Exploring the intricate world of small engine machinery can be both enlightening and essential for maintenance enthusiasts. A clear visual representation of each element significantly enhances comprehension, allowing users to identify necessary components and their functions effectively.

Maintaining optimal performance requires familiarity with every piece involved in the operation. By examining these schematics, one can quickly determine which items are vital for repairs or replacements, ensuring a seamless functioning of the equipment.

Diving into the specifics not only aids in troubleshooting but also fosters a deeper appreciation for the mechanics at play. Engaging with these illustrations provides the ultimate roadmap for anyone looking to enhance their technical knowledge and hands-on skills.

Understanding Briggs and Stratton Engines

Recognizing the intricacies of small combustion engines is essential for enthusiasts and professionals alike. These power units serve a multitude of applications, from outdoor equipment to various machinery. Familiarity with their components and functionalities can enhance performance, efficiency, and longevity.

Each engine comprises several key elements that work in harmony to generate power. Understanding the role of each part, such as the ignition system, fuel delivery mechanisms, and the cooling process, allows users to diagnose issues effectively. Additionally, knowledge of maintenance practices ensures optimal operation over time.

Moreover, various models exhibit unique characteristics, catering to different needs and environments. Familiarity with specific features and configurations can aid in selecting the right engine for any task. Thus, a comprehensive grasp of these power units is invaluable for both practical usage and troubleshooting.

Overview of Model 130 202

The Model 130 202 represents a significant advancement in small engine technology, designed for efficiency and reliability in various applications. This particular engine showcases a blend of innovative engineering and practical functionality, making it a popular choice among users seeking dependable performance.

With a focus on durability, this engine features components crafted from high-quality materials, ensuring long-lasting operation even under challenging conditions. Performance is a key highlight, as it delivers consistent power output while maintaining fuel efficiency. Users can expect an efficient operation that meets the demands of diverse tasks, from lawn maintenance to light industrial use.

Additionally, the ease of maintenance is a crucial aspect of this engine’s design. The layout allows for straightforward access to essential components, simplifying service and reducing downtime. Overall, the Model 130 202 is engineered to provide a robust solution for those requiring a small engine that combines strength with user-friendly features.

