Understanding how various elements of your equipment work together is essential for maintaining its efficiency and longevity. Each element plays a crucial role, contributing to the overall performance of the machine. Knowing the layout and structure of these components helps identify any issues and make informed decisions when maintenance is needed.

In this section, we will explore the most important elements, highlighting their roles and connections within the system. Whether you are troubleshooting or simply getting acquainted with your device, this guide provides clear insights into how everything operates. Keeping your equipment in top shape requires not only regular upkeep but also a solid understanding of how each piece interacts with the whole.

By focusing on key features and how they are linked, you can more effectively manage the upkeep and ensure smooth operation. This overview will guide you through the essentials, making it easier to understand what each part does and how to address potential problems.

Overview of Key Components

The system consists of several critical elements, each serving a unique function to ensure optimal performance. These components work together in unison, playing an essential role in the overall operation and efficiency of the equipment. A thorough understanding of each part’s role is necessary to maintain and troubleshoot the device effectively.

Engine Assembly

The core of the system is the engine, which powers the entire operation. This assembly includes vital components such as the ignition system, fuel delivery mechanism, and cooling system, all working together to generate the required energy. Regular maintenance of the engine is crucial for sustained performance and longevity.

Cutting Mechanism

Another significant aspect of the equipment is the cutting mechanism. This section consists of sharp blades or cutting heads designed for precise and efficient cutting. Proper handling and routine inspection of this mechanism are key to ensuring smooth and safe operation.

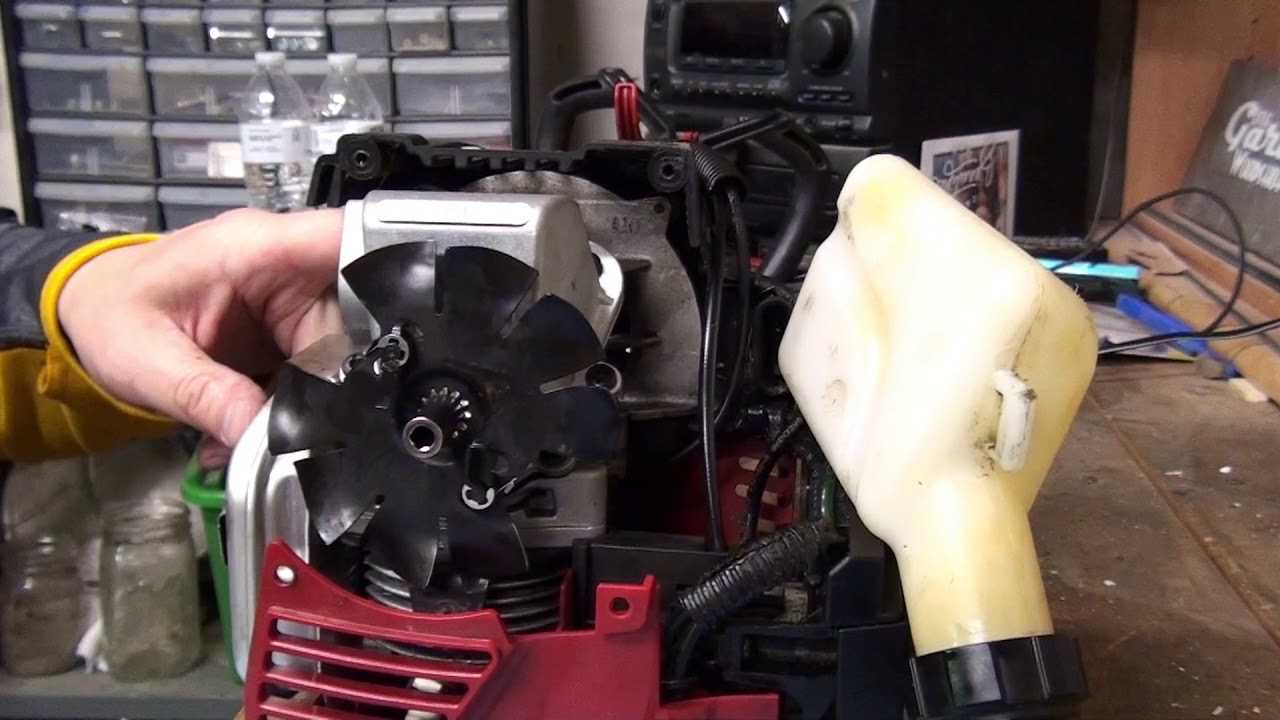

Understanding the Engine Assembly

The engine assembly is a crucial component, consisting of various interconnected parts that work together to ensure smooth operation. A solid understanding of this system helps in maintaining functionality, troubleshooting potential issues, and improving performance.

