When it comes to maintaining a lawn care machine, having a clear visual reference for its various elements can significantly enhance your efficiency. Familiarity with the intricate layout of each segment ensures that repairs and replacements are conducted with precision and care. This overview serves as a gateway to comprehending the essential structure of these machines, aiding both novice and experienced users alike.

Each component plays a crucial role in the overall functionality and performance of the equipment. Recognizing the relationship between different parts can lead to more informed decisions regarding maintenance and upgrades. This understanding can empower users to tackle issues head-on, ensuring that their lawn mower operates at its best for years to come.

In the following sections, we will delve deeper into the specifics of these components, exploring their functions and interconnections. By the end of this guide, you will possess a comprehensive insight into the machinery that helps you achieve a pristine lawn, allowing for more effective management and upkeep of your valuable investment.

Understanding the John Deere Z355E

The mower in question is a robust and efficient machine designed for maintaining lawns and gardens. Its innovative features and user-friendly design make it a popular choice among homeowners and landscaping professionals alike. This segment will explore its essential components, functionality, and advantages, providing insight into what makes this equipment stand out.

Equipped with a powerful engine, this machine offers exceptional performance and reliability. The cutting system is engineered for precision, ensuring a clean and uniform cut every time. Additionally, the ergonomic design allows for comfortable operation, reducing fatigue during extended use.

Key features include an intuitive control panel, which simplifies adjustments and enhances the user experience. Maintenance is straightforward, with easily accessible components that facilitate routine checks and repairs. This design philosophy not only improves efficiency but also extends the lifespan of the equipment.

In summary, understanding the intricacies of this mower can greatly enhance its utility and performance. Familiarizing oneself with its essential elements will lead to better maintenance practices and optimal results in lawn care tasks.

