Every piece of equipment is built from a collection of interconnected elements that ensure smooth operation and durability. Understanding how these elements work together can make a significant difference in maintenance and troubleshooting. By examining the detailed arrangement of key components, one can gain valuable insights into the overall functionality of the system.

Whether you’re maintaining machinery for optimal performance or simply curious about how various systems interact, having a clear understanding of how different segments are organized and connected is crucial. This exploration will highlight the structural layout, offering a detailed view of the various mechanical and electrical elements within the machine.

A thorough look at the internal configuration reveals the importance of each individual part. This guide aims to break down the complex structure, allowing users to easily navigate through

Overview of the John Deere X350 Components

This section provides a detailed examination of the individual elements that make up the core of this popular model. Each component is designed to ensure optimal performance, durability, and ease of use, making it suitable for a variety of tasks. Below, we will explore the main areas and systems that contribute to the overall functionality.

Key Structural Elements

- Frame and Chassis: Built to withstand heavy use, the frame supports the vehicle’s overall structure while maintaining balance and durability.

- Wheels and Tires: Designed for traction and stability, they ensure smooth operation on different types of terrain, providing excellent maneuverability.

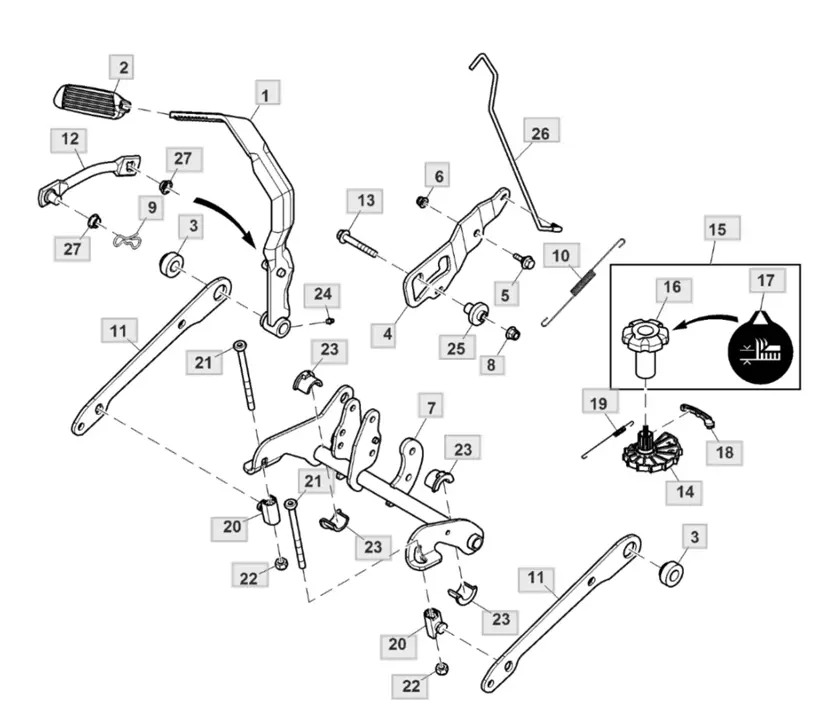

- Steering System: A precise steering mechanism that allows for easy control and navigation, even in tight spaces.

Functional Systems

Understanding the Main Mechanical Structures

The core framework of a robust machine relies on several interconnected systems that ensure smooth operation. These essential components play a vital role in maintaining efficiency, stability, and performance. By focusing on key elements, one can better appreciate how each part supports the overall function of the machine.

- Chassis and Frame: The foundational skeleton that supports and connects various other elements, providing structural integrity and balance.

- Steering Mechanism: This system allows for precise control, making it easier to navigate different terrains while ensuring safety and stability.

- Transmission System: The transmission serves as the link between the engine and the wheels, delivering power and adjusting speed based on the machine’s load and terrain conditions.

- Axles and Drive Train: These components work in unison to transfer the force from the

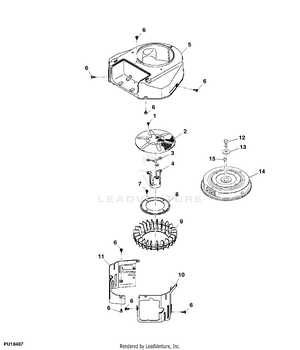

Key Engine Elements and Their Functions

The internal combustion engine relies on various interconnected components, each playing a crucial role in ensuring smooth operation. These elements work together to generate power, regulate fuel flow, and manage temperature, ensuring that the machine functions efficiently and reliably under different conditions.

