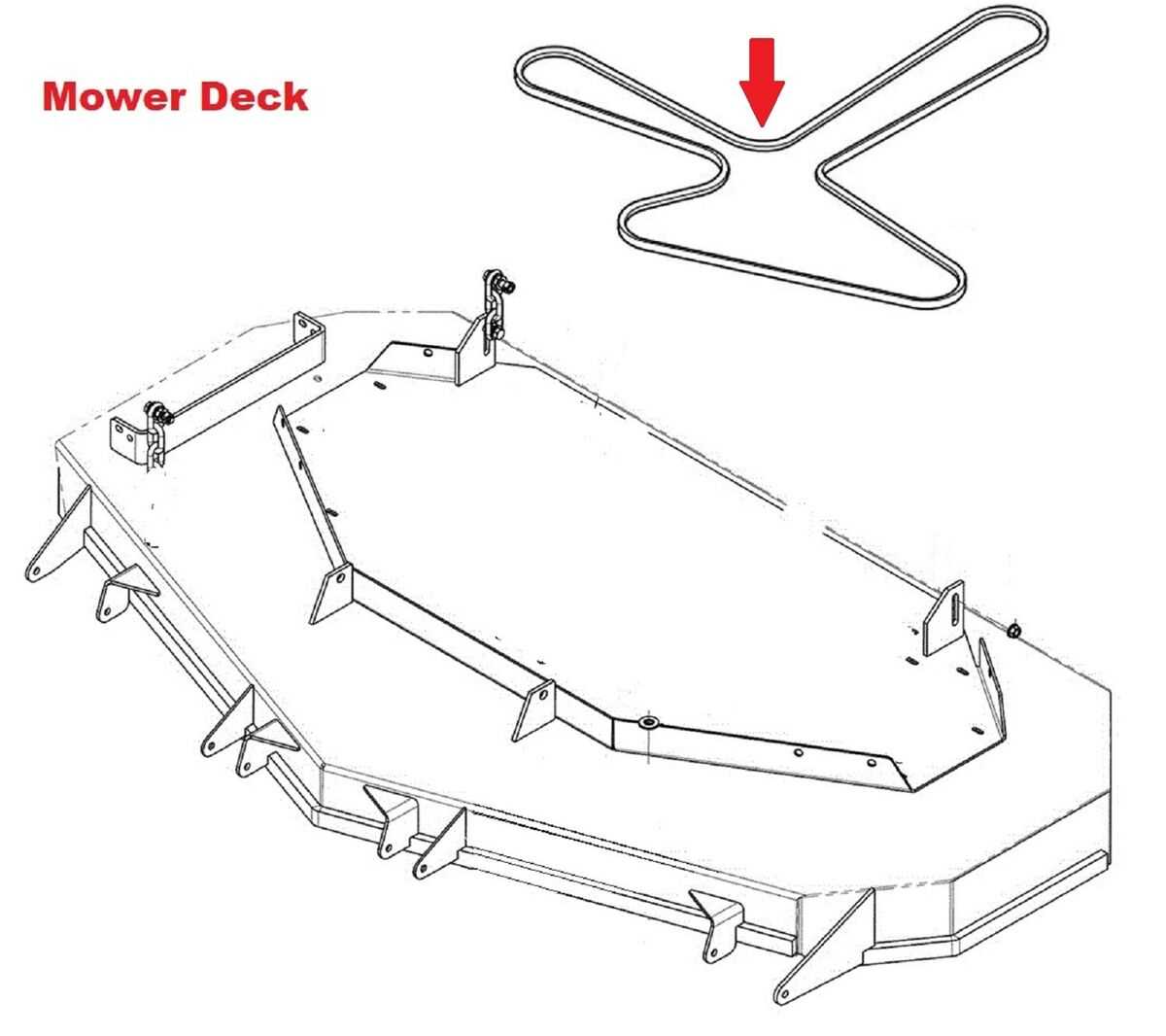

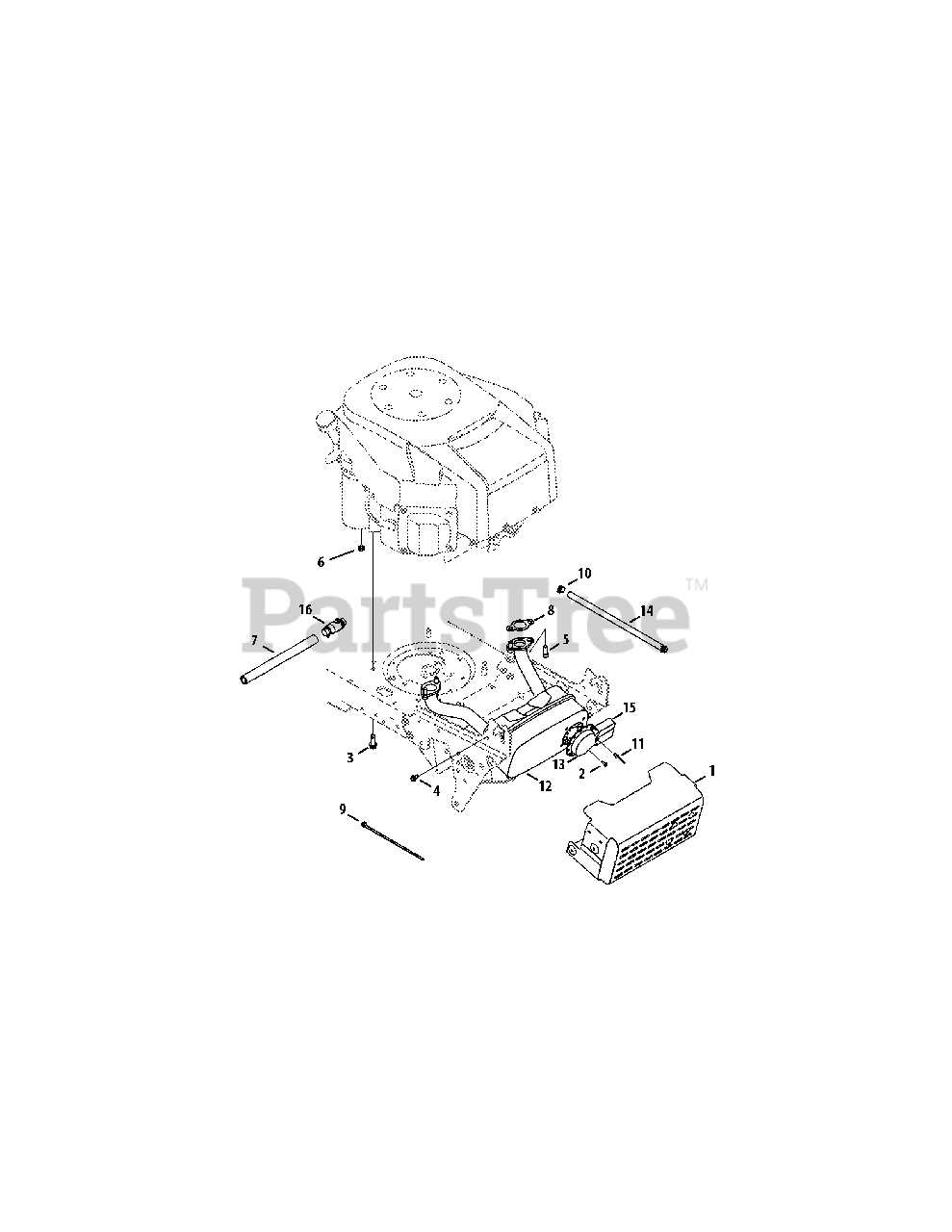

Key Components of the SLTX 1050

Understanding the essential elements of this mowing machine is crucial for effective maintenance and operation. Each component plays a significant role in the overall performance, ensuring efficiency and reliability during use. Below are the main parts that contribute to its functionality.

- Engine: The powerhouse that drives all operations, providing the necessary torque and speed.

- Transmission: Responsible for transferring power from the engine to the wheels, allowing for smooth movement and control.

- Deck: The cutting mechanism that houses the blades, essential for achieving a precise and even cut.

- Wheels: Designed for stability and maneuverability, allowing the operator to navigate various terrains.

- Steering System: Provides directional control, enabling the user to easily maneuver around obstacles.

Each of these components is integral to the machine’s functionality, and understanding them can help in troubleshooting and maintenance tasks.

