When it comes to maintaining and servicing agricultural machinery, having a clear understanding of the various components and their locations is essential. Knowing how each part fits and functions within the overall system ensures that repairs and replacements can be done efficiently and effectively.

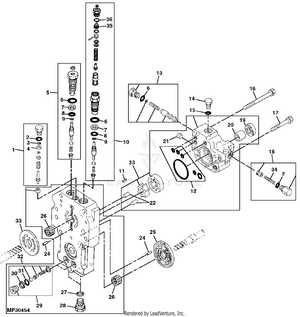

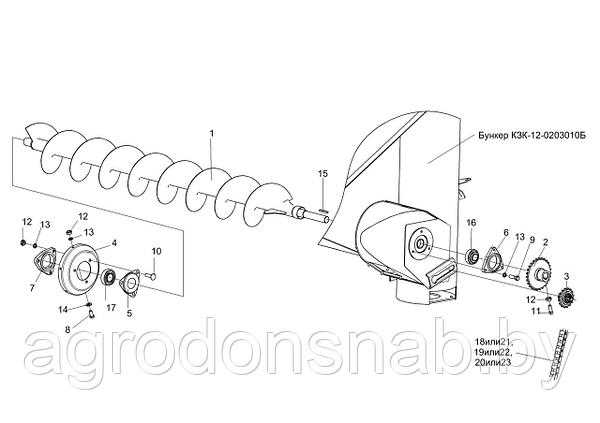

Detailed illustrations of machine elements allow technicians and operators to visualize the internal structure of complex equipment. These representations not only aid in troubleshooting, but they also simplify the process of finding the right components for upkeep and repairs.

With precise visual guides, the task of identifying mechanical elements becomes much easier, ensuring that maintenance tasks can be carried out with confidence and accuracy. This knowledge is invaluable for ensuring that machines continue to operate smoothly for years to come.

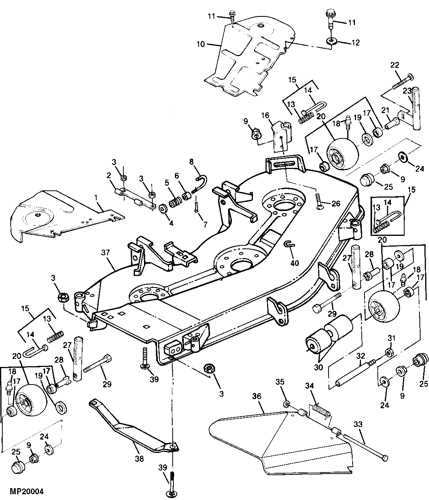

Component Overview for a Popular Garden Tractor

Understanding the key elements of this versatile garden tractor is essential for efficient maintenance and repair. Each component works together to ensure smooth operation, providing the user with reliable performance across various landscaping tasks. This section provides insight into the structure and functioning of its mechanical and electrical systems.

Engine and Transmission Systems

The power unit and drivetrain are fundamental to the vehicle’s functionality. The engine generates the necessary force, while the transmission converts it into usable energy to drive the tractor. Ensuring proper upkeep of these elements will prolong the machine’s lifespan and enhance its operational efficiency.

Hydraulics and Electrical Components

Hydraulic systems play a critical role in managing attachments and lifting mechanisms, offering flexibility for a range of tasks. Equally important are the electrical components, which control vital systems such as ignition, lighting, and