-

Cylinder: This chamber is where fuel combustion occurs, converting chemical energy into mechanical energy to drive the vehicle.

-

Piston: Positioned within the cylinder, the piston moves up and down as fuel ignites, transferring force to the crankshaft.

-

Crankshaft: Responsible for converting the piston’s linear motion into rotational motion, the crankshaft is key to transmitting power to the drivetrain.

-

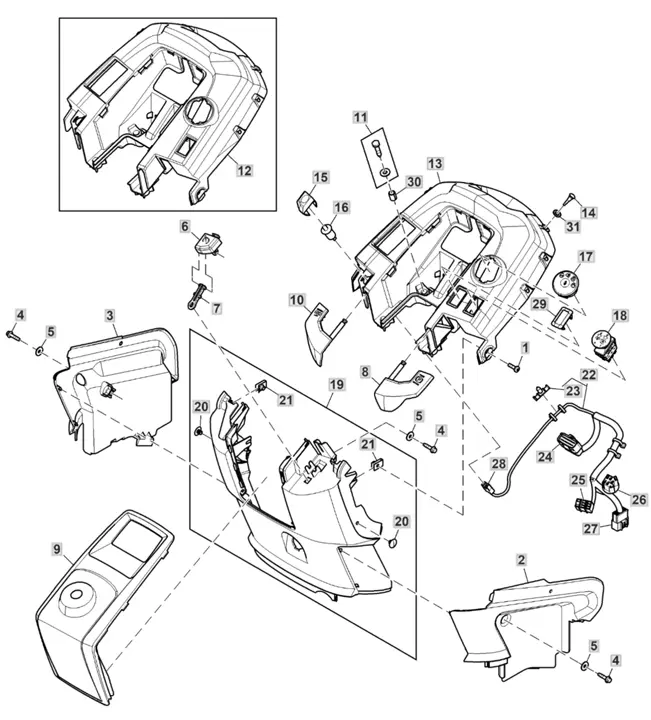

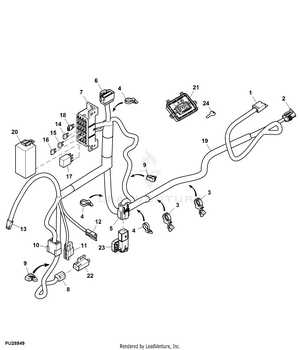

Electrical System Breakdown and Diagram

The electrical system in any mechanical device plays a critical role in ensuring the proper functioning of its various components. This system manages the distribution of power, enabling the integration of lights, ignition, sensors, and control units. Understanding the inner workings of this system allows for easier troubleshooting and maintenance, ensuring reliable performance over time. Below, we will explore how the electrical connections interact with different subsystems, focusing on key areas that help ensure smooth operation.

Power Distribution and Key Components

The power source supplies energy to the main circuit, distributing it to all necessary elements such as the ignition system, battery, and control panel. The battery stores the necessary charge, while the ignition controls the engine start sequence. Key connections ensure that all power-reliant elements receive adequate energy. Additionally, relays and fuses play a pivotal role in safeguarding the circuits from overloads, maintaining a stable flow of electricity throughout the system.

W

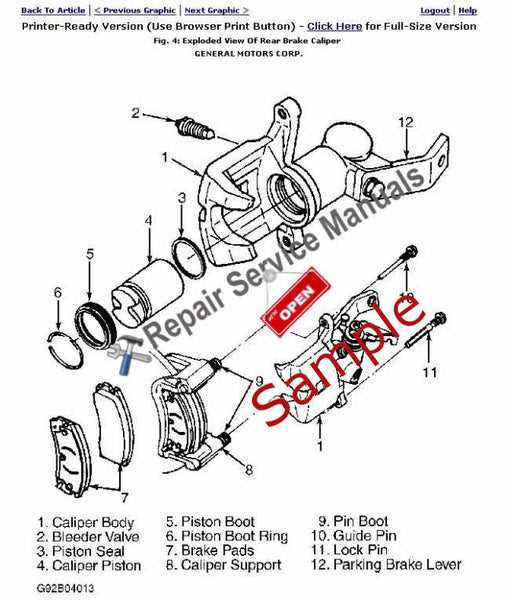

Hydraulic System Parts and Connections

The hydraulic system is an essential component in machinery, providing controlled and efficient power transfer through fluid mechanics. Understanding the various elements involved in this system helps ensure proper maintenance and optimal performance. This section outlines the key components and how they interconnect to facilitate seamless operation.

