In the world of temperature management, a comprehensive grasp of the intricate elements involved is essential. Each component plays a crucial role in ensuring efficiency and reliability, impacting overall performance and longevity. By delving into the intricate relationships between these elements, one can gain valuable insights into the mechanisms that drive effective cooling solutions.

The exploration of these essential components allows for a deeper appreciation of their functionalities. Understanding how each part interacts with the others provides clarity on maintenance and troubleshooting. This knowledge is not only beneficial for technicians but also empowers users to make informed decisions regarding repairs and upgrades.

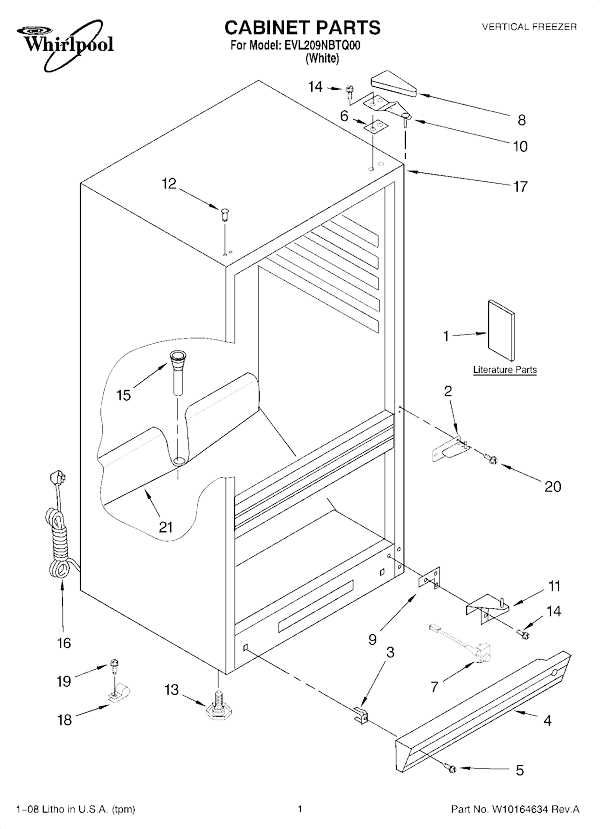

Moreover, visual representations of these intricate systems serve as valuable tools for learning. They simplify complex information, making it accessible to those seeking to enhance their understanding. A well-organized illustration can highlight key features and foster a more intuitive grasp of how refrigeration mechanisms operate in harmony.

Understanding Sub Zero Appliances

Premium refrigeration systems have become synonymous with luxury and performance in modern kitchens. These high-end units are designed to provide exceptional functionality, blending cutting-edge technology with aesthetic appeal. Understanding the intricacies of these appliances is essential for both potential buyers and users seeking to maximize their efficiency and lifespan.

To appreciate the value of these advanced units, it is crucial to recognize their key components and how they work together. A well-designed refrigeration system not only preserves food but also enhances the overall culinary experience. Below is a breakdown of some of the main features and elements that define these high-performance appliances.

| Feature | Description |

|---|---|

| Temperature Control | Advanced systems allow for precise temperature adjustments to keep food at optimal freshness. |

| Energy Efficiency | Designed to minimize energy consumption while maximizing performance, reducing environmental impact. |

| Durable Construction | High-quality materials ensure longevity and resilience against daily wear and tear. |

| Customizable Design | Various styles and configurations are available to fit seamlessly into any kitchen layout. |

| Smart Technology | Integration of smart features for remote monitoring and control enhances user convenience. |

By understanding these essential characteristics, users can make informed decisions regarding maintenance and care, ensuring that their investment continues to deliver exceptional performance over the years.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate workings of complex systems. They serve as essential tools for both professionals and enthusiasts, simplifying the identification and organization of individual elements within a mechanism. By providing a clear overview, these illustrations enhance communication and facilitate more effective troubleshooting and repairs.

Moreover, they are instrumental in maintaining the efficiency of operations. When technicians can easily reference these visual aids, the likelihood of errors decreases significantly, leading to improved performance and longevity of equipment. Additionally, these resources are vital for training purposes, enabling newcomers to grasp fundamental concepts quickly.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids simplify complex information, making it easier to comprehend. |

| Improved Efficiency | Quick identification of components reduces downtime during repairs. |

| Training Resource | They provide an effective means of educating new personnel on system functions. |

| Minimized Errors | Clear visuals reduce the risk of mistakes during assembly or maintenance. |

Common Sub Zero Models Overview

This section provides an insight into various popular refrigeration models that are renowned for their performance and reliability. These units are designed to meet diverse needs, from residential to commercial applications, showcasing innovative features that enhance user experience. Understanding the differences and specifications of each model can aid in making an informed choice tailored to specific requirements.

| Model | Type | Capacity (cu. ft.) | Special Features |

|---|---|---|---|

| BI-36UFD | Built-In | 36 | Dual refrigeration, ice maker |

| PRO-48 | Pro Style | 48 | Commercial-grade performance, advanced temperature control |

| UC-24R | Under Counter | 24 | Compact design, integrated ice maker |

| BI-30 | Built-In | 30 | Custom panel ready, energy-efficient |

| PRO-36 | Pro Style | 36 | High-capacity, professional-grade cooling |

How to Read Parts Diagrams

Understanding visual schematics is essential for efficient maintenance and repair tasks. These illustrations serve as a guide, depicting various components and their relationships within a system. Familiarity with these visuals can significantly enhance troubleshooting and assembly processes.