Several key elements are involved in the engine’s structure, each playing a specific role in its performance. Familiarity with these components can significantly assist in identifying wear and tear or the need for replacement.

- Cylinder and Piston: These form the core of the combustion process, converting energy into mechanical motion.

- Crankshaft: Responsible for transforming the piston’s linear movement into rotational motion, driving other mechanical parts.

- Carburetor: Ensures the correct mixture of air and fuel for combustion, affecting overall efficiency.

- Ignition System: Provides the spark necessary to ignite the fuel mixture, ensuring consistent power output.

Each of these components requires regular attention to ensure optimal performance. Understanding how they function together will enhance the overall longevity and efficiency of the machine.

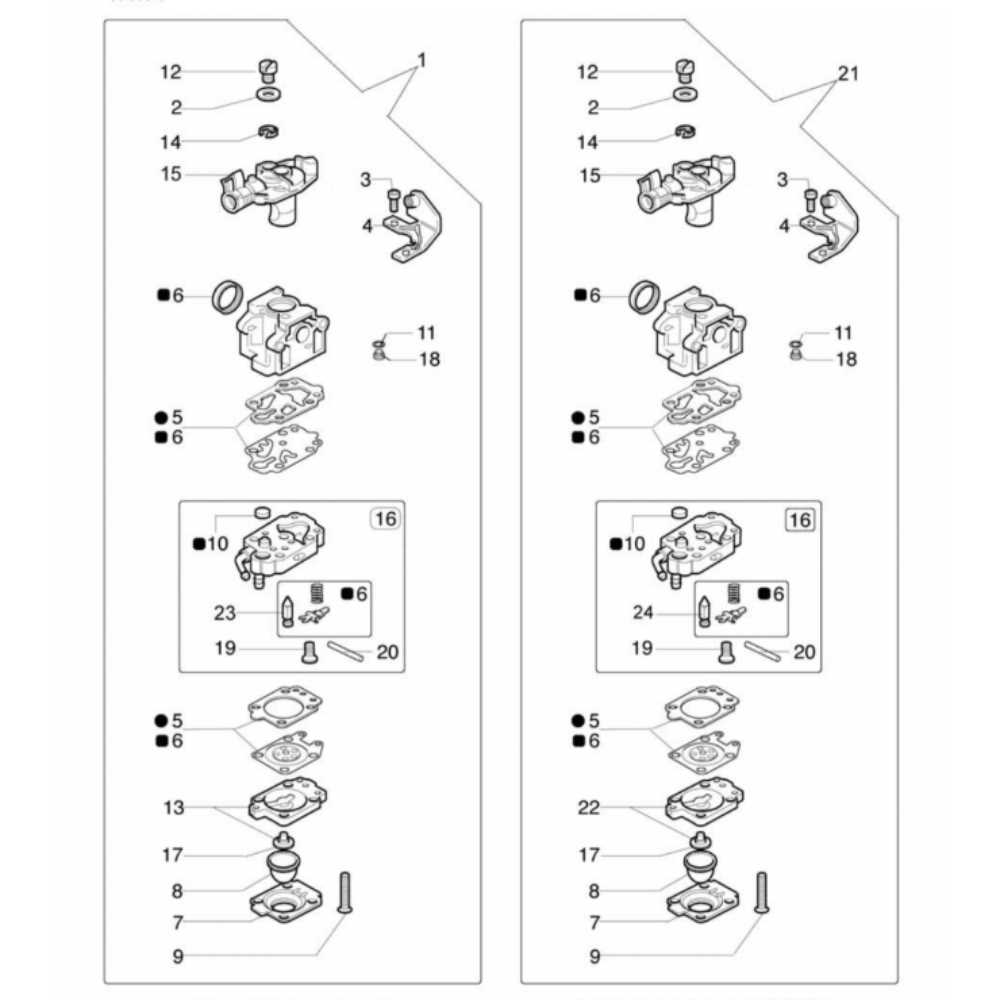

Fuel System Parts Breakdown

The fuel delivery system is a crucial aspect of maintaining smooth engine performance. Understanding the components involved helps to ensure proper function and troubleshoot potential issues. Below is an overview of the key elements that work together to keep the fuel flowing efficiently.

Main Components Overview

- Fuel Tank: The container where the fuel is stored before being directed towards the engine.

- Fuel Line: A flexible tube responsible for transporting the fuel from the tank to the carburetor or fuel injector.

- Fuel Filter: Prevents dirt and debris from entering the engine by cleaning the fuel as it passes through the system.

- Carburetor: Mixes the fuel with air in the correct ratio before sending it to the engine for combustion.

Maintenance Tips

- Regularly check the fuel line for any signs of wear or leaks.