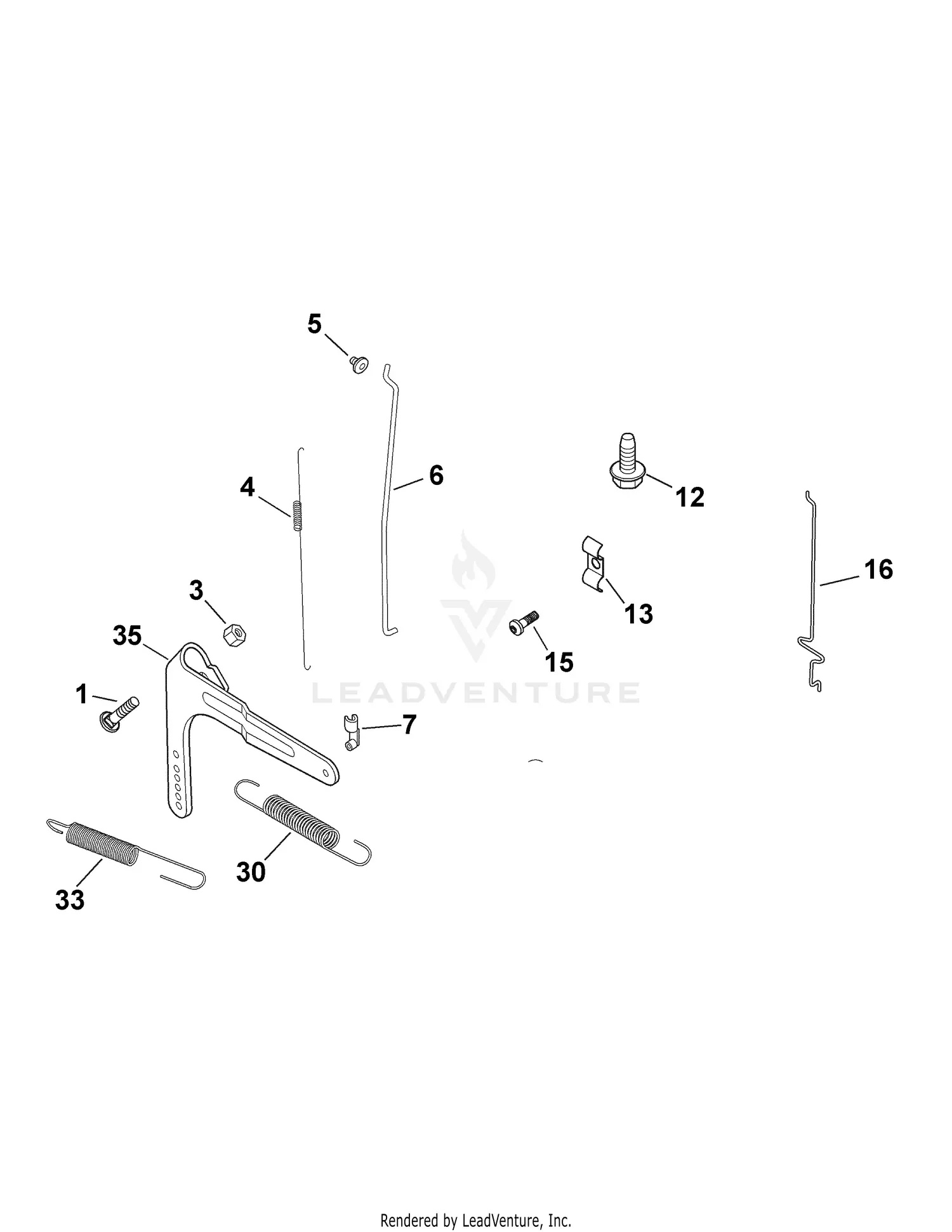

Understanding Parts Diagrams

Deciphering the visual representations of mechanical components is essential for effective maintenance and repair. These illustrations serve as guides, providing clarity on the relationships between various elements within a machine.

Key benefits include:

- Enhanced comprehension of assembly and disassembly processes.

- Improved identification of necessary components for repairs.

- Facilitated troubleshooting by visualizing potential issues.

When utilizing these representations, consider the following:

- Familiarize yourself with the symbols and notations used.

- Pay attention to the orientation and layout of components.

- Use the guide as a reference throughout your maintenance tasks.

Ultimately, understanding these visual tools can streamline your repair efforts and prolong the lifespan of your equipment.

Benefits of Using Diagrams

Visual representations serve as powerful tools for enhancing comprehension and communication. By illustrating complex systems or components, these visuals simplify intricate information, making it accessible and easier to understand. Whether in educational settings, technical fields, or everyday life, effective visuals can significantly improve learning and retention.

