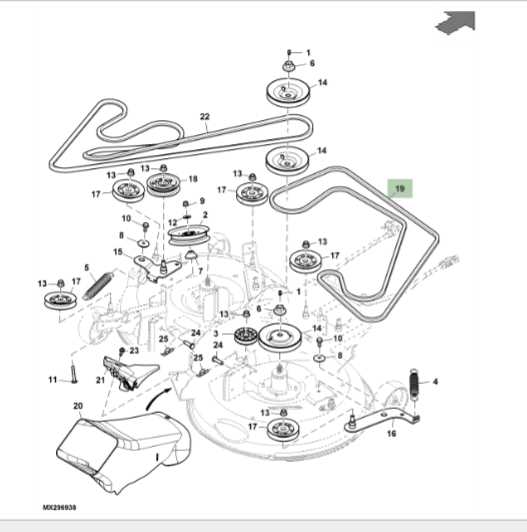

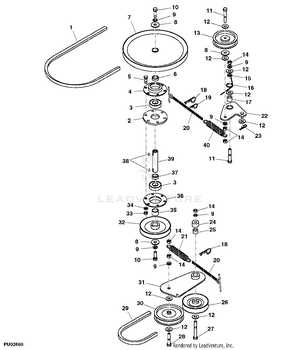

Understanding the various components of heavy machinery is essential for maintenance and repair. Each segment plays a crucial role in the overall functionality and efficiency of the equipment. By familiarizing oneself with these elements, operators and technicians can ensure optimal performance and longevity of the machinery.

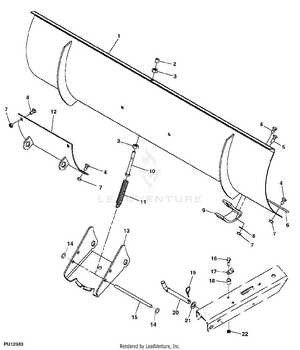

In this section, we will explore the intricate assembly of specific equipment, detailing the arrangement and interaction of different parts. A comprehensive visual representation allows for a clearer grasp of how each element contributes to the machine’s operations. This knowledge not only aids in troubleshooting issues but also enhances the ability to perform regular upkeep effectively.

For anyone involved in the operation or maintenance of such machinery, having access to a detailed outline of the components is invaluable. This resource serves as a guide for identifying necessary repairs and understanding the complex relationships among the various segments. Emphasizing the importance of each part fosters a more profound appreciation for the technology behind these powerful machines.

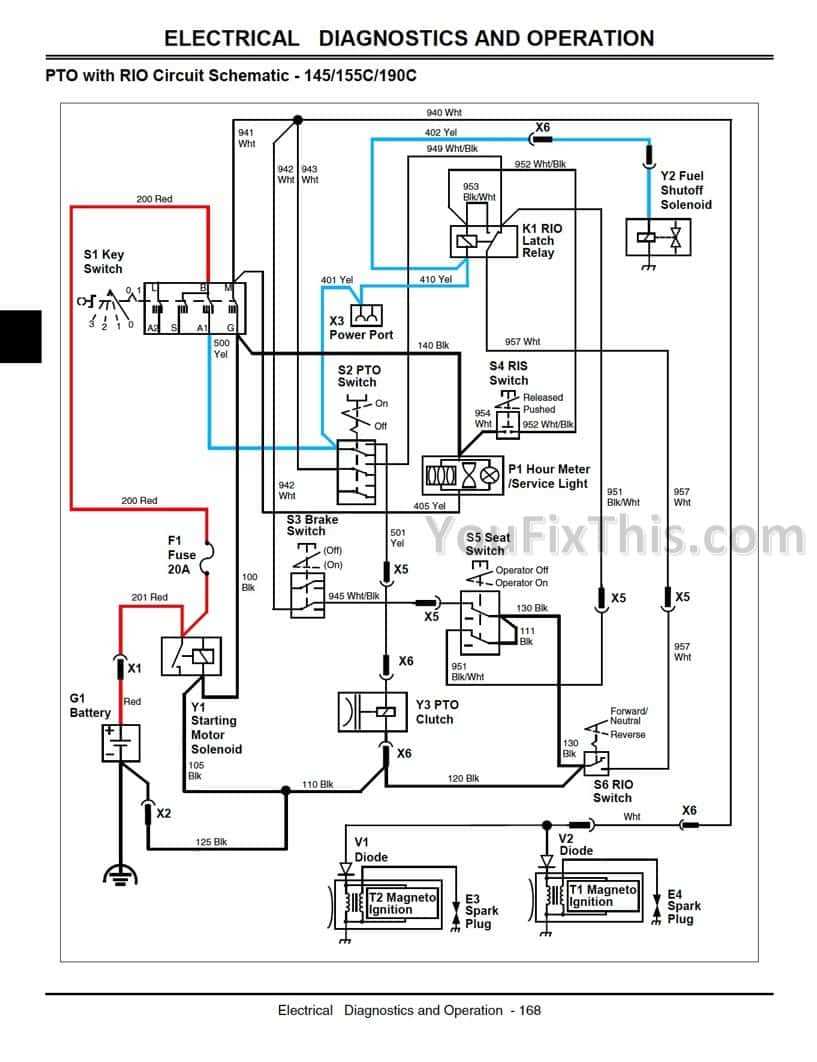

Understanding the components and their relationships within complex machinery is crucial for effective maintenance and repair. Visual representations play a significant role in providing clarity about how each element functions within a larger system.

