In any vehicle, the system responsible for navigating and controlling movement plays a crucial role in ensuring safety and efficiency. A comprehensive examination of this mechanism reveals various elements that contribute to its overall functionality. Each component is intricately designed to work in harmony, facilitating smooth handling and responsive maneuvers.

Familiarizing oneself with the intricate structure of these essential components can enhance one’s ability to maintain and troubleshoot the system effectively. Recognizing how these different elements interact allows for better insights into the mechanics involved in steering control. Understanding the arrangement and function of each piece can significantly aid in diagnosing issues and performing necessary repairs.

Whether you are a seasoned technician or an enthusiastic vehicle owner, grasping the layout and characteristics of these vital components empowers you to make informed decisions. This knowledge not only fosters a deeper appreciation for the engineering behind the mechanism but also promotes a proactive approach to maintenance and care.

Vehicle control systems are crucial for safe operation, and various complications can arise that impact performance and handling. Understanding these typical problems helps ensure safety and maintain optimal functionality.

Some prevalent challenges include:

- Worn Components: Over time, essential elements can deteriorate, leading to decreased responsiveness and increased play in the system.

- Fluid Leaks: Hydraulic fluid loss can result in reduced efficiency, causing difficulties in maneuvering.

- Noise Issues: Unusual sounds during operation often indicate underlying mechanical problems that require immediate attention.

- Alignment Problems: Misalignment can lead to uneven tire wear and unstable driving conditions, affecting overall safety.

- Electrical Failures: Malfunctions in electronic components can disrupt power assist features, resulting in increased steering effort.

Regular maintenance and timely inspections are essential to address these issues before they escalate, ensuring a smooth and safe driving experience.

Maintenance Tips for Steering Parts

Proper upkeep of the directional system is essential for ensuring a safe and smooth driving experience. Regular attention to these components can prevent costly repairs and enhance vehicle performance. Below are some practical suggestions for maintaining these crucial elements.

- Regular Inspections: Frequently check for signs of wear, damage, or looseness in the components. Early detection can help avoid more significant issues.

- Lubrication: Ensure all moving elements are adequately lubricated to reduce friction and wear. Use appropriate grease or oil as recommended by the manufacturer.

- Alignment Checks: Maintain proper alignment to improve handling and prevent uneven tire wear. Have the alignment checked at regular intervals or whenever you notice steering issues.

- Fluid Levels: Regularly monitor the hydraulic fluid levels if applicable. Low fluid levels can lead to diminished performance and potential damage.

- Cleaning: Keep the surrounding areas clean and free of debris to prevent contamination and ensure optimal functioning of the components.

By adhering to these maintenance practices, vehicle owners can extend the lifespan of the directional system and enjoy a safer driving experience.

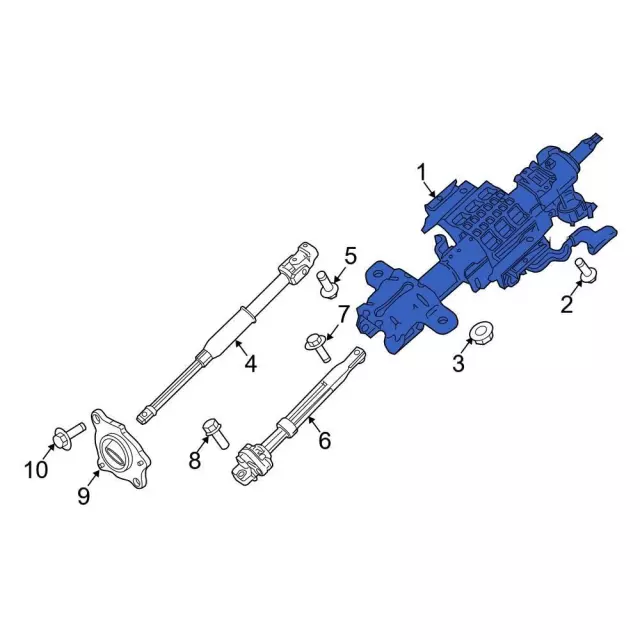

Replacing F250 Steering Components

Maintaining optimal handling and control of your vehicle often requires replacing various essential elements of the directional control system. Over time, wear and tear can affect performance, making timely replacement crucial for safety and efficiency.

