The functionality of any freezing device relies heavily on its internal components. To maintain optimal performance, it is essential to familiarize yourself with these elements and their interconnections. By doing so, users can troubleshoot issues effectively and enhance the overall efficiency of their unit.

In this exploration, we will delve into the intricate design of your cooling appliance, highlighting the ultimate significance of each element. A comprehensive understanding not only aids in repairs but also extends the lifespan of the equipment.

Whether you are experiencing a malfunction or simply wish to expand your knowledge, grasping the layout and purpose of these components will empower you to manage your device with confidence. Emphasizing maintenance and care will lead to a more satisfying user experience.

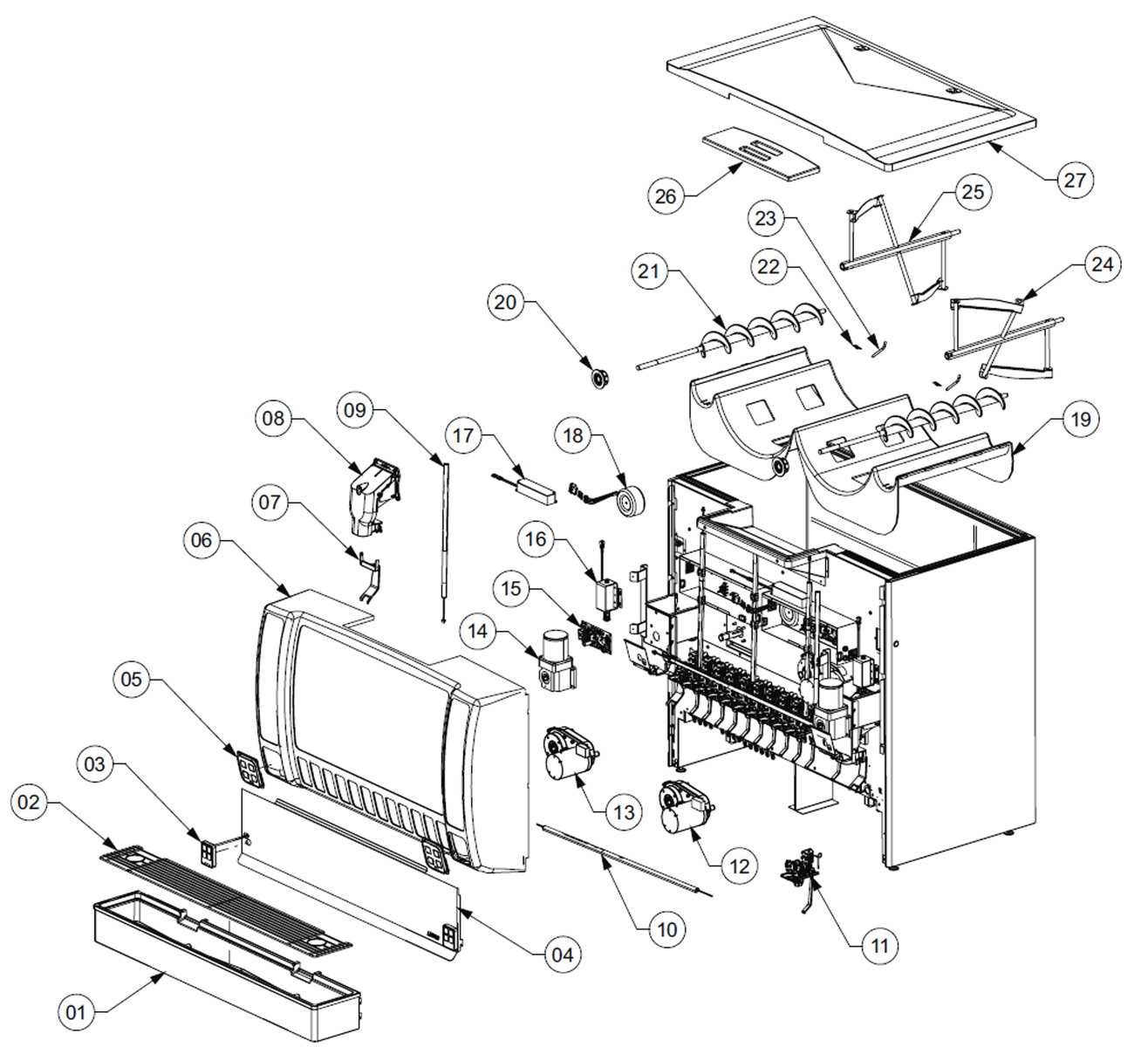

Understanding Components of a Home Ice Making Device

In this section, we delve into the intricate mechanisms that comprise a household device designed to produce ice. By exploring the fundamental parts that collaborate to create ice cubes, we gain insights into the operational framework of this essential appliance.

1. Framework Elements

- Structural components that form the foundation of the ice making process.

- Key pieces that work in harmony to facilitate the creation of ice cubes.

- Foundational elements essential for the proper functioning of the device.

2. Operational Contributors

- Components that play pivotal roles in the operational efficiency of the ice making apparatus.

- Parts that contribute directly to the ice production process.

- Key elements that ensure the smooth operation of the ice maker.

By understanding these critical components and their interplay, users gain a deeper appreciation for the technology behind this everyday convenience.

How Ice Makers Function Efficiently

The process of creating frozen water in household appliances relies on a series of interconnected components working harmoniously. These elements collaborate to ensure rapid production and consistent quality, enabling users to have a steady supply of frozen cubes for various uses.

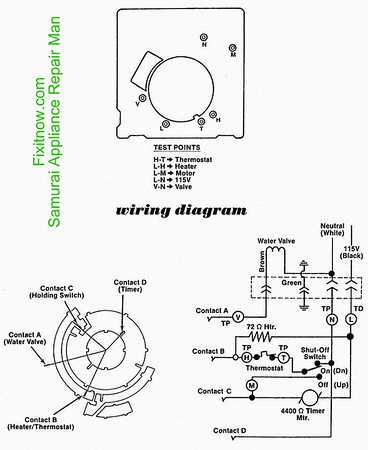

At the core of this functionality is a cycle involving cooling, forming, and releasing. The refrigeration mechanism plays a vital role, using a refrigerant to absorb heat and lower temperatures within the unit. As the temperature drops, water transforms into solid form, completing the initial stage of production.

