The intricate system of machinery involves a wide array of essential elements that contribute to its optimal performance. Understanding the layout and interconnection of these components is crucial for effective maintenance and repairs. A comprehensive visual representation can significantly aid in identifying each part’s role within the overall mechanism.

By delving into a detailed illustration of the assembly, users can gain insights into the specific functions of various sections. This knowledge empowers operators and technicians to troubleshoot issues efficiently and ensure the longevity of their equipment. Familiarity with the configuration not only streamlines repairs but also enhances the overall user experience.

In this guide, we will examine the key components and their placements within the system. This exploration aims to facilitate a deeper understanding, allowing for more informed decisions when it comes to upkeep and enhancements.

This section aims to provide a comprehensive overview of the arrangement and organization of components related to a specific mowing machine model. Understanding how these elements fit together is crucial for effective maintenance and repairs, enabling users to enhance their operational efficiency and longevity of the equipment.

Overview of Component Structure

The structural layout of the equipment involves various assemblies that work in harmony to ensure optimal performance. Familiarity with the configuration helps users identify parts quickly and efficiently.

Key Assemblies and Their Functions

Different assemblies play vital roles in the overall functionality of the machine. Recognizing these key components allows users to diagnose issues and execute repairs more effectively.

| Assembly | Description | Function |

|---|---|---|

| Engine | Power unit of the equipment | Provides energy for operation |

| Cutting Deck | Blade housing area | Houses blades for grass cutting |

| Transmission | Power transfer system | Transmits power from the engine to wheels |

| Chassis | Base framework | Supports all components |

Key Components of the Z245

The essential elements of this model play a crucial role in its performance and efficiency. Understanding these components provides insight into the machine’s overall functionality and helps in maintaining optimal operation.

Engine: The power source is designed for reliability, offering robust performance while ensuring fuel efficiency. It plays a vital role in enabling the machine to handle various tasks with ease.

Transmission: This system is responsible for transferring power from the engine to the wheels, ensuring smooth movement and control. Its design facilitates ease of operation and enhances maneuverability.

Cutting Deck: The cutting mechanism is engineered for precision, allowing for a clean and even cut. Its adjustable features enable users to customize the cutting height according to their needs.

Chassis: The framework provides structural integrity and stability. It is designed to withstand rigorous use while maintaining balance and support for the entire machine.

Wheels: The wheel assembly is crafted for durability and traction, ensuring optimal grip on various terrains. This feature contributes significantly to the overall performance of the equipment.

By familiarizing oneself with these fundamental elements, users can enhance their understanding of the equipment, facilitating better maintenance and operation.