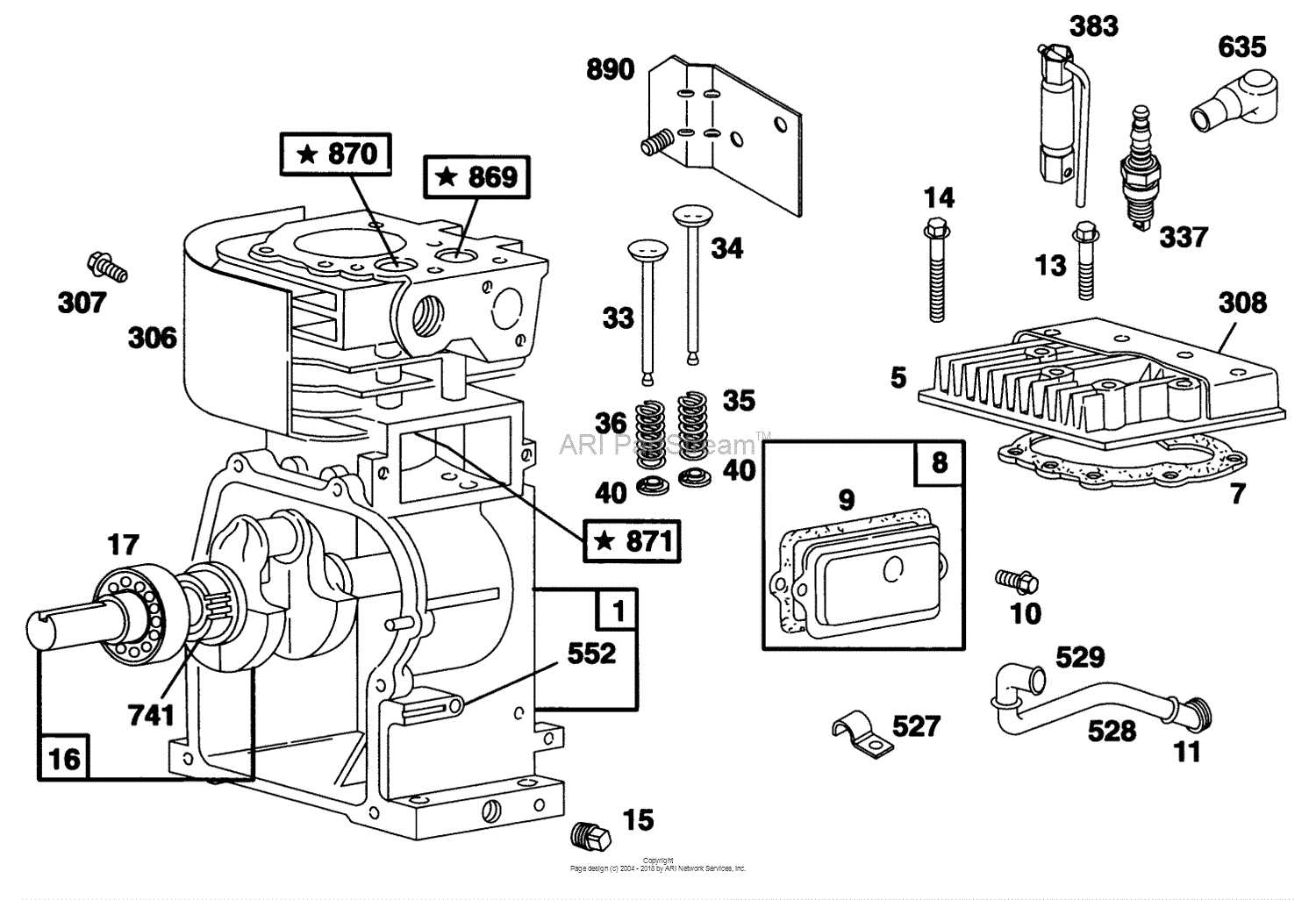

Key Components of the Engine

Understanding the fundamental elements that make up a power unit is essential for effective maintenance and troubleshooting. Each component plays a vital role in ensuring smooth operation and optimal performance, contributing to the overall efficiency of the machine.

Core Elements

- Crankshaft: This is the main rotating part that converts linear motion into rotational energy, essential for generating power.

- Piston: Moving within the cylinder, the piston compresses the air-fuel mixture and transmits force to the crankshaft.

- Cylinder: The chamber where combustion occurs, housing the piston and facilitating the energy generation process.

- Spark Plug: Ignites the air-fuel mixture, crucial for initiating the combustion cycle.

Supporting Structures

- Camshaft: Controls the timing of valve openings and closings, allowing for proper airflow into and out of the cylinder.

- Valves: Regulate the entry of the air-fuel mixture and the exit of exhaust gases, significantly impacting engine efficiency.