Main Components

- Pump: Generates the necessary pressure to move fluid through the system.

- Valves: Control the flow and direction of the hydraulic fluid, ensuring precise operation.

- Cylinders: Convert fluid pressure into mechanical force, enabling various functions.

- Reservoir: Stores the hydraulic fluid, ensuring a constant supply during operation.

Connections and Flow Paths

Proper connections between the components are

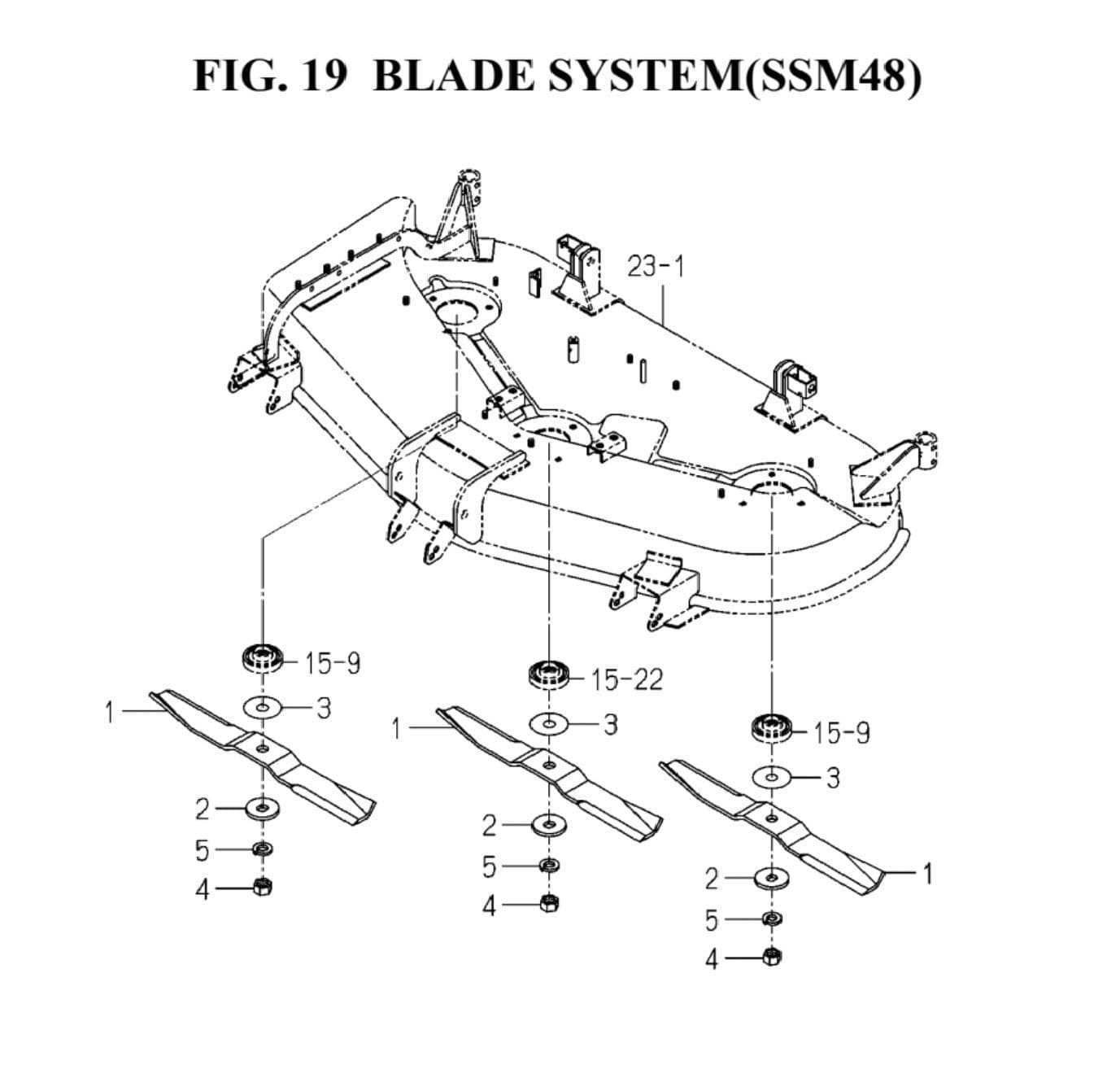

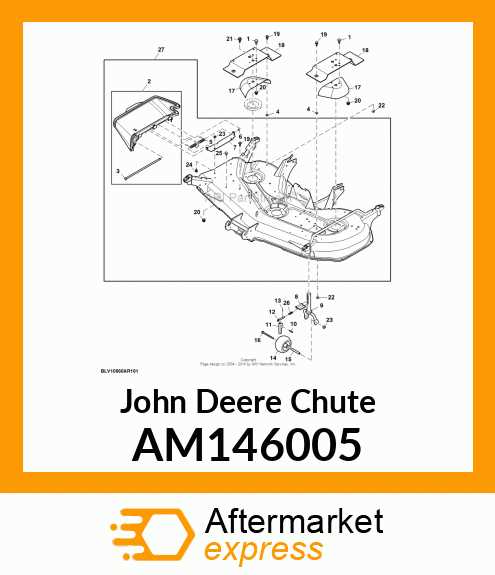

Exploring the Cutting Deck Assembly

The cutting deck assembly is a critical component of any mowing machine, designed to handle the precise task of trimming grass to the desired length. This section focuses on understanding the structure and functionality of the deck, which houses the blades and other essential elements that contribute to efficient grass cutting. A well-maintained deck ensures smooth operation and optimal performance in maintaining lawns of all sizes.

