In the realm of outdoor maintenance, having a reliable cleaning machine is essential for tackling tough grime and stains. Knowing how each element functions and fits together can significantly enhance your experience and effectiveness during tasks. This section delves into the intricate makeup of these machines, offering insights into their various components.

Comprehending the structure of your cleaning unit allows you to troubleshoot issues with ease and perform regular maintenance efficiently. Each segment plays a critical role in ensuring optimal performance, and understanding their relationships can help you identify areas that require attention or replacement.

By familiarizing yourself with the visual representation of these elements, you will gain a clearer perspective on how to operate and maintain your equipment effectively. This knowledge not only aids in proper care but also empowers you to make informed decisions when parts need to be replaced or upgraded.

Understanding Pressure Washer Components

To effectively utilize a cleaning machine, it’s crucial to grasp the various elements that contribute to its operation. Each component plays a significant role in ensuring efficient performance, enhancing the overall cleaning experience. Familiarity with these individual pieces not only aids in troubleshooting but also facilitates maintenance and upgrades.

Here are the key components commonly found in such devices:

- Motor: The power source that drives the entire system, usually electric or gas-powered.

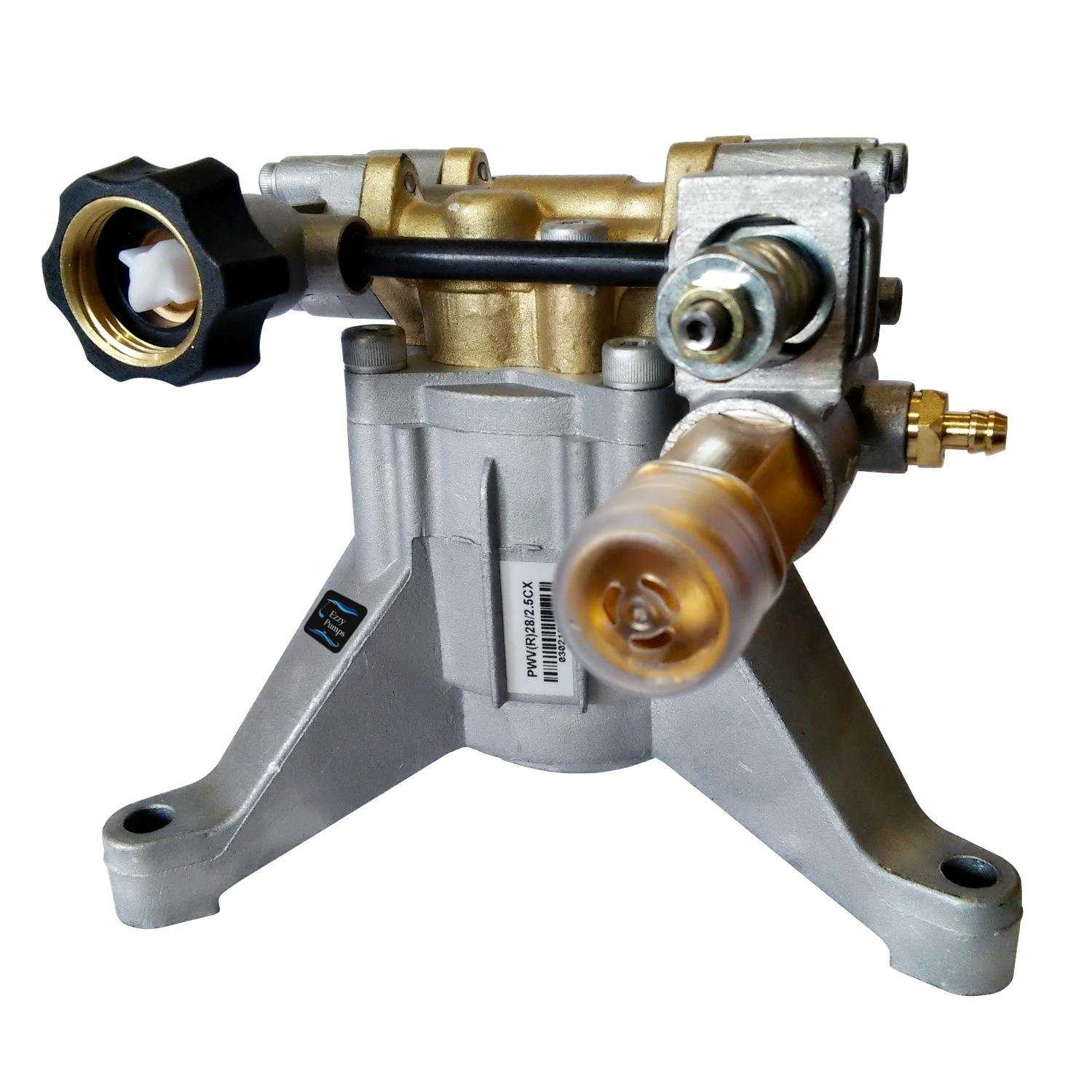

- Pump: Converts the motor’s energy into high-pressure water flow, crucial for effective cleaning.