- Ensure the fuel filter is clean to avoid any clogs that might

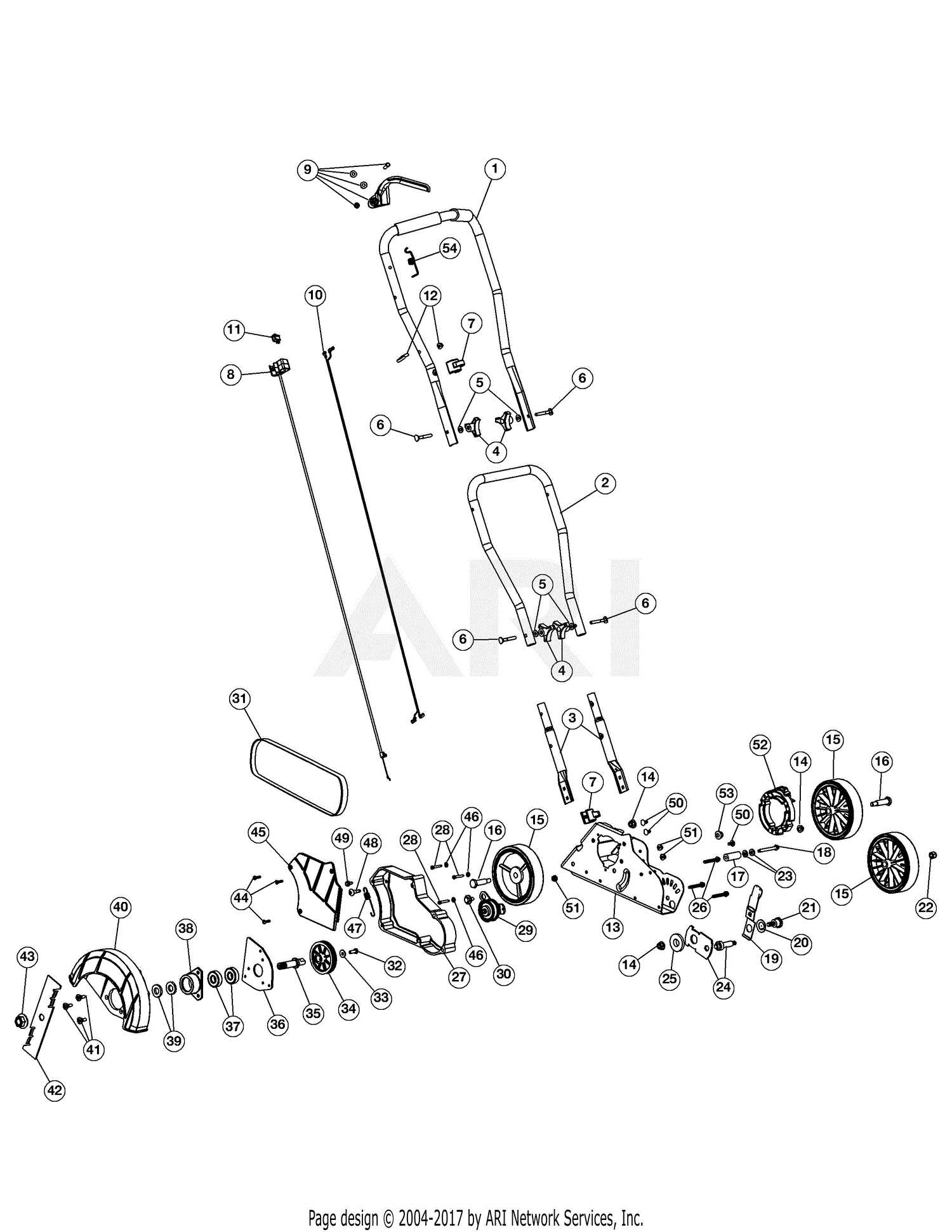

Handle and Trigger Mechanism Layout

The handle and trigger system plays a crucial role in the efficient operation of the equipment, offering the user optimal control and comfort. This section outlines the arrangement of key elements within the control mechanism, focusing on how they work together to ensure a smooth and responsive performance. The layout of these components has been designed with ergonomics and functionality in mind.

Key Components of the Handle Assembly

- Grip Section: Provides a secure hold for comfortable operation over extended periods.

- Trigger Control: Positioned within easy reach, the trigger is designed to regulate the power flow seamlessly.

- Support Brackets: These structures help stabilize the entire assembly, ensuring it remains securely attached to the main unit.

Trigger Mechanism Functionality

- Activation: Pulling the trigger initiates the flow of power, allowing the system to start or accelerate as needed.

