In the realm of lawn maintenance, having a clear grasp of the various components that contribute to the efficient operation of machinery is essential. Knowing the intricate relationships between parts can enhance both performance and longevity.

Identifying essential elements is crucial for any owner or technician seeking to optimize their equipment. Familiarity with these components allows for effective troubleshooting and timely repairs, ensuring a smooth mowing experience.

By delving into the specifics of machinery layouts and assemblies, users can gain invaluable insights. This ultimate guide serves as a resource for those looking to maintain their equipment with confidence and precision.

Overview of the Riding Mower

This riding mower represents an exceptional choice for those seeking efficiency and reliability in lawn maintenance. Engineered for performance, it combines power and precision to deliver outstanding results for both small and medium-sized landscapes.

Key Features

Designed with user comfort in mind, this model boasts a comfortable seating arrangement and an intuitive control system. Its robust engine ensures smooth operation, while the cutting mechanism offers adjustable heights for tailored grass management.

Maintenance and Support

Regular upkeep is crucial for optimal performance. Users can easily access maintenance components, allowing for straightforward servicing. Additionally, comprehensive support resources are available, ensuring that owners can keep their machine running at its best.

Key Features of the LTX1042

This model is designed for efficiency and ease of use, making it an ideal choice for homeowners seeking reliable performance in lawn maintenance. Its combination of advanced technology and user-friendly design sets it apart, allowing for a seamless mowing experience.

Performance and Efficiency

One of the standout attributes of this mower is its powerful engine, which delivers robust performance for various terrains. With a strong cutting deck, it ensures a clean and even cut, reducing the time needed for lawn care.

Comfort and Control

The ergonomic seating and intuitive controls provide exceptional comfort during operation. Features such as adjustable speed and a responsive steering system enhance maneuverability, allowing users to navigate around obstacles with ease.

| Feature | Description |

|---|---|

| Engine Power | Reliable engine offering strong performance for effective mowing. |

| Cutting Width | Generous deck size for efficient coverage, minimizing mowing time. |

| Ergonomic Design | Comfortable seating and easy-to-reach controls enhance user experience. |

