Exploring the intricate assembly of agricultural machinery offers invaluable insights into their operation and maintenance. This section aims to provide a comprehensive overview of the key elements that contribute to the efficiency and performance of these vital machines. By dissecting the components, users can enhance their understanding and ensure optimal functionality.

Identifying essential elements is crucial for anyone involved in the upkeep or operation of farming equipment. Grasping how each piece interacts with others fosters a more profound appreciation for the engineering behind these powerful machines. Detailed illustrations help visualize the relationships between various sections, leading to improved maintenance practices.

Furthermore, having a thorough grasp of the structural makeup aids in troubleshooting and repairs. Whether you are a seasoned operator or a newcomer, this knowledge empowers you to address issues swiftly and effectively. Ultimately, understanding the assembly leads to enhanced productivity and longevity of the machinery, making it an indispensable aspect of agricultural operations.

Overview of John Deere 750 Tractor

This segment provides a comprehensive insight into a well-regarded agricultural machine known for its robust performance and versatility. With a design focused on efficiency, it plays a crucial role in modern farming practices, aiding in various tasks ranging from tilling to transporting goods.

Key Features

- Powerful engine designed for high torque

- Durable construction suitable for heavy-duty applications

- Ergonomic controls for user-friendly operation

- Versatile attachment compatibility for different farming tasks

Applications

- Soil preparation and cultivation

- Hauling materials and equipment

- Maintenance of landscapes and fields

- Supporting planting and harvesting operations

Key Components of the Tractor

The effectiveness of agricultural machinery relies heavily on its essential elements. Understanding these critical components is vital for proper maintenance and optimal performance. Each segment plays a unique role in the overall functionality, ensuring the machinery operates efficiently in various tasks.

Core Parts and Their Functions

- Engine: The heart of the machine, providing the necessary power for various operations.

- Transmission: Responsible for transferring power from the engine to the wheels, enabling movement and speed adjustments.

- Chassis: The structural framework that supports all other components, ensuring stability and durability.

- Hydraulic System: Essential for lifting and controlling attachments, enhancing versatility in various agricultural tasks.

- Electrical System: Powers lights and other electronic components, ensuring functionality in low-light conditions.

Additional Elements to Consider

- Wheels and Tires: Provide traction and stability, critical for operation on various terrains.

- Cooling System: Maintains optimal engine temperature, preventing overheating during extensive use.

- Fuel System: Delivers energy to the engine, vital for sustained operation.

- Exhaust System: Manages emissions, ensuring compliance with environmental standards.

- Cabin: Provides a comfortable and safe space for the operator, enhancing overall productivity.