Once the freezing phase is accomplished, a mechanism triggers the release of the solidified product. This step is crucial as it prevents any blockages and ensures a seamless flow. The entire system is designed for efficiency, minimizing energy consumption while maximizing output.

| Component | Function |

|---|---|

| Compressor | Compresses refrigerant to facilitate heat exchange. |

| Evaporator | Absorbs heat, allowing water to freeze. |

| Water Reservoir | Holds water before it undergoes freezing. |

| Release Mechanism | Ensures easy removal of frozen cubes. |

In conclusion, the efficient operation of these appliances hinges on the integration of each component, creating a streamlined process that delivers reliable results for everyday needs.

Common Issues with Ice Maker Parts

When dealing with cold production units, several frequent complications can arise that affect their efficiency. Understanding these challenges can help in identifying solutions and ensuring optimal functionality.

Insufficient Production: One prevalent issue is inadequate output, which may stem from blockages or malfunctioning components. Regular maintenance is essential to prevent these problems.

Clogged Water Lines: Another common complication involves obstructions in the water supply lines. This can lead to diminished flow and inconsistent operation. Regular inspection can mitigate this issue.

Noise Problems: Unusual sounds often indicate underlying mechanical issues. Identifying the source of these noises is crucial for timely intervention and repair.

Temperature Fluctuations: Variations in the freezing temperature can significantly impact production efficiency. Ensuring that the temperature control mechanisms are functioning correctly is vital for consistent results.

Electrical Failures: Electrical components can sometimes fail, leading to complete operational shutdowns. Diagnosing and addressing these failures promptly is important for restoring functionality.

Step-by-Step Repair Guide

When a cooling appliance starts malfunctioning, it can be frustrating. However, with the right approach, you can restore its functionality by following a structured repair process. This guide will help you troubleshoot and resolve common issues, ensuring your unit operates smoothly again. By breaking the repair down into manageable steps, you can tackle the problem with confidence, minimizing downtime.