One of the primary advantages of using visuals is their ability to convey information quickly. Instead of processing large volumes of text, individuals can grasp key concepts at a glance. This efficiency is particularly valuable in situations requiring immediate understanding, such as troubleshooting or maintenance.

| Advantages | Description |

|---|---|

| Enhanced Clarity | Visuals break down complex ideas into simpler parts, making them easier to digest. |

| Improved Retention | People tend to remember visual information better than text alone. |

| Time Efficiency | Quickly communicate key points without extensive explanations. |

| Facilitate Collaboration | Visual aids promote discussion and understanding among team members. |

In summary, utilizing visuals offers numerous benefits that enhance the overall learning and communication experience. They streamline understanding, foster retention, and promote effective collaboration, making them invaluable in both personal and professional contexts.

Common Issues and Solutions

Understanding frequent challenges that arise with outdoor power equipment can help users maintain optimal performance and longevity. Addressing these issues promptly can prevent further complications.

- Starting Problems:

- Check the battery charge.

- Inspect the ignition system for faults.

- Uneven Cutting:

- Ensure blades are sharp and balanced.

- Adjust the cutting height settings.

- Overheating:

- Clean the air filter regularly.

- Inspect the cooling system for blockages.

- Strange Noises:

- Check for loose or damaged components.

- Lubricate moving parts as needed.

By recognizing these common concerns and implementing effective solutions, users can ensure their equipment remains in peak condition for years to come.

Where to Find Replacement Parts

Locating components for your outdoor equipment can be a straightforward task if you know where to look. Understanding the best sources for obtaining necessary items is crucial for maintaining and repairing your machinery efficiently. Here are several reliable avenues to explore for your needs.

Authorized Dealers

One of the most dependable places to find components is through authorized retailers. These vendors often have direct access to original items, ensuring quality and compatibility. To locate a dealer near you, consider the following:

- Visit the manufacturer’s official website for a dealer locator tool.

- Contact customer service for recommendations on local sellers.

- Check online directories for certified retailers in your area.

Online Marketplaces

The internet provides a plethora of options for sourcing replacement components. Various online platforms specialize in outdoor equipment and offer a wide range of items. Consider these tips when shopping online:

- Use specific keywords related to your machinery to narrow down the search.

- Read customer reviews to assess the reliability of sellers.

- Compare prices across multiple sites to ensure you’re getting the best deal.

By utilizing both local dealers and online resources, you can easily find the necessary components to keep your equipment running smoothly.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of machinery. Adopting a few key practices can significantly contribute to the overall efficiency and reliability of your device.

1. Regular Cleaning: Keeping your machinery clean is essential. Remove debris, grass, and dirt from all surfaces to prevent buildup that can lead to wear and tear. A clean machine operates more efficiently and has a longer life.

2. Fluid Checks: Regularly inspect and change the oils and fluids as recommended. Proper lubrication reduces friction, helping to maintain optimal functioning and prevent overheating.

3. Sharp Blades: Keeping blades sharp ensures clean cuts and reduces strain on the engine. Dull blades require more power, which can lead to excessive wear.

4. Tire Maintenance: Check tire pressure regularly to ensure even wear and optimal traction. Properly inflated tires enhance handling and reduce the risk of punctures.

5. Seasonal Inspections: Conduct thorough inspections at the beginning and end of each season. Look for signs of wear, loose parts, or any other issues that may need addressing before use.

6. Store Properly: When not in use, store your equipment in a dry, sheltered area to protect it from the elements. Consider using covers to further shield it from dust and moisture.

Implementing these maintenance practices will not only enhance performance but will also safeguard your investment for years to come.

Aftermarket vs. OEM Parts

When it comes to maintaining and repairing machinery, choosing the right components can significantly impact performance and longevity. Two main categories emerge in this context: those produced by the original manufacturer and those made by third-party companies. Each option carries its own set of advantages and disadvantages, influencing the decision-making process for owners and operators.

Advantages of OEM Components

Original equipment manufacturer components are specifically designed for compatibility and reliability. These items typically adhere to strict quality standards, ensuring optimal performance in conjunction with the machinery. Buyers can often rely on a warranty, which offers peace of mind in terms of durability and functionality. Additionally, using these components may help maintain the equipment’s resale value, as potential buyers often look for well-maintained machinery with original parts.

Benefits of Aftermarket Alternatives

In contrast, aftermarket options often present a more cost-effective solution. These components can be more readily available and may offer features or enhancements not found in original parts. Many users appreciate the flexibility and variety that aftermarket products provide, allowing for tailored solutions to specific needs. However, it is essential to research the manufacturer’s reputation and the quality of these alternatives, as variations in performance can occur.