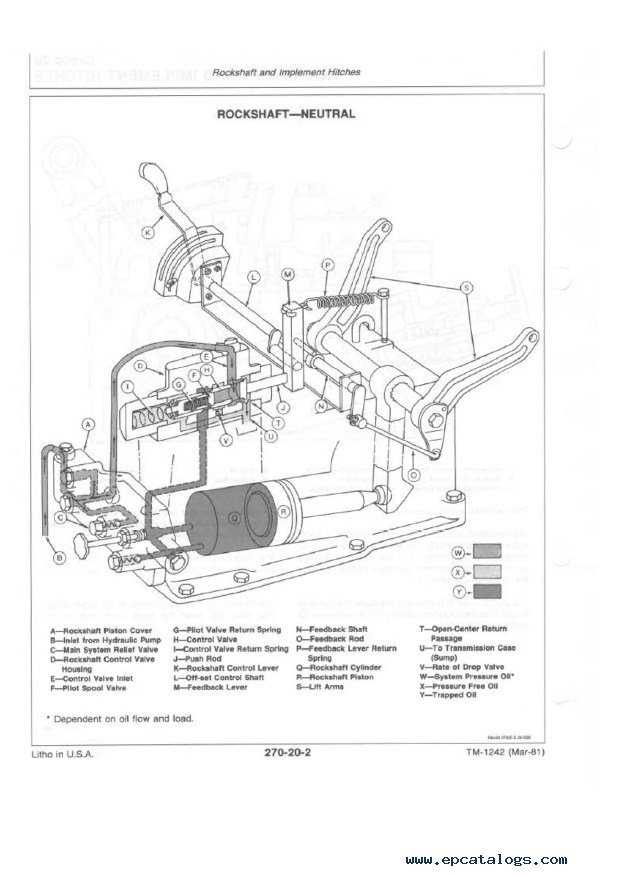

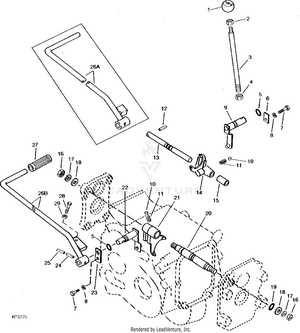

Understanding the Parts Diagram

The components of a mechanical vehicle are crucial for its optimal performance and functionality. Grasping the layout and relationships between various elements is essential for maintenance and repairs. A visual representation serves as a guide to identify and locate these crucial components, ensuring that users can effectively troubleshoot and carry out necessary tasks.

Importance of Each Element

Every component plays a specific role, contributing to the overall efficiency of the machine. Recognizing the purpose of each element allows operators to prioritize their focus during inspections and servicing. This knowledge not only aids in resolving issues but also enhances the longevity of the vehicle.

How to Read the Visual Representation

Interpreting the visual layout requires attention to detail. Familiarity with symbols and notation is key to understanding how parts are interconnected. By studying the schematic closely, users can gain insights into the mechanical workings, which ultimately aids in effective maintenance practices.

Maintenance Tips for Essential Parts

Regular upkeep of crucial components is vital for ensuring optimal performance and longevity of machinery. Implementing effective maintenance practices can prevent costly repairs and enhance operational efficiency. Here are some essential tips to consider for various key elements.

-

Inspect Fluid Levels:

Check and maintain the appropriate levels of oil, coolant, and hydraulic fluids. Ensure that fluids are clean and replace them as needed to avoid contamination and overheating.

-

Monitor Tire Condition:

Regularly inspect tires for wear and proper inflation. Keeping tires at the recommended pressure improves traction and reduces fuel consumption.

-

Examine Filters:

Replace air and fuel filters regularly to ensure clean airflow and optimal fuel efficiency. Clogged filters can lead to decreased performance.

-

Check Battery Health:

Inspect the battery for corrosion and ensure connections are tight. Regularly test the battery’s charge to avoid unexpected failures.

-

Clean and Lubricate Moving Parts:

Keep all moving components clean and well-lubricated to reduce friction and wear. Regularly apply appropriate lubricants to joints and pivot points.

By adhering to these maintenance practices, you can significantly extend the life and reliability of your equipment. Establish a routine maintenance schedule to ensure that each component receives the attention it requires.

Common Issues with the 750 Tractor

The machinery is known for its reliability, but like any equipment, it can encounter various challenges over time. Understanding the frequent problems can aid in effective maintenance and prolonging its lifespan. Operators often report specific difficulties that can arise, impacting performance and usability.

Engine-Related Problems

One of the most significant areas of concern revolves around the engine. Common issues include:

- Starting difficulties, often attributed to battery or ignition system faults

- Overheating, which can be caused by coolant leaks or radiator blockages

- Unusual noises, indicating potential wear or damage to internal components

Hydraulic System Failures

The hydraulic system is crucial for operational efficiency. However, operators frequently face:

- Leakages in hoses or connections, leading to reduced power

- Poor lifting performance, often due to low fluid levels or contaminated oil

- Erratic movements, which may suggest problems with control valves

Parts Replacement Procedures Explained

Understanding the procedures for replacing components in machinery is essential for maintaining optimal performance and longevity. Proper guidance ensures that the replacement is executed efficiently and safely, preventing potential issues that may arise from improper installation.

The following steps outline a systematic approach to component replacement:

-

Identify the Component: Determine the specific part that requires replacement. Consult the maintenance manual to ensure you have the correct specifications.