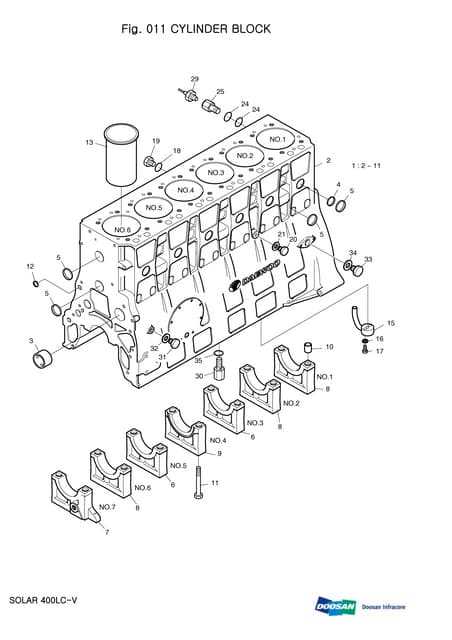

Engine Components Breakdown

The internal combustion engine is a complex system composed of various essential parts working together to generate power. Understanding how these elements interact is crucial for maintenance and repair. This section provides an overview of the major components that ensure efficient engine operation, emphasizing their roles in the overall function.

- Cylinder Block: The foundation of the engine, housing vital components such as cylinders and pistons. It forms the structural framework for the engine’s core functions.

- Pistons: These move within the cylinders, converting energy from combustion into mechanical motion, driving the crankshaft.

- Crankshaft: Responsible for translating the vertical motion of the pistons into rotational force, which powers other engine systems.