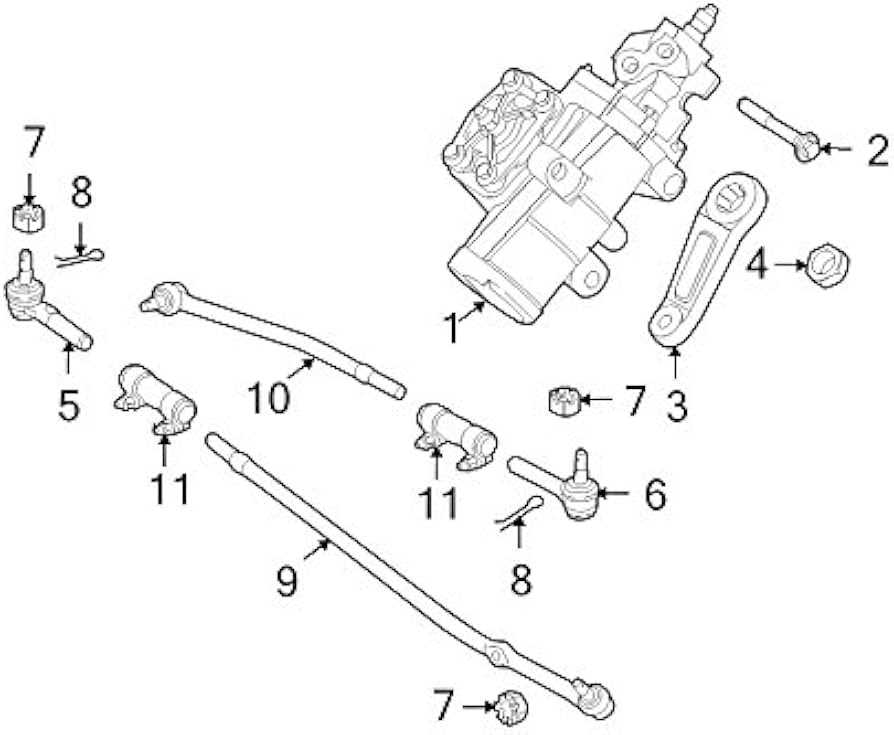

Identifying Components for Replacement

Before starting the replacement process, it’s important to identify which components require attention. Common elements that may need to be replaced include:

- Ball joints

- Linkages

- Power assist mechanisms

- Racks or boxes

Steps for Component Replacement

Follow these steps to ensure a smooth replacement procedure:

- Gather necessary tools and replacement components.

- Lift the vehicle securely and remove the wheels.

- Disconnect any connections to the affected components.

- Remove the old components carefully, noting the orientation and placement.

- Install the new components, ensuring proper alignment.

- Reattach any connections and wheels, then lower the vehicle.

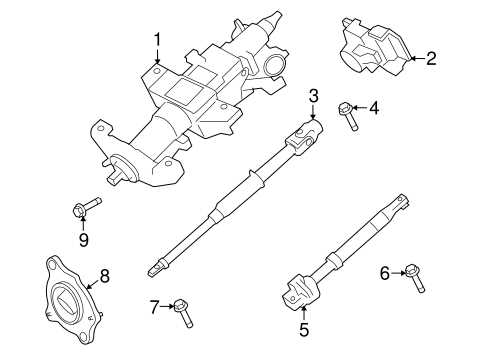

Identifying Components Using Visual Guides

Understanding the structure and functionality of various elements in a vehicle is crucial for maintenance and repair. Visual aids can simplify this process by providing clear representations of individual components and their arrangements. By utilizing these resources, one can efficiently recognize and differentiate between different pieces.

When utilizing visual guides, consider the following approaches:

- Study Labels: Pay attention to any annotations or labels on the guide, as they offer crucial information regarding each component’s name and function.

- Compare Shapes: Focus on the shapes and sizes of the components depicted. Identifying unique characteristics can aid in matching physical items with their representations.

- Trace Connections: Observe how each component connects to others. Understanding these relationships can clarify their roles within the overall assembly.

- Reference Multiple Sources: Cross-referencing different visual aids can provide a more comprehensive understanding and help identify discrepancies.

By following these guidelines, one can enhance their ability to recognize and work with individual components effectively, leading to more successful repairs and maintenance.

Tools Needed for Steering Repair

When undertaking repairs related to vehicle maneuverability, having the right tools is essential for ensuring efficiency and precision. A well-equipped toolkit can greatly simplify the process and help achieve optimal results.

Here’s a list of essential instruments that you should have on hand:

- Wrenches: A variety of sizes is necessary for loosening and tightening bolts.

- Sockets: A socket set is important for accessing hard-to-reach fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers are useful for various applications.

- Pliers: Needle-nose and regular pliers assist in gripping and manipulating components.

- Jack and Jack Stands: These are crucial for safely lifting the vehicle off the ground.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Oil Catch Pan: Helps manage fluid spills during the repair process.

- Inspection Mirror: Useful for viewing hard-to-see areas.

- Flashlight: Provides additional light in dimly lit spaces.

Having these tools readily available will streamline the repair process and contribute to a successful outcome.

Safety Considerations During Repairs

When undertaking maintenance tasks on vehicles, ensuring safety should always be a priority. Proper precautions can help prevent accidents and injuries, making the repair process more efficient and effective. Familiarizing oneself with safety protocols is essential for both novice and experienced mechanics.

Essential Safety Precautions

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Ensure the workspace is well-lit and free of clutter to minimize hazards.

- Use proper tools for each task to avoid injuries and equipment damage.

- Keep a fire extinguisher nearby in case of emergencies, especially when working with flammable materials.

Proper Vehicle Support

- Always use jack stands to support the vehicle after lifting it with a jack.

- Never rely solely on a hydraulic jack for support while working underneath a vehicle.

- Make sure the vehicle is on a flat, stable surface to prevent movement.