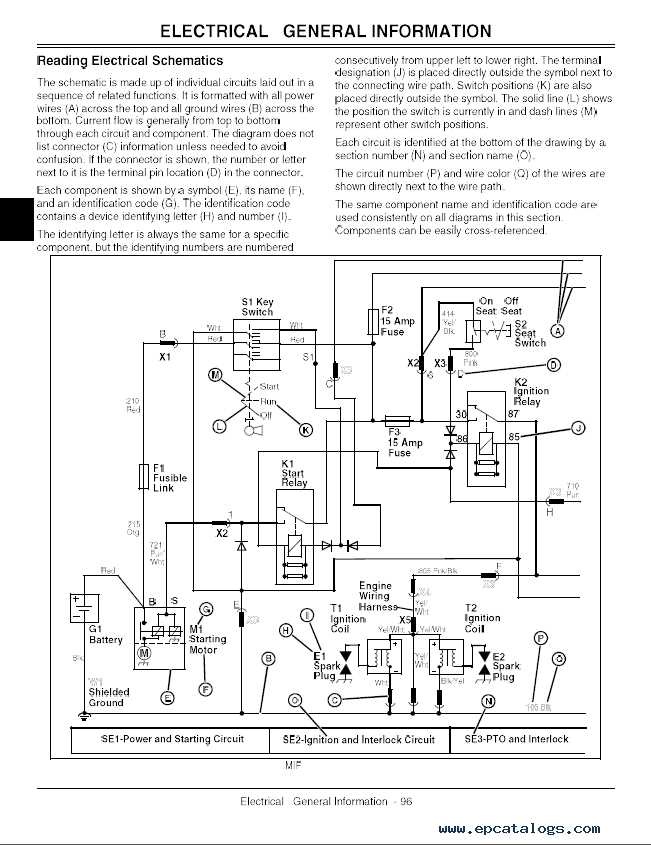

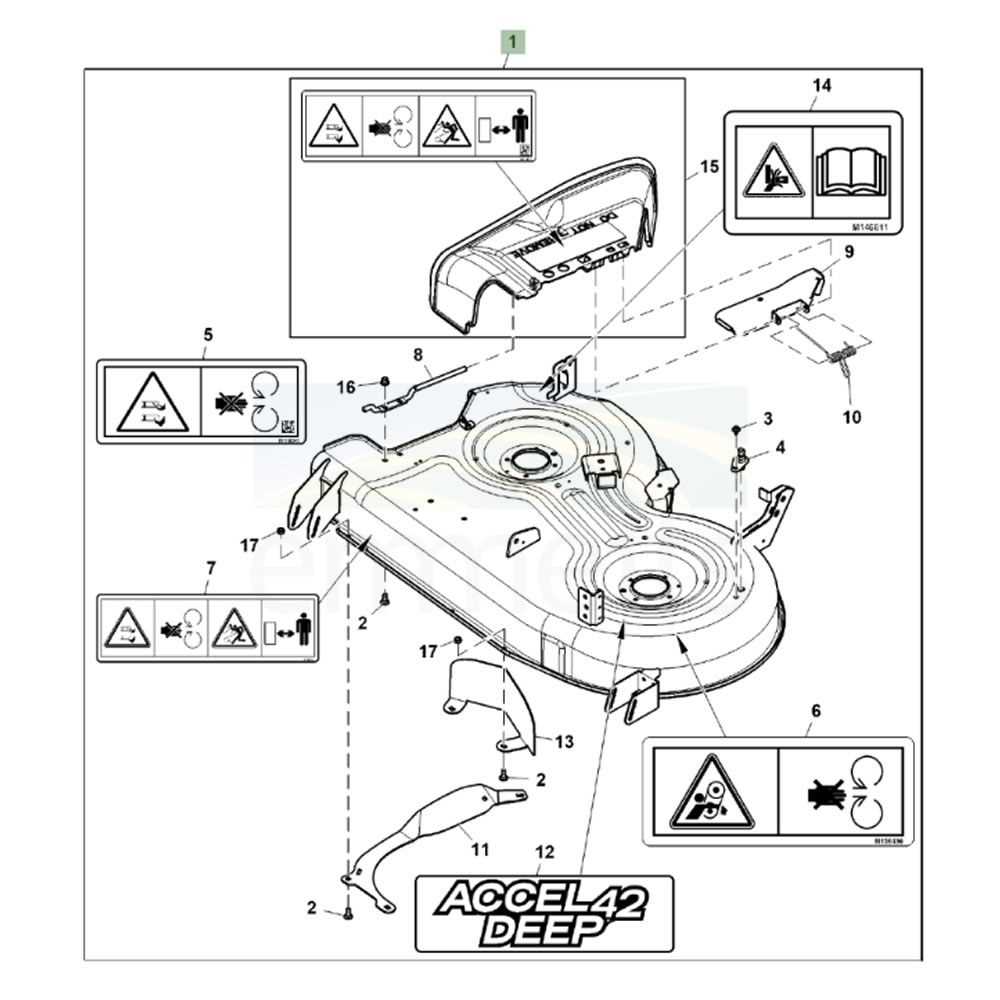

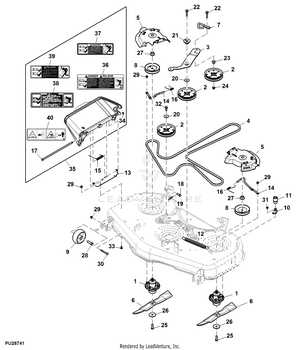

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide a clear layout that helps users identify each element and understand how they interact within the overall system. This clarity can significantly enhance the efficiency of troubleshooting and assembly processes.

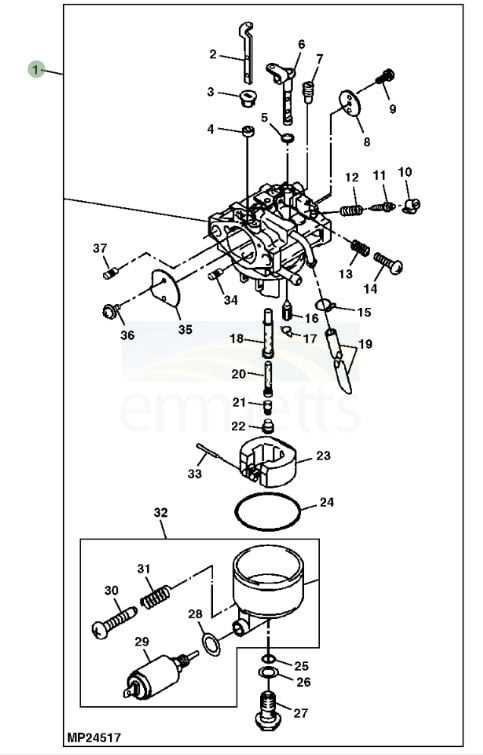

Understanding Components: These illustrations offer detailed views of individual elements, making it easier to locate specific items and comprehend their functions. This is especially beneficial for those who may not have extensive technical knowledge, as it simplifies complex assemblies.

