In the world of lawn maintenance, a comprehensive grasp of the individual components is crucial for optimal performance and longevity. This section explores the intricate network of elements that make up a modern grass-cutting machine, shedding light on their functions and interrelations.

Familiarity with each part not only enhances your ability to troubleshoot but also empowers you to undertake necessary repairs and upgrades. By recognizing how these pieces work together, you can ensure your equipment remains in peak condition throughout the seasons.

As we delve deeper into the specifics, you will discover the ultimate guide to understanding these essential features. Whether you are a seasoned gardener or a novice, this information is invaluable for maintaining efficiency and reliability in your gardening tasks.

Toro Timecutter Overview

This section provides an insight into a popular range of lawn care equipment designed for efficiency and ease of use. The machines are engineered to enhance the mowing experience, offering innovative features that cater to both residential and commercial needs. Users appreciate the balance of performance and convenience, making yard maintenance less of a chore.

Key Features

The lineup boasts advanced technology aimed at improving maneuverability and cutting precision. With varying deck sizes and engine power options, these machines can tackle diverse landscaping challenges. Ergonomic designs ensure comfort during operation, promoting a seamless mowing experience.

Maintenance and Support

Understanding Lawn Mower Components

Maintaining a healthy and beautiful lawn requires an understanding of the various elements that make up a cutting machine. Each component plays a vital role in ensuring optimal performance, longevity, and efficiency. Grasping the function of these parts can help in troubleshooting and maintenance, ultimately leading to a more enjoyable mowing experience.

| Component | Function |

|---|---|

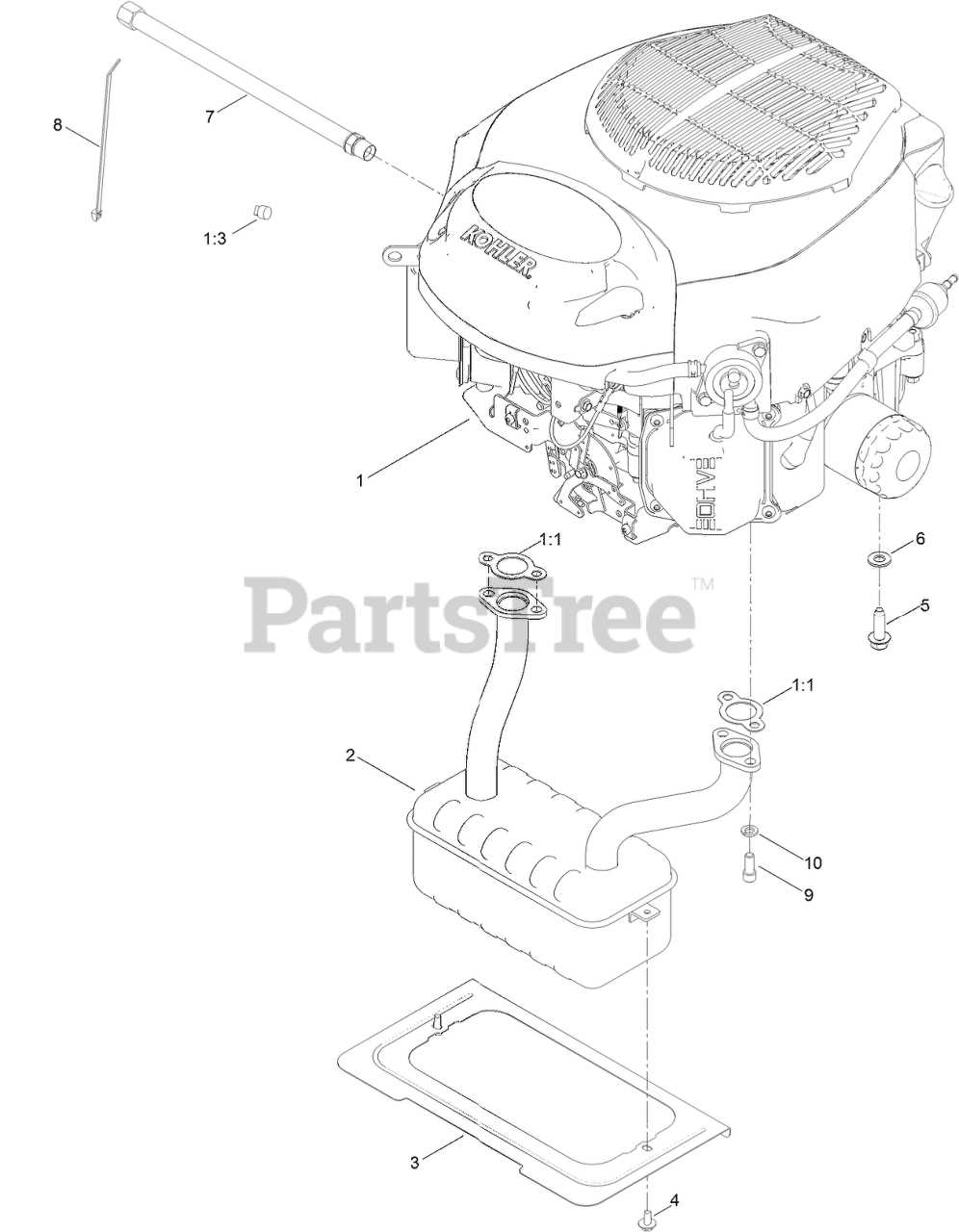

| Engine | Provides the necessary power to drive the mower and its cutting blades. |