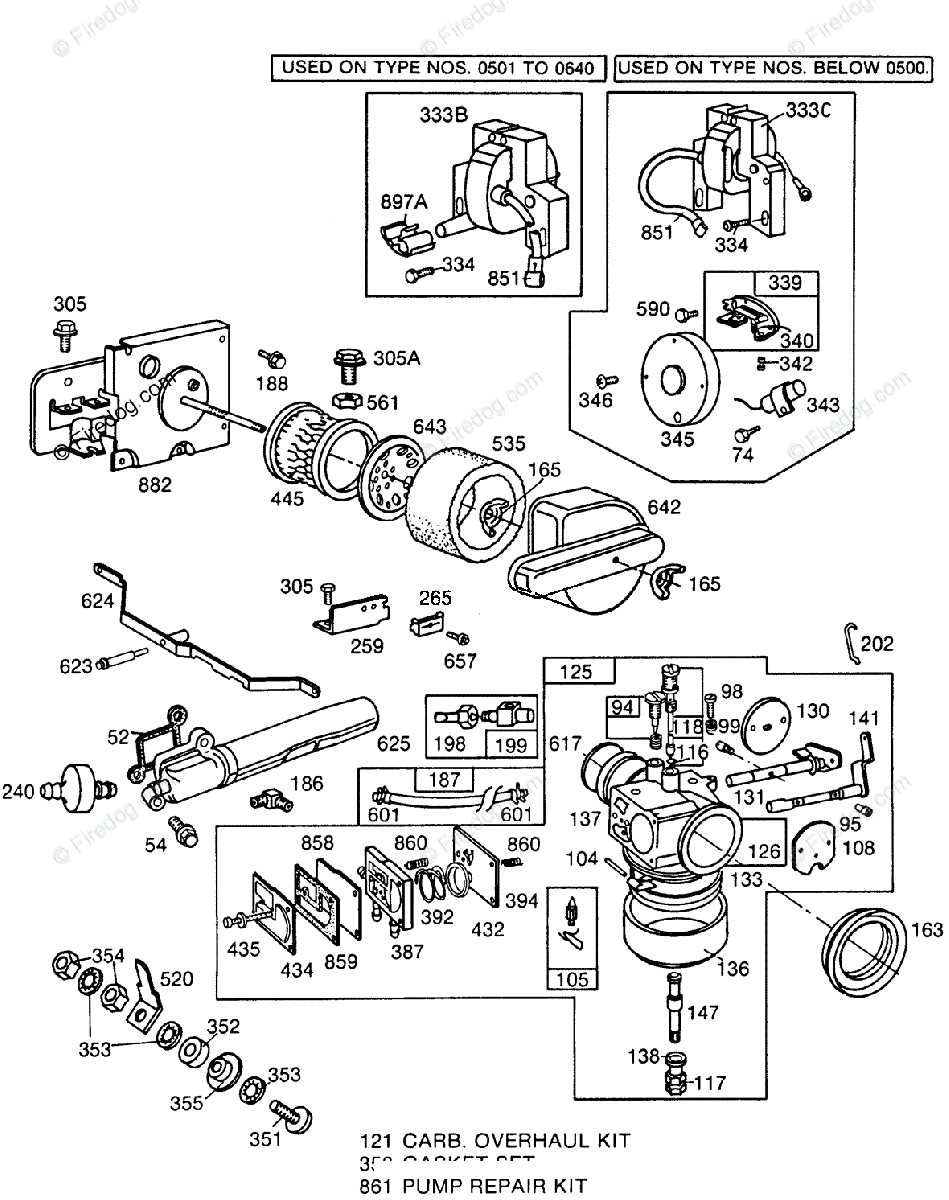

- Fuel System: Delivers the necessary fuel to the engine, ensuring optimal combustion and performance.

