When it comes to maintaining a well-functioning lawn mower, having a clear understanding of its individual components is essential. Each element plays a crucial role in ensuring smooth operation and efficiency during use. By familiarizing yourself with the key elements, you can better manage maintenance and repairs.

Knowing the layout of these components helps in diagnosing issues and ensuring timely fixes. Whether it’s adjusting certain mechanisms or replacing worn-out elements, the ability to identify and locate specific parts can significantly enhance the lifespan of the equipment.

Proper maintenance not only guarantees better performance but also extends the life of the machine. By understanding how each component works in harmony, users can make more informed decisions about care and upkeep.

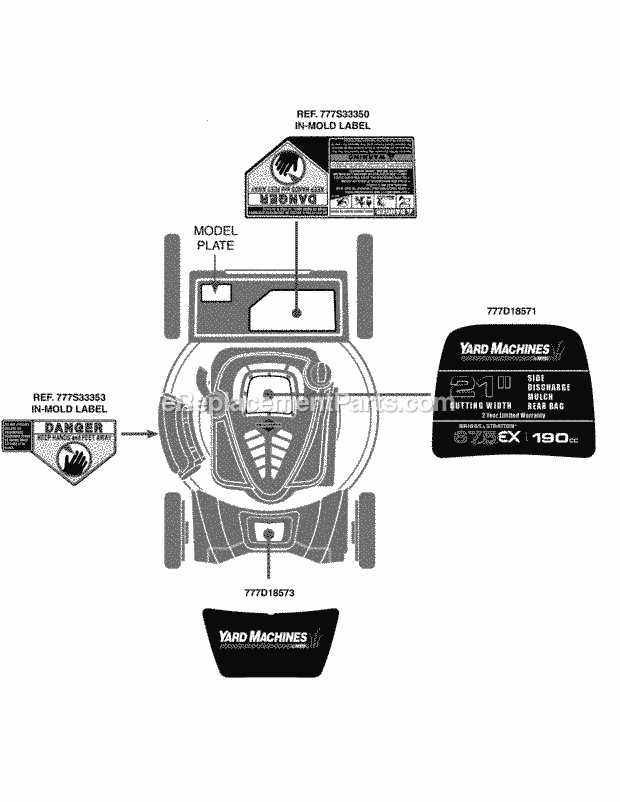

Understanding the Components of the TB360

The structure of this equipment is made up of several essential elements that work together to ensure efficient performance. These components are designed to provide stability, control, and ease of use, each contributing to the overall operation in a unique way. By exploring the key elements, one can gain a better understanding of how the machine functions as a whole.

- Engine system: This powers the device and ensures smooth operation under different conditions.

- Drive mechanism: Responsible for transferring energy to the wheels, allowing controlled movement.

- Cutting deck: The area where grass is trimmed to the desired length, supported by adjustable settings.

- Control levers: These provide the operator with full command over speed, direction, and engagement.

- Wheels and tires: Designed for traction and durability, ensuring smooth mobility over various terrains.

Each of these elements is crafted to contribute to a balanced and effective performance, enhancing the user’s experience and the machine’s longevity.

Key Features and Functions Overview

This section provides an in-depth look at the essential features and capabilities of this advanced lawn care equipment. It focuses on how different components work together to ensure efficient and smooth operation.

- Durability: Built with high-quality materials for long-lasting use, ensuring consistent performance over time.

- Ease of Use: User-friendly design makes handling and operation straightforward, even for beginners.

- Power Efficiency: Equipped with a powerful engine that optimizes fuel consumption, reducing energy waste.

- Precision Cutting: The cutting system is designed to deliver a clean and even finish, improving the quality of the lawn’s appearance.

- Adjustability: Features adjustable settings that allow for customization based on various lawn conditions and preferences.

These characteristics make this equipment highly reliable and versatile for maintaining different types of lawns.

Engine System Breakdown and Maintenance

The engine is the core component of any machine, and understanding its structure is key to keeping it running smoothly. Regular maintenance of the engine ensures not only longevity but also optimal performance during operation. By familiarizing yourself with the primary sections of the engine and their functions, you can address potential issues before they become major problems.

Key Areas to Inspect

Inspecting critical areas of the engine can help identify wear and tear early. Components like the air filter, fuel system, and cooling mechanism are all vital for ensuring efficient operation. Regular checks can prevent costly repairs and downtime.