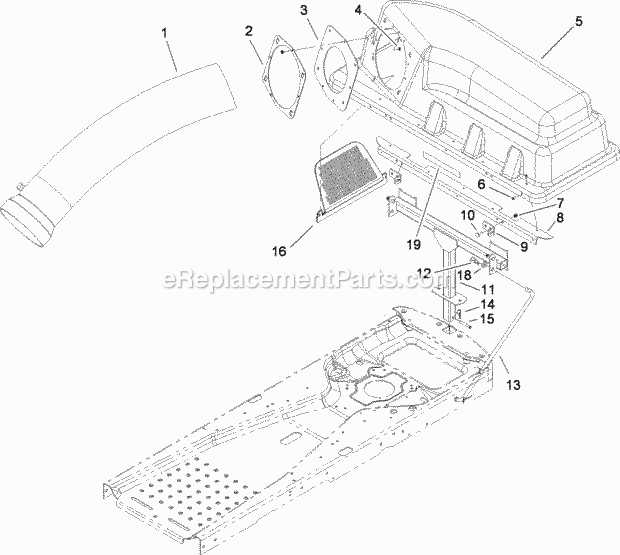

| Deck | Houses the cutting blades and protects the internal mechanisms from debris. |

| Blades | Cut the grass to the desired height and ensure a clean finish. |

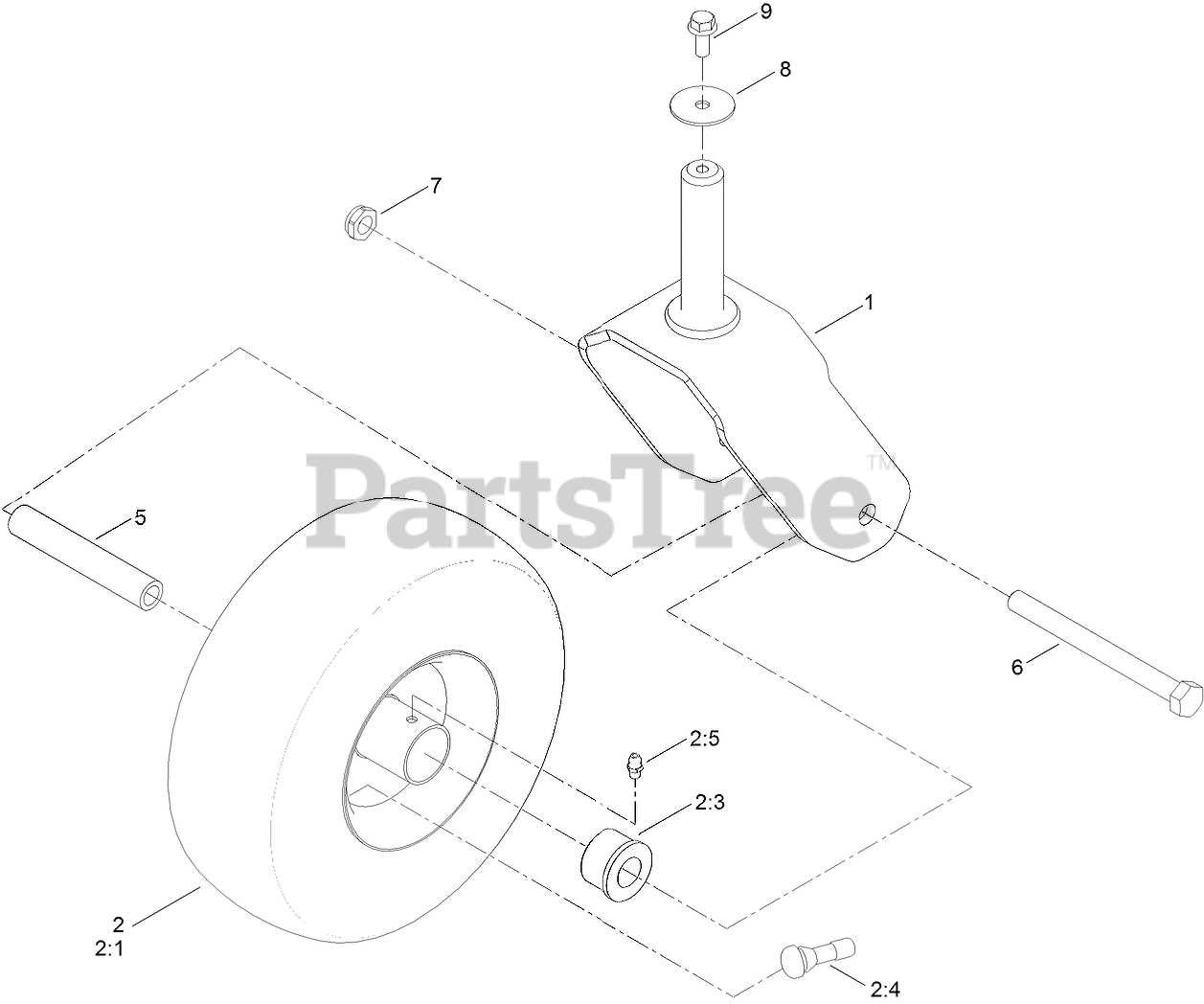

| Wheels | Facilitate movement and maneuverability across different terrains. |

| Transmission | Transfers power from the engine to the wheels, allowing for speed adjustments. |

| Handlebar | Provides control and stability while operating the machine. |

Understanding these components can empower users to make informed decisions about maintenance and repairs, leading to a more efficient mowing process.

