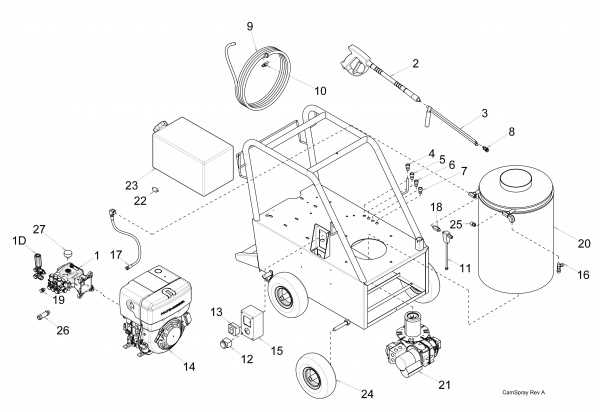

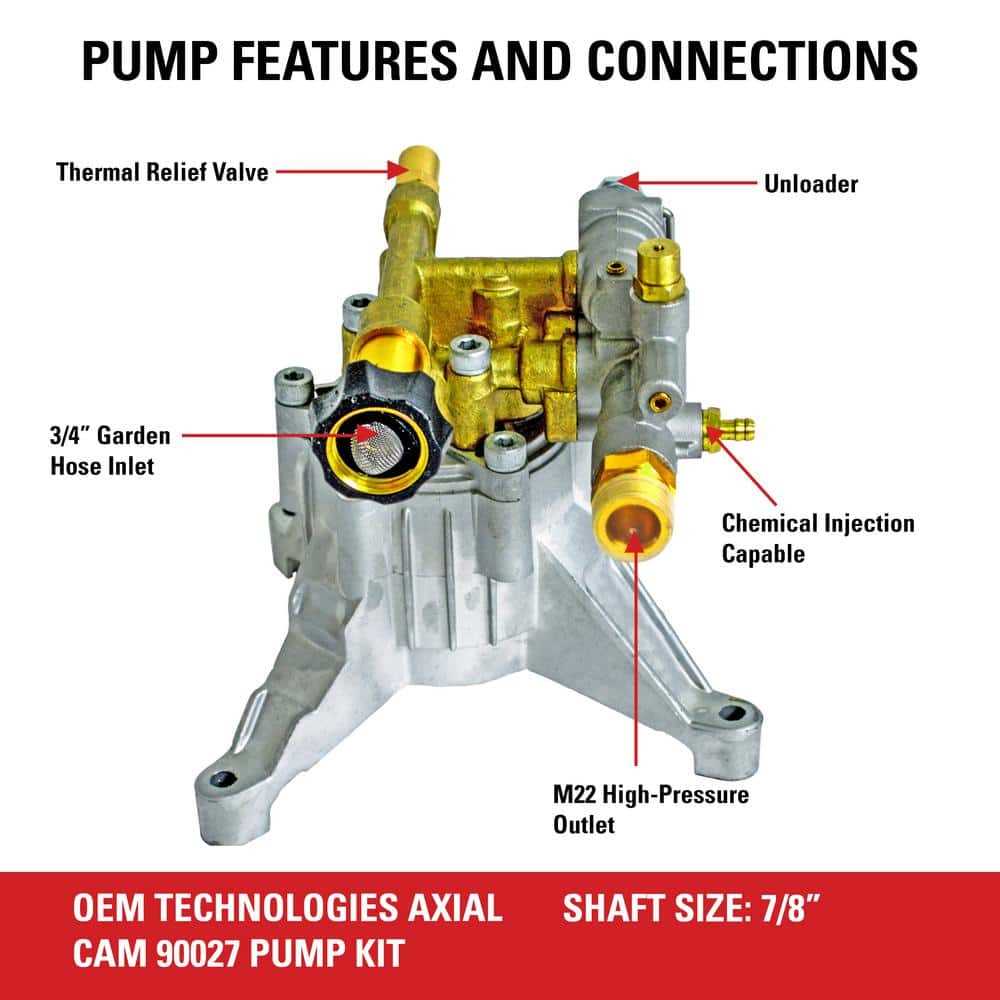

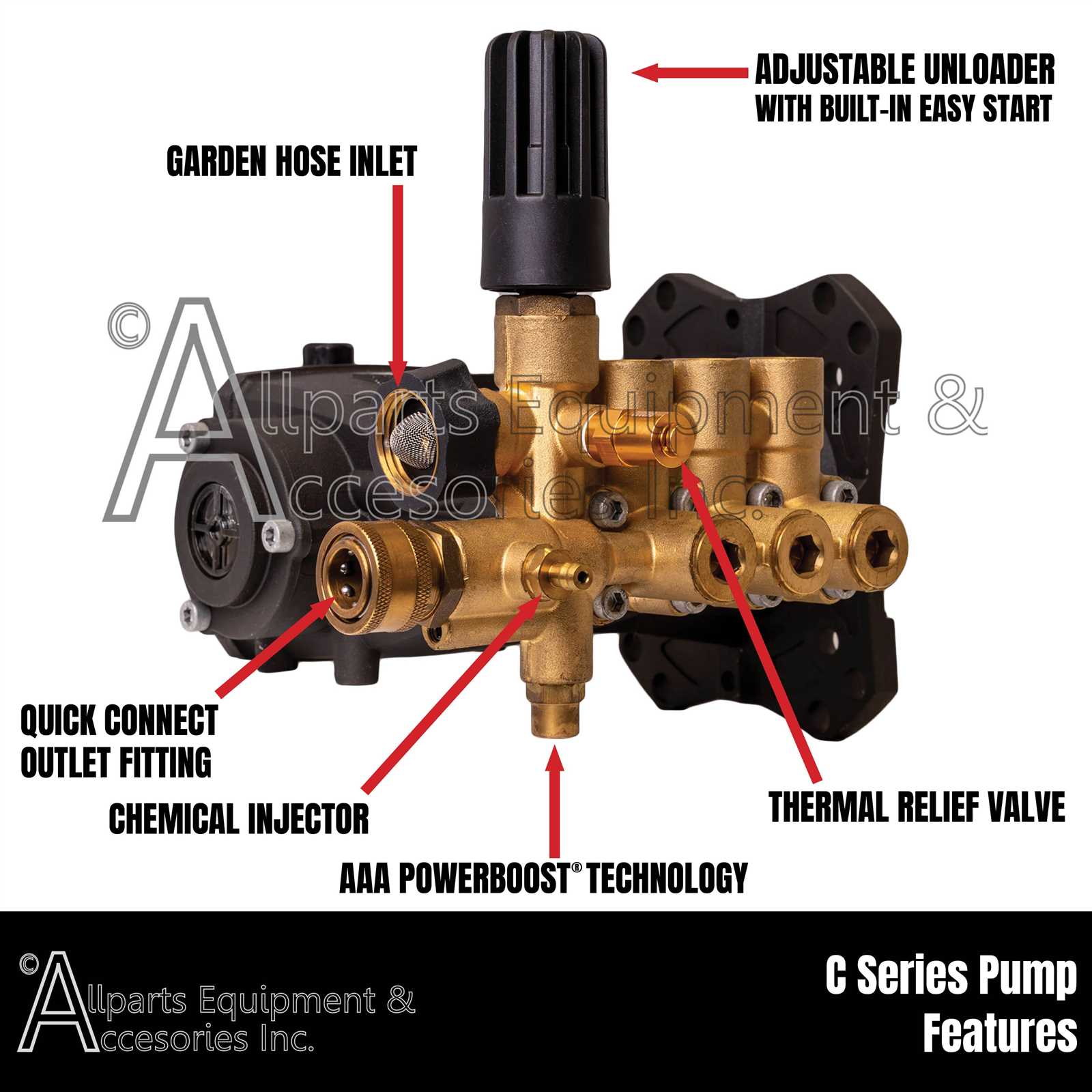

In the realm of outdoor maintenance, knowing the various components of cleaning machinery is crucial for optimal performance and longevity. Understanding how each element functions contributes to effective usage and timely repairs, ensuring that your equipment remains in excellent condition for all your cleaning tasks.