Maintenance Tips

To maintain engine efficiency, follow a routine that includes checking oil levels, replacing filters, and cleaning key components. Scheduling periodic maintenance helps ensure that the machine remains reliable over time, reducing the risk of sudden malfunctions.

How to Care for the Power Unit

Maintaining the core mechanism of your machine is essential for its long-term performance. Regular upkeep not only ensures smooth operation but also extends the lifespan of the equipment. This section provides simple yet effective tips for keeping the unit in top condition.

Regular Inspection and Cleaning

Inspecting the main components frequently helps to identify any early signs of wear or damage. Clean the exterior regularly to remove dirt, dust, and debris that could affect performance. A well-maintained system operates more efficiently and reduces the risk of breakdowns.

Lubrication and Fluid Checks

Ensure all moving parts are properly lubricated to prevent friction and wear. Check fluid levels, such as oil or fuel, to ensure the unit functions smoothly. Proper lubrication and fluid maintenance are crucial to keeping the system running optimally.

Blade Assembly and Sharpening Guide

The correct setup and maintenance of your lawnmower blade are essential for achieving smooth and efficient mowing results. Understanding how to assemble the blade and keep it sharp will help enhance both the machine’s performance and the overall lawn appearance.

Blade Assembly: To ensure the blade is properly installed, it must be securely fastened, aligned, and balanced. Double-check the positioning to avoid uneven cuts or damage to the equipment.

Sharpening Tips: Regular sharpening of the blade helps maintain a clean cut, reducing strain on the machine. A sharp blade also promotes healthier grass growth, as it minimizes tearing and damage to the lawn. It is recommended to sharpen the blade every few weeks, depending on usage frequency.

Ensuring Optimal Cutting Performance

Achieving peak cutting efficiency requires attention to various elements of your equipment. Proper maintenance and adjustment can significantly enhance the performance of your machine, ensuring a clean and precise cut each time.

- Regular Maintenance: Consistent upkeep is crucial for optimal functionality. This includes:

- Cleaning the cutting components to remove debris and buildup.

- Inspecting blades for wear and replacing them as necessary.

- Checking oil levels and topping up as needed.

- Blade Sharpness: Dull blades can lead to uneven cuts and additional strain on the motor. Ensure blades are:

- Sharpened regularly to maintain their effectiveness.

- Replaced when they show signs of significant wear.

- Proper Height Adjustment: Adjusting the height of the cutting mechanism can impact performance. Set the height according to:

- The type of grass or vegetation being cut.

- The desired finish–whether a low cut for a manicured lawn or a higher cut for rough areas.

By focusing on these aspects, users can ensure that their equipment operates at peak performance, delivering efficient and effective cutting results.

Fuel System Diagram and Troubleshooting

The fuel system is a crucial component in any outdoor power equipment, ensuring that the engine receives the proper amount of fuel for optimal performance. Understanding the layout and functionality of this system can help in diagnosing issues that may arise during operation. This section will provide insights into the various elements involved in the fuel system and offer troubleshooting tips to address common problems.

Key Components of the Fuel System

The primary elements of the fuel system include the fuel tank, lines, filter, and carburetor. Each part plays a significant role in transporting and regulating fuel flow to the engine. Regular inspection of these components is essential to prevent clogs and leaks, which can lead to performance issues.

Troubleshooting Common Fuel Issues

If the engine exhibits poor performance or fails to start, it may be due to issues within the fuel system. Start by checking for fuel blockages or leaks in the lines. Ensure the filter is clean and free from debris, as a clogged filter can restrict fuel flow. Additionally, verify that the carburetor is functioning correctly, as improper adjustment can affect fuel-air mixture and overall engine efficiency.

Common Issues and Fixes

When operating outdoor machinery, various challenges may arise, impacting performance and efficiency. Identifying these common problems and understanding their solutions can greatly enhance the longevity and effectiveness of the equipment.

One frequent issue users encounter is difficulty starting the engine. This can often be attributed to a clogged fuel filter or stale fuel. Regular maintenance and replacing fuel as needed can alleviate this problem, ensuring smooth operation.

Another common concern is a lack of power during use. This can result from worn spark plugs or air filters that require cleaning or replacement. Keeping these components in check will help maintain optimal performance.

Additionally, users may notice excessive vibrations or noise. This could signal loose bolts or damaged components. Routine inspections can help detect these issues early, preventing further damage and ensuring safe usage.

