The efficient operation of your outdoor cleaning machinery relies heavily on its internal structure and the arrangement of its various elements. Familiarizing yourself with these components not only aids in maintenance but also enhances the longevity of your equipment. A well-functioning system ensures optimal performance, saving both time and resources in your cleaning endeavors.

In this section, we will delve into a comprehensive overview of the essential elements that make up your cleaning device. Each component plays a significant role in the overall functionality, and understanding their interconnections is crucial. By exploring these elements, you will gain insights that can help you troubleshoot issues and make informed decisions regarding repairs and replacements.

Whether you’re a seasoned user or a newcomer, having a clear mental picture of how everything fits together will empower you to tackle any challenges that may arise. From routine upkeep to part identification, grasping the layout and purpose of each section will enhance your confidence and efficiency in using your machinery.

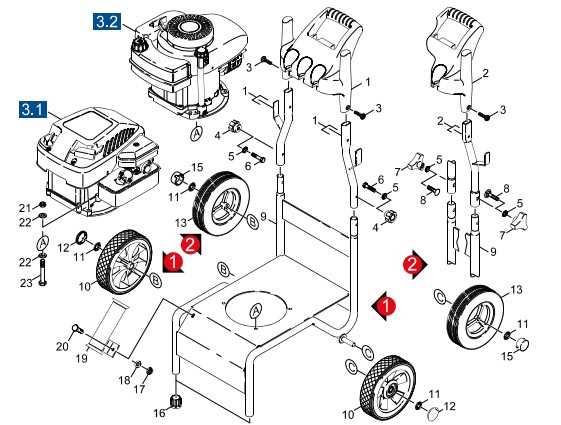

Understanding the Generac Pressure Washer

This section delves into the intricacies of a high-performance cleaning device designed for various outdoor tasks. It focuses on its essential components and their functions, ensuring users can maintain and utilize the equipment effectively. Familiarity with each element enhances operational efficiency and extends the lifespan of the machinery.

