When exploring the inner workings of any complex home appliance, it’s crucial to have a clear picture of how each mechanism contributes to the overall functionality. Whether you’re maintaining or repairing a machine, having a solid grasp of its internal setup can make the process much smoother and more efficient.

Each element plays a vital role in ensuring the appliance operates as expected. Knowing the arrangement and purpose of these various components can help not only in troubleshooting but also in extending the lifespan of your equipment. This knowledge can prove invaluable during routine checkups or when dealing with unexpected malfunctions.

By becoming familiar with the key mechanisms, you’ll gain insights into how they interact and function together. This detailed awareness helps identify issues early on, saving time and avoiding costly repairs. Regular upkeep and proper understanding are the cornerstones of long-lasting and reliable performance.

Understanding GE Front Load Washer Components

In any modern GE appliance, several key elements work together to ensure smooth operation and efficient performance. By exploring the various sections and mechanisms, you can gain a better understanding of how these machines function as a whole. This knowledge can help you identify potential issues and maintain your device for longer use.

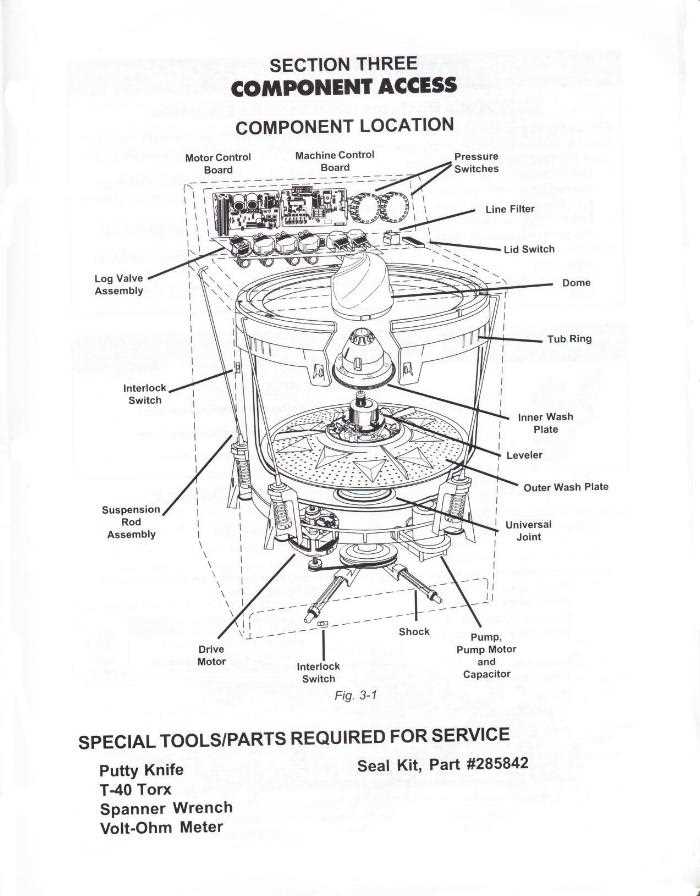

Main Structural Elements

The external casing and internal framework provide support and stability. These parts house and protect the various mechanical and electronic systems, ensuring they remain secure during the operation of the appliance.

Operational Mechanisms

At the core of the appliance’s performance are its mechanical and electrical systems. These include components responsible

How to Identify Key Washer Parts

Understanding the individual components of your laundry machine is essential for ensuring smooth operation and efficient troubleshooting. By familiarizing yourself with the primary sections and mechanisms, you can easily pinpoint potential issues and maintain optimal performance.

Main Sections of the Machine

One of the critical areas to examine is the rotating drum, which is responsible for the cleaning cycle. It spins and helps agitate the clothes, ensuring they are properly cleaned. This drum is supported by several other elements that work together to manage water levels and motion.

Supporting Mechanisms

Another important part is the control panel. This section allows users to select different settings for various cycles and temperatures. Hidden within the system, there is a network of hoses and valves that regulate water intake and drainage, ensuring that each cycle runs smoothly without interruptions.

Common Issues with Washer Mechanisms

The operation of laundry machines often faces a variety of challenges that can affect their performance. These mechanisms involve numerous components that work together to ensure efficient function, but occasional malfunctions are inevitable. Understanding the typical problems that arise can help users identify potential issues early and address them before they become more serious.

Problems with Water Flow

Water intake and drainage are critical for the machine’s efficiency. If there are blockages in the hoses or malfunctioning valves, the machine might not fill properly or could have trouble draining, leading to operational delays or incomplete cleaning cycles.

Drum Movement Issues

The movement of the drum is another area where problems can occur. Issues with the belts, pulleys, or motor may result in the drum not spinning or agitating correctly, impacting the quality of the cleaning process. Regular maintenance of these components is essential to avoid wear and tear.