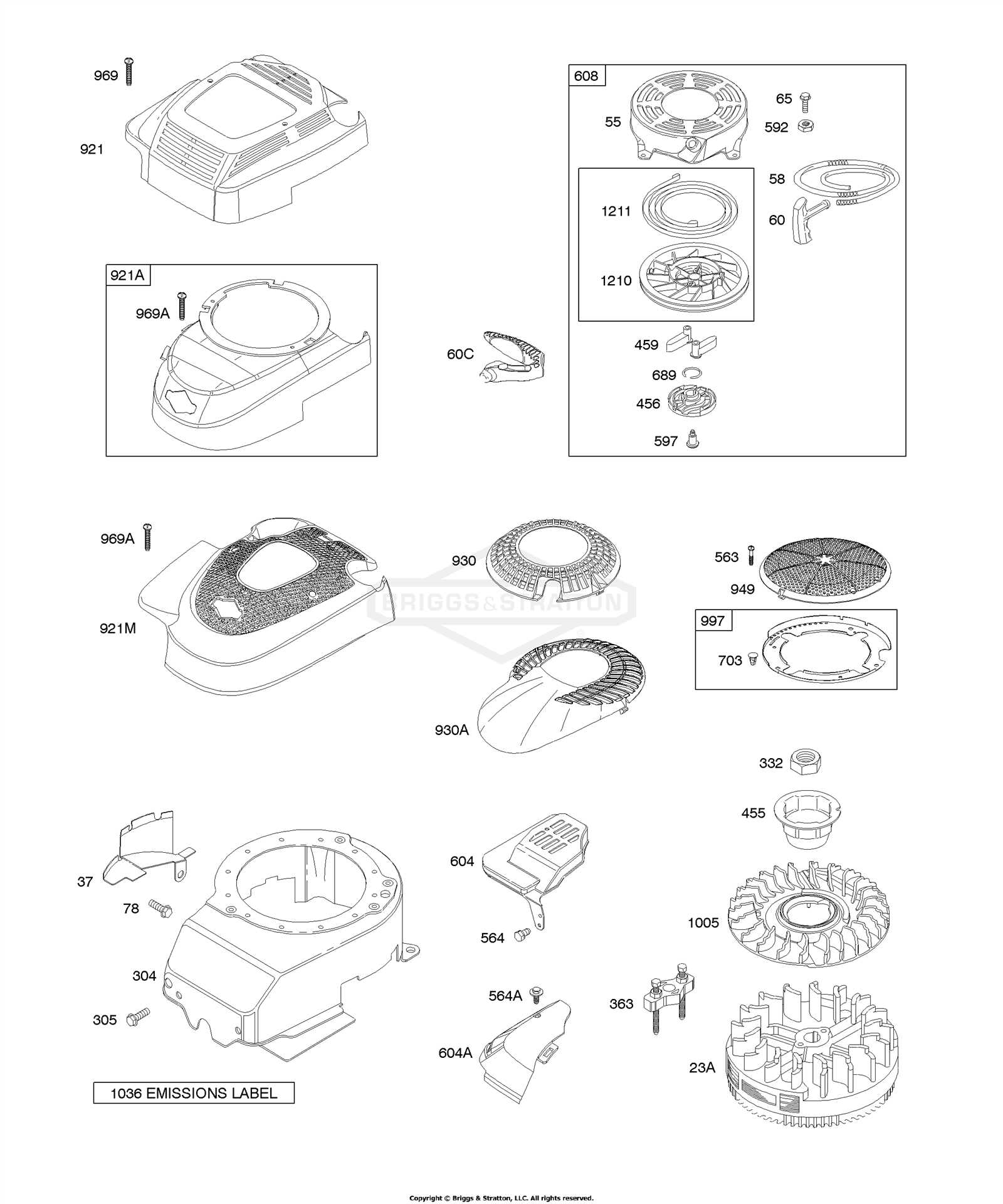

- Cooling System: Maintains an appropriate operating temperature, preventing overheating and ensuring reliability.

Recognizing these essential components helps in diagnosing issues and enhances the longevity of the equipment, making routine checks and maintenance more effective.

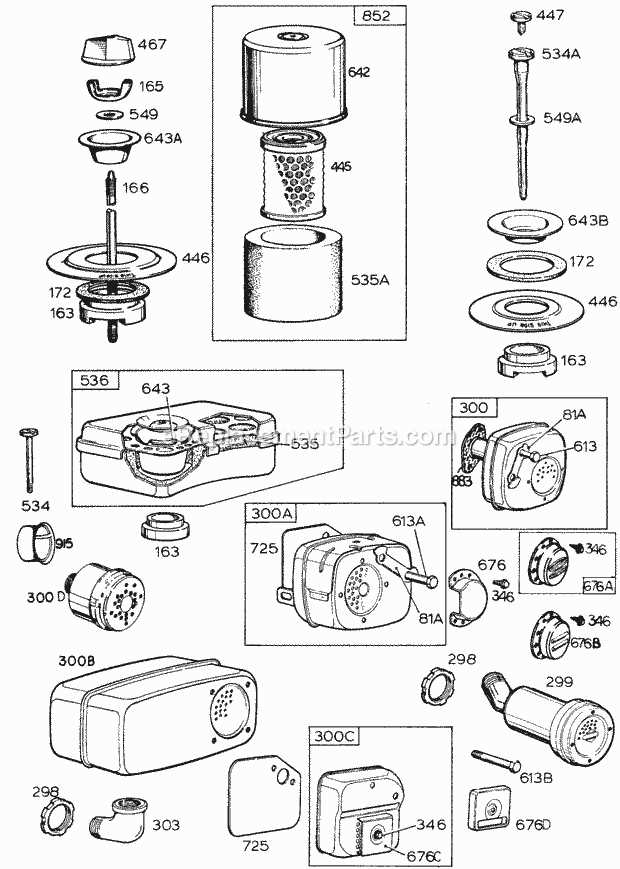

Common Issues and Solutions

This section explores frequent problems encountered with small engine equipment and offers practical solutions to enhance performance and longevity.

-

Starting Difficulties:

If the engine fails to start, check the fuel level and ensure it’s fresh. Inspect the spark plug for wear or damage and clean or replace it as necessary.

-

Overheating:

Overheating can occur due to blocked air vents or low oil levels. Regularly clean the cooling fins and check oil levels to prevent this issue.

-

Uneven Power Output:

This can result from a clogged air filter or fuel system issues. Replace or clean the air filter and ensure the fuel lines are clear.

-

Excessive Vibration:

Vibration may indicate a misaligned component or worn parts. Inspect and tighten loose screws or replace damaged elements.

-

Fuel Leaks:

Leaking fuel can stem from cracked hoses or loose connections. Examine all lines and fittings, repairing or replacing as needed.