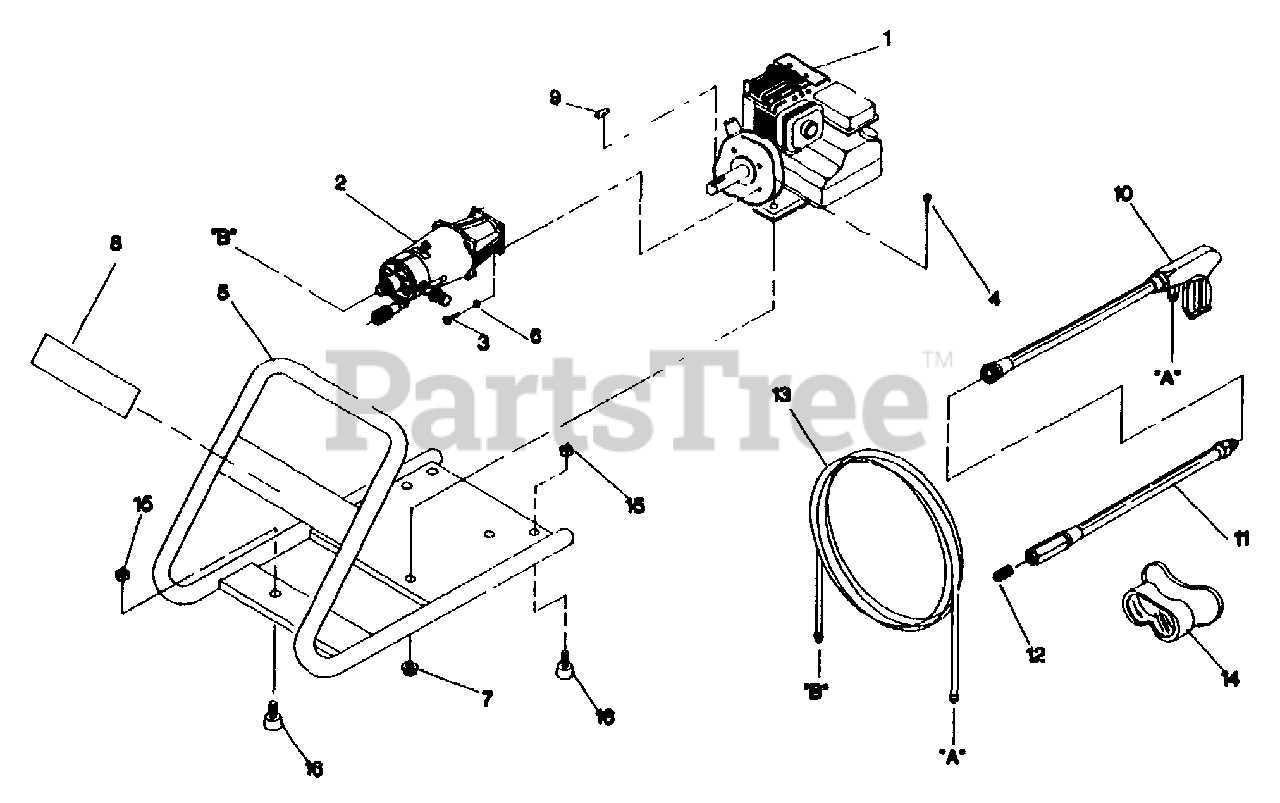

The following table outlines the key components of the cleaning unit, along with their roles:

| Component | Description |

|---|---|

| Engine | Provides power to operate the equipment. |

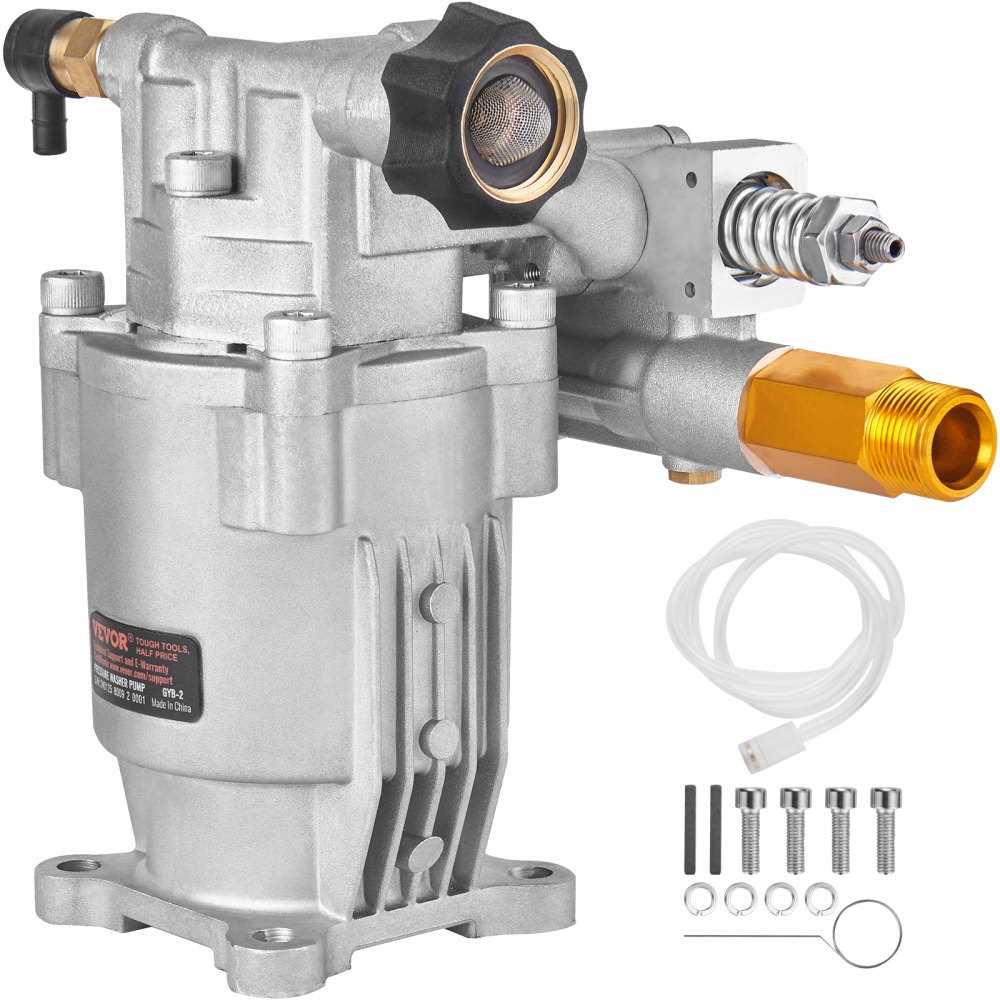

| Pump | Generates water pressure for cleaning tasks. |

| Trigger Gun | Controls the flow of water and pressure settings. |

| Hose | Transfers water from the unit to the nozzle. |

| Nozzle | Adjusts the spray pattern for different cleaning needs. |

| Frame | Houses all components and provides stability during operation. |

Understanding these components will empower users to troubleshoot common issues and perform regular maintenance, ultimately improving the overall effectiveness of the equipment.