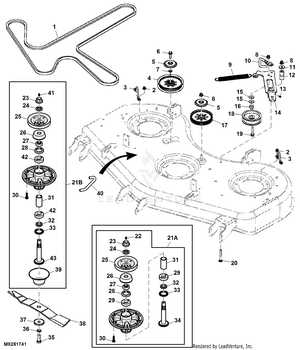

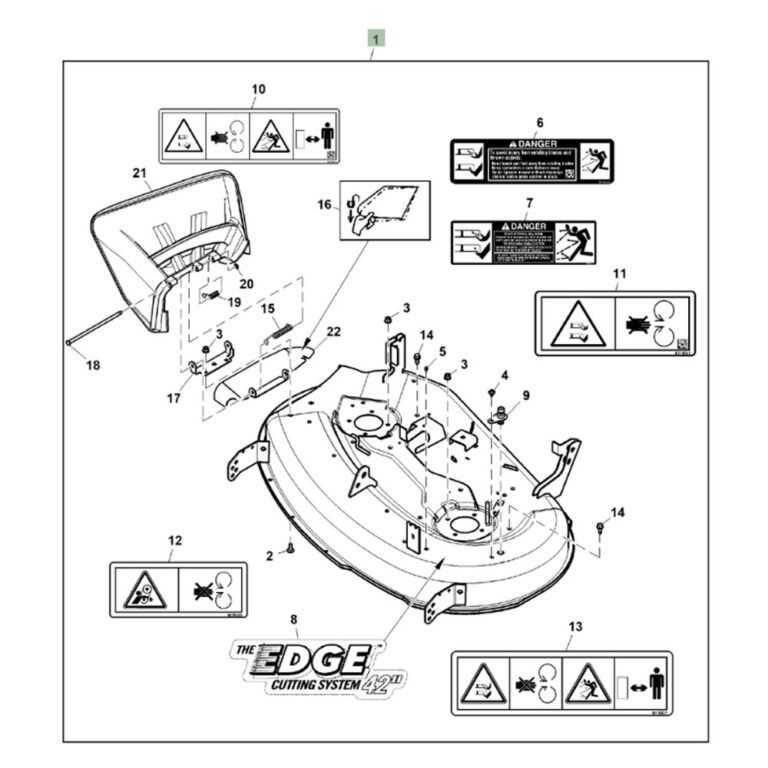

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations of assemblies serve as invaluable tools for both professionals and enthusiasts. They provide clarity on how individual elements interact, enabling users to make informed decisions about repairs or replacements.

Enhanced Clarity

Visual aids eliminate ambiguity in identifying components, making it easier to understand the relationship between different parts. By referring to these representations, users can quickly locate the necessary items, ensuring that repairs are executed efficiently and accurately.

Facilitated Maintenance

Regular upkeep of machinery is crucial for longevity. Comprehensive visuals assist in pinpointing wear and tear, allowing for proactive measures before issues escalate. This foresight not only prolongs the life of the equipment but also enhances its performance.

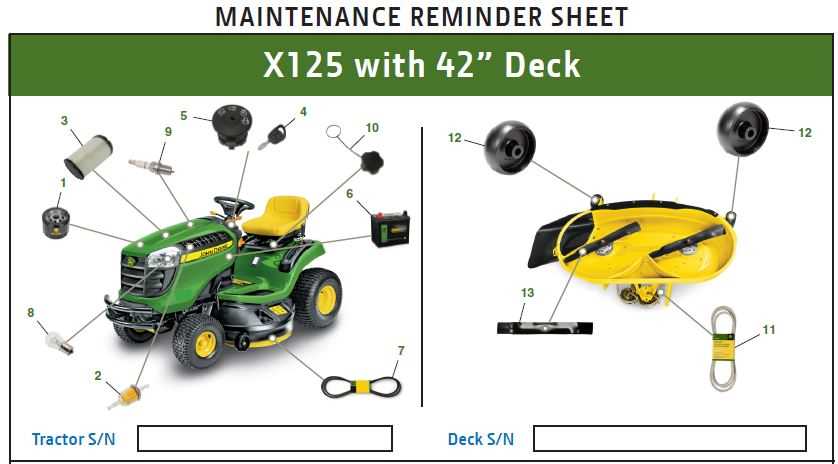

Common Replacement Parts Needed

When maintaining outdoor machinery, understanding the essential components that may require replacement is crucial for optimal performance. Regular wear and tear can lead to the need for specific items to ensure that equipment operates smoothly and efficiently.

Among the frequently needed components are belts, which play a vital role in the functioning of the machinery. These elements can wear out over time and may need replacement to maintain proper operation.

Another important category includes blades, which are essential for cutting and trimming tasks. Dull or damaged blades can affect the quality of work, necessitating timely replacements.

Additionally, filters should not be overlooked. Regularly changing air and oil filters is necessary to maintain engine efficiency and prolong the lifespan of the machinery.

Finally, components like spark plugs are critical for ignition and should be inspected and replaced as needed to ensure reliable starts and optimal engine performance.

Identifying Parts by Diagram

Understanding the components of your machinery is essential for effective maintenance and repair. A visual representation of the elements can significantly simplify the process of identifying and locating each segment. This method allows users to enhance their familiarity with the equipment, ensuring they can efficiently manage any necessary replacements or repairs.