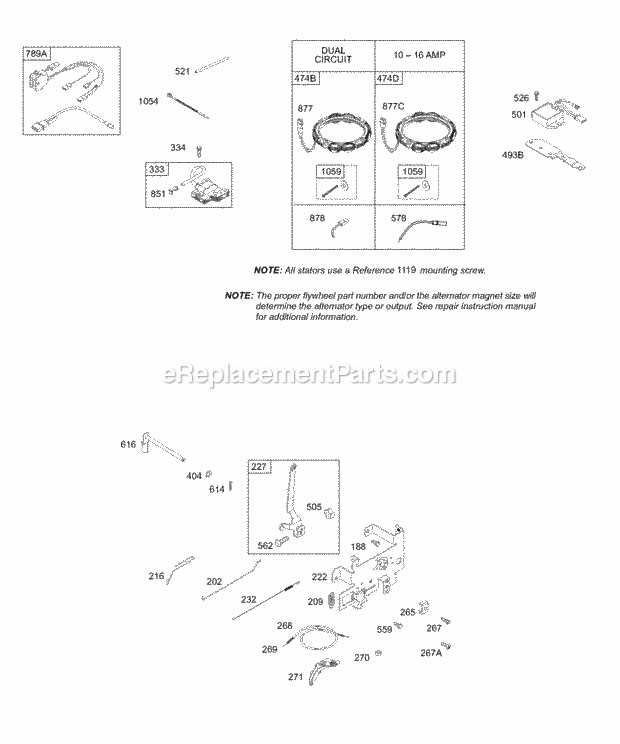

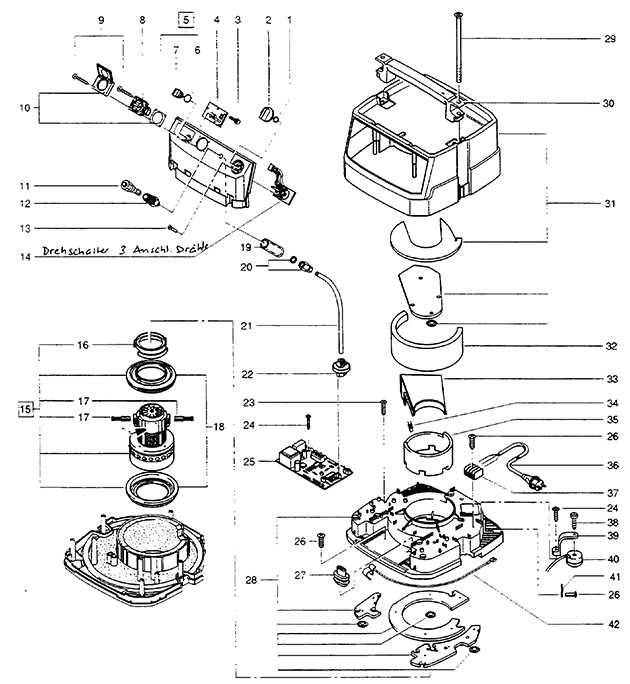

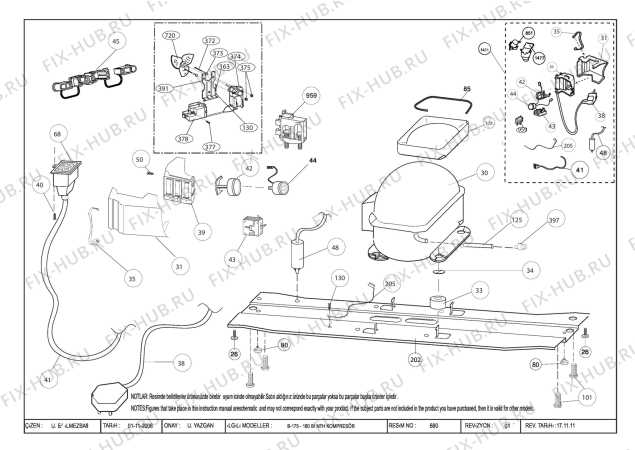

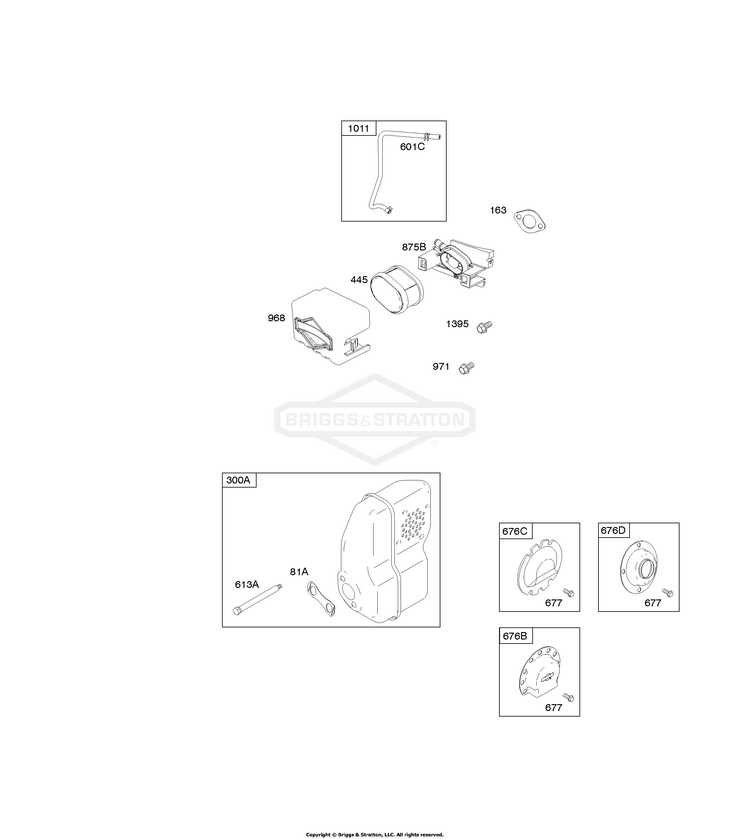

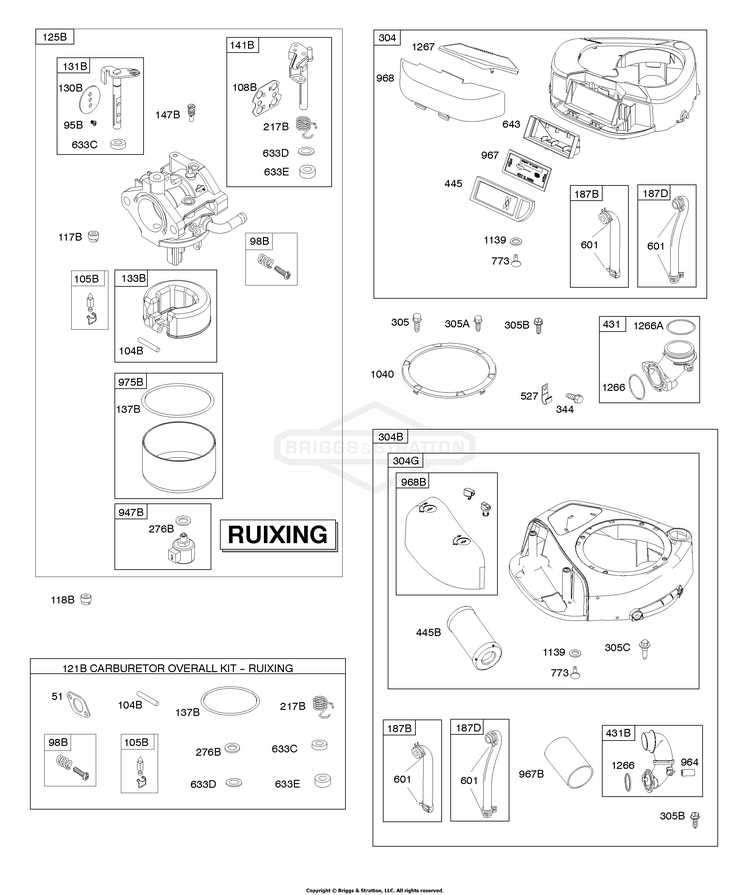

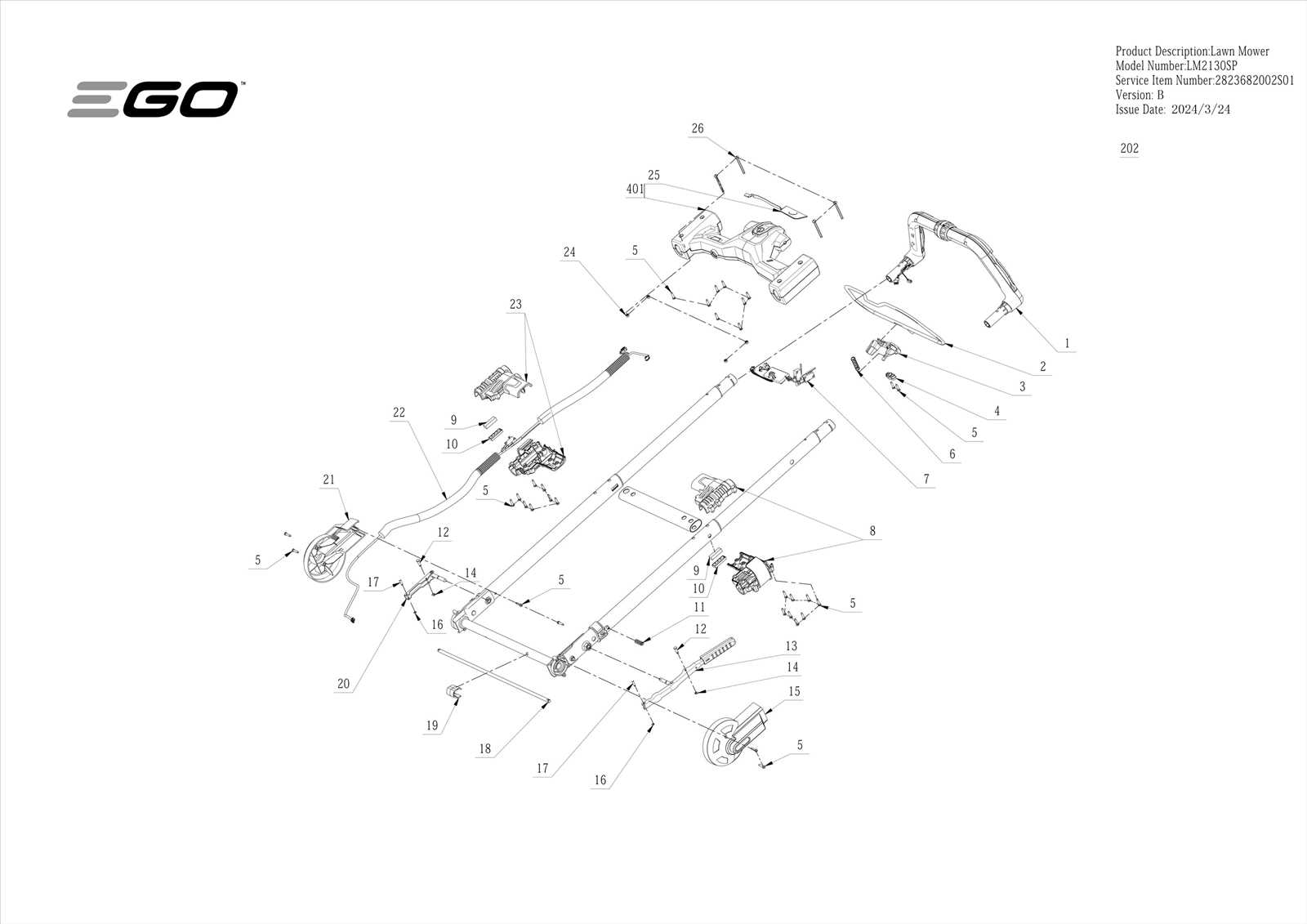

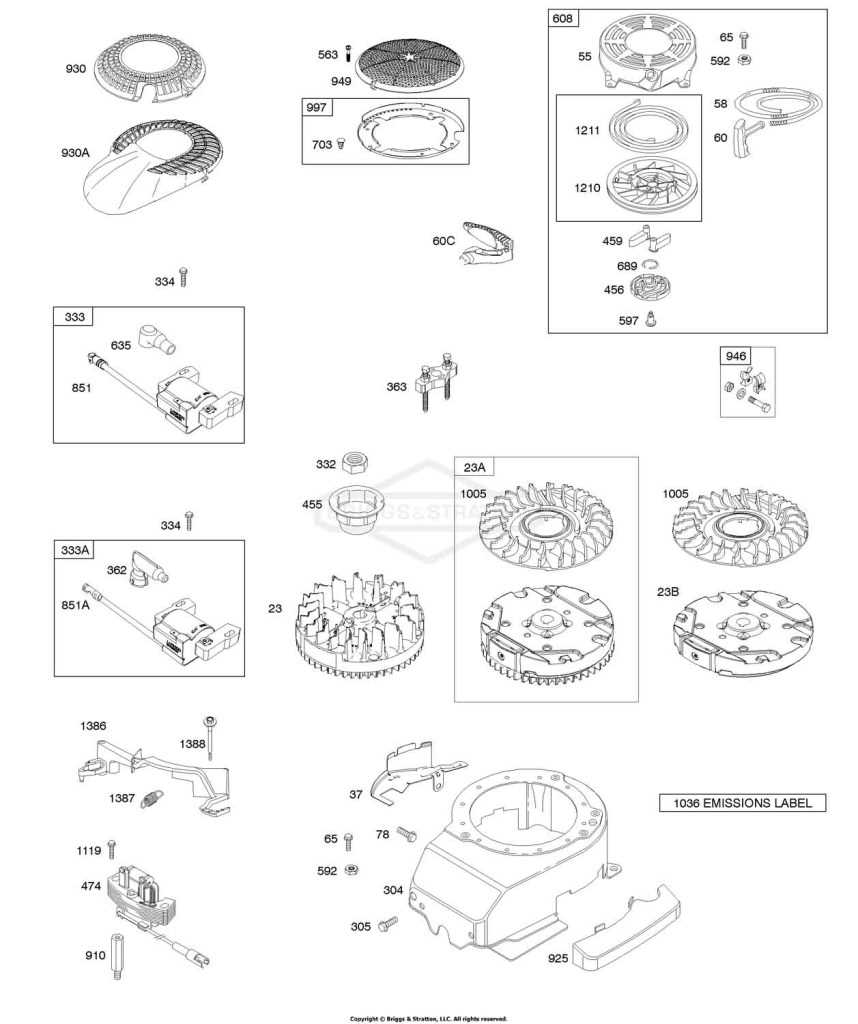

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations provide clarity and facilitate the identification of each element, ensuring that tasks are performed accurately and efficiently.

- Enhances understanding of the assembly.

- Streamlines the repair process.

- Minimizes the risk of errors.

- Facilitates ordering the correct replacements.

Moreover, these illustrations serve as a valuable resource for both novices and experienced technicians, enabling them to delve deeper into the mechanics of the device.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process if you know where to look. Various sources offer reliable options, making it easier to ensure your machinery remains functional.

Online Retailers

- Visit specialized websites that focus on machinery components.

- Explore major e-commerce platforms for user reviews and competitive pricing.

- Check manufacturer sites for authenticity and warranty information.

Local Stores

