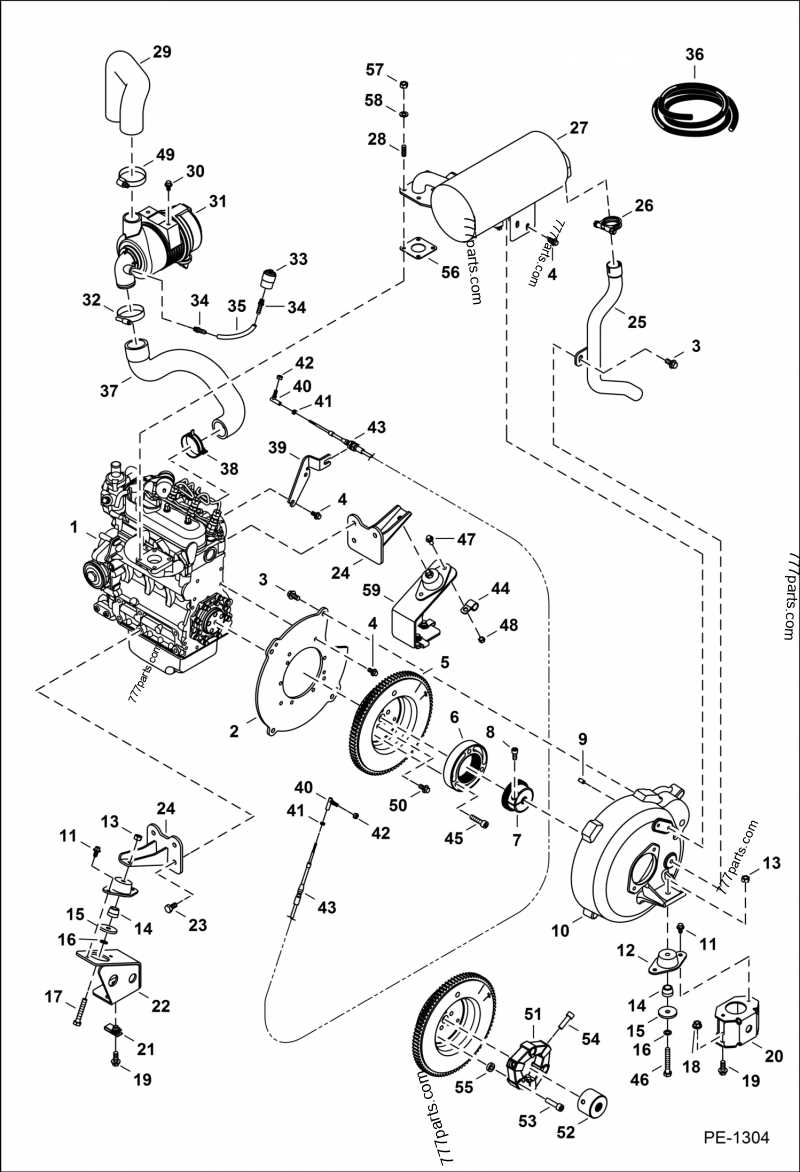

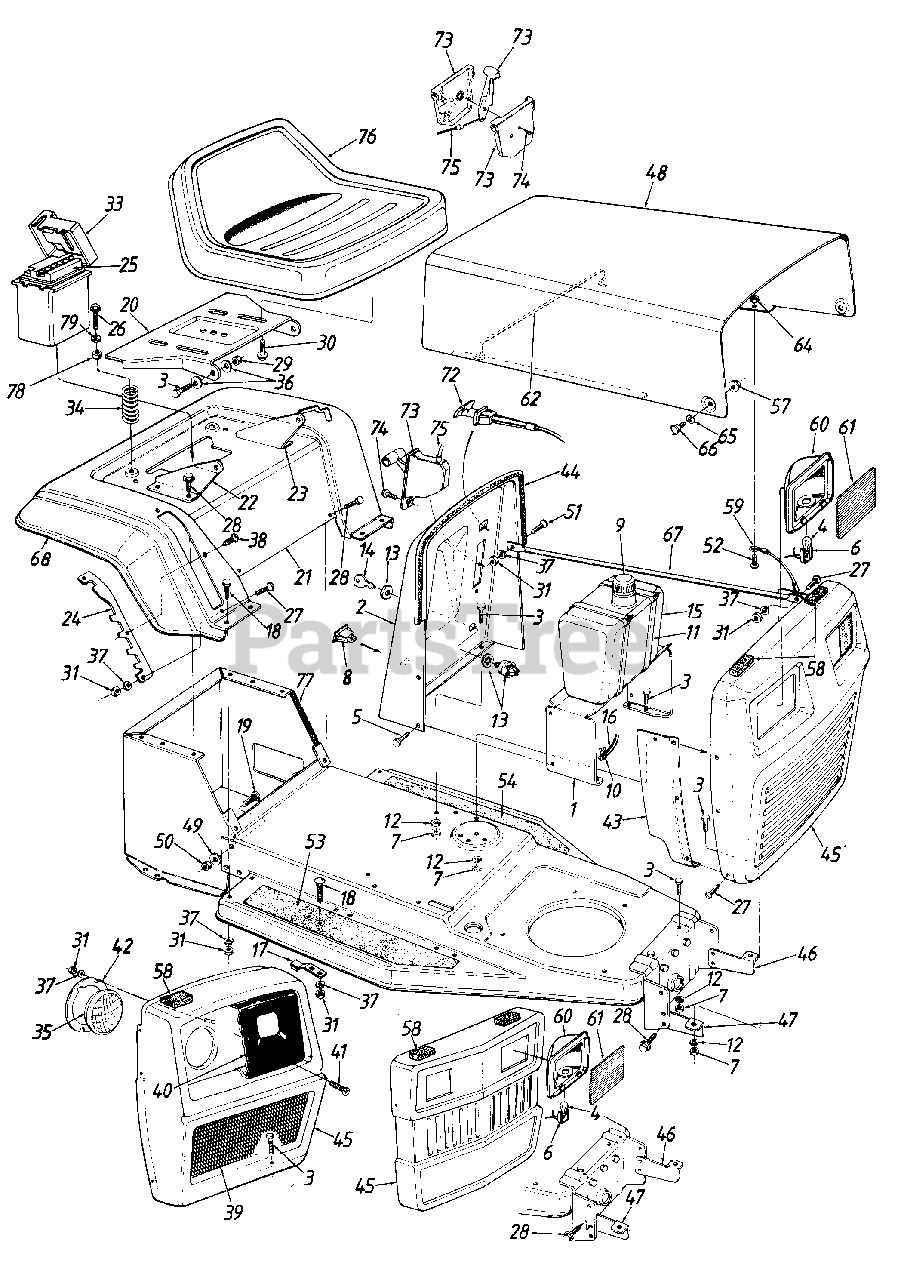

When working with specialized machinery, it’s essential to understand the detailed breakdown of its various elements. Each unit relies on numerous components, and a clear visualization of how these pieces interact is crucial for effective maintenance and repair. A well-organized layout of these components can simplify the process of identifying individual elements and their respective roles.

For anyone tasked with maintaining or repairing such equipment, an accurate reference of its structural layout is invaluable. It provides a roadmap to locating specific elements, understanding their function, and ensuring that everything is in its proper place. This becomes especially useful during troubleshooting or routine inspections, where quick identification can save time and prevent errors.

By examining the internal and external configuration of these systems, operators can confidently carry out repairs, replacements, or upgrades. The correct understanding of how these various elements connect and interact helps in ensuring smooth operation and extends the longevity of the machinery.

Overview of John Deere 322 Components

The machine in question is a versatile and robust piece of equipment designed for various tasks in agricultural and landscaping applications. Its engineering highlights include a well-thought-out system of interconnected elements that ensure optimal performance and reliability over time. This section provides a closer look at the essential components that contribute to its functionality.

Engine: The heart of the machine is powered by a highly efficient motor, which is designed to offer both power and fuel economy. It ensures smooth operation across different terrains, adapting to various load demands.

Hydraulic System

Engine Parts and Key Elements

The functioning of any internal combustion system depends on several essential components that work together to ensure smooth performance and efficiency. This section provides an overview of the critical elements that contribute to the operation and overall reliability of the machinery.