Guide to Replacing Faulty Parts

When a household appliance stops working properly, it’s essential to identify and replace the malfunctioning components. Replacing damaged or worn-out elements ensures the machine continues to function efficiently. This guide provides clear steps on how to swap out the necessary pieces in a few easy steps.

- First, unplug the device from the power source to avoid any accidents during the repair process.

- Next, inspect the machine carefully to locate the faulty section. This may involve removing outer panels or accessing internal areas.

- Once the problem has been identified, refer to the manufacturer’s manual to determine the correct replacement piece.

- Order the necessary component, ensuring it matches the model specifications of your equipment.

- After receiving the replacement, carefully follow the disassembly steps to remove the broken part, keeping screws and fasteners organized.

- Install the new piece, securing it properly to ensure everything fits as intended.

- Finally, reassemble the device and perform a test run to

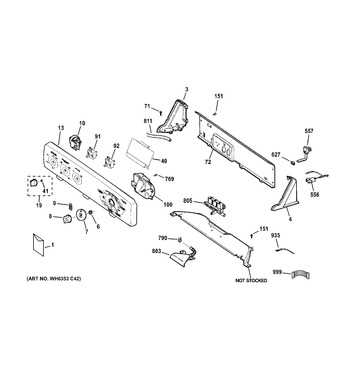

Locating the Washer Control Panel

The control panel is an essential component, where all the primary settings and adjustments are made. Its placement varies depending on the model, but it is usually positioned for easy access to operate the machine’s different functions. Knowing its location ensures a smooth operation when setting up or troubleshooting.

Step Description 1 Identify the area where the buttons and display are located on the upper or front section of the machine. 2 Ensure that this section is free from any obstructions or residue to keep controls functioning properly. 3 If necessary, refer to the user manual for precise placement in case of unfamiliar models. Inner Drum Structure and Functions

