Exploring the internal workings of household machines can provide valuable insight into their functionality. When considering the components that contribute to efficient operation, it is important to understand the layout and purpose of each element. This knowledge can aid in maintenance and troubleshooting, ensuring longevity and optimal performance.

Each system is composed of various interconnected elements designed to work seamlessly together. From the heating mechanisms to the control units, each part plays a crucial role in the overall function. Identifying these elements allows users to better grasp how the entire system operates and what steps are necessary for upkeep.

In this section, we will delve into the essential components that contribute to the functionality of such systems. By gaining an understanding of how these elements interact, one can make informed decisions regarding care and repair, ensuring smooth operation over time.

Understanding the Key Components

To ensure efficient operation and long-lasting performance, it’s important to familiarize yourself with the essential elements of the machine. Each piece plays a critical role in maintaining the overall functionality and contributes to smooth, daily operation. By understanding the main components, you can troubleshoot potential issues and maintain the system with confidence.

Main Functional Units

The primary units within the system are designed to handle core tasks such as heating, airflow, and movement. These units include the heating element, which is responsible for generating warmth, and the blower assembly that controls airflow. Together, they ensure proper circulation and temperature, essential for optimal performance.

Supportive Mechanisms

Several supportive mechanisms are integral to the system’s operation. The control panel manages the system’s settings, allowing for adjustments in temperature and time. Additionally, sensors and switches monitor various aspects of the operation, providing feedback to prevent overheating and ensure safety.

How the Control Panel Works

The control panel serves as the primary interface between the user and the machine, enabling efficient operation through a simple set of commands. It provides the ability to configure various settings, manage cycles, and monitor the overall functionality. The design is intuitive, ensuring that adjustments can be made quickly and accurately, without unnecessary complexity.

Main Features and Functions

The panel is equipped with a variety of buttons and indicators that allow users to select specific modes, set timers, and track progress. Each function is designed to be accessible and easy to understand, offering a seamless experience for different preferences and needs.

Customization Options

In addition to basic functions, the interface offers customization options that adapt to various operational requirements. Users can adjust the settings based on personal preferences, allowing for more precise control over performance and outcomes. This level of flexibility ensures a more tailored and efficient use of the equipment.

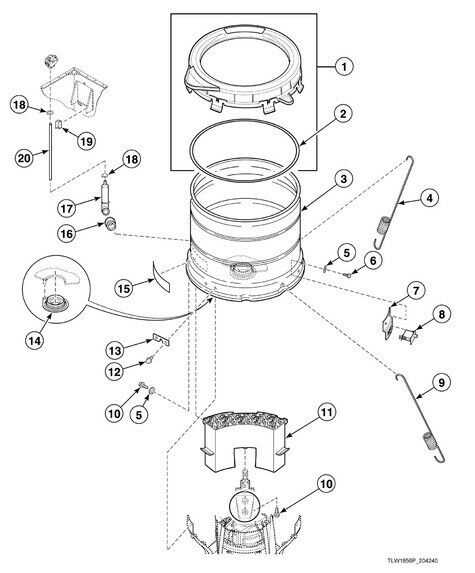

Exploring the Drum and Belt Mechanism

The drum and belt mechanism plays a vital role in ensuring efficient rotation and proper functioning within the unit. This system relies on the seamless interaction of components that work together to create smooth, continuous movement during the drying process. Understanding how these elements cooperate helps in maintaining optimal performance and longevity of the appliance.

- Drum Structure: The drum is the central component that holds the fabrics, rotating them to allow for even heat distribution and effective drying. Its durable construction ensures it can withstand frequent use while maintaining balance and stability.

- Belt Functionality: The belt is responsible for driving the rotation of the drum. Connected to the motor and tension pulley, it ensures a consistent turning motion, crucial for the drying cycle.

- Motor Interaction: The motor provides the necessary force to rotate the belt, which in turn moves the drum. Its synchronized operation with the belt system guarantees efficient functioning.

- Tension Pulley: This component maintains the correct tension on the belt, preventing slippage and ensuring the drum spins smoothly without

Thermal Fuse and Its Importance

The thermal fuse plays a crucial role in ensuring the safety and efficiency of modern appliances. Acting as a safeguard, this component is designed to prevent overheating by interrupting the electrical flow when a temperature limit is exceeded. This not only helps protect the machine from potential damage but also prevents hazards such as fires.