- Locking Mechanism: A safety lock ensures the system doesn’t activate unintentionally, preventing unw

Air Filter and Carburetor Connections

The proper interaction between the air intake system and the fuel delivery mechanism is crucial for optimal engine performance. Understanding how these components work together can enhance efficiency and longevity of the equipment. This section delves into the connections and functions of the air filter and carburetor, highlighting their importance in maintaining an effective combustion process.

Key Components

- Air Filter: This element prevents debris and contaminants from entering the engine, ensuring a clean airflow.

- Carburetor: Responsible for mixing air and fuel in the correct ratio, allowing for efficient combustion.

Connections Overview

- Mounting: The air filter securely attaches to the carburetor, creating a tight seal that prevents unfiltered air from entering.

- Hoses and Tubes: Flexible hoses connect the carburetor to the engine, allowing for the transfer of the air-fuel mixture.

- Adjustment Screws: These allow for fine-tuning of the air-fuel mixture, optimizing performance based on environmental conditions.

Maintaining these connections is essential for the overall efficiency of the engine. Regular checks and cleanings can help prevent performance issues and extend the life of the equipment.

Starter Recoil and Clutch Assembly

The starter recoil and clutch assembly plays a crucial role in the operation of small engines, providing the necessary mechanism to initiate the engine’s power cycle. This assembly ensures that the engine starts smoothly while also managing the engagement and disengagement of power to the drive components.

At the core of this system is the recoil starter, which allows the operator to manually pull a cord to engage the engine. This mechanism consists of a spring-loaded component that recoils after being pulled, enabling the flywheel to turn and start the combustion process. The efficiency of this system is vital for reliable engine performance.

The clutch assembly complements the recoil starter by connecting the engine to the drive system. It regulates the transfer of power, ensuring that the engine engages at the right moment. A well-functioning clutch allows for smooth operation, preventing stalling and enabling optimal performance during use.

Regular maintenance of both the starter recoil and clutch assembly is essential for longevity and reliability. Inspecting for wear, replacing damaged components, and ensuring proper tension are key practices that help maintain the efficiency of the overall system.

Exploring the Trimmer Head Components

The cutting mechanism of any string trimmer is essential for effective lawn maintenance. Understanding its various components can enhance performance and ensure longevity. Each part plays a vital role in achieving a clean and efficient cut, making it important for users to familiarize themselves with these elements.

Cutting Line: This is the most critical component, responsible for the actual cutting action. Typically made from nylon, the line comes in various thicknesses to suit different types of vegetation. A thicker line is ideal for tougher weeds, while a finer line works well for lighter trimming.

Spool: The spool serves as the housing for the cutting line. It allows for easy loading and replacement of the line, ensuring that the trimmer can operate continuously without interruptions. A well-maintained spool prevents tangles and ensures the line feeds smoothly during operation.

Trimmer Head: The trimmer head is the part that holds the spool and line in place. It can vary in design, including fixed or bump feed types. Bump feed heads allow users to extend the cutting line by tapping the head on the ground, promoting efficiency during use.

Drive Shaft: This component connects the engine to the trimmer head, transmitting power for line rotation. A robust drive shaft ensures that the cutting line operates at optimal speed, facilitating effective trimming and edging.

Guard: The guard serves as a protective shield around the trimmer head. It helps to prevent debris from being thrown during operation and protects the user from potential injuries, making it an essential safety feature.

By comprehending these essential components, users can ensure that their trimming equipment operates efficiently and safely, leading to better results in garden care and maintenance.

Drive Shaft and Gearbox Assembly

The drive shaft and gearbox assembly plays a crucial role in the overall functionality of outdoor power equipment. This assembly transfers rotational motion from the engine to the cutting mechanism, ensuring efficient operation and performance.

Components of this assembly typically include a drive shaft, which connects to the engine, and a gearbox that helps regulate speed and torque. The gearbox contains various gears that adapt the engine’s output to the specific needs of the tool, optimizing its performance in various conditions.

Proper maintenance of this assembly is essential for longevity and effectiveness. Regular inspection and timely replacement of worn components can prevent operational failures and ensure the equipment runs smoothly.

Maintenance and Replacement Tips for Parts

Regular upkeep and timely substitutions are essential for ensuring optimal performance and longevity of your equipment. Understanding the common wear items and how to care for them can greatly enhance efficiency and reliability.

Routine Inspection

Conduct frequent assessments to identify any signs of wear or damage. Pay close attention to components that experience high levels of stress, as early detection can prevent more significant issues down the line. Replace worn elements promptly to maintain peak functionality.

Proper Storage and Care

Store your machinery in a dry, clean environment to protect it from moisture and debris. Regular cleaning not only prolongs life but also helps in spotting potential problems early. Utilizing the correct lubricants and following the manufacturer’s guidelines will ensure smooth operation.