Before starting, make sure you have the necessary tools and safety equipment on hand. These include screwdrivers, pliers, a multimeter, and any replacement components you may need. Additionally, it’s important to disconnect the unit from the power source to prevent any accidents during the repair process.

- Identify the issue: Begin by carefully observing the symptoms. Is the appliance not producing cold air? Are there unusual noises? Identifying the problem will help you determine which component is at fault.

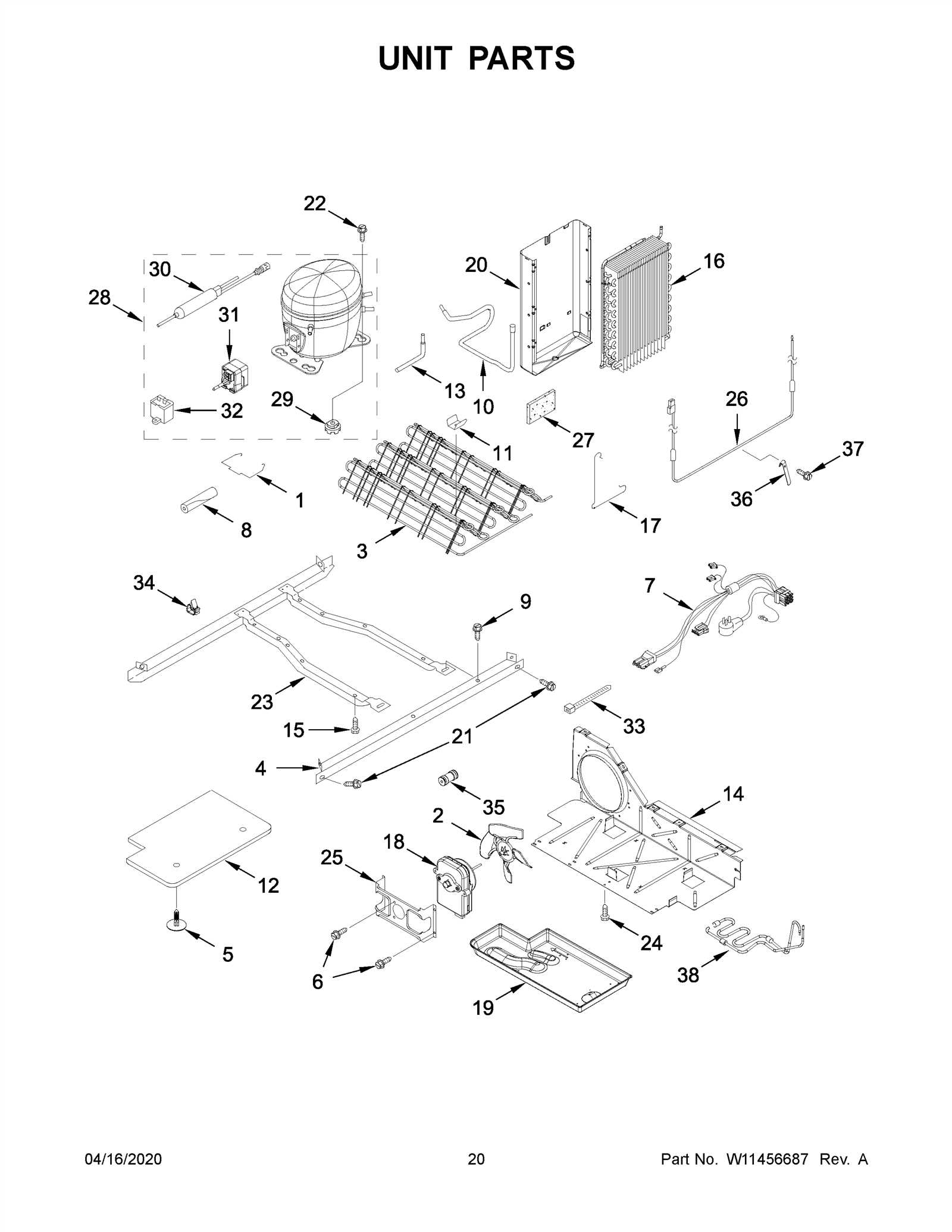

- Access the internal components: After diagnosing the issue, remove the necessary panels to gain access to the internal mechanisms. Be cautious not to damage any surrounding parts during this step.