Such illustrations offer numerous advantages:

- Enhanced Understanding: They simplify intricate assemblies, making it easier for technicians to identify and comprehend each component’s role.

- Improved Efficiency: Clear visuals reduce the time spent searching for parts, allowing for quicker repairs and maintenance tasks.

- Streamlined Communication: Diagrams facilitate discussions among team members, ensuring everyone is on the same page regarding repair procedures.

- Accurate Ordering: When replacement components are required, visual aids help ensure that the correct items are ordered, minimizing errors and delays.

Utilizing these resources effectively contributes to the longevity and performance of the machinery, ultimately leading to reduced downtime and enhanced productivity.

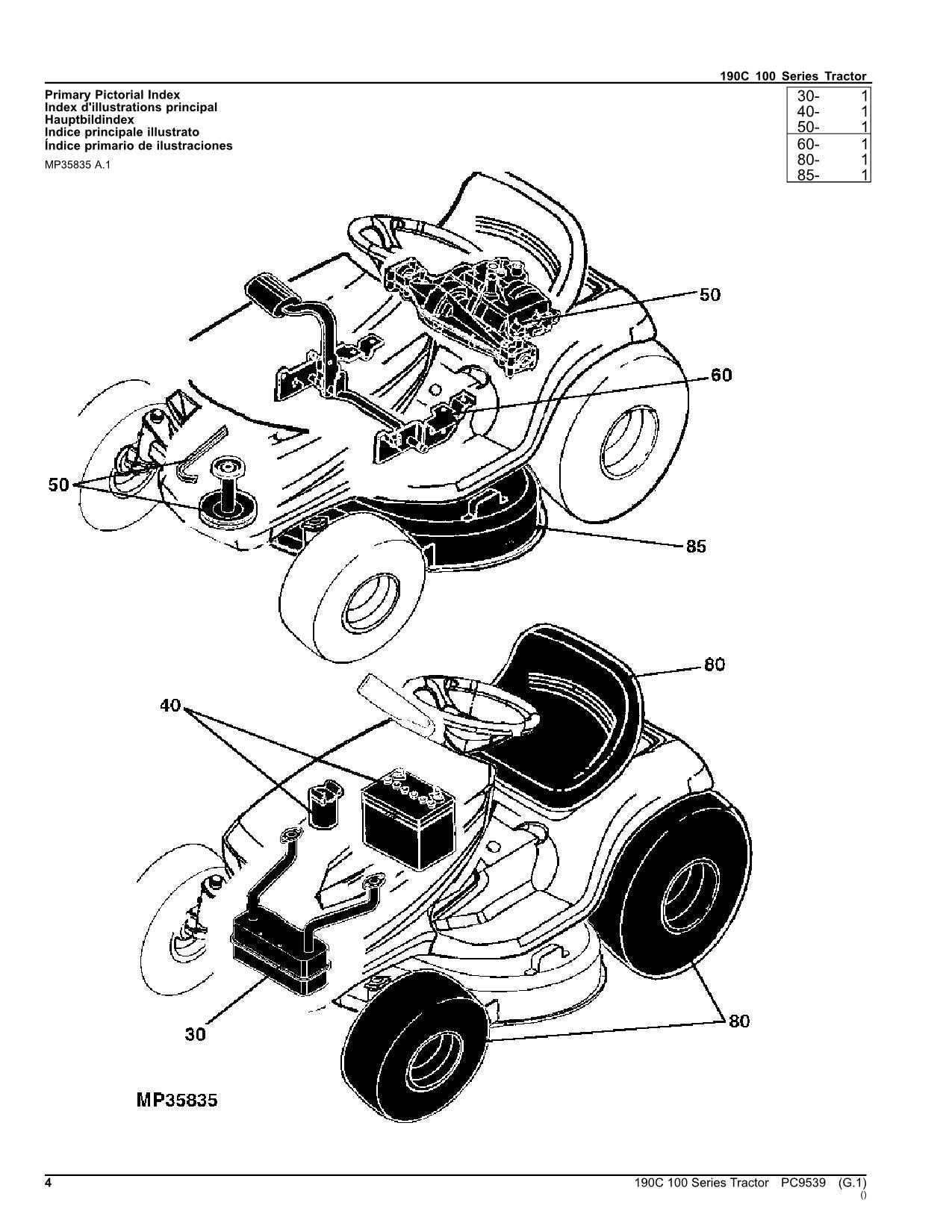

Key Components of the 190C

This section focuses on the essential elements that contribute to the functionality and efficiency of this machinery. Understanding these components is crucial for anyone involved in maintenance, repair, or operation, as they play vital roles in overall performance.