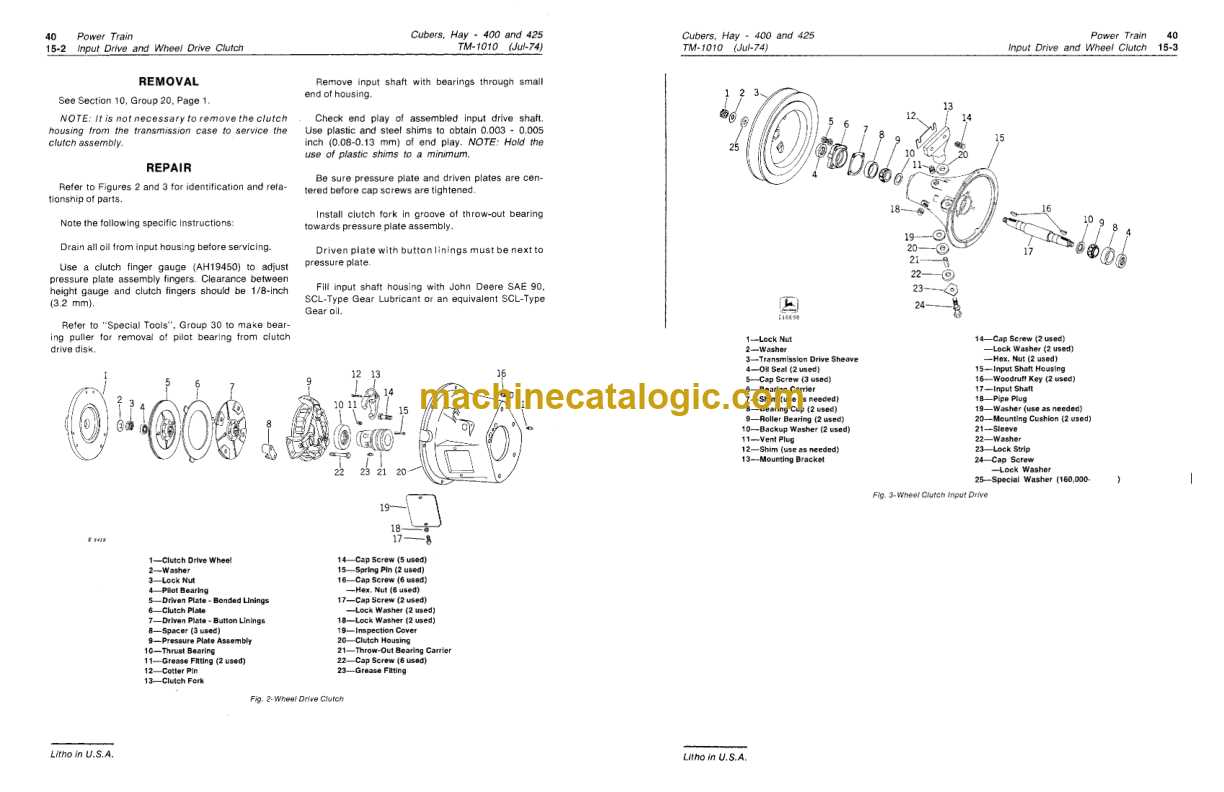

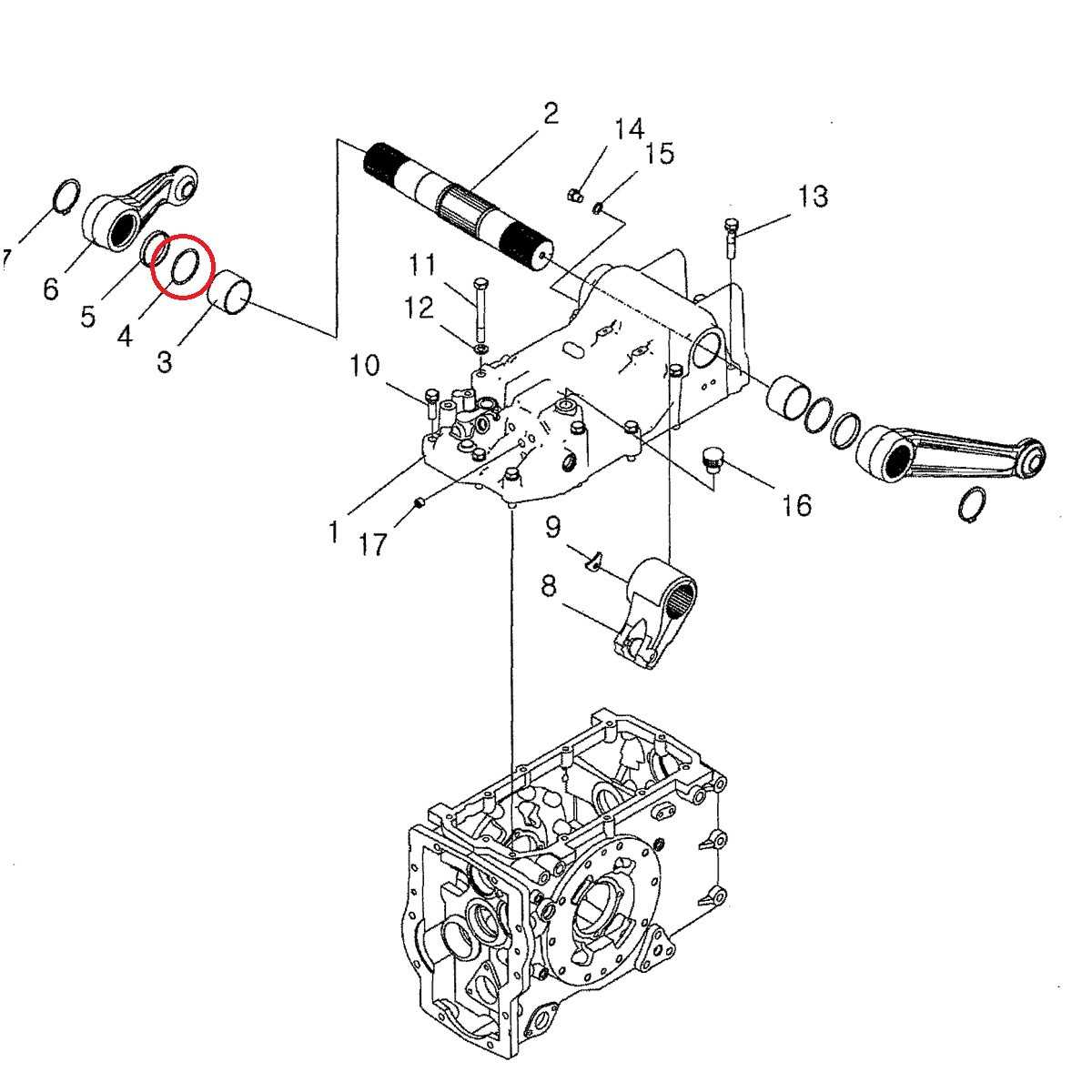

- Transmission System Details

The transmission system plays a critical role in ensuring smooth operation and performance. It is responsible for transferring power efficiently, allowing for seamless transitions between gears and delivering the necessary force to drive the vehicle under various conditions. Understanding the components and their functions within this system is key to maintaining optimal performance and reliability.