- Inspect each element: Look over the key parts such as the motor, water lines, and electrical connections. Ensure no visible wear or damage is present. If you find any malfunctioning components, make a note of them for replacement.

- Test electrical connections: Use a multimeter to check voltage at key points. This step is crucial if you suspect an electrical fault is involved. If any readings are off, the affected component may need to be replaced.

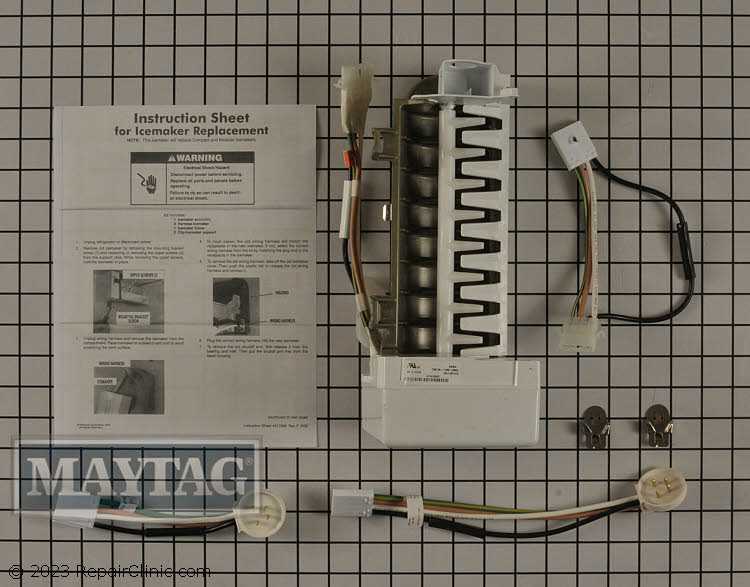

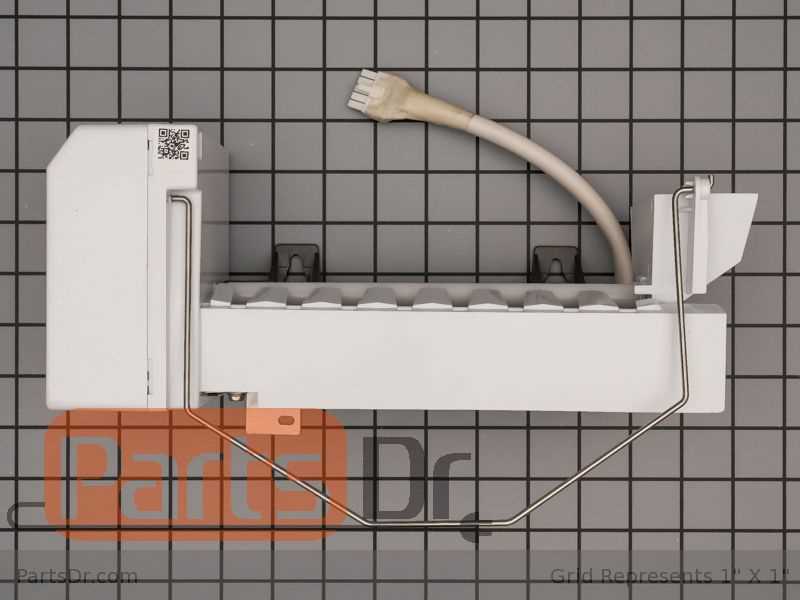

- Replace faulty components: Once you’ve identified the damaged parts, order replacements and install them. Ensure that each new part fits correctly and is secured in place.

- Reassemble and test: After replacing the faulty component, carefully reassemble the unit and reconnect the power. Run the appliance for a short period to ensure the repair was successful.

By following these steps methodically, you can ensure that the repair is done correctly and efficiently. Always remember that if you are uncertain about any part of the process, it is advisable to consult a professional technician for assistance.