| Durability | Built with high-quality materials for long-lasting performance. |

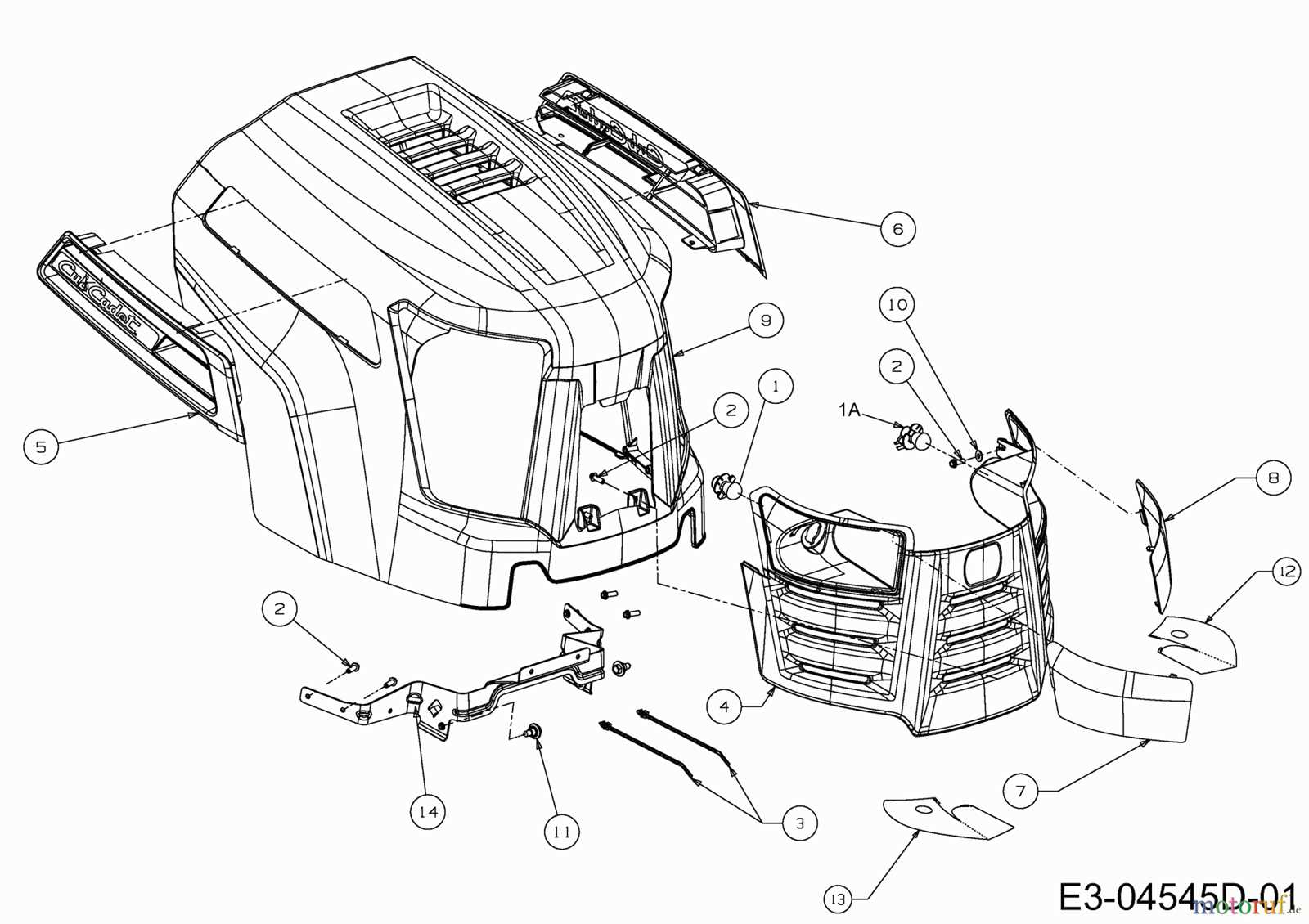

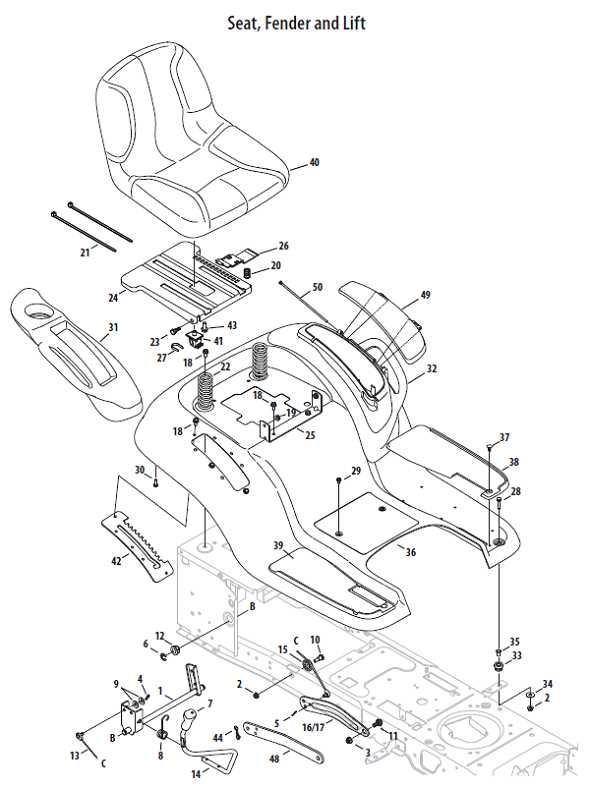

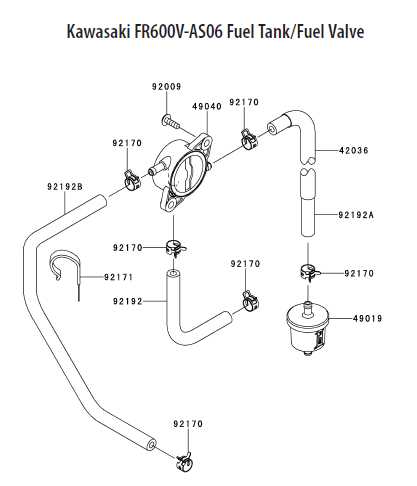

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for identifying components and their interrelations within complex systems. They enable users to grasp how different elements function together, ensuring efficient troubleshooting and replacement processes.

These illustrations are not merely decorative; they play a vital role in guiding users through assembly and disassembly procedures. Clarity in visual documentation helps prevent errors, saving time and resources. Additionally, having a reference point aids in ordering the correct items when replacements are necessary, minimizing the risk of mismatches.

Furthermore, such resources enhance knowledge sharing among enthusiasts and professionals alike. By promoting a better understanding of individual elements, they contribute to overall expertise in equipment management. Ultimately, the accessibility of these visuals empowers users, leading to improved performance and longevity of their machinery.

Common Replacement Parts for LTX1042

Maintenance is essential for the longevity and performance of any lawn care equipment. Over time, certain components may wear out and require replacement to ensure optimal functionality. Understanding which elements are frequently replaced can help you keep your machine running smoothly.