Core Components and Functions: The transmission is comprised of various interconnected parts that work together to regulate speed and torque. These elements include the clutch mechanism, gear assembly, and drive shafts, each playing a distinct role in power distribution. Regular maintenance of these components is crucial to avoid issues like slipping gears or reduced efficiency.

Maintenance and Care: Regular inspections and timely lubrication can extend the lifespan of the transmission system. Issues such as leaks, unusual noises, or delayed gear shifts should be addressed promptly to prevent more severe problems. Following a structured maintenance

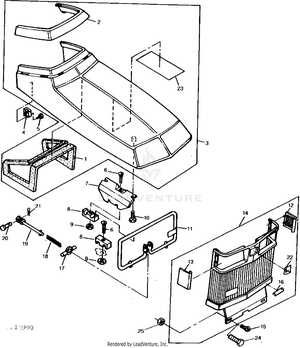

Electrical System and Wiring

The electrical system plays a vital role in ensuring the reliable functioning of any machine. It consists of several interconnected components that work together to distribute power to various elements, ensuring smooth operation. Proper wiring is essential for maintaining system efficiency and avoiding issues like short circuits or component failures.

Below is an overview of the main aspects that should be considered when assessing the electrical setup:

- Power distribution – how energy flows from the power source to key components.

- Wiring harnesses – organized bundles of cables that connect different parts of the system.

- Connectors and terminals – points where wires join or interface with other components.

- Fuse and circuit protection – safeguards to prevent electrical overloads.

- Grounding – ensuring safe discharge of excess electricity to protect the system.

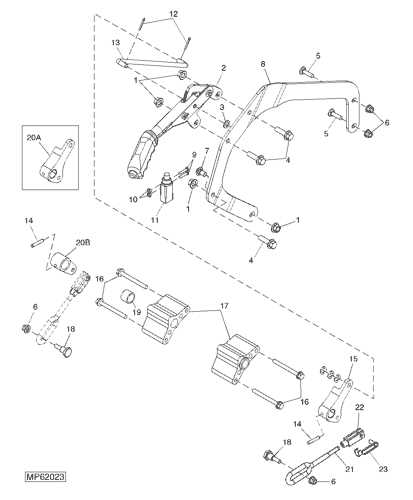

Steering Mechanism Assembly

The steering mechanism plays a crucial role in ensuring smooth and controlled maneuverability of the vehicle. This system consists of multiple interconnected components that work together to translate the driver’s input into precise directional movements. Regular maintenance and understanding the arrangement of these elements are essential for optimal performance and safety.

Main Components

- Steering wheel – the primary input device for controlling direction.

- Steering shaft – connects the wheel to the rest of the mechanism.

- Gearbox – transfers input from the wheel to the wheels, adjusting the angle of turn.

- Linkage system – transmits force from the gearbox to the wheels, ensuring accurate movement.