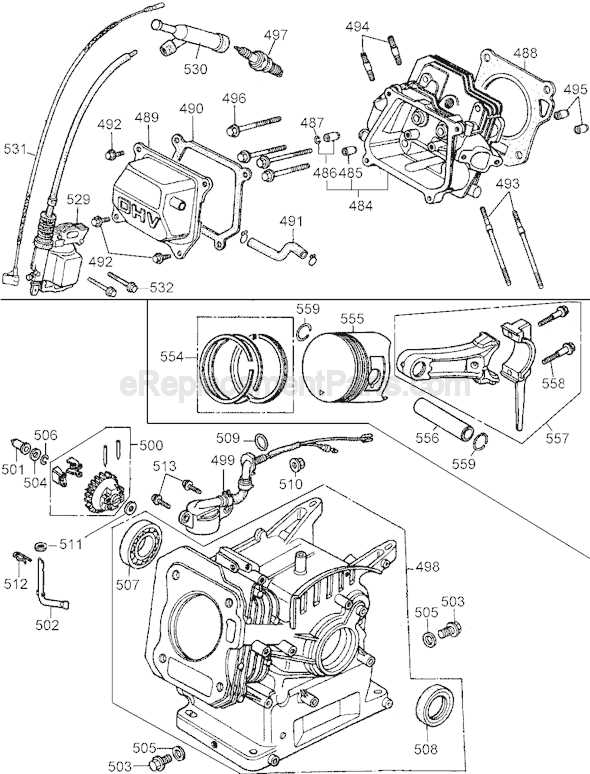

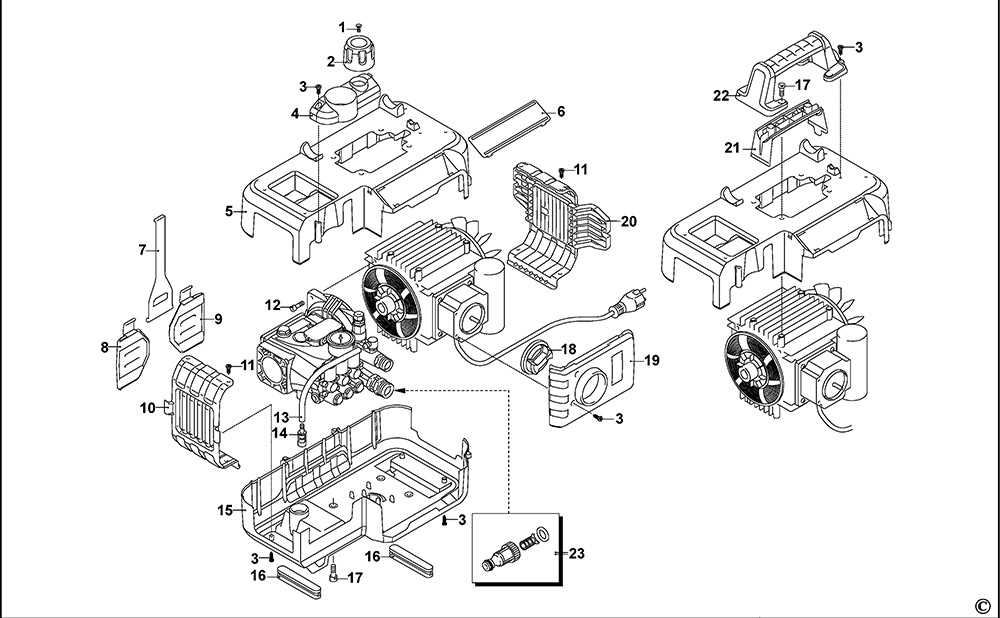

The inner workings of these machines can often seem complex. Familiarizing yourself with the different segments can demystify the operation, allowing users to diagnose issues and make informed decisions about replacements and repairs. Each component plays a vital role in the overall functionality, influencing everything from water flow to energy efficiency.