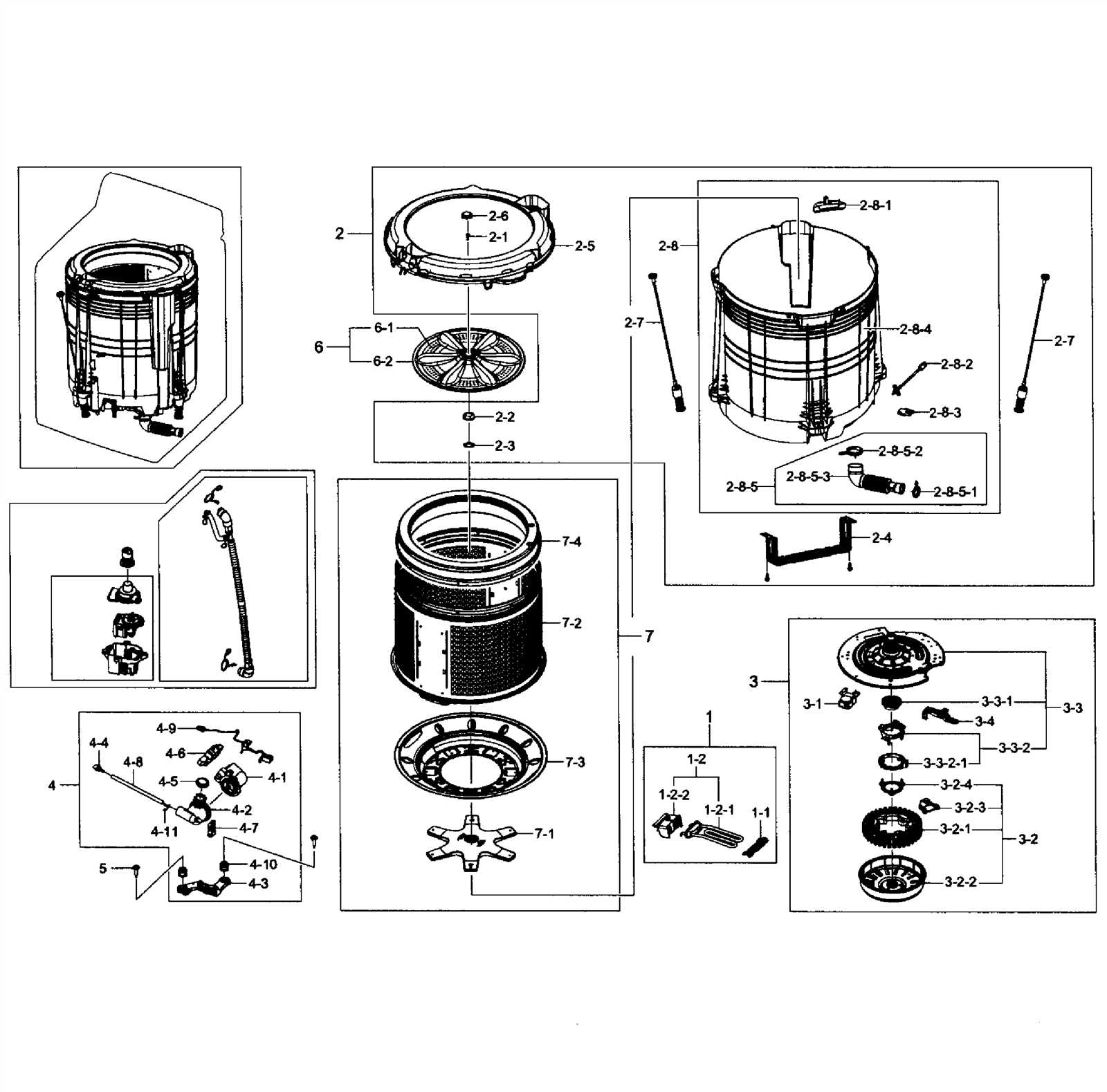

The central component of a cleaning appliance’s drum is crucial for the efficient performance of the entire system. This element plays a key role in the interaction between clothes and water, ensuring that the cleaning process is effective and gentle on fabrics. Its design is carefully engineered to allow optimal movement and agitation, ensuring that dirt is thoroughly removed while maintaining the integrity of garments.

The structure of this drum consists of several key parts that work together to facilitate the movement of laundry. These parts include the perforated surface, support mechanisms, and the rotation system. Each component is designed with durability and efficiency in mind, aiming to improve both cleaning performance and energy consumption.

Component Function Perforated Shell Allows water to pass through, helping to clean clothes by facilitating the movement of water and detergent. Support Rings Provide stability and minimize movement during the rotation cycle, preventing damage to the appliance. Drive Shaft Responsible for the rotation of the drum, powered by the motor, ensuring smooth and consistent agitation. Importance of the Drain Pump Assembly

The drain pump assembly plays a crucial role in the proper functioning of a laundry appliance, ensuring that water is efficiently removed after each cycle. This component is responsible for expelling used water, allowing the appliance to prepare for the next phase of operation. Without it, excess water could accumulate, leading to performance issues or potential damage to the machine.

Key Functions of the Drain Pump

The drain pump is responsible for facilitating the water drainage process by pushing out water through the drainage system. It ensures that water is removed quickly and thoroughly, preventing any water retention that could cause mildew, mold, or unpleasant odors within the appliance.

Impact of a Faulty Drain Pump

When the drain pump assembly malfunctions, it can result in poor drainage, causing water to remain inside the appliance. This not only hinders the overall efficiency of the machine but also increases the likelihood of flooding or leaking. Regular maintenance and timely repairs of this component are essential to ensure optimal performance.

Tips for Maintaining Door Seals

Door seals are vital components in ensuring the efficiency and longevity of your appliance. Proper care of these seals prevents leaks and enhances performance. Regular maintenance can extend the lifespan of the seals and help avoid costly repairs.

Regular Cleaning

Keeping the door seals clean is essential for optimal performance. Dirt and moisture can cause mold buildup, which not only damages the seals but also affects the overall functionality of the appliance.

- Wipe the seals with a soft cloth and mild detergent to remove dirt and grime.

- Avoid harsh chemicals that could damage the material of the seals.

- Make sure to dry the seals thoroughly after cleaning to prevent mold growth.

Inspect for Wear and Tear

Frequent inspections of the door seals can help you spot early signs of wear or damage. Look for cracks, tears, or any signs of degradation.

- Check the seals for any visible cracks or holes that could lead to leaks.

- If you notice any damage, it is recommended to replace the seals promptly to avoid further issues.

- Inspect the seals’ flexibility, ensuring they are not too stiff or brittle.

Overview of Washer Motor Operation

The motor is a crucial component responsible for driving the mechanical movements within a cleaning appliance. It ensures the smooth rotation of various elements, such as drums or agitators, by converting electrical energy into motion. The efficiency and longevity of the motor play a significant role in the overall performance of the device, influencing factors like spin speed and energy consumption.

How the Motor Works

The motor functions by generating rotational force that powers the drum or agitator to spin during different phases of the cleaning process. It receives electrical power from the main control system, which directs the motor’s movement depending on the selected cycle. This electrical input is then transformed into mechanical energy that drives the motion.

Common Motor Types

Motor Type Key Features Universal Motor Versatile, high speed, used in many household appliances Direct Drive Motor Directly connected to the drum, reducing mechanical parts and noise Induction Motor Energy-efficient, operates without brushes, long lifespan