Common Issues and Maintenance Tips

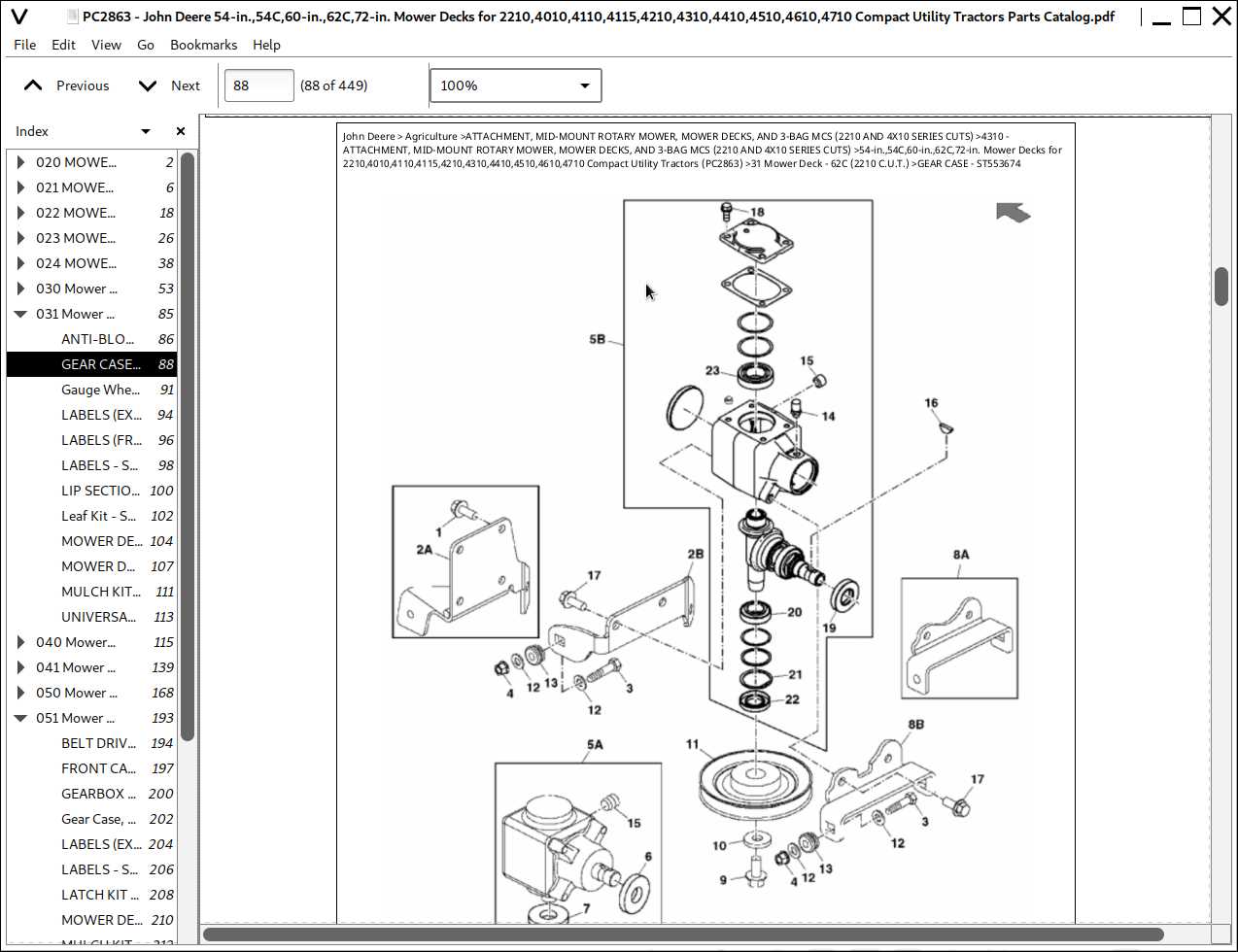

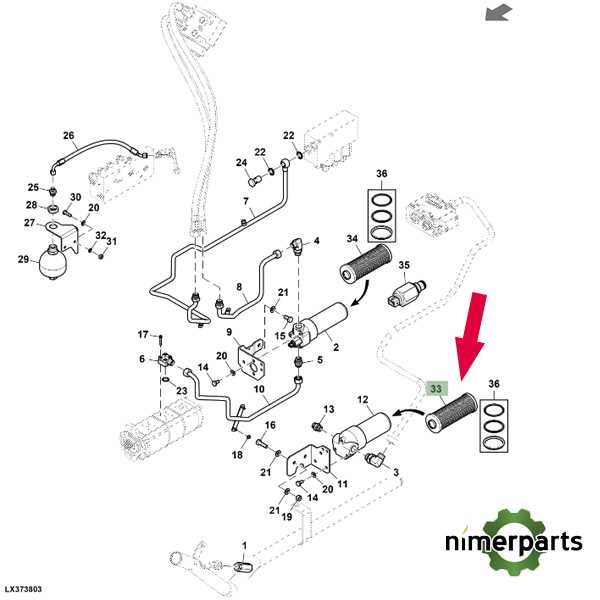

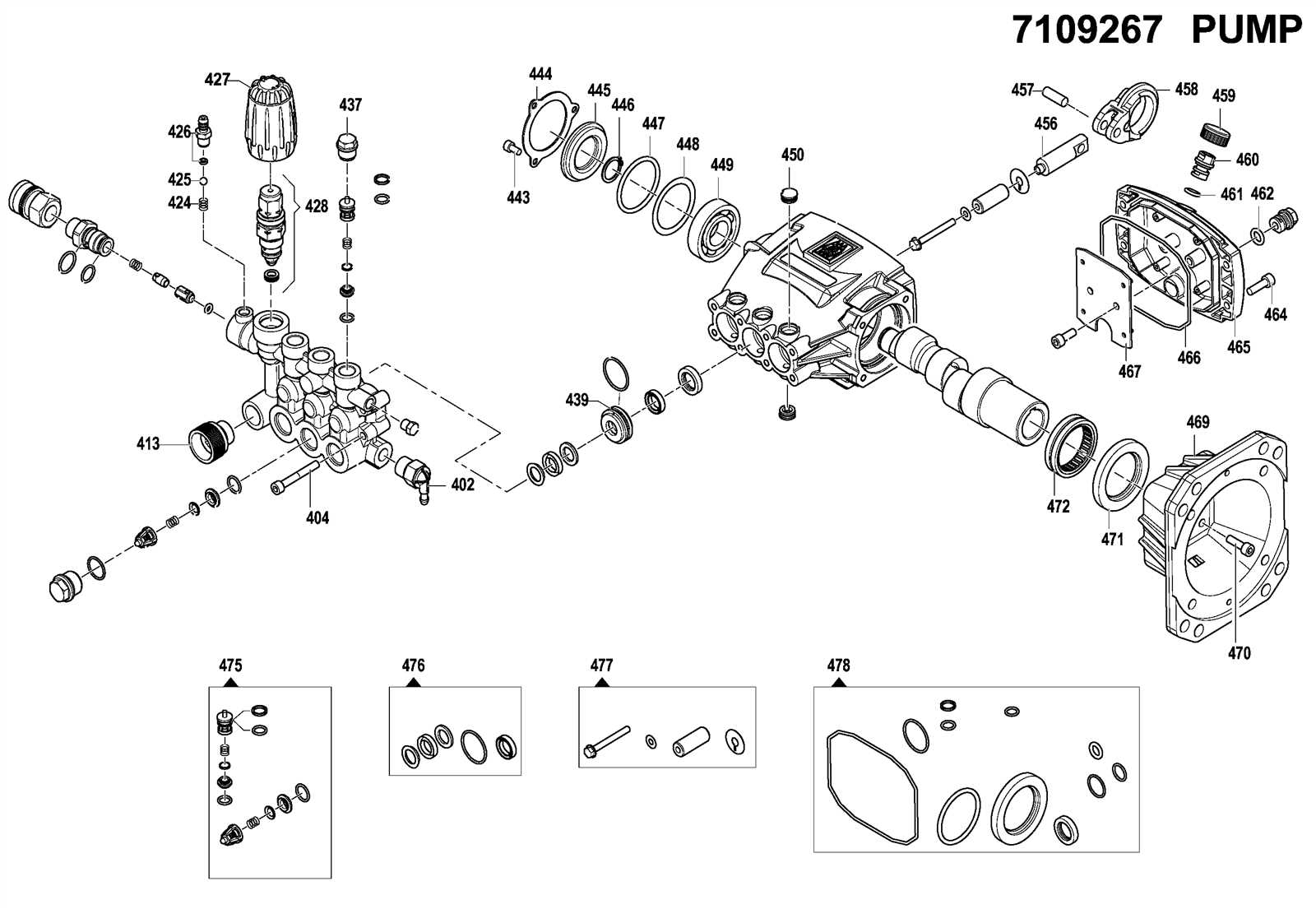

Hydraulic Parts and Functionality

The hydraulic system plays a crucial role in the operation of various machinery, ensuring the efficient transfer of power and control over different functions. This system utilizes fluid mechanics to create force, enabling the movement and manipulation of components with precision and strength. Understanding the key elements of this system is essential for maintaining optimal performance and achieving desired outcomes.