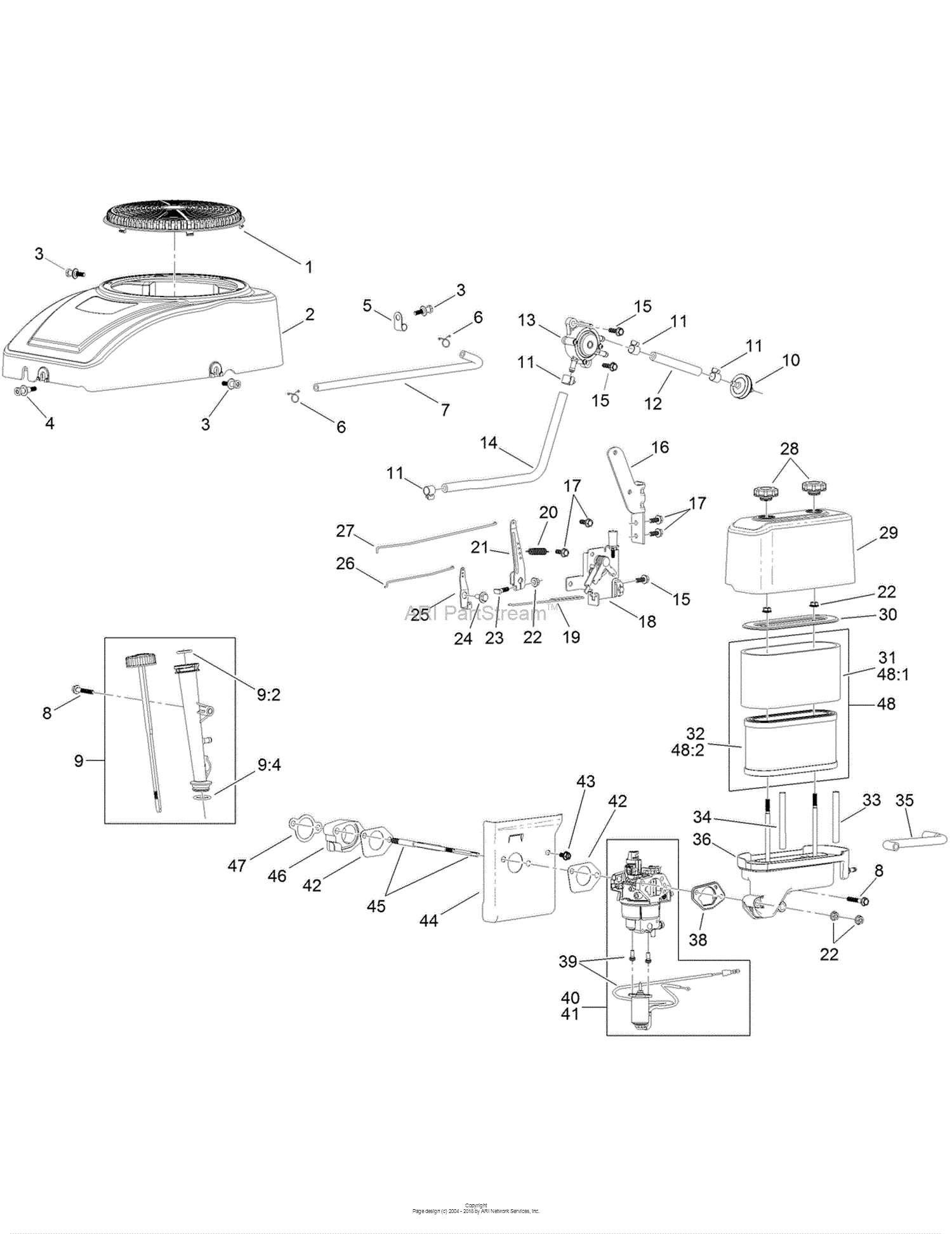

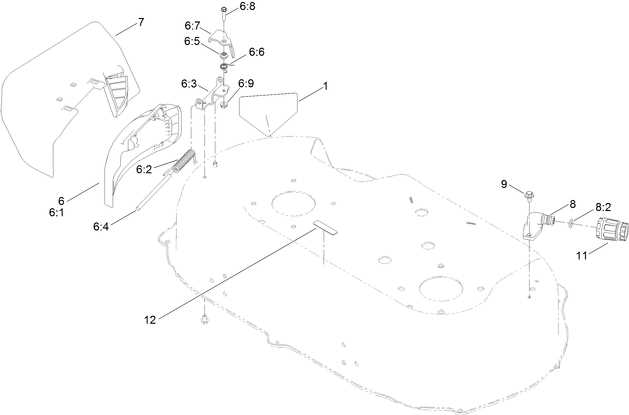

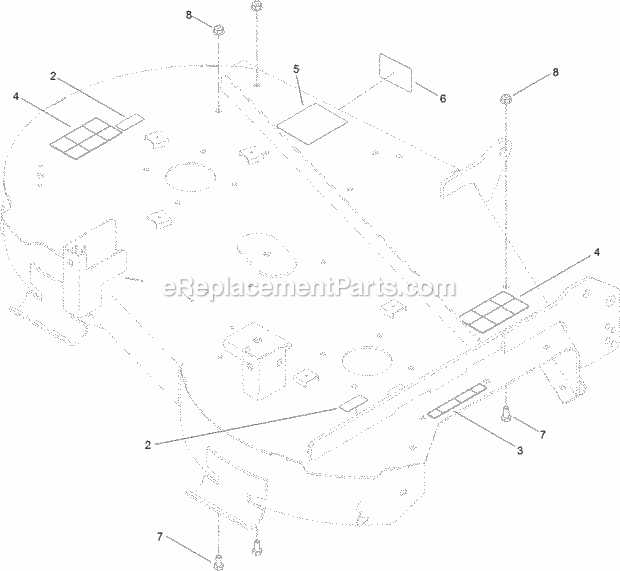

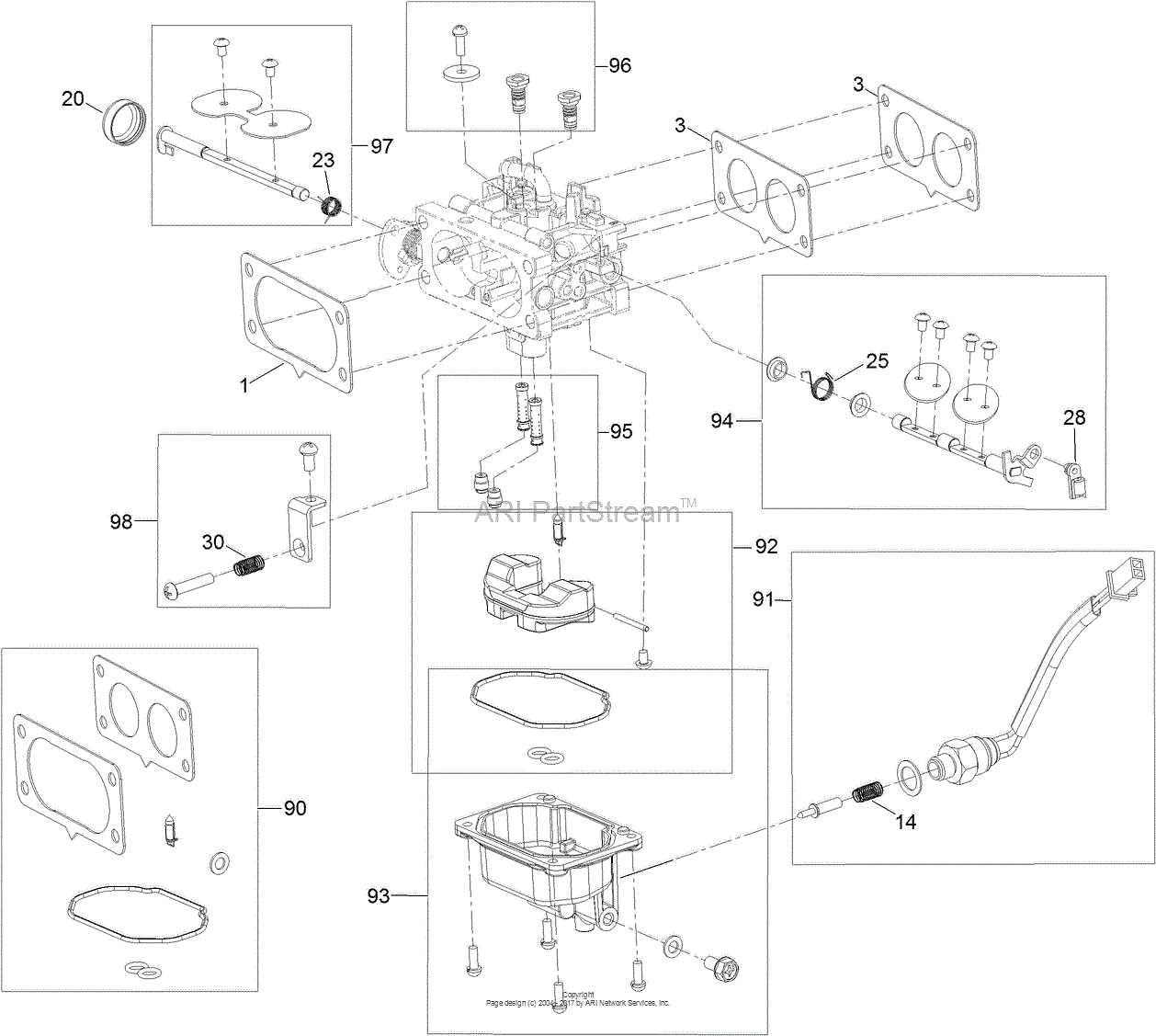

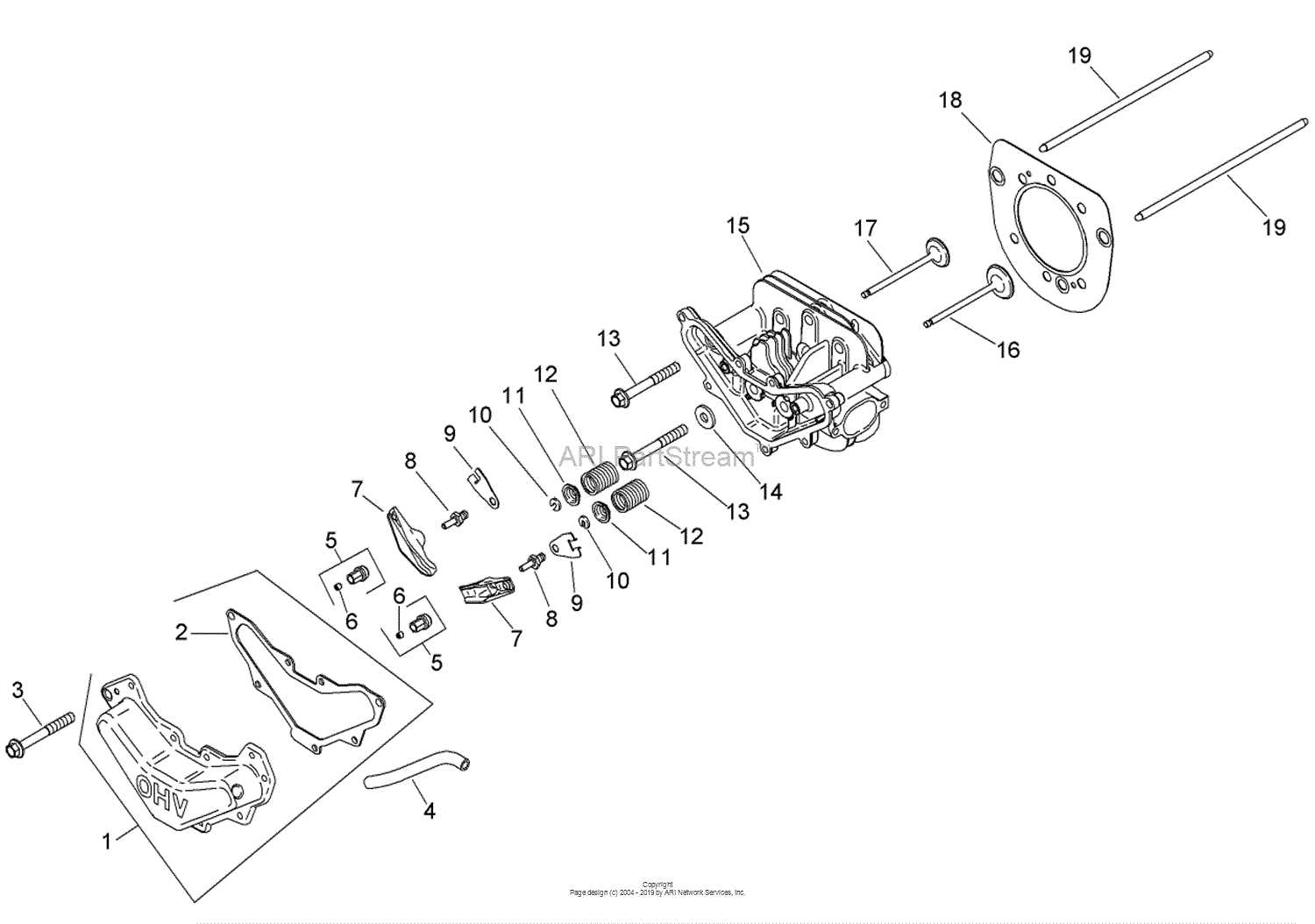

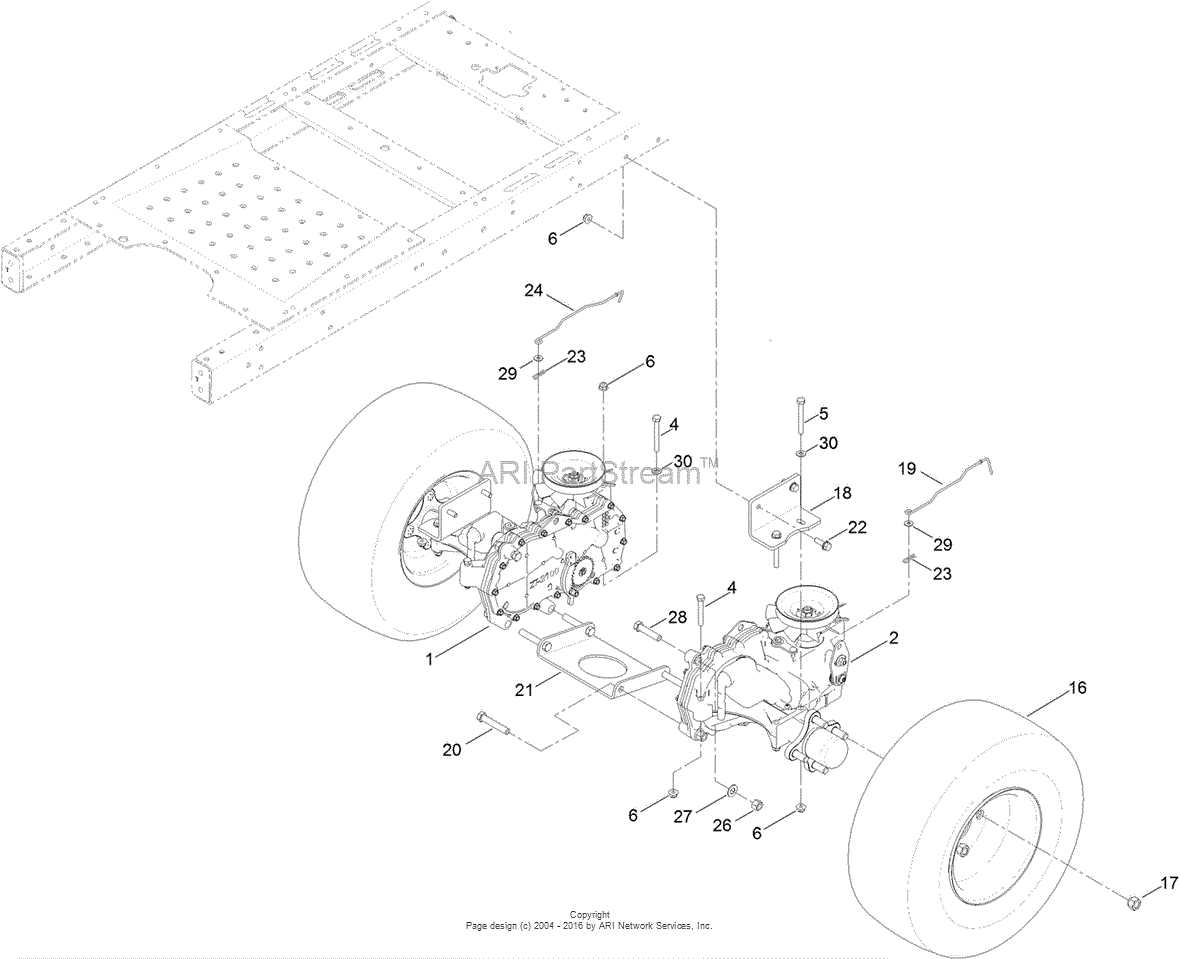

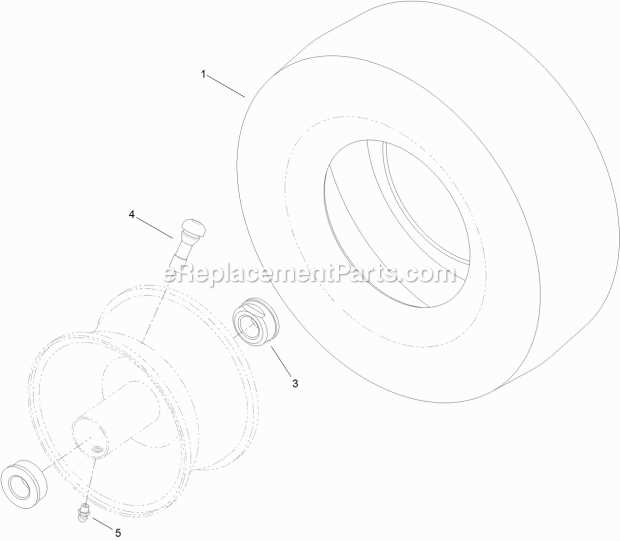

Importance of Parts Diagrams

Understanding the components of machinery is crucial for efficient maintenance and repair. Visual representations of individual elements provide invaluable insights into how each piece interacts within the whole system. Such illustrations not only aid in identifying specific components but also enhance troubleshooting and assembly processes.

Having a clear overview of the elements can significantly reduce downtime and increase productivity. When users are equipped with accurate references, they can quickly locate the necessary pieces, ensuring that repairs are executed swiftly and effectively. This not only saves time but also minimizes the risk of errors during reassembly.

| Benefits | Description |

|---|---|

| Efficiency | Streamlines the repair process by providing clear visual guidance. |

| Accuracy | Reduces the likelihood of mistakes during assembly or disassembly. |

| Time-saving | Allows for quicker identification of components, minimizing downtime. |

| Enhanced Understanding | Offers a comprehensive view of how different elements function together. |

Common Issues with Toro Timecutter

When operating a popular model of riding mower, users may encounter several recurring problems that can affect performance and efficiency. Understanding these common challenges can aid in timely troubleshooting and maintenance, ensuring a smoother mowing experience.

Frequent Problems

- Engine Starting Issues

- Uneven Cutting

- Excessive Vibrations

- Stalling During Operation

- Clogged Decks

Troubleshooting Tips

- Check Fuel Levels: Ensure there is sufficient fuel, and examine the quality of the gasoline used.