Identifying Key Elements

Every illustration includes specific symbols and numbers that represent different elements. Pay attention to the legend, as it often explains these symbols and provides crucial information about each component. Look for annotations that indicate size, quantity, and material, which can help in selecting the correct items for repairs.

Interpreting Connections and Layout

Another important aspect is understanding how the components interact. Lines or arrows typically indicate connections or flow, illustrating how each part fits into the whole. Take your time to trace these paths, as they reveal the functionality and integration of each element, enabling you to approach repairs with greater confidence.

Identifying Key Components

Understanding the essential elements of a cooling system is crucial for effective maintenance and troubleshooting. Familiarizing yourself with these components can enhance efficiency and prolong the lifespan of your unit.

Essential Elements

- Compressor: The heart of the system, responsible for circulating refrigerant.

- Evaporator Coil: This component absorbs heat, cooling the air within the space.

- Condenser Coil: Here, refrigerant releases its heat, allowing it to return to a liquid state.

- Expansion Valve: Regulates the flow of refrigerant, ensuring optimal performance.

- Fan: Helps circulate air over the coils to maintain consistent temperatures.

Recognizing Functionality

Each component plays a vital role in the overall operation:

- Compressor compresses refrigerant gas, raising its pressure and temperature.

- Evaporator Coil cools the air by absorbing heat from the environment.

- Condenser Coil facilitates the release of heat to the outside atmosphere.

- Expansion Valve controls the refrigerant flow, optimizing cooling efficiency.

- Fans ensure proper airflow, enhancing heat exchange processes.

Common Issues and Solutions

In the realm of refrigeration units, various challenges may arise, impacting performance and efficiency. Identifying these common complications and implementing effective remedies is crucial for maintaining optimal functionality.

-

Temperature Fluctuations:

Inconsistent cooling can often lead to temperature irregularities. This can be caused by:

- Blocked vents or airflow restrictions

- Faulty thermostat settings

- Insufficient door sealing

Solution: Regularly check vents for obstructions, calibrate the thermostat, and ensure door gaskets are intact.

-

Unusual Noises:

Strange sounds can indicate underlying issues. Common culprits include:

- Loose components

- Worn-out fans

- Ice buildup in the evaporator

Solution: Inspect and tighten any loose parts, replace damaged fans, and defrost any excessive ice.

-

Leaking Fluids:

Fluid leaks may signal serious malfunctions. These can arise from:

- Damaged seals or gaskets

- Punctured refrigerant lines

- Clogged drainage systems

Solution: Examine seals for wear, repair or replace any damaged lines, and ensure the drainage system is clear.

-

Energy Inefficiency:

Higher energy bills may suggest inefficiency. Factors include:

- Dirty condenser coils

- Poor insulation

- Old or malfunctioning compressors

Solution: Clean condenser coils, assess insulation quality, and consider compressor replacement if necessary.

By addressing these frequent issues with the proposed solutions, users can significantly enhance the reliability and efficiency of their refrigeration systems.

Ordering Replacement Parts Effectively

Ensuring the availability of necessary components can significantly enhance the longevity and functionality of your equipment. Understanding the right approach to procure these items is essential for a seamless experience.

Identifying the Right Components

Begin by meticulously assessing the specific requirements of your machinery. Gather detailed information, such as model numbers and serial identifiers, to facilitate accurate identification. This diligence minimizes errors in procurement.

Utilizing Reliable Suppliers

Seek out trustworthy vendors with a solid reputation for quality and service. Comparing prices and reading reviews can guide you toward reputable sources, ensuring that you acquire reliable and durable replacements.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your cooling equipment requires regular upkeep and attention. By following a set of straightforward maintenance practices, you can significantly extend the lifespan of your appliances and enhance their efficiency. Here are some essential guidelines to keep in mind.

Regular Cleaning

One of the most crucial aspects of maintenance is routine cleaning. Dust and debris can accumulate over time, affecting performance. Ensure that the condenser coils and air filters are clean to promote better airflow and heat exchange.

Inspection and Monitoring

Frequent inspections can help identify potential issues before they become serious problems. Check for any unusual noises, leaks, or irregular functioning. Keeping a close eye on the unit will aid in early detection of maintenance needs.

| Task | Frequency | Importance |

|---|---|---|

| Clean Air Filters | Monthly | Improves Airflow |

| Inspect Coils | Quarterly | Enhances Efficiency |

| Check for Leaks | Biannually | Prevents Damage |

| Professional Servicing | Annually | Ensures Optimal Performance |

Resources for Further Assistance

When it comes to understanding complex systems and ensuring their optimal functionality, having access to the right resources is essential. Whether you are troubleshooting, seeking maintenance tips, or looking for specific components, a variety of platforms and materials can enhance your knowledge and aid in your endeavors.

Online Forums and Communities

- Discussion Boards: Engage with experts and enthusiasts in specialized forums where you can ask questions and share experiences.

- Social Media Groups: Join Facebook groups or Reddit communities dedicated to similar interests for real-time advice and insights.

- Q&A Websites: Utilize platforms like Stack Exchange or Quora to find answers to specific inquiries.

Official Documentation and Manuals

- Manufacturer Websites: Access detailed manuals and user guides directly from the manufacturer’s site for the most accurate information.

- Technical Publications: Look for service bulletins and technical notes that provide advanced troubleshooting tips.

- Instructional Videos: Explore platforms like YouTube for visual guides and step-by-step tutorials.