In the realm of agricultural equipment, comprehending the intricate network of components is essential for efficient maintenance and repair. Every machine is a culmination of various elements that work harmoniously to achieve optimal performance. Grasping how these pieces interconnect can greatly enhance one’s ability to troubleshoot and execute repairs effectively.

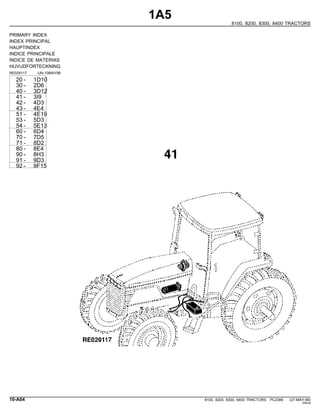

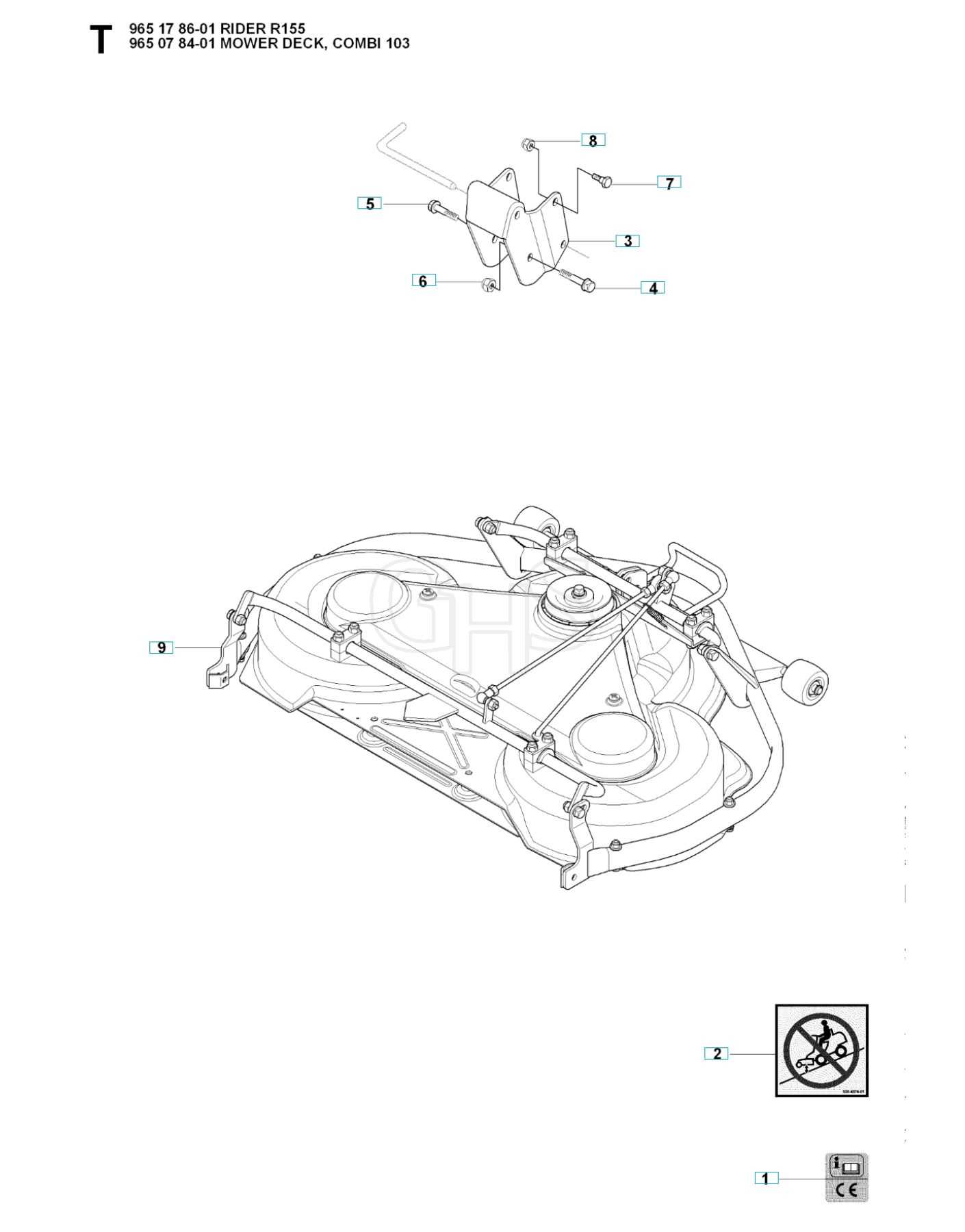

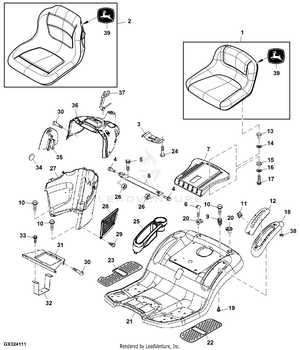

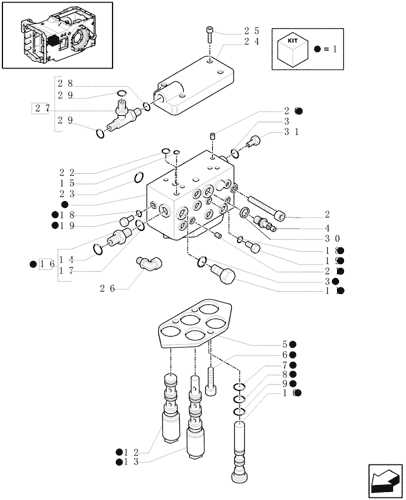

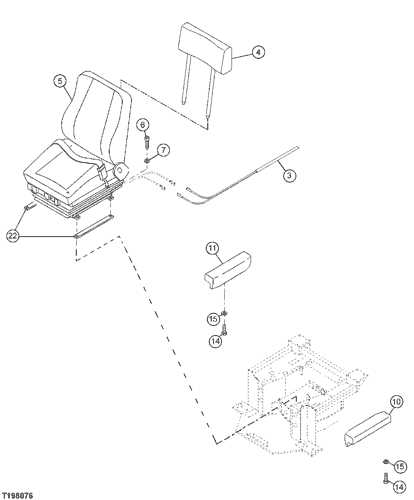

Detailed visual representations serve as invaluable tools for anyone looking to delve deeper into machinery specifics. These illustrations not only highlight the layout of each component but also offer insights into their functionality and placement. By examining these visual aids, users can gain a clearer understanding of the mechanical structure and operational dynamics.

Whether you are a seasoned technician or a novice enthusiast, having access to these resources can elevate your knowledge to the ultimate level. Engaging with these materials fosters a comprehensive grasp of how various sections contribute to the machine’s overall efficiency, paving the way for informed decision-making and successful upkeep.

Understanding John Deere 115 Components

Grasping the essentials of agricultural machinery is crucial for optimal performance and maintenance. Familiarity with the various elements involved can enhance operational efficiency and prolong the lifespan of the equipment. By examining the intricate network of components, users can identify issues promptly and ensure smooth functionality.

Key Elements

The primary components consist of the engine, transmission, and cutting mechanism. Each plays a vital role in the overall effectiveness of the machine. Regular inspection and maintenance of these units are essential for seamless operation.

Maintenance Tips

To keep everything running smoothly, it’s important to follow a consistent maintenance routine. Check fluid levels, replace worn-out components, and ensure all connections are secure. Preventive care can save time and resources in the long run, ultimately enhancing productivity.