- Inspect the Blades: Dull or damaged blades can lead to uneven cutting; regular sharpening is recommended.

- Tighten Loose Parts: Vibrations may stem from loose bolts or components; inspect and tighten as necessary.

- Clean the Deck: A clogged deck can hinder performance; routine cleaning is essential for optimal airflow.

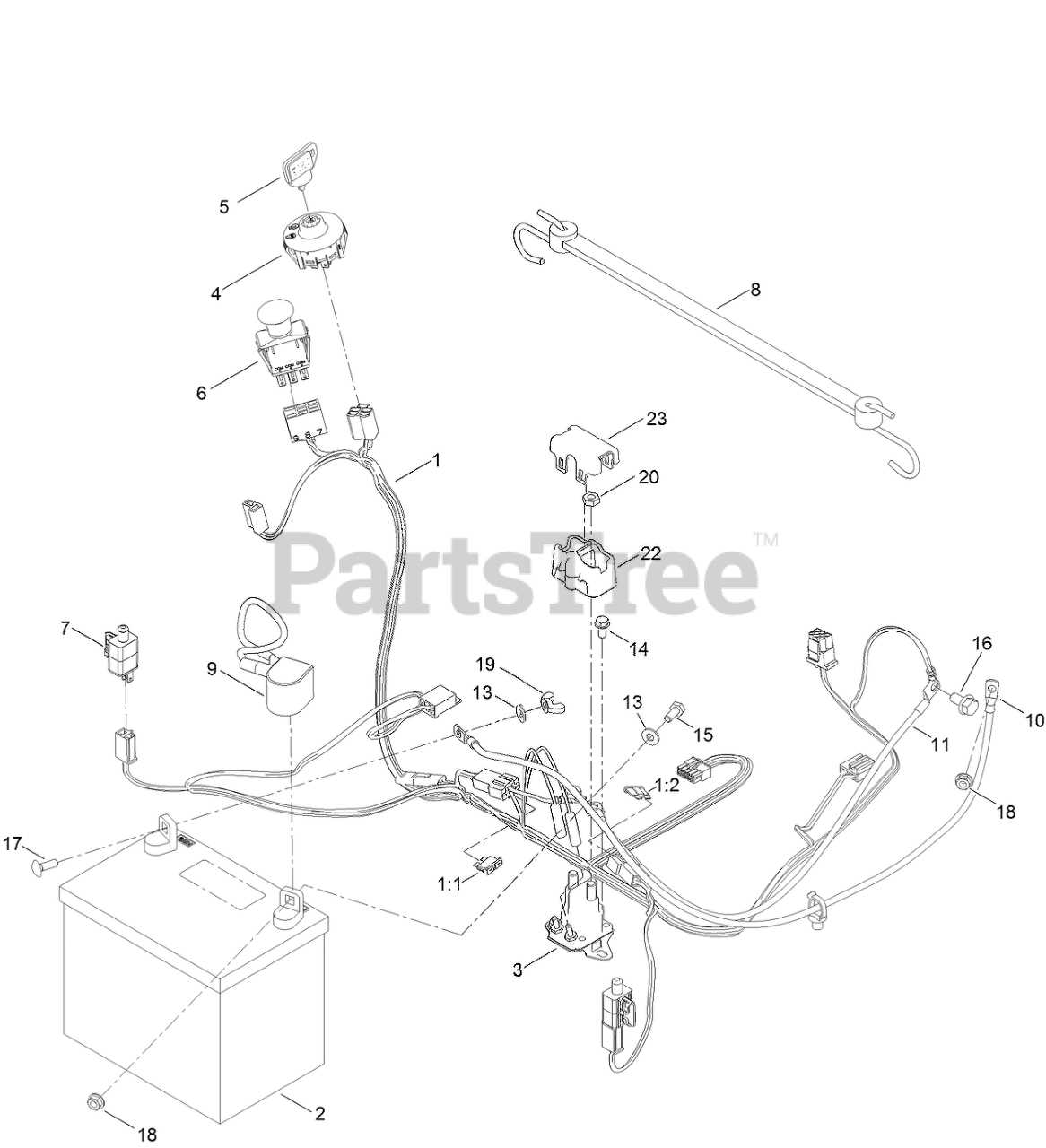

- Monitor Battery Condition: Starting issues may relate to a weak or failing battery; regular checks are advised.

How to Access Parts Diagrams

Finding the right components for your machinery can be a straightforward process if you know where to look. Understanding how to access visual guides can save you time and ensure you get the correct items needed for repairs or upgrades.

Online Resources

Numerous websites offer detailed illustrations and specifications for various models. By visiting the manufacturer’s official site or authorized dealers, you can often find user-friendly interfaces that allow for easy navigation through model-specific resources.