- Hose: Connects the machine to the water source, allowing fluid to travel through at high speeds.

- Nozzle: Directs the water flow and varies the spray pattern, enabling different cleaning applications.

- Trigger Gun: A handheld device that allows the user to control water flow and pressure easily.

- Frame: The structural component that houses all parts and provides stability during operation.

- Filter: Protects the pump by preventing debris and contaminants from entering the system.

Understanding these components empowers users to make informed decisions regarding repairs and upgrades, leading to more efficient cleaning results.

Overview of Troy-Bilt XP Models

The XP series embodies a blend of power and versatility, designed to tackle various outdoor cleaning tasks with ease. These models offer enhanced performance, making them suitable for both residential and commercial use. Users can expect durability and efficiency, providing an ultimate solution for maintaining cleanliness around homes and properties.

Key Features

Each unit in the XP lineup showcases robust engineering and thoughtful design elements. Features often include high-output engines, adjustable settings, and ergonomic handles, ensuring comfort and effectiveness during operation. Convenience and performance are prioritized, enabling users to achieve professional-grade results.

Applications

These models excel in a variety of applications, from washing vehicles to revitalizing outdoor surfaces. Whether removing stubborn stains from driveways or cleaning decks, the XP series is versatile enough to meet diverse cleaning demands. Their reliability makes them a favorite choice among homeowners and professionals alike.