Key Components

Several fundamental elements comprise the hydraulic mechanism, each contributing to its overall effectiveness. Pumps are vital for generating fluid flow, while cylinders convert hydraulic energy into mechanical motion. Additionally, valves regulate the flow and pressure of the fluid, ensuring that the system operates smoothly.

Functionality Overview

In essence, the hydraulic system allows for enhanced operational capabilities, such as lifting, pushing, and pulling heavy loads with minimal effort. By controlling fluid flow through various channels, operators can achieve precise movements and adjustments. This functionality not only improves productivity but also ensures that tasks are completed safely and efficiently.

Chassis and Frame Components

The structural foundation of any machinery is vital for its overall performance and durability. The assembly of the framework significantly influences stability, strength, and the machine’s ability to withstand various operating conditions. Understanding these components is essential for maintenance and ensuring optimal functionality.

- Frame: The primary support structure that holds all other components together. It provides rigidity and balance during operation.

- Subframe: An additional framework that supports specific parts, enhancing the overall strength of the main frame.

- Brackets: These components connect different parts to the main structure, allowing for secure attachments and stability.

- Hitch: A critical component for connecting various attachments or trailers, ensuring secure transportation and operation.

- Cross members: Reinforcement pieces that add strength to the frame, preventing flexing and improving durability.

Each of these elements plays a crucial role in the machine’s performance and longevity. Regular inspection and maintenance of the frame and its components are necessary to prevent issues that may arise from wear and tear.