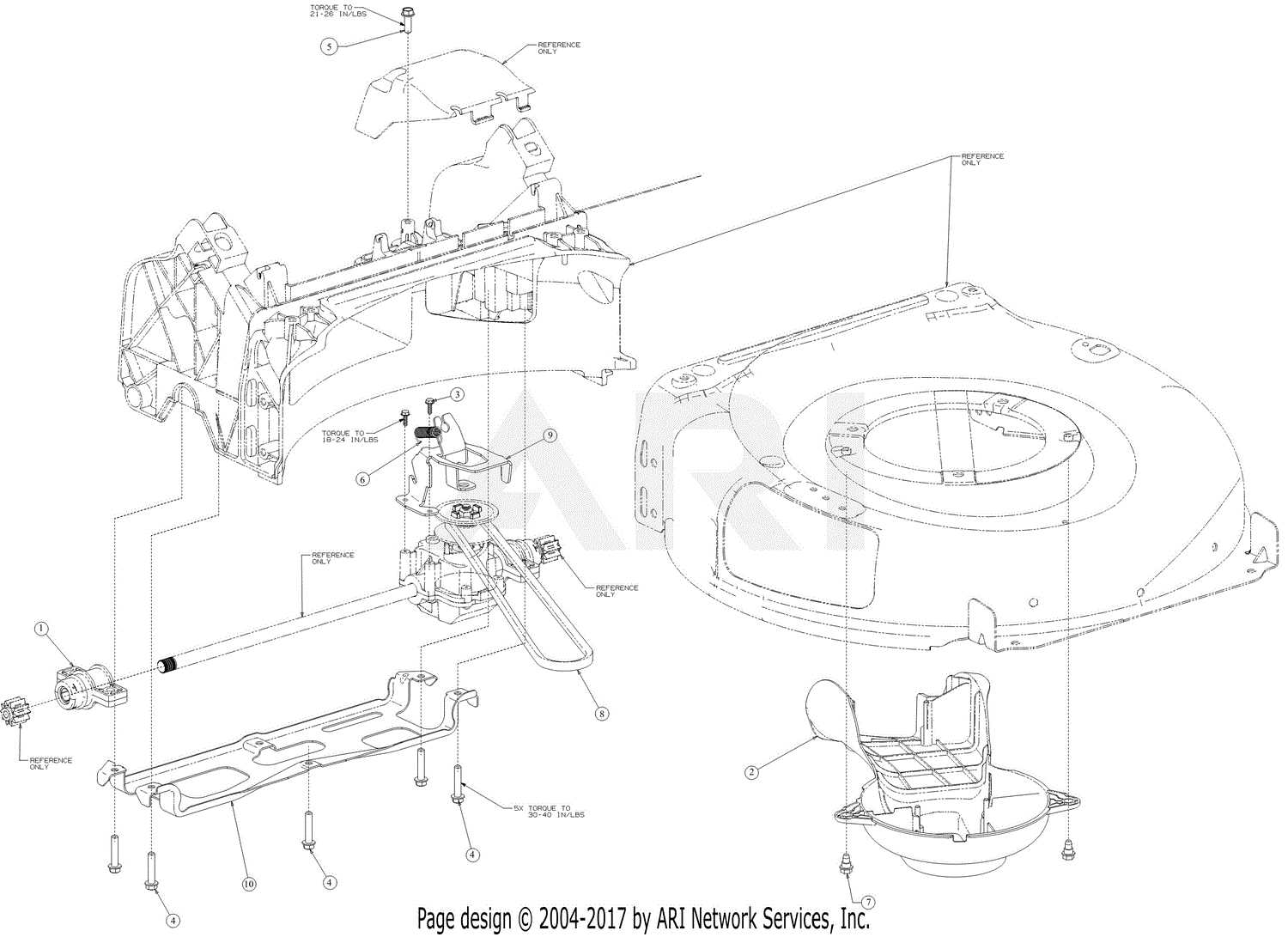

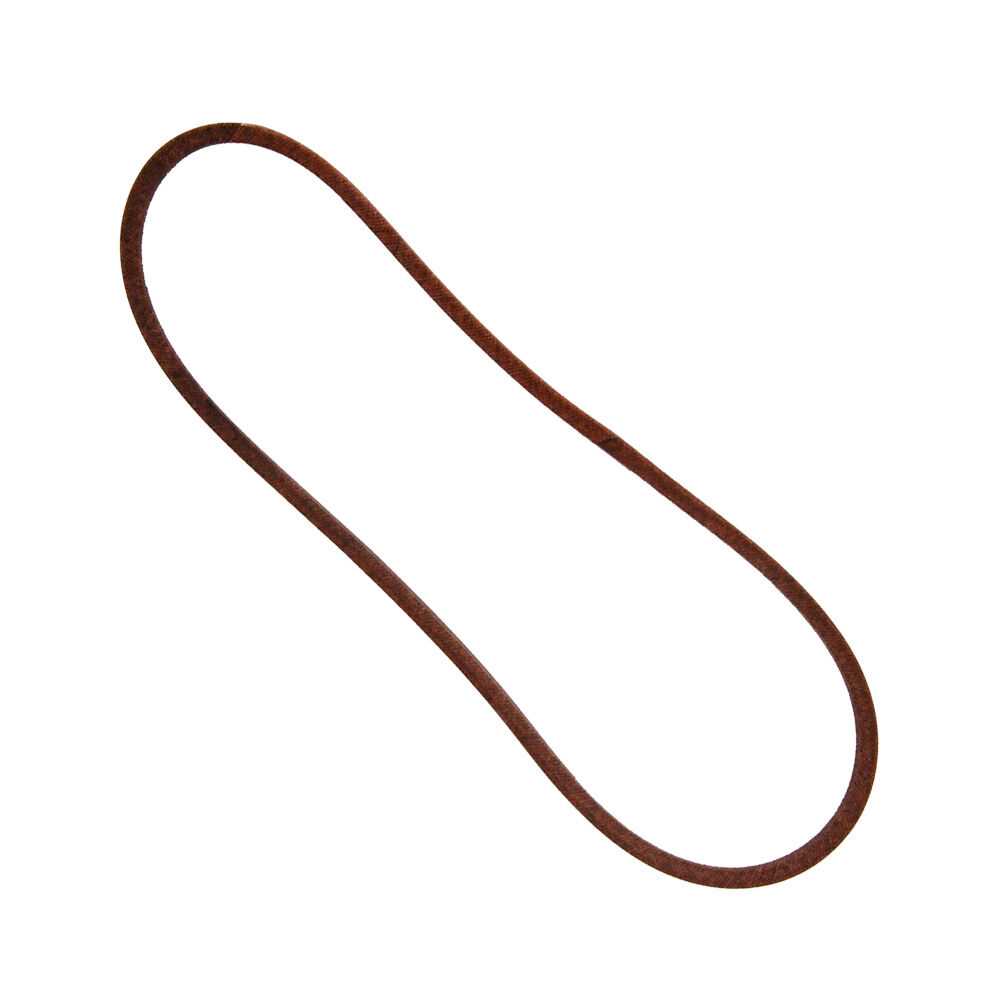

Drive System and Belt Adjustments

The drive mechanism is essential for ensuring the efficient operation of your equipment. Proper maintenance and adjustment of this system are crucial for optimal performance and longevity. This section explores the key components of the drive system and how to effectively manage belt adjustments.

Key aspects of the drive system include:

- Transmission of power from the engine to the wheels.

- Components that ensure smooth operation and responsiveness.

- Maintenance practices to prolong the lifespan of the system.

Adjusting the belt is a critical part of maintaining the drive system. Follow these steps for proper belt adjustment:

- Ensure the equipment is turned off and completely cool before starting.

- Locate the belt tension adjustment mechanism.

- Check the current tension; it should be snug but not overly tight.

- To increase tension, turn the adjustment bolt clockwise. To decrease, turn it counterclockwise.

- Once adjusted, ensure that the belt is aligned correctly and is free from wear or damage.

Regularly checking and adjusting the drive system and belts will lead to better efficiency and reduced wear on components. Always consult the manufacturer’s guidelines for specific maintenance schedules and recommendations.

Maintaining Smooth Operation

To ensure optimal performance and longevity of your equipment, regular upkeep is essential. A well-maintained machine operates efficiently, reducing the risk of unexpected breakdowns and enhancing overall functionality.

Key Maintenance Practices

- Regularly inspect and clean all components to remove dirt and debris.

- Lubricate moving parts as recommended to minimize friction and wear.

- Check and adjust belts and cables to ensure proper tension and alignment.

Scheduled Service Intervals

Establishing a routine maintenance schedule can help identify potential issues before they escalate. Adhere to the following recommendations:

- Inspect filters and replace them as needed, usually every season.

- Sharpen blades to ensure a clean cut and reduce strain on the motor.

- Test safety features regularly to ensure they function properly.