-

Gather Necessary Tools: Collect all required tools and replacement components. This may include wrenches, screwdrivers, and any special tools specified in the manual.

-

Ensure Safety: Before starting, make sure to disconnect the power source to prevent accidental activation. Use personal protective equipment as needed.

-

Remove the Old Component: Carefully detach the component, following the instructions in the manual. Take note of any screws, bolts, or clips that need to be removed.

-

Install the New Component: Position the new part in place, ensuring it aligns correctly with surrounding components. Secure it using the appropriate fasteners.

-

Test Functionality: Reconnect the power and perform a test to ensure the new component operates correctly. Monitor for any unusual sounds or performance issues.

By following these outlined procedures, operators can ensure that components are replaced effectively, enhancing the functionality and reliability of their machinery.

Where to Find Replacement Parts

Locating components for machinery can be a straightforward process when you know the right resources. Whether you are looking for genuine items or aftermarket alternatives, there are various channels available to assist you in acquiring the necessary components for effective maintenance and repair. Understanding where to search can save time and ensure the reliability of your equipment.

Authorized Dealers

One of the most reliable sources for obtaining components is through authorized distributors. These suppliers typically offer original items that meet the manufacturer’s specifications, ensuring compatibility and performance. Moreover, they often provide guidance and expertise, making it easier for you to find exactly what you need.

Online Retailers

The internet offers a plethora of options for sourcing components. Numerous websites specialize in machinery components, providing extensive catalogs with detailed descriptions. You can compare prices, read reviews, and find items that fit your needs from the comfort of your home.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Original items, expert guidance | Potentially higher prices |

| Online Retailers | Convenient, price comparisons | Quality may vary |

| Local Salvage Yards | Affordable, used components | Limited availability |

| Manufacturer’s Website | Direct access, latest items | Shipping costs |

Upgrades for Improved Performance

Enhancing the efficiency of agricultural machinery involves implementing several modifications that can significantly boost overall functionality. These enhancements can range from minor tweaks to more comprehensive adjustments, all aimed at optimizing performance and extending the lifespan of the equipment. By investing in the right upgrades, operators can ensure their machinery remains competitive and capable of meeting demanding agricultural tasks.

Engine Modifications

One of the most impactful areas for improvement lies within the engine. Upgrading to a high-performance air intake system can enhance airflow, resulting in better combustion and increased power output. Additionally, considering a chip tuning option may further fine-tune engine parameters, enhancing torque and fuel efficiency. Such modifications not only improve performance but also reduce emissions, contributing to a more environmentally friendly operation.

Transmission Enhancements

Another crucial aspect is the transmission system. Upgrading to a more efficient gearbox can facilitate smoother shifting and better power delivery to the wheels. Implementing a hydraulic system upgrade can also enhance responsiveness and control, making it easier to tackle various terrains and challenging conditions. These improvements lead to a more productive operation, allowing for quicker task completion and reduced operator fatigue.

Resources for Tractor Owners

Owning a farming vehicle comes with a unique set of responsibilities and challenges. To effectively maintain and operate this type of machinery, it is crucial to have access to various resources that provide valuable information and support. Whether you’re looking for technical guidance, maintenance tips, or community forums, numerous options can help you enhance your experience and keep your equipment running smoothly.

Essential Online Resources

- Manufacturer Websites: Official sites often have manuals, maintenance schedules, and troubleshooting guides specific to your machinery.

- Forums and Community Groups: Online platforms where enthusiasts share experiences, advice, and solutions to common issues.

- YouTube Channels: Video tutorials can offer step-by-step instructions on repairs and upgrades.

- Parts Retailers: Websites that provide diagrams and detailed information about available components and accessories.

Books and Guides

- Repair Manuals: Comprehensive resources detailing the assembly, disassembly, and maintenance procedures for various models.

- Technical Handbooks: These publications often include in-depth explanations of the systems and components used in farming equipment.

- Safety Guidelines: Literature that emphasizes safe operating practices and maintenance procedures to ensure longevity and reliability.