- Cylinder Block: The central housing where fuel combustion takes place, holding various mechanisms needed for power generation.

- Pistons: Move within the cylinders, transforming energy from the fuel-air mixture into mechanical motion.

- Crankshaft: Converts the reciprocating motion of the pistons into rotational force, which powers other connected systems.

- Valves: Control the intake of air and fuel, as well as the release of exhaust gases, ensuring the right timing for combustion.

- Radiator: Regularly check for any blockages, as dirt and debris can reduce airflow, affecting performance. Periodic cleaning is recommended to ensure maximum efficiency.

- Coolant Fluid: Ensure the coolant is at the recommended level. Over time, it may lose its effectiveness, so replacing the fluid according to the manufacturer’s guidelines is essential.

- Water Pump: Inspect for leaks and ensure that the pump is circulating fluid properly. Any unusual noises or a decrease in performance may signal the need for imme

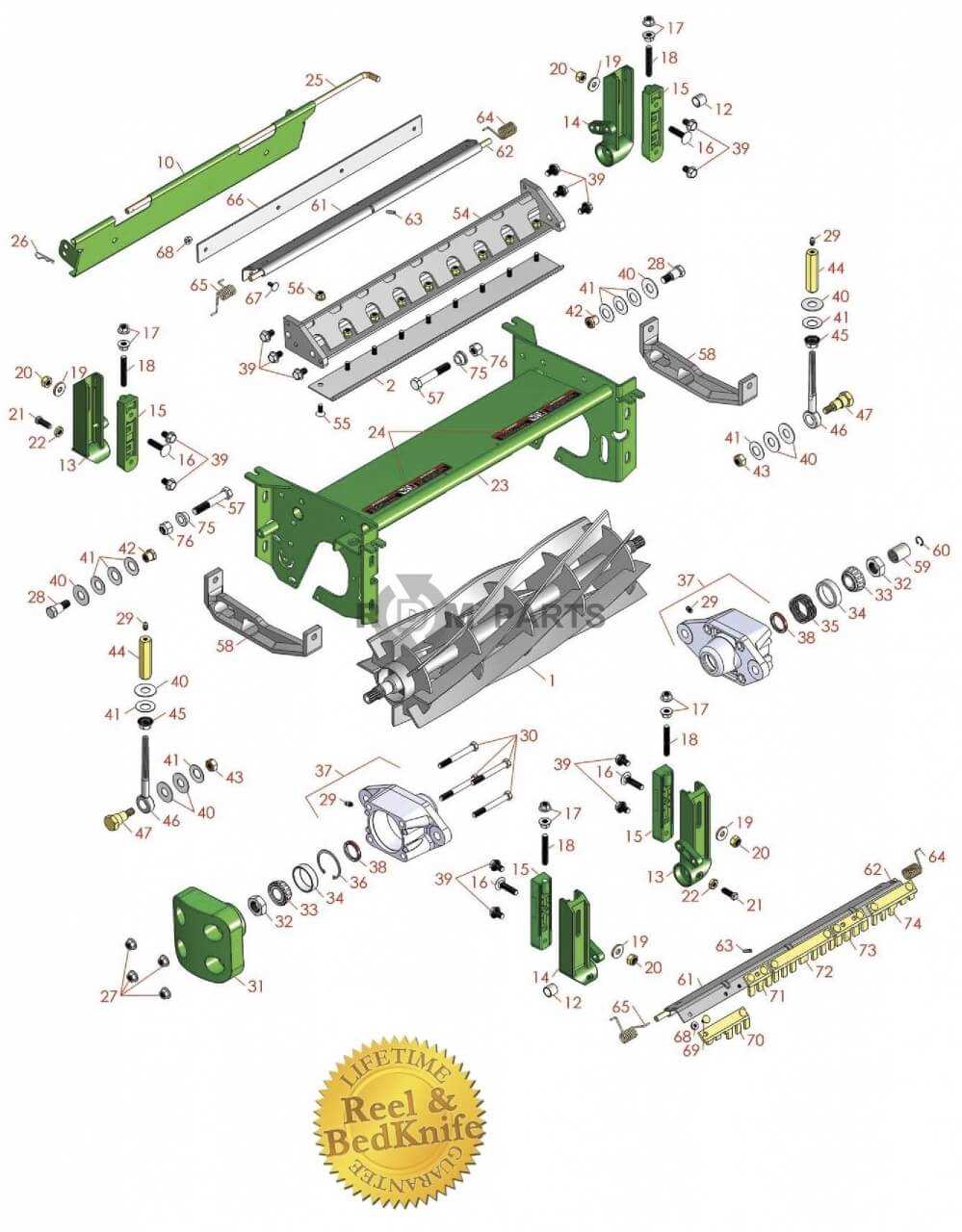

Hydraulic System Structure and Functions

The hydraulic system is a critical component in ensuring smooth operation and efficient performance in machinery. By utilizing pressurized fluid, it enables the movement and control of various mechanical parts, allowing for precision and reliability. Understanding the framework and functions of this system is essential for maintaining optimal functionality and addressing any potential issues that may arise during its use.

Key Components of the System

At the core of the hydraulic mechanism are various essential elements that work together to deliver power and control. These include a reservoir for fluid storage, a pump that generates pressure, and valves that regulate flow and direction. Each part plays a pivotal role in transferring energy, ensuring smooth motion and force where needed.

How the System Operates

The operation of the hydraulic system relies on the movement of fluid under pressure, which is then converted into mechanical force. This process allows for efficient control over lifting, rotating, or moving heavy loads. The precision of fluid distribution ensures that

Fuel System Diagram and Components

The fuel system is a crucial aspect of any machinery, ensuring that the engine receives the necessary fuel for optimal performance. This section explores the key elements involved in this system, detailing how they work together to provide efficient fuel delivery and maintain engine functionality.

At the heart of this system lies the fuel tank, which stores the liquid fuel before it is sent to the engine. Connected to the tank is the fuel pump, responsible for moving the fuel through the lines and into the engine. This component is vital for maintaining proper fuel pressure, allowing the engine to run smoothly.