Below is a basic overview of key details regarding the thermal fuse:

Function Effect of Failure Replacement Frequency Prevents overheating Can stop the system from functioning When overheating occurs Maintaining a functional thermal fuse is vital for the long-term performance of the appliance. Regular inspections and timely replacements can ensure optimal safety and prevent unexpected issues.

Lint Filter Functionality and Maintenance

The lint filter is an essential component that helps ensure the efficiency of air circulation within the system. By trapping debris, it prevents blockages and maintains optimal performance, allowing the machine to function smoothly over time. Regular cleaning of this filter is necessary to avoid potential issues and to prolong the appliance’s lifespan.

To maintain the lint filter effectively, it is recommended to follow these steps:

Step Action 1 After every cycle, remove the filter from its housing. 2 Carefully wipe off any collected particles using a soft cloth or by hand. 3 Rinse the filter under running water occasionally to remove any finer residues. Moisture Sensor and Drying Efficiency

The integration of humidity detection technology significantly enhances the performance of modern laundry appliances. By accurately measuring the moisture levels in fabric, these devices optimize the drying process, ensuring that garments emerge perfectly dried without unnecessary energy consumption.

Functionality of Moisture Sensors

Humidity detection systems operate by utilizing various mechanisms to assess the wetness of clothes. This technology plays a critical role in:

- Preventing over-drying, which can lead to fabric damage.

- Minimizing energy use by adjusting cycle times based on real-time data.

- Improving the overall efficiency of the drying process.

Benefits of Enhanced Drying Processes

Implementing advanced moisture detection contributes to several advantages:

- Cost savings on energy bills due to reduced operation time.

- Prolonged lifespan of textiles by avoiding excessive heat exposure.

- Increased convenience, as users can rely on the system to determine optimal drying conditions.

Heating Element Troubleshooting

When a garment drying appliance fails to produce heat, it can lead to prolonged drying cycles and unsatisfactory results. Identifying issues related to the heating component is essential for restoring optimal performance. This section provides guidance on diagnosing and resolving common problems associated with this crucial element.

Signs of Malfunction

Several indicators may suggest that the heating component is not functioning correctly. If items remain damp after a full cycle, or if the unit emits unusual noises, it may signal a malfunction. Additionally, if the appliance trips circuit breakers frequently, the heating element might be at fault.

Troubleshooting Steps

To effectively address potential issues, begin by inspecting the electrical connections to the heating element. Ensure that all wires are secure and free of corrosion. Next, utilize a multimeter to test the heating component for continuity. A reading of zero indicates a break in the element, necessitating replacement. If the element appears intact, further examination of the thermal fuse and thermostat is recommended, as these components can impact the heating process.

Replacing the Door Switch

Replacing a faulty switch that controls the access panel of your appliance is essential for ensuring proper functionality. This component plays a crucial role in the operation, as it detects whether the door is securely closed. When this part malfunctions, it can lead to various issues, such as the machine not starting or unexpectedly shutting off during a cycle.

To begin the replacement process, first, ensure the appliance is disconnected from the power source to prevent any electrical hazards. Next, remove the access panel by unscrewing the necessary fasteners, allowing you to access the switch. Take note of the wiring configuration for proper reconnection.

After removing the old switch, install the new one by securing it in place and reconnecting the wires according to your previous notes. Once everything is in position, reattach the access panel and restore power to the unit. Test the new switch by opening and closing the door, verifying that it functions correctly. This straightforward repair can extend the life of your appliance and enhance its performance.

Drive Motor Role and Issues

The drive motor is a crucial component in any appliance that relies on rotation for its functionality. This part is responsible for powering the mechanical elements, enabling the device to operate smoothly and efficiently. Understanding its role is essential for maintaining the overall performance of the unit.

Common issues related to the drive motor can significantly impact the effectiveness of the appliance. Over time, wear and tear can lead to reduced performance, unusual noises, or even complete failure. Identifying symptoms early on, such as inconsistent spinning or failure to start, can prevent further damage and costly repairs.

Regular maintenance and timely intervention are vital in addressing motor-related problems. Keeping the motor clean and ensuring proper alignment with other components can enhance its lifespan. In case of persistent issues, consulting a professional can provide the necessary insights and solutions to restore optimal functionality.