Streamlining Repairs: When faced with a malfunction, having a visual guide allows technicians to quickly assess what needs attention. By following these detailed illustrations, they can avoid unnecessary errors, saving both time and resources during repair tasks.

Facilitating Ordering: Accurate visual references assist in identifying the correct components needed for replacements. This reduces the chances of ordering the wrong items, which can lead to delays and increased costs.

Enhancing Communication: In team environments, these visuals serve as a common language, enabling effective communication between team members. They help ensure everyone is on the same page regarding which parts need to be addressed or replaced.

Key Components of Z355E

This section delves into the essential elements that contribute to the efficiency and performance of this lawn maintenance machine. Understanding these vital components can aid in proper upkeep and enhance operational longevity.

Engine and Transmission

The heart of any mower is its engine, which powers the entire system. Coupled with a robust transmission, this combination ensures smooth acceleration and effective power transfer to the cutting deck. Regular maintenance of these components is crucial for optimal functionality.

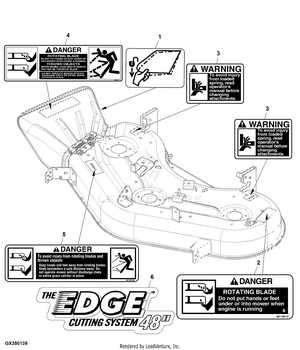

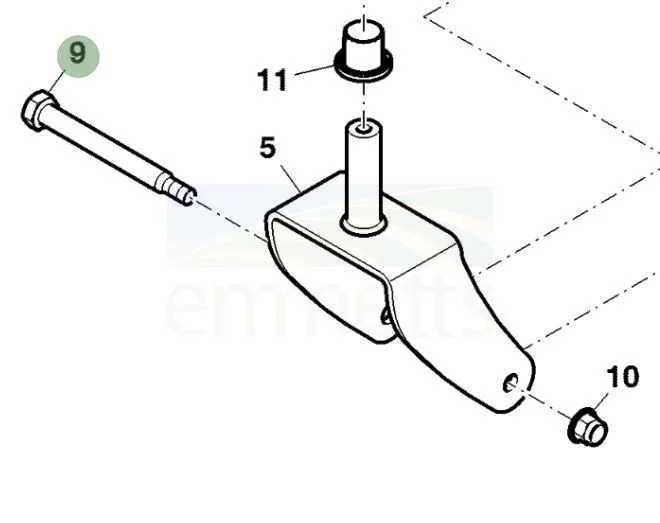

Cutting Deck and Blades

The cutting deck is integral for achieving a precise lawn finish. Equipped with sharp blades, it enables efficient grass cutting while minimizing clumping and unevenness. Keeping these parts sharp and well-maintained enhances cutting performance and prolongs their lifespan.

Common Repairs and Maintenance

Proper upkeep and timely repairs are essential for ensuring the longevity and efficiency of your equipment. Regular attention to various components not only enhances performance but also minimizes the likelihood of unexpected breakdowns. This section outlines common maintenance tasks and repairs that can help keep your machinery in optimal working condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace engine oil to ensure smooth operation and reduce wear. |

| Air Filter Replacement | Every 100 hours | Change the air filter to maintain proper airflow and engine efficiency. |

| Blade Sharpening | As needed | Sharpen or replace cutting blades to achieve clean cuts and prevent damage. |

| Tire Inspection | Monthly | Check tire pressure and tread for safety and performance. |

| Battery Maintenance | Every season | Inspect battery terminals and clean as necessary to ensure reliable starts. |

Identifying Replacement Parts

When maintaining and servicing outdoor machinery, recognizing the components that require substitution is crucial for optimal performance. Understanding the various elements involved can greatly enhance the longevity and efficiency of your equipment. This section delves into the methods for identifying necessary replacements and ensuring a smooth operational flow.