Key Components of Pressure Washers

Understanding the essential elements of a cleaning machine enhances its effective usage and maintenance. Each component plays a crucial role in ensuring optimal performance and longevity.

- Motor or Engine: Powers the system, generating the necessary force.

- Pump: Converts the engine’s power into high-pressure water flow.

- Nozzle: Directs and adjusts the water spray for different cleaning tasks.

- Hose: Facilitates the movement of water from the pump to the nozzle.

- Frame: Provides structural support and houses various components.

Familiarizing yourself with these fundamental parts allows for better maintenance and troubleshooting, ultimately enhancing your cleaning experience.

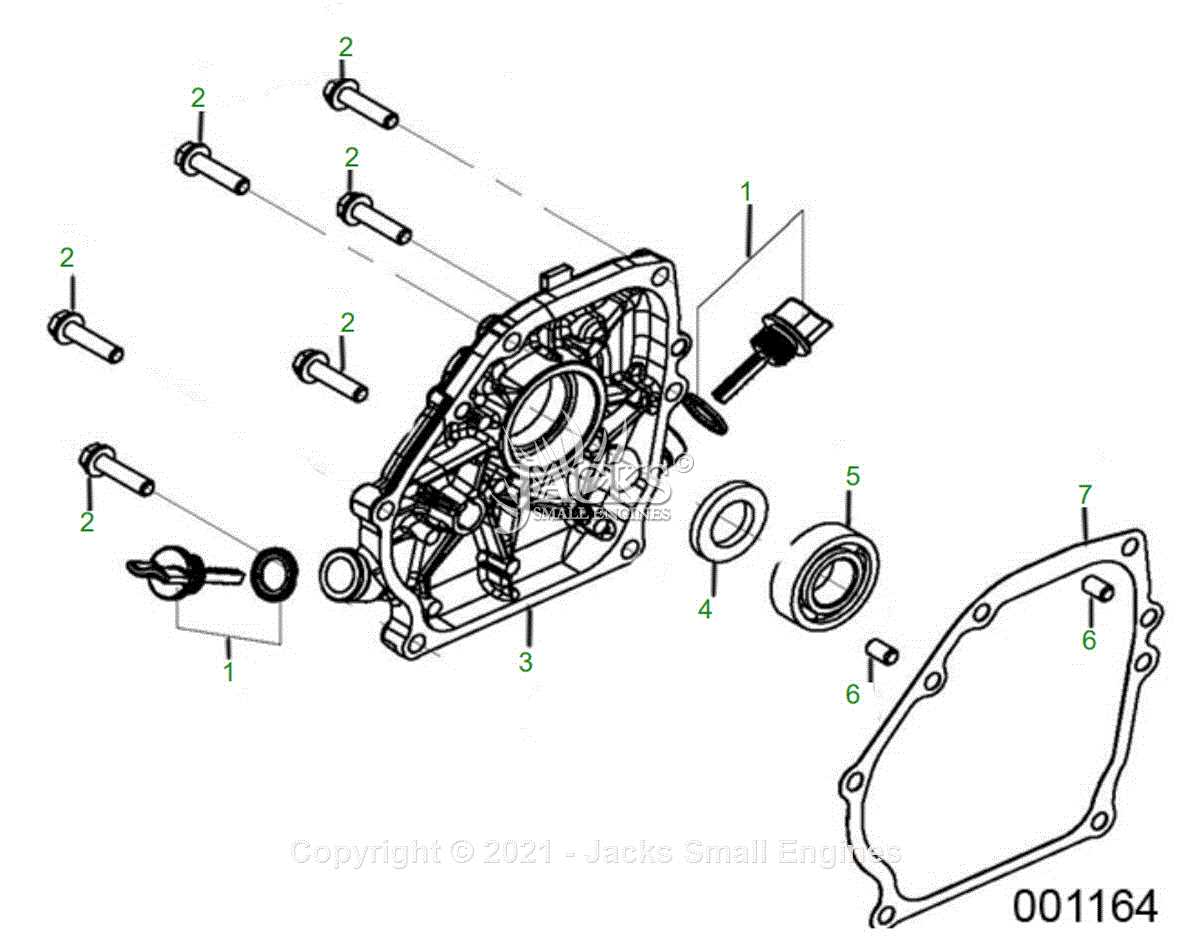

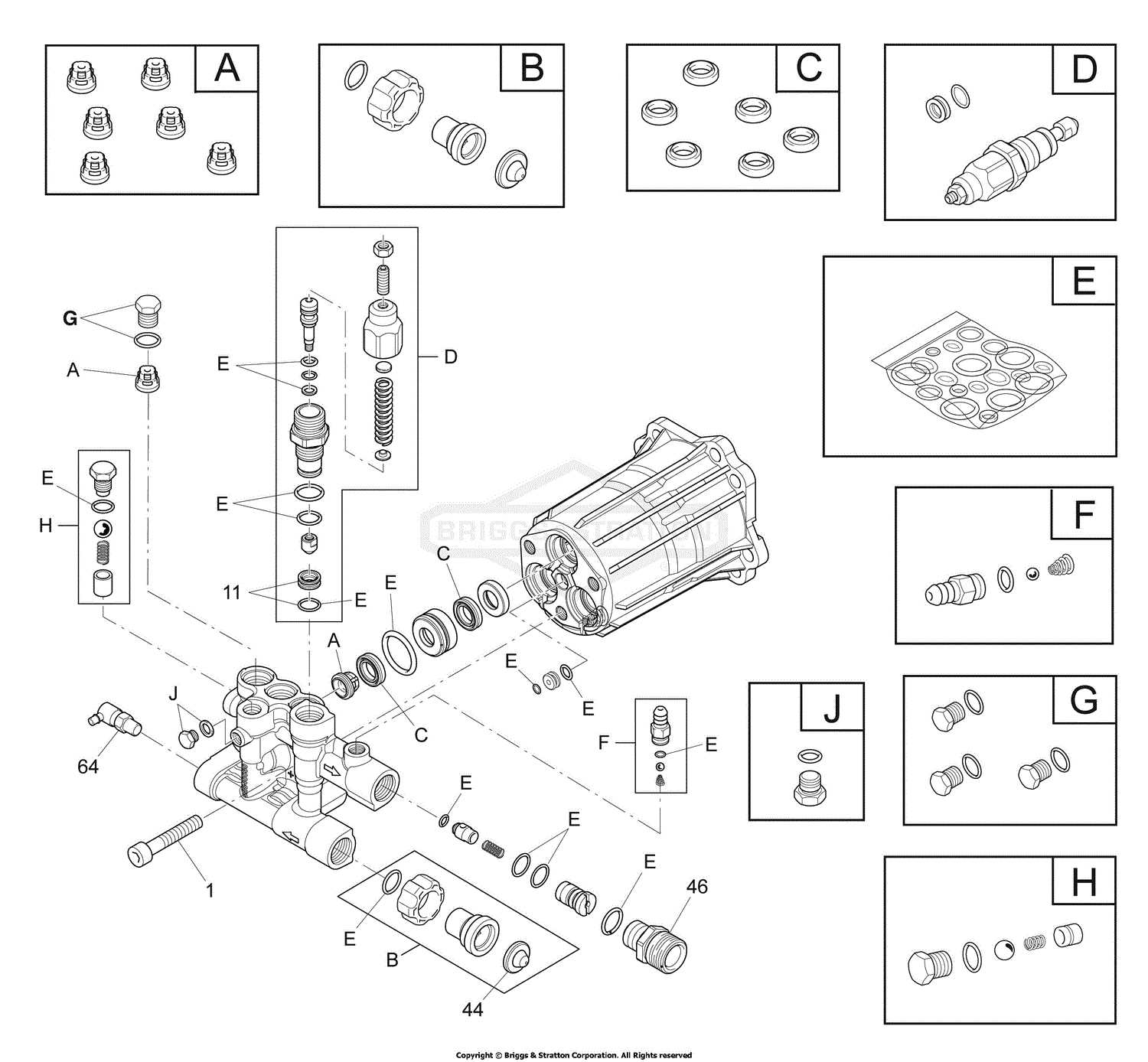