Below, we will break down the main components involved in the assembly:

- Blades: These sharp, rotating elements are responsible for cutting the grass. Proper sharpening and balancing are key to ensuring smooth and even cuts.

- Spindles: These parts secure the blades and enable their rotation. They must be regularly inspected for wear to maintain performance.

- Belt System: The belt connects the engine to the blades, transferring power to ensure their rotation. Keepin

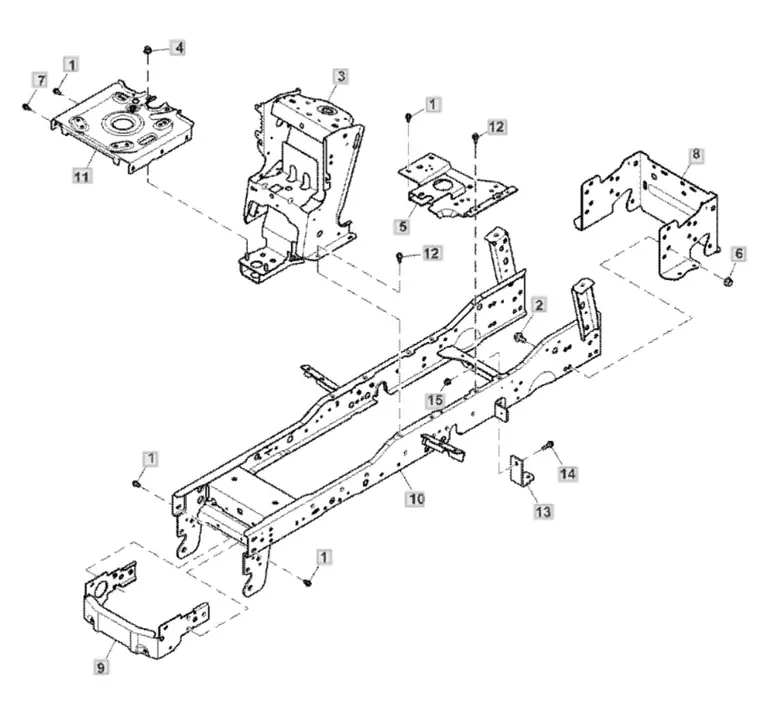

Chassis and Frame Structure Details

The chassis and frame of a lawn care vehicle play a vital role in determining its stability, durability, and overall performance. This structure serves as the foundation, supporting various components and ensuring the machine operates efficiently across different terrains. A well-designed frame enhances maneuverability while providing the necessary strength to withstand operational stresses.