To navigate through the visual representation effectively, consider the following steps:

- Familiarize Yourself with the Layout: Begin by studying the overall structure of the representation. This will help you understand how different elements relate to one another.

- Identify Key Components: Look for labels or markers that highlight essential elements. Take note of their positions and functions.

- Refer to Additional Resources: Utilize manuals or online guides that provide further details about each segment to gain a deeper understanding of their roles.

By following these steps, you can efficiently pinpoint the necessary components, making maintenance tasks much more manageable.

Furthermore, it’s beneficial to maintain a list of frequently required elements for quick reference during repairs. Here are some tips for creating an effective reference:

- Organize items by categories such as mechanical, electrical, and structural components.

- Include part numbers or alternative names to facilitate the search process.

- Keep the list accessible for easy consultation during maintenance sessions.

With these strategies in place, identifying and managing components will become a streamlined aspect of your equipment care routine.

Maintenance Tips for Z245

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular attention to various components can prevent common issues and enhance efficiency. Below are some helpful recommendations for maintaining your machinery effectively.

Regular Inspections: Conduct routine checks on key elements such as the engine, belts, and tires. This practice helps identify potential problems before they escalate, allowing for timely repairs.

Lubrication: Ensure that all moving parts are adequately lubricated. This minimizes friction and wear, contributing to the overall efficiency and lifespan of the equipment.

Clean Air Filters: Frequently inspect and clean or replace air filters as needed. Clogged filters can reduce engine performance and lead to increased fuel consumption.

Check Fluids: Regularly monitor fluid levels, including oil, coolant, and hydraulic fluid. Maintaining proper fluid levels is crucial for optimal operation and can prevent overheating and other issues.

Sharpen Blades: Keep blades sharp for effective cutting. Dull blades can strain the engine and lead to uneven results, so regular sharpening is vital for optimal performance.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s maintenance manual for specific recommendations and schedules. Adhering to these guidelines will ensure your equipment runs smoothly and remains in excellent condition.

Where to Find Genuine Parts

Finding authentic components for your equipment is crucial to ensure optimal performance and longevity. It’s essential to source these items from reliable suppliers to maintain the quality and reliability of your machinery. There are various avenues to explore when searching for original replacements, each offering unique benefits.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealers. These retailers are certified to sell genuine items and often provide expert advice regarding compatibility and installation.

DIY Repairs with Parts Diagrams

Engaging in home maintenance can be a rewarding experience, particularly when utilizing visual aids. These resources simplify the repair process, making it easier for individuals to identify components and understand their functions. By following a systematic approach, enthusiasts can successfully tackle various repair projects.

Understanding the Components

Familiarizing oneself with the different elements of a machine is crucial. Visual representations provide clarity, allowing individuals to see how parts interact. This knowledge empowers users to troubleshoot issues more effectively, leading to efficient repairs.

Step-by-Step Approach

To ensure successful repairs, it is advisable to adopt a structured method. Begin by gathering all necessary tools and resources. Carefully study the visuals to comprehend the assembly and disassembly processes. This meticulous preparation can significantly enhance the likelihood of a smooth repair experience.

Benefits of Regular Maintenance

Consistent upkeep of machinery is essential for optimal performance and longevity. Routine servicing not only enhances efficiency but also minimizes the likelihood of unexpected breakdowns. By prioritizing maintenance, operators can ensure that their equipment operates smoothly and reliably over time.

Improved Performance

Regular inspections and adjustments can lead to improved functionality. When components are well-maintained, machines tend to perform at their best, providing superior results in various tasks. This efficiency translates to time savings and increased productivity.

Cost Savings

Investing in routine maintenance can lead to significant financial benefits. Preventive measures help avoid costly repairs and replacements that can arise from neglect. Additionally, well-maintained equipment typically consumes less fuel and energy, further enhancing overall cost efficiency.