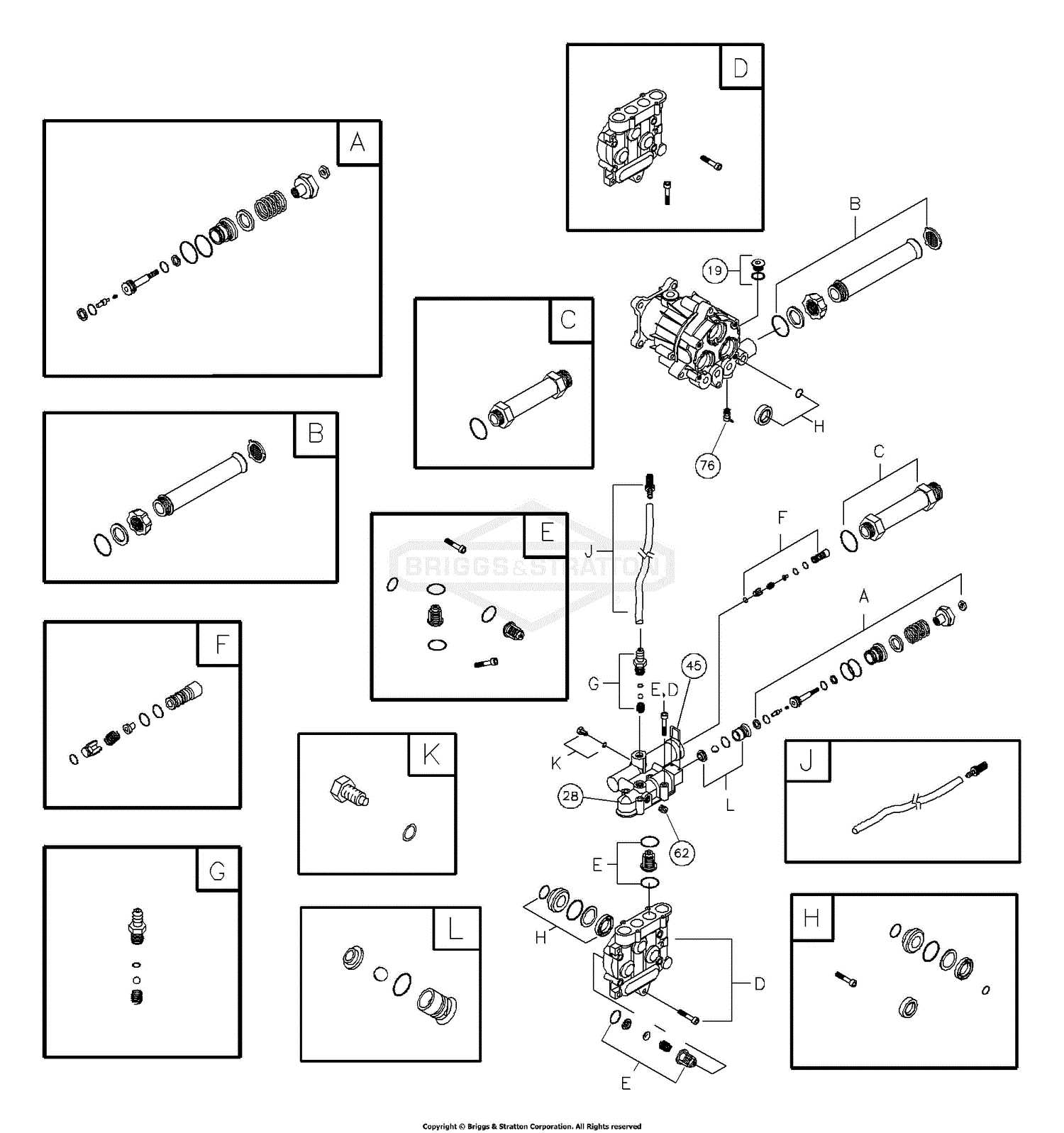

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual aids provide a comprehensive overview of components and their interrelationships, enabling users to identify specific elements quickly. Familiarity with these diagrams enhances your ability to troubleshoot and replace items efficiently.

1. Familiarize Yourself with Symbols: Each illustration uses standardized symbols to represent different components. Take the time to learn what each symbol means, as this will streamline your understanding.

2. Follow the Numbering System: Most diagrams include a numbering system that corresponds to a parts list. This list typically provides detailed information about each component, including part numbers and descriptions.

3. Note the Assembly Order: Pay attention to how components are arranged. The layout often reflects the assembly order, which can be crucial during reassembly.

4. Refer to Additional Resources: Don’t hesitate to consult manuals or online resources that accompany the illustration. These documents often provide context and troubleshooting tips that enhance your comprehension.

By mastering these techniques, you’ll find it easier to navigate through any technical illustration, making your repair and maintenance tasks more manageable.

Common Issues and Solutions

Understanding typical problems that may arise with outdoor cleaning devices can greatly enhance their longevity and efficiency. Identifying these issues early and applying effective solutions can prevent larger breakdowns and ensure optimal performance.