Physical Manuals

In addition to online options, many products come with printed manuals that include valuable images and information. Keeping these manuals organized can help you quickly locate what you need when performing maintenance or troubleshooting issues.

| Resource Type | Access Method | Notes |

|---|---|---|

| Online Website | Visit the official site | Search by model number |

| Printed Manual | Refer to the included booklet | Check the index for relevant sections |

| Support Forums | Join community discussions | Members often share useful links |

Identifying Replacement Parts Easily

Finding the right components for your equipment can often feel overwhelming, especially when faced with a myriad of options. Understanding how to navigate through various elements and specifications can simplify the process and ensure you acquire exactly what you need for effective maintenance and repair.

Utilizing Visual Guides

Visual aids are invaluable when it comes to recognizing the specific items required for your machinery. Here are some effective strategies:

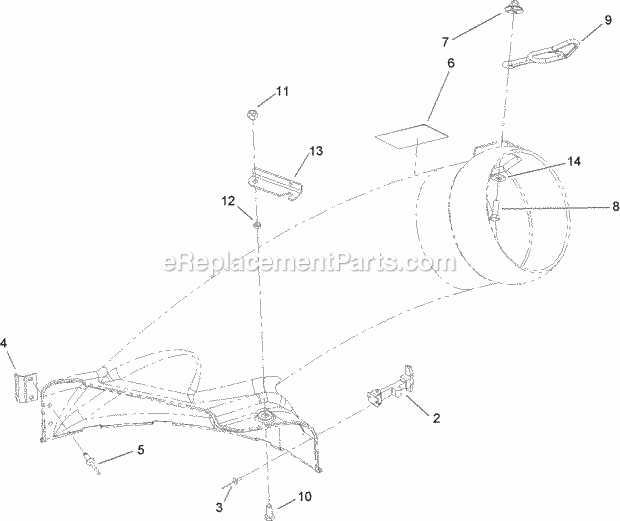

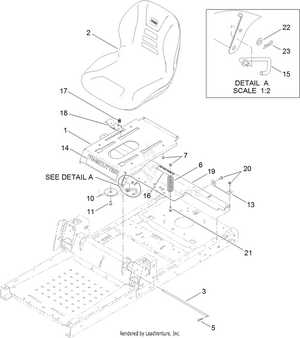

- Exploded Views: Diagrams that show components in an expanded format can help you visualize how parts fit together.

- Annotated Images: Detailed pictures with labels can direct you to the correct item by highlighting key features.

- Color Coding: Using different colors for various parts can make identification quicker and easier.

Leveraging Online Resources

In today’s digital age, numerous resources are available to aid in the identification process:

- Manufacturer Websites: Official sites often provide detailed breakdowns and descriptions of components.

- Online Forums: Communities of users can offer insights and recommendations based on shared experiences.

- Video Tutorials: Step-by-step guides can visually demonstrate how to identify and replace elements efficiently.

By employing these methods, you can streamline your search for the necessary components, making maintenance and repairs more straightforward and effective.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires a consistent approach to upkeep and care. By following a few essential practices, you can enhance performance and extend the lifespan of your equipment.

Regular Inspections

Frequent checks can help identify potential issues before they escalate. Pay attention to moving parts, fluid levels, and overall condition to ensure everything is functioning smoothly.

Proper Cleaning

Keeping your equipment clean helps prevent rust and buildup that can hinder performance. Regularly removing debris and dirt will promote better efficiency and longevity.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect Moving Parts | Weekly | Detect issues early |

| Change Fluids | Monthly | Ensure smooth operation |

| Clean Surfaces | After Each Use | Prevent damage and rust |

Where to Buy Toro Parts

When seeking components for your lawn maintenance equipment, several reliable options are available to ensure you find what you need. Whether you are looking for genuine items or high-quality alternatives, it’s essential to know where to look for the best selections and prices.

Authorized Dealers are often the first choice for those wanting original equipment. These retailers typically have a comprehensive inventory and can provide expert advice tailored to your machine.

Online Marketplaces offer a vast array of choices, allowing you to compare prices and read customer reviews. Websites dedicated to outdoor machinery frequently have extensive catalogs that make searching convenient.

Local Repair Shops can be a valuable resource as well. Many of these establishments not only sell but also service equipment, giving you the chance to get professional guidance on the best items for your specific model.

Finally, consider second-hand options through community boards or classified ads. This route can yield significant savings if you are willing to inspect the condition of used components.

DIY Repair vs. Professional Help

When it comes to fixing equipment, individuals often face the choice between tackling the task themselves or seeking assistance from experts. This decision can greatly influence the outcome, time, and costs involved. Understanding the benefits and drawbacks of each approach is essential for making an informed choice that best suits your needs.

Advantages of DIY Repairs

One of the primary benefits of handling repairs on your own is the potential for significant cost savings. By eliminating labor expenses, you can allocate funds towards quality components or tools. Additionally, DIY projects offer a sense of accomplishment and enhance your technical skills, which can be valuable for future tasks. Flexibility is another advantage; you can work on the project at your own pace without being constrained by professional schedules.

When to Seek Professional Assistance

While self-repairs can be rewarding, there are situations where enlisting the help of a professional is advisable. Complex issues may require specialized knowledge and experience that an average individual might lack. Furthermore, professionals often have access to advanced tools and resources, which can lead to a quicker and more reliable resolution. In cases where safety is a concern, relying on an expert ensures that repairs are conducted properly, minimizing the risk of accidents or further damage.