Essential Tools for Ice Maker Maintenance

Proper upkeep of your frozen water production unit ensures efficiency and longevity. Having the right equipment on hand simplifies the process, allowing for swift repairs and adjustments.

Key tools to consider include:

- Screwdrivers: Both flathead and Phillips for accessing compartments.

- Wrench set: Useful for loosening and tightening various fittings.

- Multimeter: Essential for checking electrical connections and diagnosing issues.

- Clean cloths: Necessary for wiping down surfaces and removing debris.

- Water filter replacement tool: Helps ensure optimal filtration performance.

Investing in these essentials can streamline maintenance tasks and enhance the performance of your equipment.

Identifying Ice Maker Model Numbers

Understanding the unique identifiers of your refrigeration unit is essential for effective maintenance and troubleshooting. These identifiers often consist of a combination of letters and numbers that provide critical information about the appliance’s specifications and capabilities.

To locate the model number, check common areas such as the interior walls or near the door. It may be affixed to a label or plate, making it easier to find if you know where to look.

Once identified, this number can be used to access specific resources, including repair guides and compatible components. Accurate identification ensures you receive the ultimate support and service for your unit.

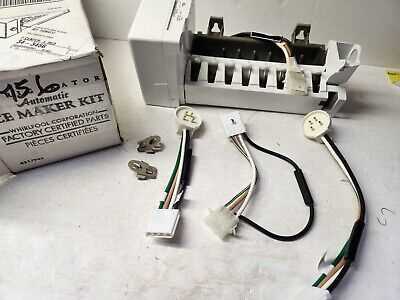

Where to Find Replacement Parts

Locating essential components for your appliance can be a straightforward process if you know where to look. Various resources are available, offering both convenience and a wide selection of options to ensure your unit functions optimally.

| Source | Description |

|---|---|

| Online Retailers | Websites such as Amazon or eBay often have a vast inventory of necessary components, allowing for easy comparison of prices and reviews. |

| Manufacturer’s Website | Visiting the official site of the appliance brand can lead you directly to OEM components, ensuring compatibility and quality. |

| Local Repair Shops | Nearby repair centers can offer a personalized experience, often with knowledgeable staff to help identify the right parts. |

| Appliance Parts Stores | Specialty stores dedicated to appliance components provide a focused selection and often have staff ready to assist with specific inquiries. |

Tips for Preventing Ice Maker Problems

Maintaining the efficiency of your freezing appliance is crucial for consistent performance. By following a few proactive steps, you can minimize the risk of issues and ensure a steady supply of frozen cubes. Here are some effective strategies to keep your device running smoothly.

Regular Maintenance

- Clean the interior regularly to prevent buildup that can impede functionality.

- Check and replace water filters as needed to ensure clean water supply.

- Inspect and clear any debris from drainage areas to avoid blockages.

Monitor Water Supply

- Ensure the water line is properly connected and free from kinks.

- Check for leaks or drips that may affect performance.

- Keep the water supply valve fully open for optimal flow.

By adhering to these tips, you can enhance the longevity and reliability of your appliance, reducing the chances of unexpected failures.

Importance of Regular Maintenance Checks

Regular inspections and upkeep are essential for ensuring optimal performance and longevity of household appliances. Neglecting these practices can lead to inefficiencies and unexpected breakdowns, ultimately resulting in increased costs and inconvenience.

Routine maintenance helps to identify potential issues before they escalate. Here are some key benefits:

- Enhanced Efficiency: Keeping components clean and functional allows appliances to operate at peak performance.

- Extended Lifespan: Regular care can significantly prolong the life of your devices, saving you money in the long run.

- Improved Safety: Frequent checks can uncover hazards, preventing accidents and ensuring safe operation.

- Cost Savings: Addressing minor repairs early can prevent the need for costly replacements.

To maintain your appliances effectively, consider the following practices:

- Schedule routine inspections at least twice a year.

- Clean filters and internal components regularly to avoid buildup.

- Monitor for unusual sounds or behaviors that may indicate a problem.

- Consult professional services for comprehensive checks when necessary.

By prioritizing maintenance, you can ensure that your appliances remain reliable and efficient, ultimately enhancing your daily life.