- Seek out hardware stores that stock a range of machinery components.

- Consult with local repair shops that might carry necessary items or can order them.

- Attend trade shows for direct access to suppliers and industry experts.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. By implementing a few simple practices, you can extend the lifespan of your machinery significantly. A proactive approach not only enhances performance but also minimizes the risk of costly repairs down the line.

1. Regular Cleaning: Keep all components free from dirt and debris. Accumulated grime can lead to overheating and inefficiencies. Regularly inspect and clean air filters, cooling fins, and any accessible areas.

2. Routine Oil Changes: Fresh oil is crucial for lubrication and performance. Follow the manufacturer’s recommendations for oil change intervals to ensure smooth operation and prevent engine wear.

3. Inspect Belts and Cables: Check for any signs of wear or damage. Replacing frayed or cracked belts and cables promptly can prevent further complications and enhance overall reliability.

4. Fuel Quality: Use high-quality fuel and consider adding a fuel stabilizer if your equipment will be idle for an extended period. This helps to prevent fuel degradation and keeps the system clean.

5. Seasonal Checks: Prepare your machinery for seasonal changes. Before winter or heavy use periods, conduct thorough inspections to identify any issues that could arise during operation.

By following these essential maintenance tips, you can ensure your equipment remains in optimal condition, leading to reliable performance and extended service life.

Exploring Engine Specifications

Understanding the intricate details of engine specifications is crucial for anyone looking to optimize performance and ensure longevity. These specifications provide essential insights into the operational capabilities, efficiency, and maintenance needs of the engine. By delving into these aspects, users can make informed decisions regarding repairs, upgrades, and overall functionality.

Key characteristics include displacement, power output, and torque ratings, which collectively define the engine’s performance potential. Additionally, factors such as fuel type, ignition system, and cooling methods play significant roles in determining how effectively the engine operates under various conditions. Analyzing these parameters enables users to tailor their approach, ensuring that the engine performs at its best.

Furthermore, understanding the configuration and layout of components is vital. Each element, from the cylinder head to the crankshaft, contributes to the overall performance. Recognizing how these parts interact allows for better troubleshooting and enhancements, making it easier to achieve desired results in various applications.

Frequently Asked Questions About Repair

This section aims to address common inquiries related to maintenance and restoration processes. Understanding the essentials can significantly enhance your repair experience and efficiency.

What should I check before starting repairs? It’s essential to inspect the equipment for visible damage, ensure safety measures are in place, and gather the necessary tools and components.

How do I identify which component needs replacement? Refer to user manuals or schematics to pinpoint problematic parts, and look for signs of wear or malfunction.

Are there specific maintenance tips to prolong equipment life? Regular cleaning, lubrication, and timely replacements are crucial for longevity and optimal performance.

Can I perform repairs myself, or should I seek professional help? Assess your skill level and the complexity of the issue; simple fixes can often be handled independently, while intricate problems may require expert assistance.