In any modern kitchen, efficient waste management is essential for maintaining cleanliness and convenience. Devices designed to compress refuse play a crucial role in minimizing space and simplifying disposal. A comprehensive grasp of the internal mechanisms and elements of these appliances enhances their functionality and longevity.

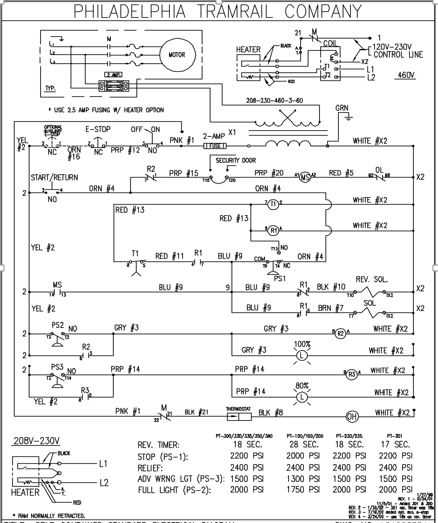

Visual aids can significantly assist in understanding how various components interact within these systems. By examining a detailed representation of the device’s construction, users can better identify potential issues and streamline maintenance. This knowledge empowers homeowners to perform repairs and replacements more effectively, ensuring optimal performance.

Additionally, familiarity with the key elements involved in waste compression allows users to make informed decisions when selecting replacements. Whether it’s upgrading for enhanced efficiency or addressing specific malfunctions, understanding the intricacies of these components ultimately leads to a more sustainable and efficient kitchen environment.

Understanding Whirlpool Trash Compactors

This section explores the essential features and functions of a popular waste reduction device designed to minimize refuse volume in kitchens. With various components working in harmony, users can efficiently manage waste while maintaining a clean environment.

Key Components

- Motor: Powers the compression mechanism.

- Container: Holds the waste before and after compression.

- Control Panel: Allows users to operate the device easily.

Benefits of Usage

- Space-saving: Reduces the size of waste for easier disposal.

- Environmentally friendly: Decreases the frequency of waste collection.

- Convenient: Simplifies kitchen waste management.

Key Components of Trash Compactors

Understanding the essential elements of waste management devices can significantly enhance their functionality and longevity. These components work in unison to ensure efficient compression and disposal of materials, making them invaluable in both residential and commercial settings.

Compression Mechanism

The compression mechanism is crucial as it applies pressure to reduce the volume of waste. This process not only maximizes space but also minimizes the frequency of disposal, leading to more efficient waste management.

Control System

The control system governs the operation of the device, allowing users to manage cycles, timing, and power. A reliable control interface ensures smooth functionality, contributing to an optimal waste handling experience.

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to identify and replace necessary items. These illustrations serve as valuable guides, helping you navigate through intricate designs and pinpoint specific elements with ease.

Familiarize Yourself with Symbols

Every illustration contains unique symbols and notations. Take time to learn what these icons represent, as they often indicate functions, sizes, and connections. Recognizing these symbols is crucial for accurate interpretation.

Follow the Flow

Observe the layout and flow of the representation. Typically, components are arranged logically, leading from one part to another. This sequence can help you understand how each element interacts within the system, making troubleshooting more effective.

Common Issues and Solutions

In any household device designed to minimize waste, occasional problems can arise, impacting performance and efficiency. Understanding typical challenges and their remedies can ensure your equipment functions optimally and lasts longer. Below are some frequent issues you may encounter along with effective solutions.

1. Overheating: If the unit becomes excessively hot during operation, it may lead to shutdowns. This can often be resolved by ensuring the airflow is not obstructed. Regularly clean the vents and ensure that the unit is placed in a well-ventilated area.

2. Jamming: A common issue is the inability to compress due to foreign objects being lodged inside. To remedy this, turn off the device and carefully remove any obstructions. Always check for loose items before operation.

3. No Power: If the equipment fails to start, check the power supply and ensure that it is properly connected. Inspect the circuit breaker for any tripped switches. Resetting the breaker can often solve the problem.

4. Unpleasant Odors: Lingering smells can be a nuisance. To combat this, regularly clean the interior and utilize deodorizing agents designed for such equipment. Keeping the area dry will also help minimize odors.

5. Inefficient Compression: If the device is not compressing waste effectively, it may indicate wear on the compression mechanism. Inspect the components for damage and consider replacing any worn parts to restore functionality.

By addressing these common challenges with appropriate solutions, you can enhance the reliability and longevity of your waste management appliance, ensuring it continues to serve you well.

Maintenance Tips for Longevity

Proper upkeep of your waste management device can significantly extend its lifespan and enhance its efficiency. Regular attention and a few simple practices can prevent common issues and ensure optimal performance. Here are some essential tips to keep your unit running smoothly.