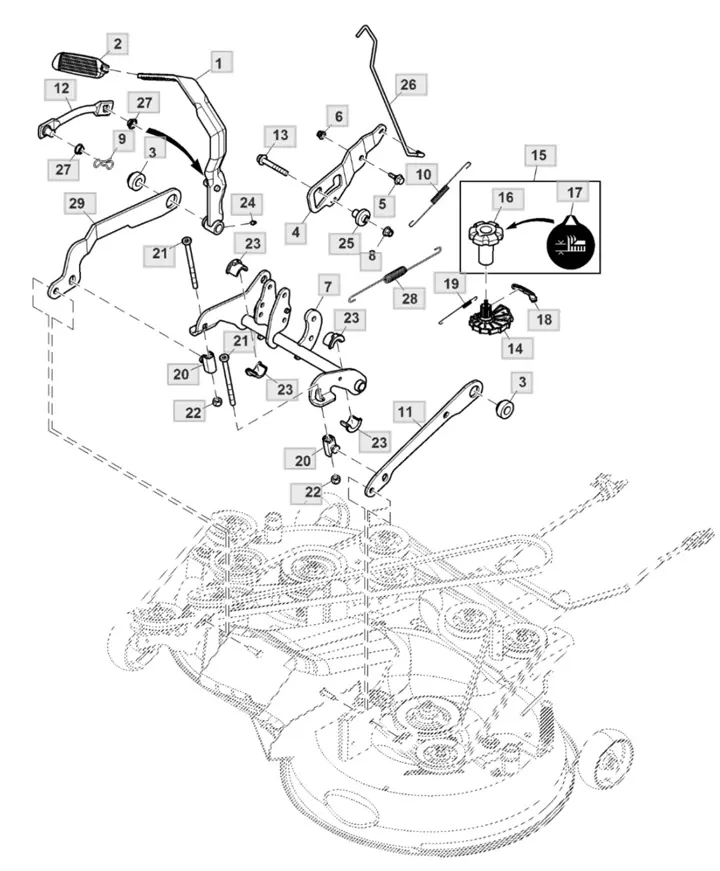

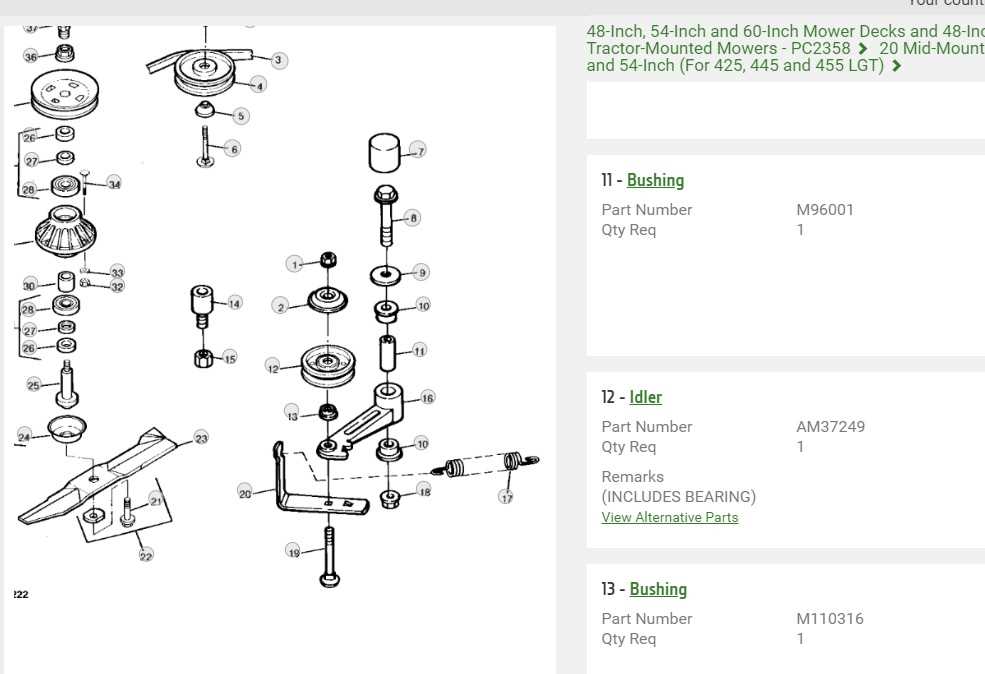

Attachment Compatibility and Diagrams

Understanding the various attachments available for your equipment is essential for optimal performance and versatility. Different implements are designed to enhance functionality, enabling users to tackle a wide range of tasks efficiently. This section explores the compatibility of various accessories and provides visual representations to facilitate informed decision-making.

Each attachment is tailored to specific models, ensuring a proper fit and seamless integration. By referring to detailed schematics, operators can easily identify compatible implements, enhancing their operational capabilities. These visual aids serve as invaluable resources for users looking to expand their equipment’s functionality and maximize productivity.

In summary, knowing which attachments work best with your machinery can significantly impact efficiency and effectiveness. Utilizing the provided diagrams will streamline the selection process, ensuring you choose the right tools for your tasks.

Maintenance Tips for Key Parts

Proper upkeep of essential components is vital for the longevity and efficiency of any machine. Regular attention ensures that all elements function harmoniously, reducing the likelihood of unexpected failures and costly repairs. Understanding the requirements of specific components can significantly enhance performance and reliability.

Regular Inspections

Frequent examinations of critical elements are crucial. Look for signs of wear, rust, or damage. Timely detection of issues allows for prompt repairs or replacements, preventing further complications down the line. Establish a routine that includes checking fluid levels and assessing overall condition.

Lubrication and Cleaning

Maintaining cleanliness and lubrication is essential for smooth operation. Accumulation of debris can lead to inefficiencies, while proper lubrication minimizes friction and wear. Use recommended lubricants and clean surfaces regularly to keep everything running smoothly and prolong the lifespan of components.