Importance of Parts Diagrams

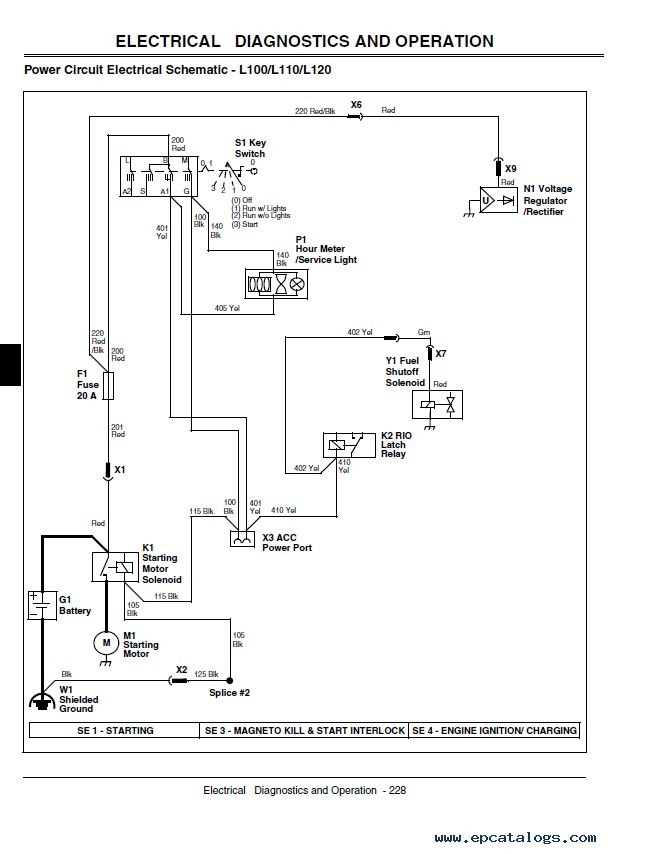

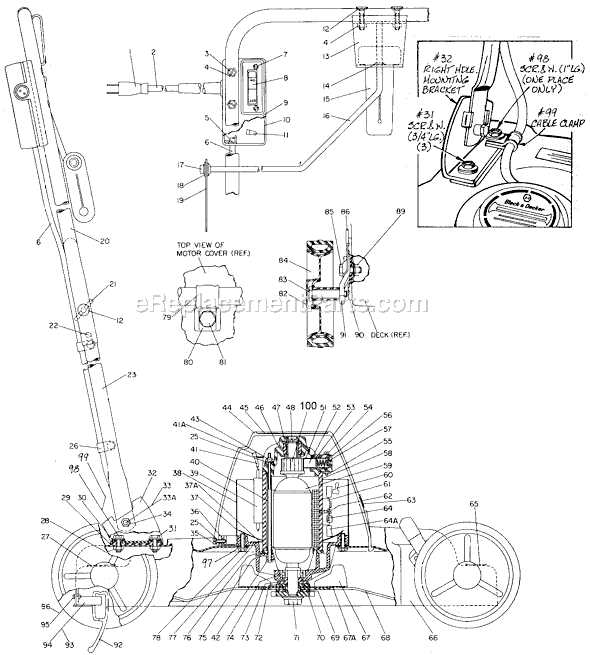

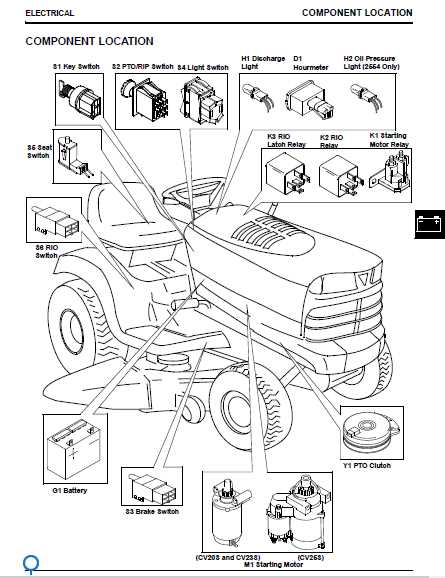

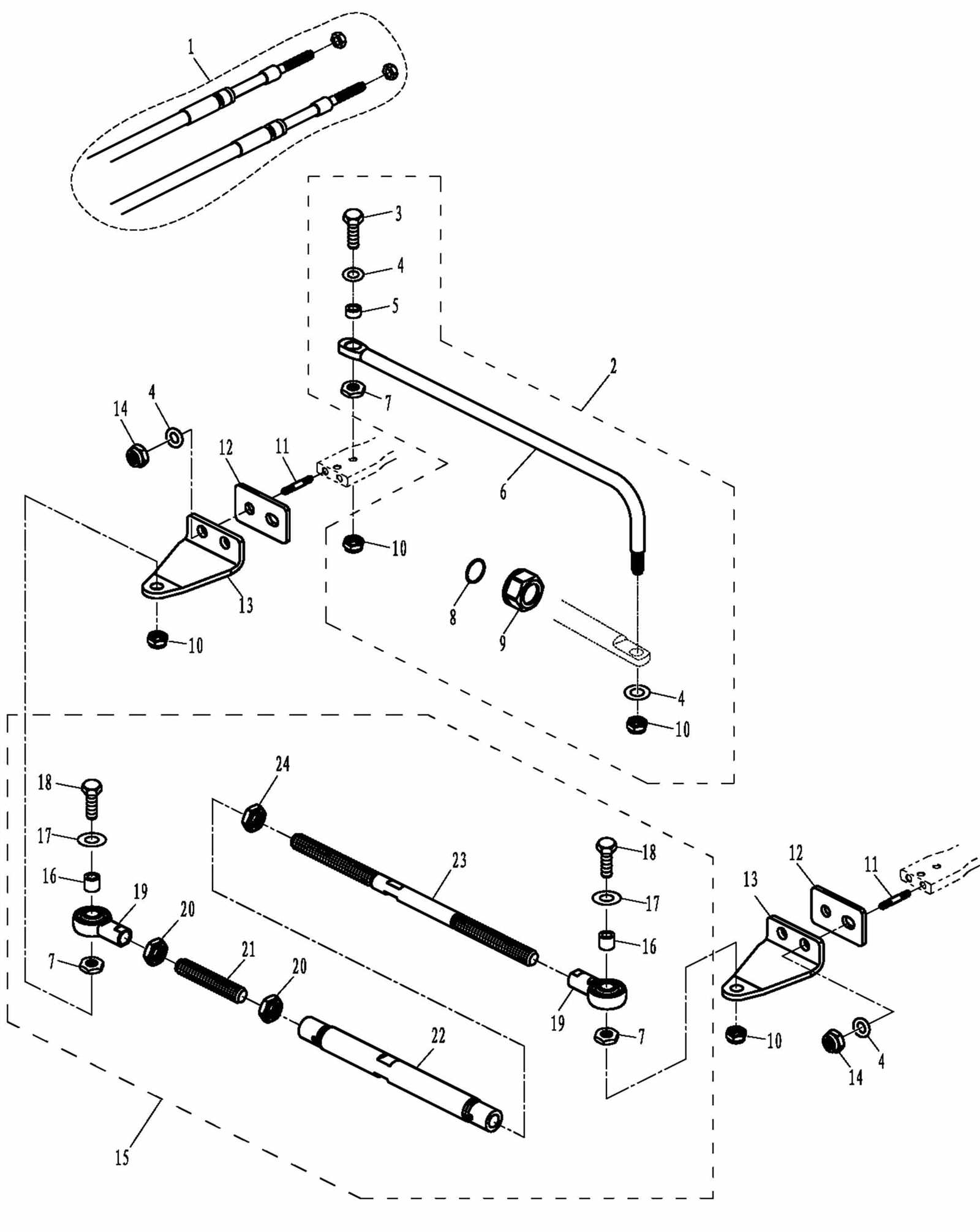

Visual representations of components play a crucial role in understanding and maintaining complex machinery. These illustrations serve as essential tools for users, enabling them to identify various elements and their functions within a system. By utilizing these resources, operators can enhance their knowledge and improve their ability to troubleshoot and repair equipment effectively.

Moreover, these visuals promote efficiency during maintenance tasks. When technicians have access to clear schematics, they can quickly locate specific components, ensuring timely and accurate repairs. This not only minimizes downtime but also reduces the risk of errors that could arise from misidentifying parts.

| Benefits | Description |

|---|---|

| Improved Understanding | Enhances knowledge of machinery and its components. |

| Efficient Repairs | Facilitates quicker identification of necessary elements. |

| Reduced Errors | Minimizes mistakes during maintenance and troubleshooting. |

| Time Savings | Decreases downtime by streamlining repair processes. |

In conclusion, having access to clear and detailed visual guides is vital for effective equipment maintenance. These resources empower users to navigate the complexities of their machines, leading to more informed decisions and improved operational reliability.

Common Issues with John Deere 115

Various challenges can arise when operating certain models of lawn and garden equipment, impacting their performance and longevity. Understanding these common problems can help users maintain their machines effectively.

- Engine Starting Difficulties

- Electrical System Failures

- Transmission Issues

- Overheating Problems

- Blade Malfunction

Regular maintenance and timely troubleshooting are essential for resolving these concerns. Here are some frequent symptoms associated with each issue:

- Engine Starting Difficulties

- Weak battery

- Fuel delivery problems

- Electrical System Failures

- Corroded connections

- Defective switches

- Transmission Issues

- Slipping gears

- Fluid leaks

- Overheating Problems

- Blocked air vents

- Low coolant levels

- Blade Malfunction

- Dull or damaged blades

- Improper alignment

Addressing these issues promptly can ensure a smoother and more efficient operation of the equipment.