Common Signs of Wear and Tear

Regular use of machinery can lead to deterioration of specific components. It is essential to be aware of common indicators that suggest parts may need replacing:

- Unusual noises during operation

- Decreased performance or power

- Visible wear, such as cracks or fraying

- Leaks or fluid loss

How to Locate Component Information

Once signs of damage are identified, locating accurate information about the required components is the next step. Here are some effective ways to find details:

| Method | Description |

|---|---|

| Owner’s Manual | Consult the manual for specifications and diagrams that outline component details. |

| Manufacturer’s Website | Visit the official site for resources, including part listings and support. |

| Online Forums | Engage with communities of users who may share insights and recommendations. |

| Retailers | Contact local or online retailers who specialize in outdoor equipment for advice. |

By understanding the signs of damage and utilizing available resources, you can effectively identify the necessary components for replacement, ensuring your machinery remains in top condition.

Where to Find Diagrams Online

Locating visual schematics for machinery can significantly enhance your understanding of its components and assembly. These resources are invaluable for both maintenance and repair tasks, offering clear representations of how each element fits together. Fortunately, numerous platforms provide easy access to these visual aids.

Manufacturer Websites often host a wealth of resources, including downloadable illustrations and detailed manuals. Navigating to the official site of the manufacturer can yield high-quality, reliable documentation tailored specifically for their products.

Online Forums and Communities can also be a treasure trove of information. Engaging with fellow enthusiasts allows you to share insights and access user-uploaded materials that may not be found elsewhere. These platforms foster collaboration and provide diverse perspectives on maintenance strategies.

Specialized Retailers frequently offer parts catalogs that include detailed illustrations. These catalogs are designed to assist customers in identifying components, making them a practical tool for anyone looking to understand their machinery better.

Social Media Groups dedicated to machinery enthusiasts can be surprisingly useful. Members often share links to useful resources, including diagrams and manuals, providing a collective pool of knowledge that can simplify your search.

By exploring these avenues, you can easily access the visual aids necessary for a comprehensive understanding of your equipment’s intricacies.

Benefits of Using OEM Parts

Opting for original equipment manufacturer components ensures that your machinery operates at peak performance. These specialized items are designed specifically for your equipment, guaranteeing a perfect fit and reliable functionality. When maintenance or replacement is necessary, choosing authentic parts can significantly enhance the longevity and efficiency of your investment.

Quality Assurance

One of the primary advantages of using genuine components is the assurance of quality. These items undergo rigorous testing and adhere to strict manufacturing standards, ensuring they meet or exceed the specifications set by the original manufacturer. This reliability translates into improved performance and reduced risk of failure, which can save time and costs associated with repairs.

Enhanced Performance

Using authentic components can lead to improved overall performance. Since these items are engineered specifically for your machinery, they contribute to optimal operation, providing better power, efficiency, and safety. By maintaining the integrity of your equipment with high-quality parts, you can expect consistent results and a more enjoyable experience during use.

Tips for Efficient Repairs

When it comes to maintaining and fixing your outdoor equipment, efficiency can save you time and money. Knowing the right strategies can streamline the repair process and enhance your overall experience. Here are some essential tips to help you tackle repairs more effectively.

Preparation is Key

Before starting any repair work, ensure you have all necessary tools and materials at hand. Organizing your workspace will minimize distractions and interruptions. Take the time to review any manuals or guides related to your equipment to familiarize yourself with its components and functionality. This preparation will empower you to work more confidently and efficiently.

Follow a Systematic Approach

Adopt a step-by-step methodology when addressing issues. Begin with a thorough inspection to identify the root cause of any malfunction. Document your findings and follow a logical sequence when disassembling parts, as this will help you remember the order for reassembly. Additionally, keep track of any small components in labeled containers to avoid misplacement.

Utilizing these strategies will not only enhance your repair skills but also extend the lifespan of your equipment, ensuring it operates at peak performance for years to come.