Importance of Regular Maintenance

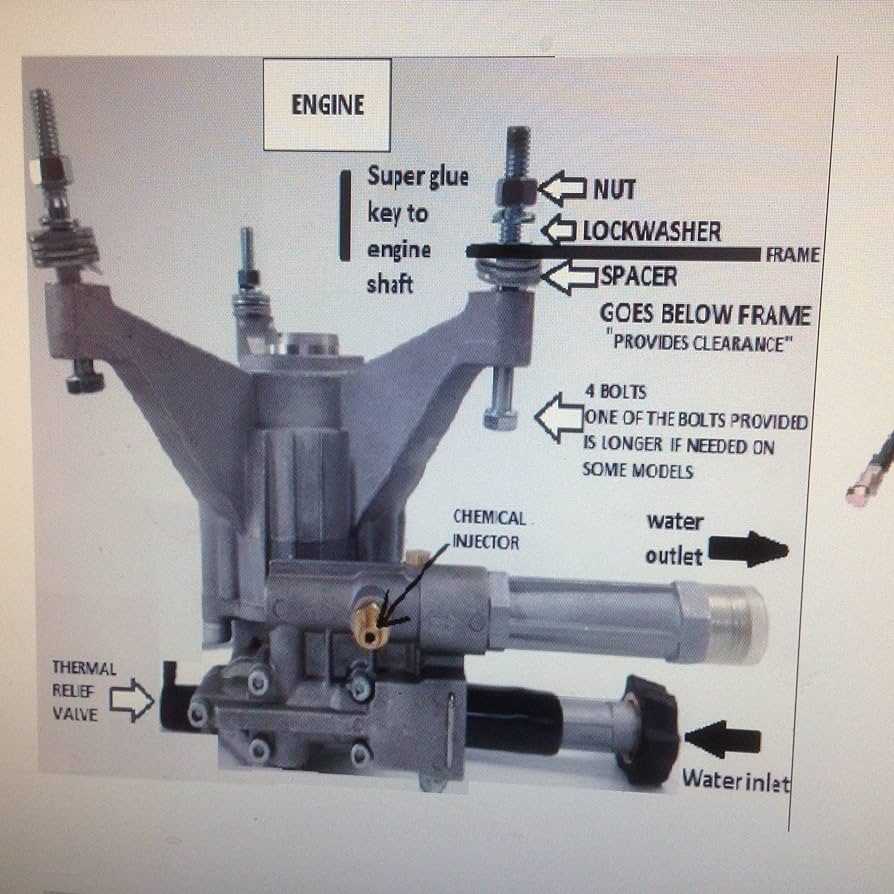

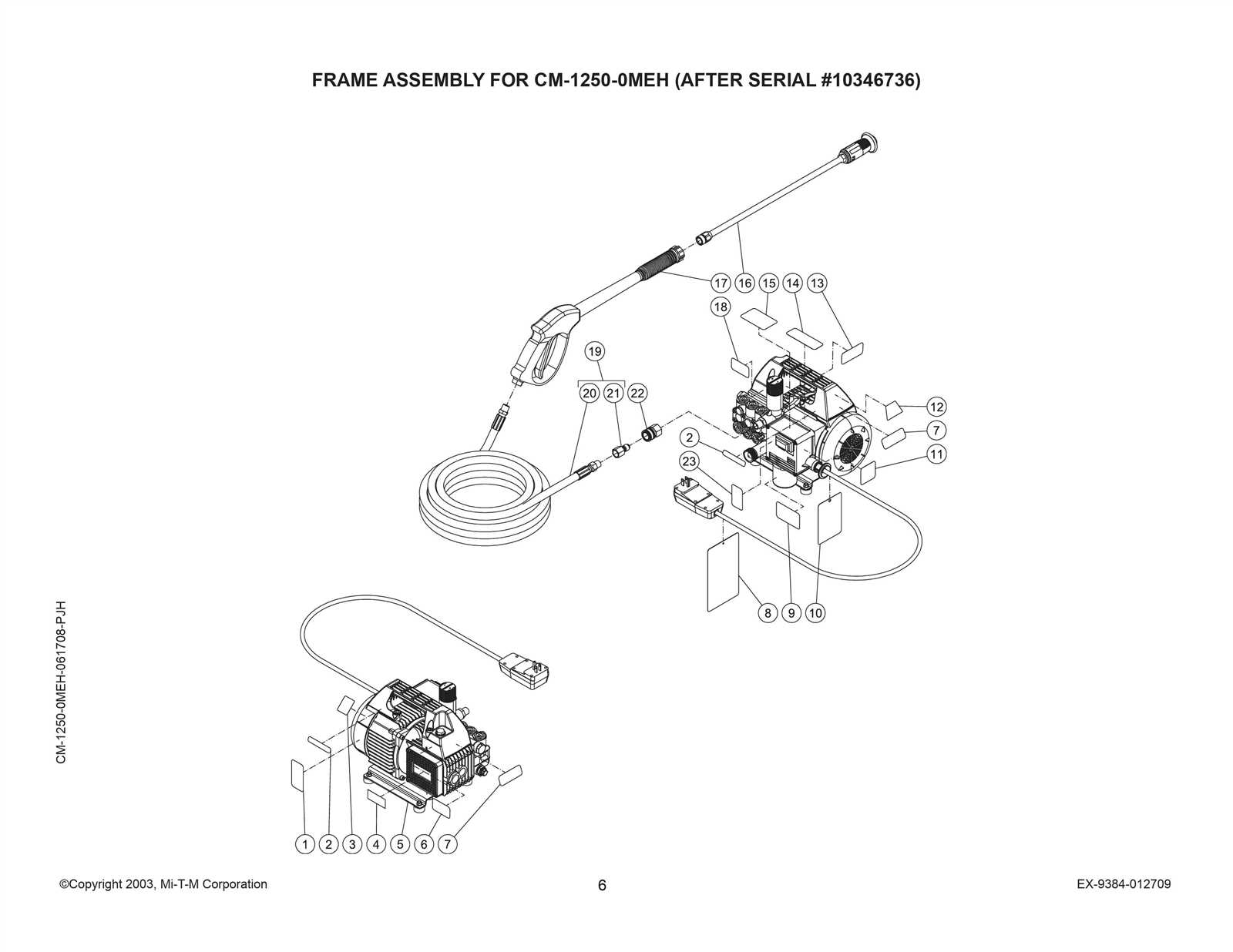

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. This visual guide not only helps identify individual elements but also illustrates their interconnections, ensuring a comprehensive grasp of the entire assembly.

Identifying Components

Start by locating the key elements in the illustration. Each part is typically labeled, either through numbers or letters, allowing you to match them with the corresponding descriptions in the manual.