Key Components to Monitor

Regular inspections can help identify parts that may need to be changed. Here are some common components that users often replace:

- Blades: Essential for effective cutting, these can dull or become damaged.

- Batteries: Over time, batteries can lose their ability to hold a charge.

- Filters: Air and fuel filters may become clogged, affecting engine performance.

- Belt: Drive belts can wear out, leading to decreased efficiency.

- Tires: Proper traction is crucial; tires may need replacement due to wear.

Maintenance Tips

To prolong the lifespan of these components, consider the following maintenance tips:

- Regularly inspect and sharpen blades to maintain cutting efficiency.

- Check battery connections and clean terminals to prevent corrosion.

- Replace filters as per manufacturer recommendations to ensure clean airflow.

- Monitor belt condition for signs of wear or fraying.

- Inspect tires for proper inflation and tread wear.

How to Read Parts Diagrams

Understanding visual schematics is crucial for effective maintenance and repairs. These illustrations provide a detailed overview of components, making it easier to identify and source individual pieces. Familiarity with these visuals enhances your ability to navigate through assembly and disassembly processes with confidence.

To begin, familiarize yourself with the layout. Typically, these visuals are organized in a way that groups related items together, often with numbers or labels indicating specific parts. By noting these identifiers, you can easily cross-reference with inventory lists or catalogs.

Pay attention to the orientation and connection points shown in the visuals. This information is vital for reassembly, as it illustrates how parts fit together and interact with one another. Understanding the flow of the assembly can prevent common mistakes during the repair process.

Moreover, be aware of any accompanying notes or legends. These can provide additional context, such as specifications or recommendations for installation. Taking the time to study these details can save you from potential pitfalls and enhance your overall efficiency.

Lastly, practice makes perfect. The more you work with these illustrations, the more intuitive they will become. Over time, you’ll develop a sharper eye for recognizing essential components and their functions, leading to smoother maintenance and repair experiences.

Where to Find OEM Parts

Finding original equipment components is essential for maintaining optimal performance and longevity of your machinery. Quality and compatibility are paramount, ensuring that your equipment operates as intended.

Here are some reliable sources to consider:

- Manufacturer’s Website: Directly visit the official site to browse available components.

- Authorized Dealers: Locate nearby dealers who specialize in genuine items.

- Online Retailers: Websites dedicated to outdoor equipment often carry a range of original parts.

- Local Repair Shops: Technicians may have access to or knowledge of OEM components.

- Forums and Community Groups: Engaging with other users can yield valuable recommendations.

Utilizing these resources will help you secure the highest quality items for your equipment’s needs.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for extending the life of your machinery. By implementing a few simple practices, you can ensure optimal performance and prevent premature wear and tear. Consistency in maintenance not only enhances functionality but also saves time and costs in the long run.

Begin by routinely checking and changing the oil, as this lubricates the engine and minimizes friction. Keeping air filters clean ensures efficient airflow, while sharpening blades improves cutting performance. Additionally, inspect belts and cables for signs of wear to avoid unexpected breakdowns.

Regularly cleaning the exterior and undercarriage prevents debris buildup, which can affect operation. Store the equipment in a dry place to protect it from rust and corrosion. Following these guidelines will significantly contribute to the longevity and reliability of your investment.

Customer Reviews and Experiences

This section explores user feedback and personal encounters with a particular lawn care machine. Insights from customers can illuminate its reliability, efficiency, and overall satisfaction, providing prospective buyers with valuable information.

User Feedback Highlights

| Reviewer | Experience |

|---|---|

| John D. | Highly reliable and easy to maneuver; great for small to medium yards. |

| Lisa M. | Powerful engine, but the maintenance can be a bit challenging. |

| Mark S. | Exceptional cut quality; truly enhanced my lawn’s appearance. |

Common Themes

Many users emphasize the machine’s ease of use and effectiveness in delivering a clean cut. However, some highlight the need for regular upkeep to maintain optimal performance. Overall, the feedback indicates a generally positive reception among users.

Comparative Models to Consider

When exploring alternatives in the realm of lawn care machinery, it’s essential to evaluate various models that offer similar functionalities. Each machine presents unique features and specifications, making the selection process crucial for optimal performance.

Key Alternatives

- Model A: Known for its durability and user-friendly controls.

- Model B: Features advanced technology for enhanced efficiency.

- Model C: Offers a compact design, ideal for smaller lawns.

Features to Compare

- Engine power and performance

- Cutting width and quality

- Maneuverability and ease of use

- Maintenance requirements and costs