Where to Find Replacement Parts

Finding suitable components for your equipment can be essential for maintaining optimal performance and longevity. Whether you’re looking to restore functionality or upgrade certain features, identifying reliable sources for these items is crucial. Here are some effective avenues to explore.

Online Retailers

- Search for specialized websites that focus on agricultural machinery.

- Check e-commerce platforms that offer a wide range of options from various brands.

- Visit manufacturer websites for official offerings and recommendations.

Local Dealers and Distributors

- Contact nearby dealerships that specialize in heavy machinery.

- Ask about local distributors who may have the necessary components in stock.

- Inquire about any partnerships with manufacturers for exclusive products.

By exploring these resources, you can enhance your chances of finding the right components for your machinery efficiently.

Maintenance Tips for Lawn Tractors

Proper upkeep of your lawn tractor is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. Here are some key practices to help you keep your machine in top shape.

- Regular Inspections: Check your tractor frequently for signs of wear and tear. Look for loose bolts, frayed belts, and leaks.

- Clean the Deck: After each use, remove grass clippings and debris from the mower deck to prevent buildup and rust.

- Change the Oil: Regularly changing the oil is crucial for engine health. Follow the manufacturer’s recommendations for oil type and change intervals.

- Sharpen Blades: Keeping the blades sharp ensures a clean cut and reduces strain on the engine. Aim to sharpen them at least once a season.

- Check Tire Pressure: Properly inflated tires improve traction and help achieve an even cut. Inspect them regularly.

- Replace Air Filters: A clean air filter promotes efficient engine performance. Change it as recommended in the owner’s manual.

- Fuel Maintenance: Use fresh fuel and consider adding a fuel stabilizer if the tractor will sit unused for an extended period.

By adhering to these maintenance tips, you can ensure your lawn tractor operates smoothly and efficiently, helping you maintain a beautiful lawn with minimal hassle.

Using Diagrams for Troubleshooting

Visual representations play a crucial role in identifying and resolving issues within machinery. These illustrations provide a clear overview of components and their interconnections, allowing users to pinpoint problems more efficiently. By breaking down complex systems into understandable sections, one can enhance the troubleshooting process significantly.

Effective problem-solving often relies on these visual aids, as they help users to quickly recognize discrepancies or malfunctions. Furthermore, utilizing such resources minimizes the risk of oversight, ensuring that no critical element is neglected during inspections.

Incorporating diagrams into maintenance routines fosters a more systematic approach, ultimately leading to improved performance and longevity of equipment. By understanding how parts interact, operators can take proactive measures to prevent potential failures before they arise.

Benefits of Genuine John Deere Parts

Using authentic components for machinery ensures optimal performance and longevity. These elements are designed to fit seamlessly, offering superior reliability and efficiency compared to generic alternatives. Here are some key advantages of choosing genuine items for your equipment.

| Advantage | Description |

|---|---|

| Quality Assurance | Authentic components undergo rigorous testing to meet high standards, ensuring durability and effectiveness. |

| Perfect Fit | These components are engineered specifically for your machine, promoting seamless integration and reducing wear. |

| Enhanced Performance | Utilizing original elements can significantly improve the overall functionality and efficiency of your equipment. |

| Warranty Protection | Using genuine components helps maintain warranty coverage, safeguarding your investment against unexpected repair costs. |

| Long-Term Savings | Though initial costs may be higher, authentic components often result in lower maintenance costs over time due to their reliability. |

Aftermarket vs. OEM Components

When it comes to machinery maintenance, choosing between different types of components can significantly impact performance and longevity. One crucial distinction is between original equipment manufacturer (OEM) parts and their aftermarket counterparts. Understanding the differences can help users make informed decisions tailored to their specific needs.

OEM components are produced by the original manufacturer of the equipment, ensuring a perfect fit and adherence to the original specifications. These items often come with a warranty and are designed to maintain the integrity of the machine as intended by the designer. As a result, users can have peace of mind regarding compatibility and performance.

On the other hand, aftermarket parts are created by third-party manufacturers. They may offer a variety of options, sometimes at a lower cost, and can provide enhanced features or improved performance. However, the quality and fit can vary, and potential compatibility issues may arise. While many aftermarket parts are reliable, it is essential for users to research and select reputable brands to avoid pitfalls.

Ultimately, the choice between these two types of components hinges on individual priorities, including budget, performance expectations, and warranty considerations. Evaluating these factors will guide users in selecting the most suitable option for their machinery needs.