Typically constructed from high-quality steel or reinforced materials, the framework is engineered to endure the rigors of outdoor use. The design often incorporates strategic reinforcements and a balanced layout, which contribute to the vehicle’s ability to handle various attachments and loads. Moreover, a solid chassis design minimizes vibrations, providing a smoother ride for the operator.

Understanding the intricacies of the frame layout can assist users in identifying potential areas for maintenance or upgrades. This knowledge can lead to improved longevity and performance of the equipment. Regular inspections of the frame and its connections are recommended to ensure that all components remain securely in place, thereby enhancing the overall functionality and safety of the machine.

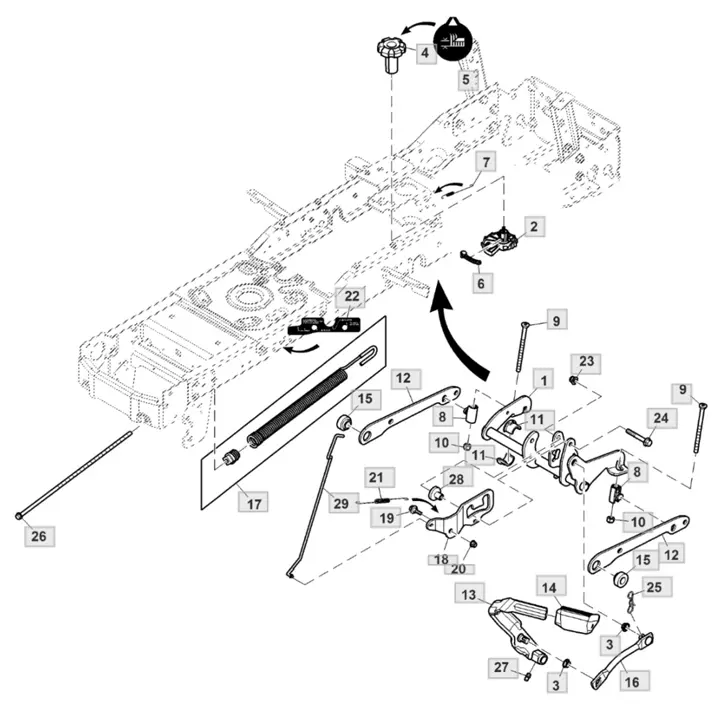

Transmission Parts and Their Arrangement

The functionality of any vehicle heavily relies on the effective coordination of its transmission components. These elements work in harmony to ensure smooth power transfer from the engine to the wheels, allowing for efficient operation and enhanced performance. Understanding the layout and role of each component is crucial for maintenance and repair, as it helps identify potential issues and optimize the overall system.

Key Components of the Transmission System

Within the transmission assembly, several vital elements contribute to its performance. The main components include the gearbox, clutch assembly, and drive shafts. The gearbox facilitates the changing of gears, allowing the vehicle to adapt to various speeds and loads. The clutch assembly plays a crucial role in engaging and disengaging the engine from the transmission, enabling smooth transitions between gears. Drive shafts transmit the torque generated by the engine to the wheels, propelling the vehicle forward.

Arrangement and Interaction of Components

The arrangement of these components is essential for the effective operation of the transmission system. Each part is strategically positioned to optimize space and facilitate seamless interaction. For instance, the gearbox is typically located centrally, allowing for direct connection to both the engine and the drive shafts. The clutch assembly is often placed between the engine and the gearbox, enabling quick engagement and disengagement. Proper alignment of these components is critical to prevent wear and tear, ensuring longevity and reliability.

Identifying Commonly Replaced Components

When it comes to maintaining and enhancing the performance of a specific type of equipment, recognizing frequently substituted elements is essential. These components often wear out due to regular use and exposure to various environmental factors, leading to a decline in overall functionality. Understanding which parts are prone to replacement can significantly aid in effective upkeep and prolong the lifespan of the machinery.

Component Description Signs of Wear Blades Essential for cutting grass and other vegetation. Dull edges, visible nicks or bends. Batteries Provides the necessary power for operation. Difficulty starting, reduced run time. Belts Transfers power between the engine and the cutting deck. Cracks, fraying, or slipping during operation. Filters Prevents dirt and debris from entering the engine. Reduced airflow, visible dirt buildup. Spark Plugs Ignites the fuel-air mixture for combustion. Hard starting, rough engine operation.

-