By exploring the intricate details of these systems, users can gain insights into maintenance practices and troubleshooting techniques. This knowledge empowers owners to maintain their machinery effectively, enhancing its lifespan and ensuring consistent, high-quality results for various cleaning applications.

When certain components of your cleaning equipment begin to malfunction, timely replacement becomes essential to ensure smooth operation. Replacing worn or damaged elements can prolong the life of the machine and maintain its efficiency. Below is a guide on how to correctly handle this process, helping you restore functionality.

Identifying the Problem

The first step in replacing broken components is to diagnose which part is causing the issue. Common symptoms of failure can include unusual noises, reduced performance, or visible wear. Once you have pinpointed the faulty component, you can move on to replacing it with a compatible one.

Step-by-Step Replacement Process

Follow these general steps to replace a defective component. Make sure the device is turned off and disconnected from any power or water source. Gather the necessary tools and a compatible replacement part before beginning.

| Step | Description |

|---|---|

| 1 | Turn off the equipment and disconnect it from power and water supplies. |

| 2 | Remove any

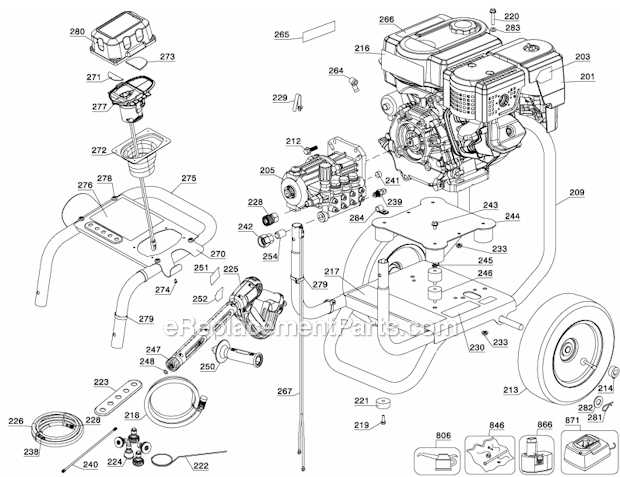

Upgrading Your Pressure Washer

Enhancing the performance of your cleaning equipment can lead to more efficient results and extend the life of your machine. By making thoughtful improvements, you can increase its overall power and adaptability for various cleaning tasks. Choosing the Right Accessories: When upgrading, it’s important to select the proper attachments that suit your specific needs. These can include enhanced nozzles, stronger hoses, or even specialized tools that tackle specific surfaces more effectively. Improving Efficiency: Modern upgrades can help optimize water usage and reduce the time spent on heavy-duty tasks. Many modernized components are designed to provide consistent, powerful output while conserving energy. By investing in these improvements, you can maximize the capabilities of your cleaning equipment, ensuring it delivers top performance and adapts to various demands. Comparing Different Models

When selecting equipment for outdoor cleaning tasks, it’s important to understand the differences between various models. Each option offers unique features designed for specific purposes, and identifying the right one depends on your needs. In this section, we will explore key factors that set these models apart, helping you make a more informed decision. Power and Performance

The power levels of cleaning tools can vary greatly between models. Some are designed for light residential use, while others are more suitable for heavy-duty tasks. Consider how frequently and intensively you plan to use the equipment when comparing models.

Additional Features

Many modern options come with features aimed at enhancing ease of use and efficiency. Look for models that include adjustable settings, ergonomic handles, and easy-to-use attachments. These can significantly affect your overall experience and the time it takes to complete your tasks.

|