Another essential element is the fuel filter, which removes impurities from the fuel before it reaches the engine. This helps prevent clogs and ensures the engine operates efficiently. Additionally, the fuel injector plays a significant role by atomizing the fuel, allowing for a more effective combustion process.

Understanding the components and their functions within this system is critical for troubleshooting and maintenance. Regular checks and replacements of these elements can lead to improved performance and longevity of the machinery.

Steering Mechanism and Related Parts

The steering system is essential for controlling the direction and maneuverability of the vehicle. This intricate assembly comprises various components that work together to provide precise handling and stability. Understanding the different elements involved in the steering mechanism can enhance maintenance efforts and ensure optimal performance.

Key Components of the Steering System

At the heart of the steering mechanism is the steering wheel, which allows the operator to guide the vehicle’s path. Connected to the steering column, this component transmits motion to the steering gear, translating rotational input into linear movement. The gear assembly includes critical parts such as the pitman arm and the idler arm, which facilitate the connection to the front wheels.

Importance of Proper Maintenance

Regular inspection and upkeep of the steering components are vital for safe operation. Worn-out or damaged elements can lead to compromised handling and increased risk of accidents. It is crucial to monitor parts like the tie rods and ball joints for signs of wear, as these directly affect the vehicle’s responsiveness and alignment.

Transmission System Overview

The transmission system is a crucial component in various machinery, enabling efficient transfer of power from the engine to the wheels. This mechanism plays a vital role in determining the operational capabilities and overall performance of the equipment.

This system typically consists of several key elements:

- Gearbox: Converts engine speed into torque suitable for driving.

- Clutch: Engages and disengages the engine’s power flow, allowing smooth transitions during operation.

- Drive Shafts: Transmit power from the gearbox to the wheels, facilitating movement.

- Differential: Allows for variations in wheel speed, especially when turning, enhancing stability and control.

Maintaining the transmission system is essential for optimal functionality. Regular inspections can prevent potential issues, ensuring longevity and reliability. Some common maintenance practices include:

- Checking fluid levels and quality regularly.

- Inspecting components for wear and tear.

- Replacing filters and fluids as needed.

In summary, a well-functioning transmission system is integral to the efficiency and effectiveness of machinery, significantly impacting performance and user experience.