Regular Cleaning

Keeping the interior and exterior clean is crucial for functionality. Consider the following practices:

- Wipe down surfaces weekly to remove debris and residue.

- Use a mild detergent to clean the interior, avoiding harsh chemicals that could damage components.

- Inspect and clean any filters or screens according to the manufacturer’s recommendations.

Routine Inspections

Frequent examinations can help identify potential issues before they escalate. Follow these steps:

- Check for any signs of wear or damage, especially on seals and hinges.

- Listen for unusual noises during operation, which may indicate mechanical problems.

- Ensure that electrical connections are secure and free from corrosion.

By implementing these maintenance strategies, you can promote durability and enhance the overall performance of your device.

Finding Replacement Parts Easily

Locating components for home appliances can often feel overwhelming. However, with the right approach and resources, you can simplify the process significantly. Whether you’re facing a minor malfunction or a major issue, understanding how to effectively search for replacements is key to restoring functionality.

Utilizing Online Resources

The internet is a treasure trove of information. Websites dedicated to appliance repair offer extensive catalogs of components, along with detailed descriptions and specifications. Use search engines to find reputable sites where you can browse options by model number or type. Online forums and communities can also provide valuable insights and recommendations.

Consulting Local Suppliers

Don’t overlook local hardware and appliance stores. Many carry a range of essential components and can order specific items if needed. Building a relationship with a knowledgeable staff member can lead to useful advice and assistance in locating hard-to-find items.

In summary, a combination of online research and local resources can greatly enhance your ability to find the necessary components quickly and efficiently. Staying organized and informed will save you time and effort in the long run.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to fixing your waste compression device. By following these organized steps, you can effectively troubleshoot common issues and restore functionality.

1. Identify the Problem: Begin by assessing the symptoms. Is there an unusual noise, or does the machine fail to operate? Understanding the specific issue is crucial.

2. Gather Tools: Collect the necessary tools for the repair. Typically, you will need a screwdriver, pliers, and possibly a multimeter for electrical tests.

3. Disconnect Power: Always ensure the device is unplugged before starting any repairs to prevent accidents.

4. Access the Interior: Remove the outer casing carefully to expose the inner components. Refer to your user manual for specific instructions on how to disassemble.

5. Inspect Components: Check all visible parts for wear, damage, or blockages. Look for loose connections, burnt wires, or any debris that might hinder operation.

6. Replace or Repair: Depending on your findings, either replace faulty components or repair them as needed. Ensure all replacements match the original specifications.

7. Reassemble: Once repairs are complete, carefully reassemble the unit. Ensure all screws and parts are securely fastened.

8. Test the Device: Plug the device back in and run a test cycle to ensure everything is functioning as intended.

9. Routine Maintenance: After repairs, establish a regular maintenance schedule to prevent future issues and prolong the lifespan of your machine.

Benefits of Using a Trash Compactor

Utilizing an efficient waste management system offers numerous advantages for households and businesses alike. By significantly reducing the volume of refuse, these systems enhance cleanliness, minimize disposal frequency, and contribute to environmental sustainability.

Space Efficiency

One of the primary benefits is the optimization of space. By compressing waste materials, users can store more refuse in a smaller area, thereby keeping kitchens and waste storage zones organized. This feature is especially advantageous in smaller living spaces where every square foot counts.

Environmental Impact

Moreover, these systems play a crucial role in promoting eco-friendliness. By decreasing the volume of waste sent to landfills, they help lower greenhouse gas emissions and reduce the carbon footprint. Additionally, compacting waste often encourages recycling, as users become more conscious of their waste production.

In conclusion, investing in an efficient waste reduction system not only improves organization and cleanliness but also supports sustainable practices, making it a wise choice for both individuals and communities.

Safety Precautions to Consider

Ensuring a safe environment during maintenance or repair activities is crucial. Adopting appropriate safety measures protects both the individual and the equipment involved. Awareness of potential hazards and adherence to guidelines can significantly reduce the risk of accidents or injuries.

General Guidelines

When engaging with machinery, it is important to follow standard safety protocols. Here are some fundamental practices to keep in mind:

| Precaution | Description |

|---|---|

| Disconnect Power | Always unplug the unit or turn off the circuit breaker before beginning any maintenance work. |

| Wear Protective Gear | Use safety glasses, gloves, and steel-toed boots to protect against potential injuries. |

| Work in a Ventilated Area | Ensure proper airflow to avoid inhaling harmful fumes or dust. |

Handling Components Safely

When dealing with various components, it is essential to handle them with care to prevent damage and ensure personal safety. Here are specific tips for component management:

| Tip | Details |

|---|---|

| Inspect Before Use | Check all parts for wear or damage before installation to prevent failures. |

| Store Components Properly | Keep parts organized and in a dry place to avoid corrosion or degradation. |

| Follow Manufacturer Instructions | Always refer to the manual for guidance on handling and installation procedures. |