| Component | Description |

|---|---|

| Engine | The heart of the machine, responsible for generating power and driving the various systems. |

| Hydraulic System | Facilitates movement and operation of attachments, providing the necessary force for lifting and digging tasks. |

| Transmission | Transfers power from the engine to the wheels, enabling smooth movement and speed control. |

| Chassis | The frame that supports all other components, providing stability and durability during operation. |

| Electrical System | Manages power distribution to various electronic components, ensuring proper functionality of lights, controls, and sensors. |

How to Read Parts Diagrams

Understanding the visual representations of components is crucial for effective maintenance and repair. These illustrations serve as a guide, showcasing the various elements and their interconnections within a machine. By familiarizing oneself with these visuals, one can streamline the process of identifying necessary components and ensuring proper assembly.

Initially, it is essential to grasp the layout. Typically, these illustrations will feature a key or legend that explains the symbols used. Familiarizing yourself with these symbols will enable you to quickly recognize specific elements and their functions. Additionally, pay attention to any annotations that provide further details on installation or adjustment procedures.

As you analyze the representation, note how the elements are grouped. Often, related components are depicted together, which can help in understanding their interactions. This grouping not only aids in identification but also assists in visualizing how each part fits into the overall system.

Lastly, cross-referencing the visual guide with the manufacturer’s documentation can enhance your comprehension. This practice ensures that you have the most accurate information at your disposal, facilitating successful repairs or replacements. By applying these strategies, reading these visuals becomes an intuitive and effective task.

Common Replacement Parts

Maintenance and repair of machinery often necessitate the replacement of various components to ensure optimal functionality. Understanding which elements frequently require substitution can significantly enhance the longevity and performance of the equipment. This section outlines essential components typically replaced during servicing.

Filters: Regularly changing oil and air filters is crucial for maintaining clean systems and ensuring efficient operation. Neglecting these can lead to engine damage and decreased performance.

Belts: Over time, belts can wear out due to constant use and exposure to environmental factors. Timely replacement of these items helps avoid breakdowns and operational inefficiencies.

Batteries: Power sources can degrade over time, leading to starting issues. Replacing batteries ensures reliable functionality and prevents unexpected failures.

Hoses: Rubber hoses may deteriorate from wear and tear or exposure to heat. Regular inspections and timely replacements are essential for preventing leaks and maintaining performance.

Lubricants: Keeping machinery well-lubricated is vital for smooth operation. Regularly replenishing lubricants minimizes friction and extends the life of moving parts.