Understanding Relationships

Pay attention to how parts are connected. Lines and arrows often indicate interactions or flows, providing insights into the functionality and assembly process.

| Label | Component Name |

|---|---|

| 1 | Component A |

| 2 | Component B |

| 3 | Component C |

Common Issues and Solutions

When operating high-performance cleaning machines, users often encounter a variety of problems that can affect the efficiency and functionality of the equipment. These challenges can range from mechanical malfunctions to issues with water flow, all of which can be resolved with the proper troubleshooting steps. Understanding the most frequent issues and their solutions is crucial to maintaining the device in optimal condition.

| Issue | Solution |

|---|---|

| Weak or uneven water flow | Check for clogs in the nozzle or hose, and ensure that the water source is providing adequate pressure. Clean or replace any blocked components. |

| Engine failure to start | Inspect the fuel system, including the fuel filter and spark plug. Refill fuel and ensure the ignition system is functioning properly. |

| Leaks around the connections | Examine all hose and nozzle connections for tightness. Replace any worn or damaged seals and gaskets. |

| Excessive vibration or noise | Check for loose bolts or components. Tighten any loose parts and ensure all connections are secure. |

| Machine stops unexpectedly | Inspect the engine for overheating or fuel starvation. Ensure the oil levels are correct and the air filter is clean. |

Replacement Parts Availability

When maintaining high-performance equipment, ensuring the availability of replacement components is crucial for uninterrupted use. Having easy access to quality replacements ensures that the device operates efficiently and extends its lifespan. This is particularly important for those who rely on their equipment for regular tasks and cannot afford downtime.

Where to Find Components

Replacement components can be sourced through a variety of channels, including specialized online stores, authorized distributors, and local service centers. Online retailers often provide comprehensive catalogs, making it convenient to compare options and find compatible items. Authorized dealers ensure that you are receiving high-quality, genuine components designed specifically for your model.

Choosing the Right Option

It is important to verify compatibility when selecting replacement items. Some alternatives may offer cost savings, but they might not match the performance or durability of the original parts. Always check product specifications and reviews before purchasing to ensure you are getting a reliable replacement.

Step-by-Step Repair Guide

When it comes to restoring the functionality of your high-powered cleaning equipment, understanding the repair process can make all the difference. This guide will walk you through each crucial step, ensuring a smooth and effective restoration, from initial inspection to final testing. Follow the instructions carefully for a comprehensive and efficient repair.

Tools and Equipment Needed

- Wrench set

- Replacement components

- Lubricant

- Cleaning supplies

- Screwdriver set

Repair Process

- Start by turning off the machine and disconnecting from the power source.

- Inspect the components for wear and tear. Focus on the areas that show signs of damage or malfunction.

- Carefully remove any damaged or faulty parts. Take note of their arrangement for easier reassembly.

- Replace the worn components with new or compatible ones, ensuring a proper fit and alignment.

- Apply lubricant to moving parts to ensure smooth operation.

- Reassemble the machine, making sure all connections are secure and components are correctly positioned.

- Test the equipment to confirm that it functions as expected, ensuring optimal performance.

Upgrading Your Cleaning Equipment

Enhancing the capabilities of your cleaning device can significantly improve its efficiency and versatility. By upgrading various components, you can tailor the machine to handle more demanding tasks, increase its lifespan, and optimize performance. Whether you’re looking to increase power output or improve ease of use, selecting the right upgrades is key to achieving the best results.

Key Upgrades for Enhanced Performance

Focusing on the most crucial areas for improvement can make a noticeable difference in how your equipment operates. Here are a few areas to consider:

| Upgrade | Benefit |

|---|---|

| High-Quality Nozzles | Improved spray control and water efficiency |

| Enhanced Hoses | Increased durability and flexibility for harder-to-reach areas |

| Pressure Control Valves | Better regulation of water pressure for delicate tasks |

| Durable Motors | Higher longevity and more reliable power output |

Choosing the Right Upgrades

When upgrading, it’s important to select components that match the needs of your tasks. Consider whether you need higher power, better precision, or more durability. Additionally, ensuring compatibility with your current setup will make the transition smoother and avoid costly mistakes.

Safety Tips for Pressure Washing

Using high-powered cleaning equipment requires caution and preparation to ensure a safe and efficient experience. Following basic safety guidelines can help you avoid accidents and extend the lifespan of your tools. Always prioritize safety to protect both yourself and your surroundings when using intense cleaning machines.

Personal Protection

Before starting any cleaning job, make sure you wear the appropriate protective gear. This includes safety goggles, non-slip footwear, gloves, and hearing protection. The powerful spray from these machines can easily cause injury if you’re not properly equipped.

Proper Usage and Maintenance

Always read the manufacturer’s instructions thoroughly and ensure the equipment is in good working condition. Regular maintenance, such as checking hoses, nozzles, and water supply, is essential to avoid malfunctions and accidents during operation.

| Safety Equipment | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris and high-pressure water spray. |

| Gloves | Prevents hand injuries and protects from harmful chemicals. |

| Non-Slip Footwear | Provides stability and reduces the risk of slipping during operation. |

| Hearing Protection | Minimizes hearing damage from the loud noise produced by the equipment. |