1. Lack of Pressure

A common issue encountered is insufficient force during operation. This may stem from clogged nozzles or low fluid levels. Regularly cleaning the nozzle and checking the fluid supply can resolve this issue swiftly.

2. Unusual Noises

Unwanted sounds during use often indicate mechanical problems. Loose components or damaged parts can be the culprits. Inspecting and tightening loose fittings, as well as replacing any worn parts, will typically remedy this situation.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your cleaning equipment requires regular upkeep and attention to detail. Adopting a proactive maintenance routine can significantly extend the lifespan of your device while enhancing its functionality.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Check Oil Level | Before Each Use | Ensure oil is clean and filled to the recommended level. |

| Inspect Hoses | Monthly | Look for cracks or leaks; replace if damaged. |

| Clean Filter | Every 3 Months | Remove debris to maintain airflow and efficiency. |

| Check Spark Plug | Every 6 Months | Replace if worn or dirty for optimal performance. |

| Store Properly | Off-Season | Keep in a dry place to prevent rust and damage. |

Replacement Parts Overview

When it comes to maintaining high-performance cleaning equipment, understanding the various components is essential for optimal functionality. This section delves into the critical elements that ensure your machine operates efficiently, offering insights into their roles and how to identify when replacements are necessary.

Key Components and Their Functions

Each element of your cleaning device serves a specific purpose, contributing to the overall effectiveness of the equipment. Familiarizing yourself with these components will aid in timely replacements and help prolong the lifespan of your unit.

| Component | Function |

|---|---|

| Motor | Powers the unit, providing the necessary force for operation. |

| Hose | Conveys water from the source to the nozzle, ensuring a steady flow. |

| Nozzle | Directs and adjusts the spray pattern for various cleaning tasks. |

| Pump | Pressurizes the water, enhancing its cleaning capability. |

Identifying Replacement Needs

Recognizing signs of wear or malfunction is vital for maintaining efficiency. Common indicators that a component may need replacement include unusual noises, decreased performance, or visible damage. Regular inspections and timely interventions can prevent further issues and keep your equipment running smoothly.

Finding Genuine Generac Parts

When it comes to maintaining outdoor equipment, ensuring you have the right components is essential for optimal performance. Authentic elements not only guarantee compatibility but also enhance the longevity of your machine. This section explores how to identify and procure original items that meet the highest quality standards.

Purchasing legitimate components can prevent potential issues that arise from using inferior substitutes. Here are some key aspects to consider when searching for authentic parts:

| Criteria | Description |

|---|---|

| Source | Buy from authorized dealers or directly from the manufacturer to ensure authenticity. |

| Packaging | Check for proper branding and packaging that indicates the product’s legitimacy. |

| Part Numbers | Always verify part numbers to ensure you are purchasing the correct item. |

| Reviews | Look for customer feedback to assess the reliability of the seller. |

By following these guidelines, you can confidently source the necessary components that will keep your equipment running smoothly and efficiently for years to come.

DIY Repairs for Pressure Washers

Maintaining and fixing cleaning devices can be a rewarding endeavor for enthusiasts and homeowners alike. Understanding the fundamental components and common issues can empower you to tackle repairs efficiently. This guide will explore various troubleshooting techniques and offer insights into the DIY approach, ensuring your machine operates at its best.

Identifying Common Issues

Before diving into repairs, it’s essential to recognize frequent problems. Leaking hoses or inefficient cleaning are often signs of wear or blockage. Begin by examining the main components such as the motor, pump, and connections. Addressing these issues promptly can prevent further damage and extend the lifespan of your equipment.

Simple Repair Techniques

Many repairs can be handled with basic tools and a little know-how. For example, replacing a worn-out nozzle can significantly improve performance. Regularly checking and cleaning filters will also enhance efficiency. Always consult your user manual for specific guidance and safety precautions before starting any repair task.

Upgrading Your Pressure Washer

Enhancing your cleaning equipment can significantly improve its performance and efficiency. By selecting high-quality components and accessories, you can transform a standard model into a powerful tool that meets your specific needs.

Evaluate Your Needs: Consider the tasks you frequently tackle. Upgrading components such as nozzles, hoses, or motors can optimize your machine for different surfaces and jobs.

Choose Quality Components: Investing in durable and reliable accessories ensures longevity and effectiveness. Look for options that provide better flow rates or improved spray patterns.

Enhance Mobility: Adding wheels or a better handle can make maneuvering easier, allowing for greater reach and convenience during use.

Ultimately, a thoughtful upgrade can elevate your cleaning experience, making it more efficient and enjoyable.