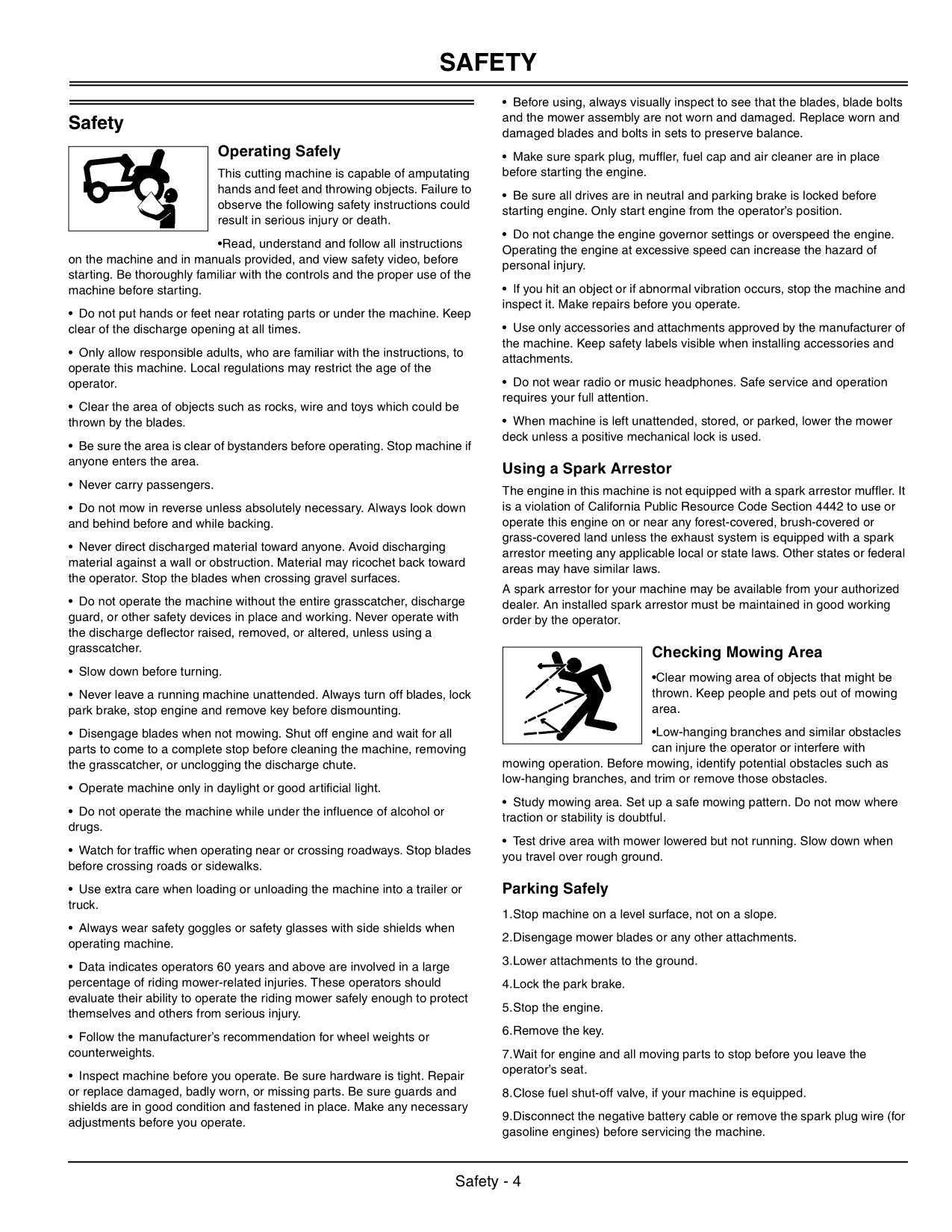

Maintenance Tips for Longevity

Ensuring the long-lasting performance of machinery requires diligent care and regular upkeep. By following best practices in maintenance, you can significantly extend the lifespan of your equipment and enhance its efficiency. This section highlights essential tips to keep your machinery in optimal condition.

- Regular Inspections: Conduct frequent visual checks for any signs of wear or damage. Early detection of issues can prevent costly repairs.

- Fluid Checks: Regularly monitor and replace fluids such as oil, coolant, and hydraulic fluid to ensure smooth operation.

- Clean Components: Keep the machine free from dirt and debris. Regular cleaning of filters and air intakes will promote better performance.

- Tighten Bolts and Fasteners: Periodically check and tighten bolts and other fasteners to avoid unnecessary vibrations and potential failures.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule recommended by the manufacturer for optimal performance and reliability.

- Use Quality Parts: When replacements are necessary, opt for high-quality components to ensure compatibility and durability.

By implementing these maintenance strategies, you can enhance the reliability and efficiency of your machinery, ensuring it remains a valuable asset for years to come.

Where to Find Genuine Parts

When it comes to maintaining machinery, sourcing authentic components is essential for ensuring optimal performance and longevity. Reliable suppliers provide the assurance that each replacement item meets the original specifications, which is crucial for the smooth operation of your equipment.

Authorized Dealers

One of the most dependable avenues for acquiring genuine components is through authorized dealers. These establishments are officially recognized and typically maintain a comprehensive inventory of original products. Engaging with an authorized dealer not only guarantees authenticity but also offers expert guidance tailored to your specific needs.

Online Retailers

The digital marketplace has expanded significantly, presenting a convenient option for sourcing authentic items. Reputable online platforms often feature extensive selections, competitive pricing, and customer reviews to assist in making informed decisions. Ensure that the retailer is verified to avoid counterfeit products, as this can compromise the quality and reliability of your machinery.

Understanding Part Numbering System

The organization of component identification is crucial for effective maintenance and repairs in machinery. A systematic approach to labeling each element enables operators and technicians to quickly locate and reference the necessary items. This structured method of identification not only simplifies the ordering process but also enhances communication among different stakeholders in the industry.

Typically, the numbering system comprises a combination of letters and numbers, which convey specific information about the item. Each segment of the code can represent various attributes such as size, type, or compatibility with other units. Understanding this structure is essential for anyone involved in equipment management or repair services.

| Code Segment | Description |

|---|---|

| Prefix | Indicates the category of the component (e.g., hydraulic, electrical). |

| Numeric Sequence | Represents the unique identifier for the specific item. |

| Suffix | Denotes special features or revisions related to the item. |

By familiarizing oneself with the numbering convention, individuals can improve their efficiency in acquiring and managing machinery elements. This knowledge is invaluable for ensuring proper operation and longevity of equipment.