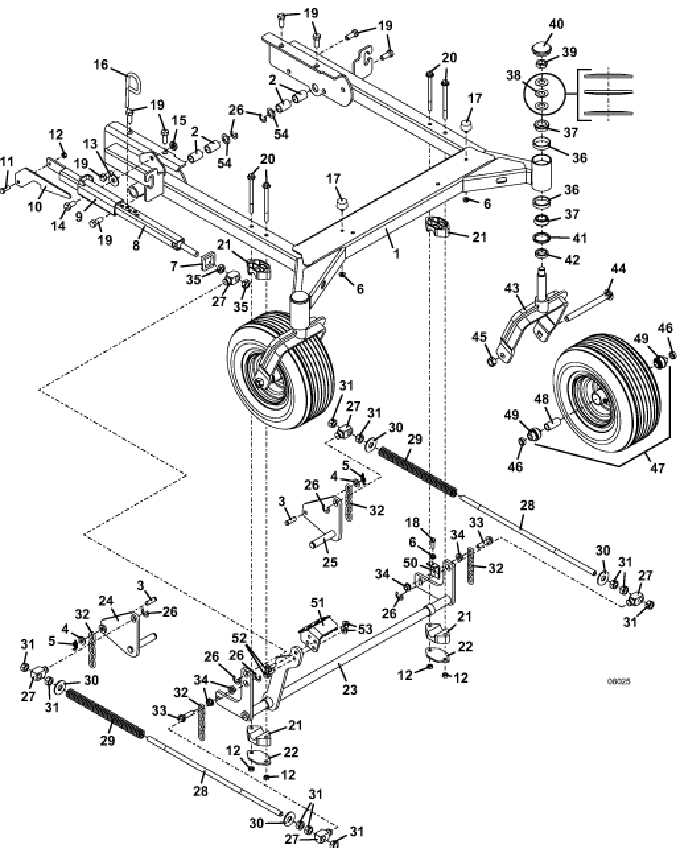

Front and Rear Axle Assembly

The axle assembly plays a crucial role in the functionality of any vehicle, providing stability and support during operation. It connects the wheels to the frame, allowing for movement and weight distribution. Understanding the components and assembly of both the front and rear axles is essential for maintenance and repair tasks.

Components of the Axle Assembly

Each axle assembly consists of several key elements, including the axle shafts, differential, bearings, and suspension links. The axle shafts transmit power from the transmission to the wheels, while the differential allows for smooth turning by compensating for differences in wheel speed. Proper functioning of the bearings ensures that the axles rotate freely, minimizing friction and wear.

Maintenance and Repair Tips

Regular inspection and maintenance of the axle assembly are vital for optimal performance. Look for signs of wear, such as unusual noises or vibrations during operation. Lubricating the components can prevent premature wear, while timely replacement of worn parts will help maintain overall efficiency and safety. Following the manufacturer’s recommendations can significantly extend the lifespan of the axle assembly.

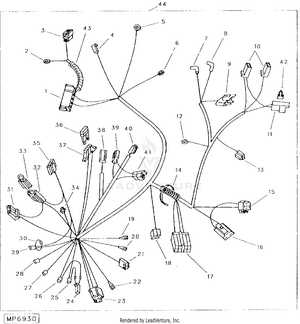

Understanding the Electrical System Layout

The electrical setup of machinery is a crucial aspect that ensures all components operate in harmony. Proper wiring and connections are essential for delivering the right amount of power to various functions. A well-organized network allows the engine, lighting, and control systems to work efficiently without overloads or short circuits.

By comprehending the layout of this system, operators can troubleshoot issues and maintain functionality with ease. Each component is strategically placed to balance power distribution, ensuring both performance and safety standards are met. Familiarity with this layout can significantly reduce downtime during repairs or upgrades.

Cooling System Breakdown and Maintenance

The cooling mechanism is a critical component for ensuring optimal operation, preventing overheating, and extending the machine’s overall life. Regular upkeep of this system not only avoids costly repairs but also helps maintain efficient performance under various conditions. Understanding how different elements of the system work together is essential for proper care and service.

Below is a detailed breakdown of key parts involved in the cooling setup and tips for maintaining each: