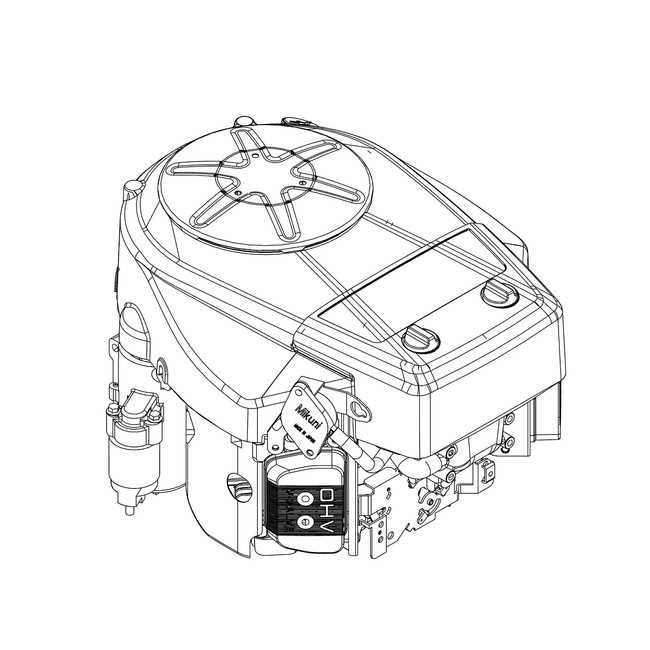

The functionality of a 26 HP power unit relies on a well-designed assembly of various elements that work harmoniously together. Each component plays a vital role in ensuring the smooth operation and efficiency of the system. Gaining insight into these components not only helps in effective maintenance but also enhances performance over time.

In this section, we will explore the intricate relationships between the different components that make up this powerful machine. By familiarizing oneself with the structure and arrangement, users can better appreciate how each segment contributes to overall functionality. Recognizing these aspects is crucial for anyone looking to optimize their equipment’s performance.

Whether for routine maintenance or troubleshooting, understanding the intricate layout of a power unit empowers users to make informed decisions. This knowledge can lead to increased longevity and reliability, allowing the unit to serve its purpose effectively. Engaging with this information fosters a deeper connection between the operator and their machinery.

In this section, we will delve into the essential elements that comprise the 26 HP power unit. By exploring these components, readers will gain a clearer understanding of how each part contributes to the overall functionality and efficiency of the machinery. This knowledge is crucial for effective maintenance and troubleshooting.

Key Elements of the Power Unit

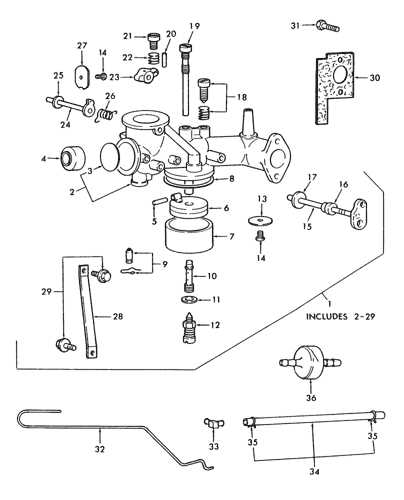

- Fuel System: This includes components responsible for fuel delivery, ensuring optimal combustion.

- Ignition System: Vital for initiating the power cycle, this system includes spark plugs and ignition coils.

- Cooling Mechanism: Keeps the unit at an appropriate temperature to prevent overheating during operation.

- Lubrication Components: Essential for reducing friction and wear between moving parts.

Common Issues and Solutions

- Fuel delivery problems can often be traced back to clogged filters or faulty pumps.

- Ignition failures may arise from worn spark plugs or issues within the ignition coil.

- Overheating can result from insufficient cooling; check for blockages in the cooling fins.

- Inadequate lubrication can lead to increased wear; ensure oil levels are maintained.

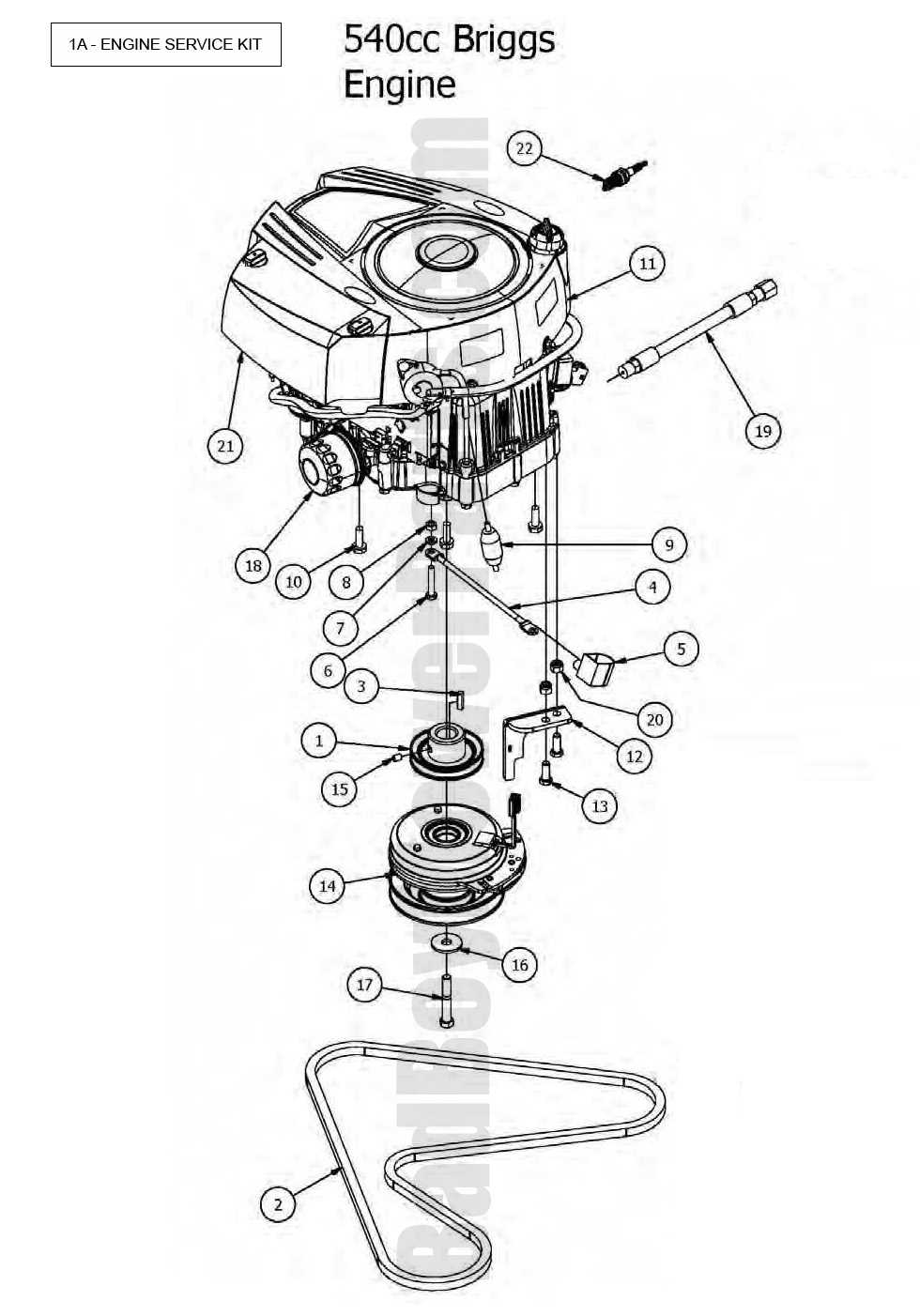

Overview of Briggs and Stratton Engines

This section provides a comprehensive look at small power units commonly used in various outdoor equipment. Renowned for their reliability and performance, these machines are integral to many gardening and landscaping tasks. Their design focuses on delivering optimal power while ensuring ease of maintenance and durability.

Key Features

- Robust construction for longevity

- Efficient fuel consumption

- Easy starting mechanisms

- Wide range of models suited for different applications

Applications

- Lawn mowers

- Pressure washers

- Generators

- Snow blowers

Each model is engineered to meet specific needs, making them versatile choices for both residential and commercial use. The innovation behind these power units continues to evolve, incorporating advanced technologies to enhance performance and user experience.

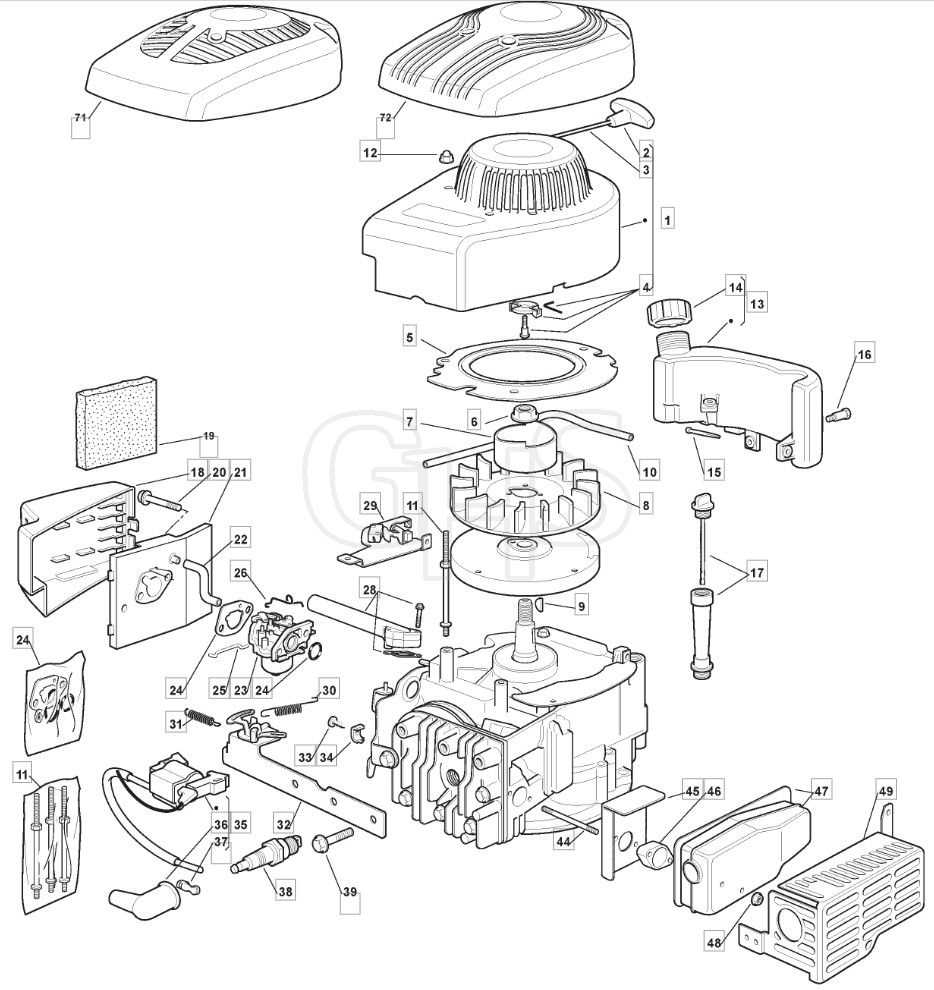

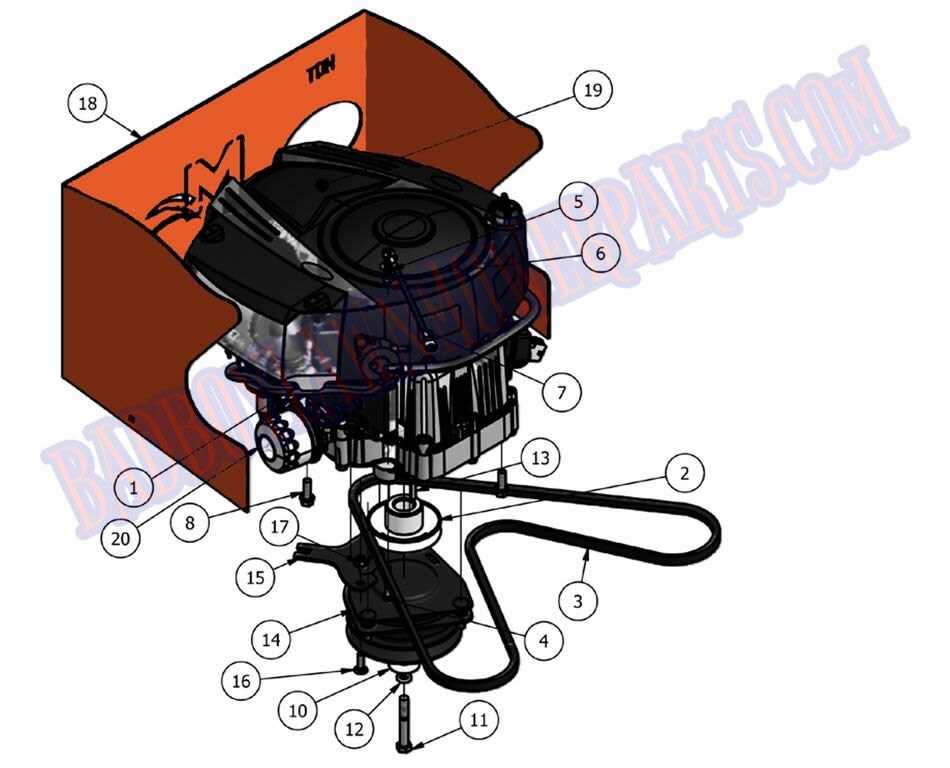

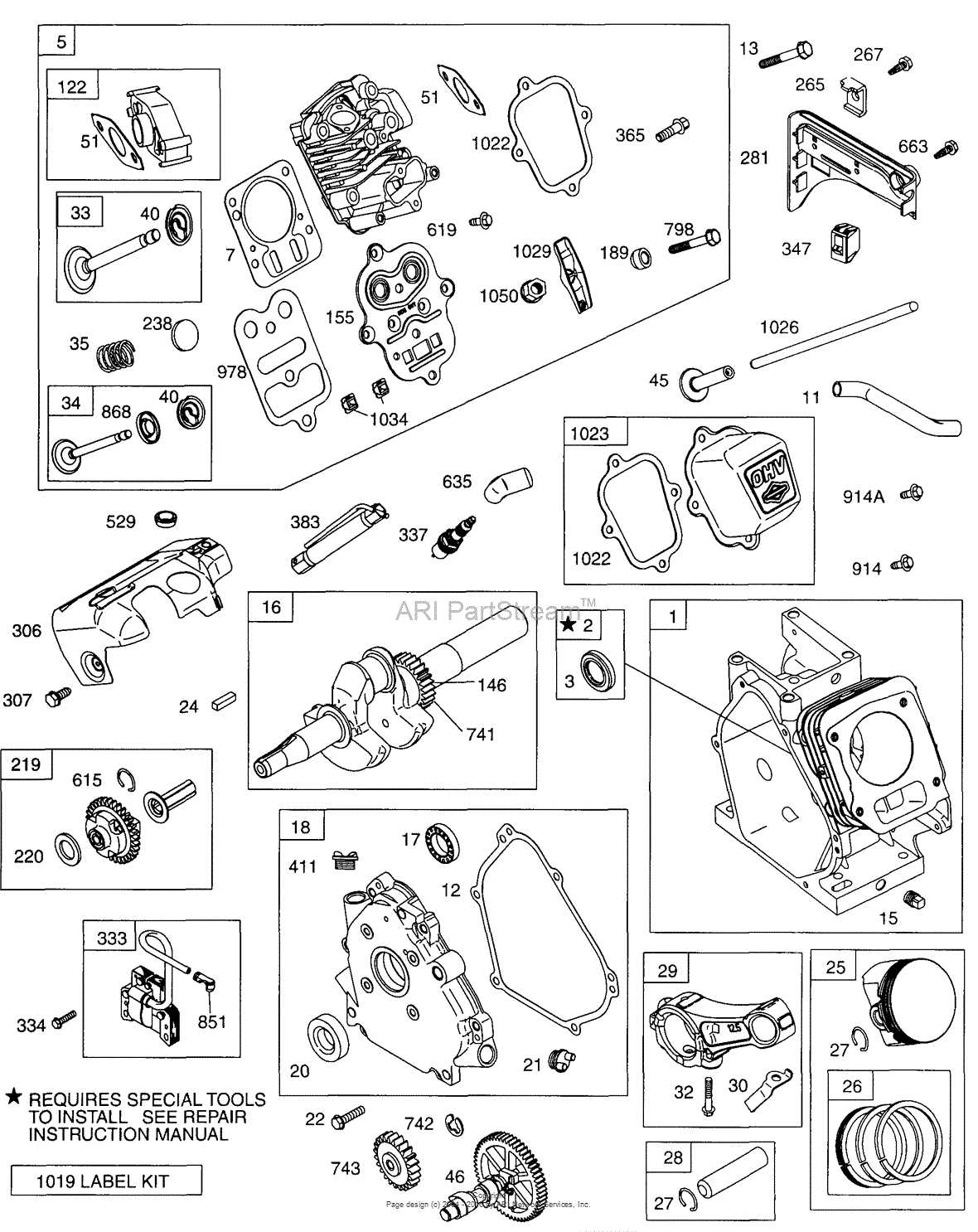

Key Parts of the Engine Assembly

This section focuses on the essential components that make up the assembly of a power unit. Understanding these elements is crucial for maintenance, troubleshooting, and ensuring optimal performance. Each part plays a significant role in the overall functionality and efficiency of the machinery.

Critical Components

- Cylinder Block: This is the main structure that houses various internal parts and is crucial for the combustion process.

- Piston: A vital component that moves up and down within the cylinder, compressing the fuel-air mixture for combustion.

- Crankshaft: Converts the linear motion of the piston into rotational energy, driving the output shaft.

- Valves: These control the intake of the fuel-air mixture and the exhaust of combustion gases, playing a crucial role in the cycle of operation.

- Camshaft: Operates the valves in synchronization with the piston movement, ensuring efficient airflow during the combustion cycle.

Supporting Elements

- Flywheel: Helps maintain the engine’s momentum and smooths out the power delivery.

- Ignition System: Responsible for initiating the combustion process by creating a spark at the right moment.

- Fuel System: Delivers the necessary fuel to the combustion chamber, ensuring the engine receives the right mixture for optimal performance.

- Cooling System: Prevents overheating by circulating coolant, maintaining the operating temperature within safe limits.

Common Engine Maintenance Practices

Regular upkeep is essential for the longevity and performance of any mechanical device. Adhering to a structured maintenance routine helps prevent potential issues, ensuring that the equipment operates smoothly. This section outlines several vital practices that should be incorporated into maintenance schedules to optimize performance and reliability.

Routine Checks and Fluid Changes

One of the most important aspects of maintenance involves frequently inspecting components and replacing fluids. This includes checking oil levels and quality, as well as replacing it as needed. Using the right type of lubricant is crucial for smooth operation. Additionally, coolant levels should be monitored to prevent overheating, while fuel filters should be cleaned or replaced to ensure optimal fuel flow.

Air Filter Maintenance

Another key maintenance practice is keeping the air filter clean. A clogged filter can restrict airflow, negatively impacting efficiency and performance. Regularly checking and replacing the air filter as necessary allows for better combustion and can lead to improved fuel efficiency. By ensuring that the air intake system remains unobstructed, overall functionality is enhanced.

Identifying Engine Issues and Solutions

Recognizing problems with small motors can be crucial for maintaining their performance and longevity. Early detection of irregularities can prevent more severe damage and costly repairs. This section outlines common issues encountered with these machines and practical solutions to address them effectively.

Common Symptoms of Malfunction

Various signs can indicate that a motor is not functioning correctly. For instance, unusual noises, excessive vibrations, or failure to start are often primary indicators of underlying problems. Fuel supply issues, such as clogged filters or empty tanks, can lead to performance declines. Additionally, overheating might stem from a lack of oil or obstructions in the cooling system.

Troubleshooting Steps

To troubleshoot effectively, start by examining the fuel system. Ensure there are no blockages and that the fuel is fresh. Next, inspect the ignition components; faulty spark plugs or connections can prevent the machine from starting. Regular maintenance, including oil changes and air filter replacements, is also essential for optimal operation. If problems persist, consult the manual for specific guidance related to the model in use.

Importance of OEM Replacement Parts

Using original equipment manufacturer (OEM) components is crucial for maintaining the optimal performance and longevity of your machinery. These specific replacements are designed to meet the exact specifications set by the manufacturer, ensuring compatibility and reliability in every operation.

One of the primary advantages of opting for OEM components is the assurance of quality. These items are subjected to rigorous testing and quality control measures, resulting in a higher level of durability compared to generic alternatives. When you invest in OEM components, you can trust that they will function as intended and support the overall efficiency of your machinery.

Moreover, choosing original replacements often leads to better warranty coverage. Many manufacturers stipulate that using non-OEM items can void warranties, potentially leaving you responsible for costly repairs. By selecting OEM components, you can safeguard your investment and maintain the manufacturer’s support for your equipment.

Additionally, OEM components typically offer enhanced performance. They are engineered to work seamlessly with the existing system, minimizing the risk of malfunctions and ensuring that your machinery operates at peak efficiency. This not only helps to prolong the life of the equipment but also contributes to smoother and more effective operation.

In summary, the use of OEM replacements plays a significant role in the maintenance and efficiency of your machinery. Prioritizing these components can lead to improved performance, reliability, and longevity, making them a wise choice for any owner.

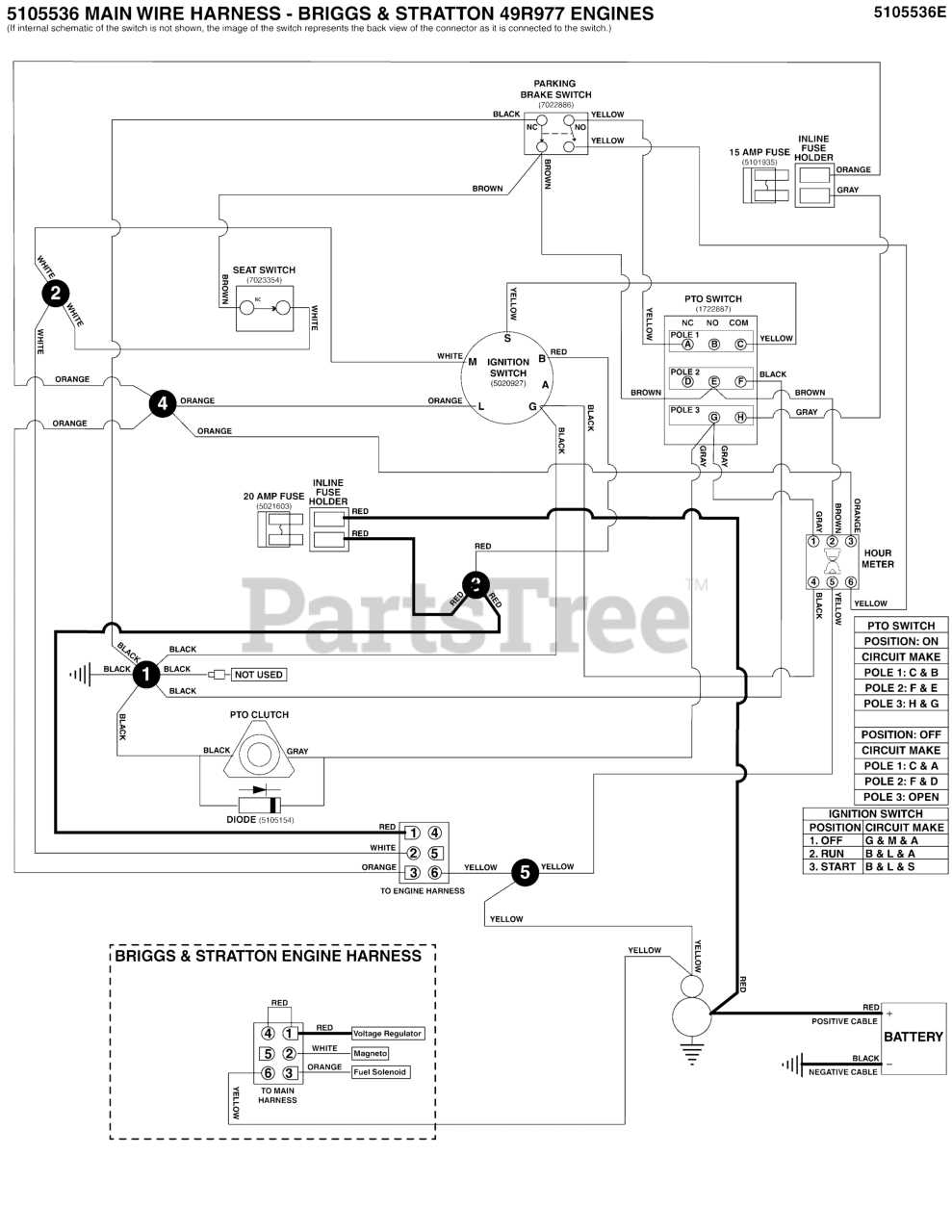

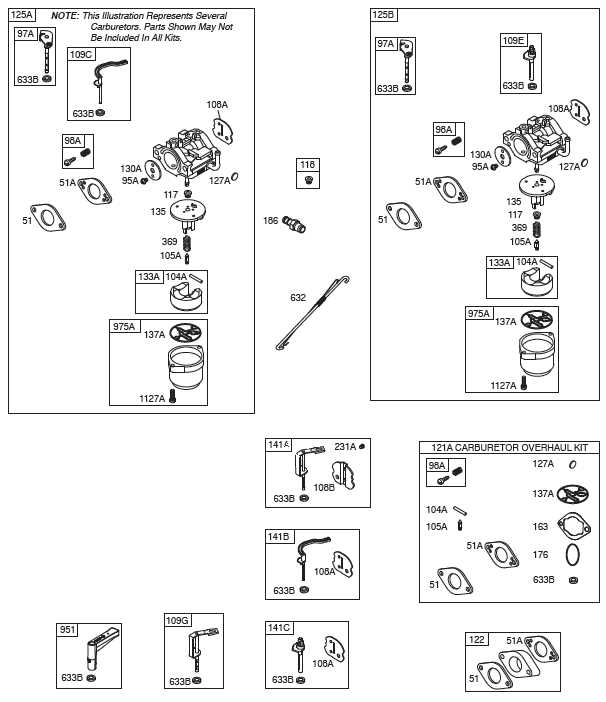

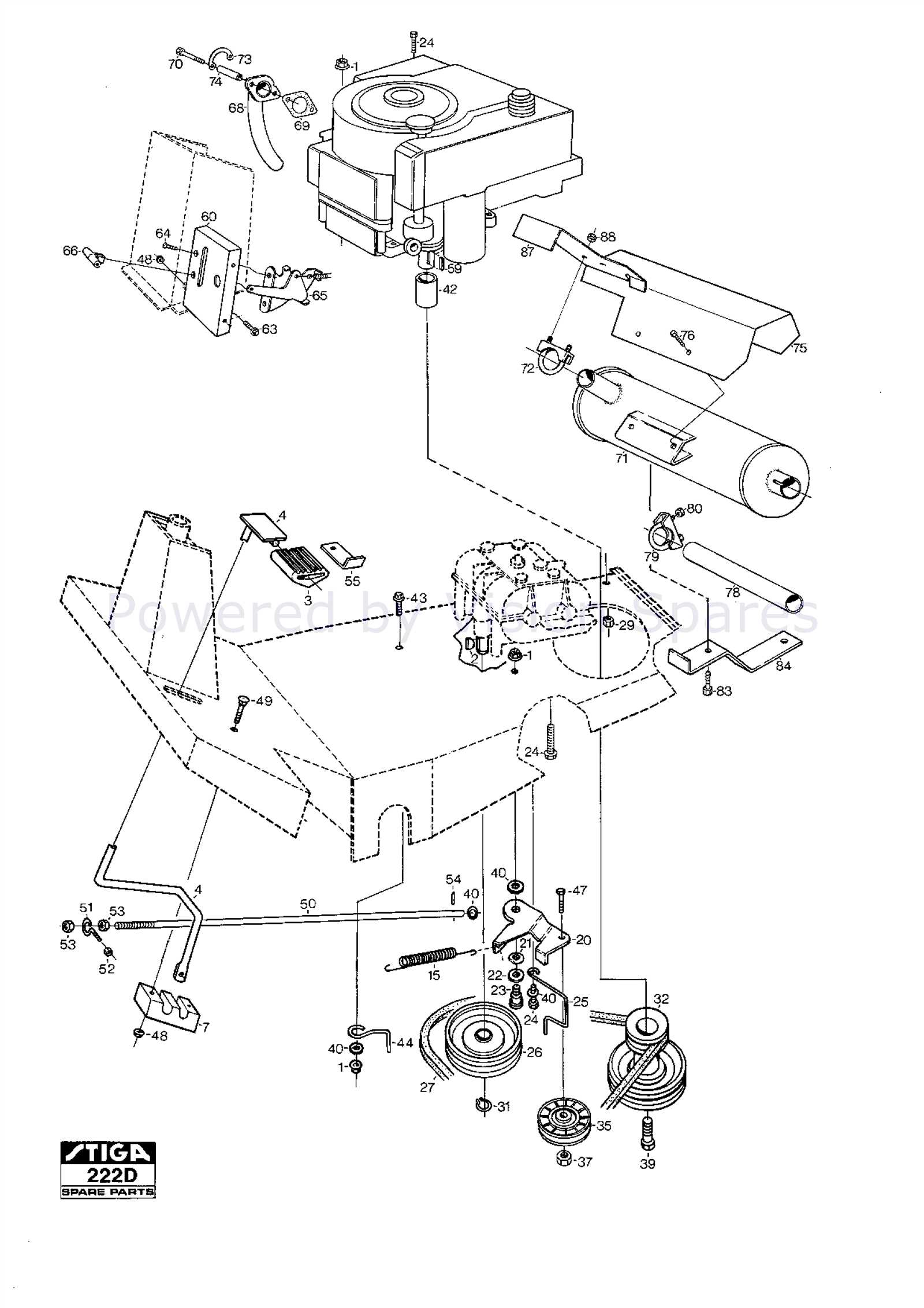

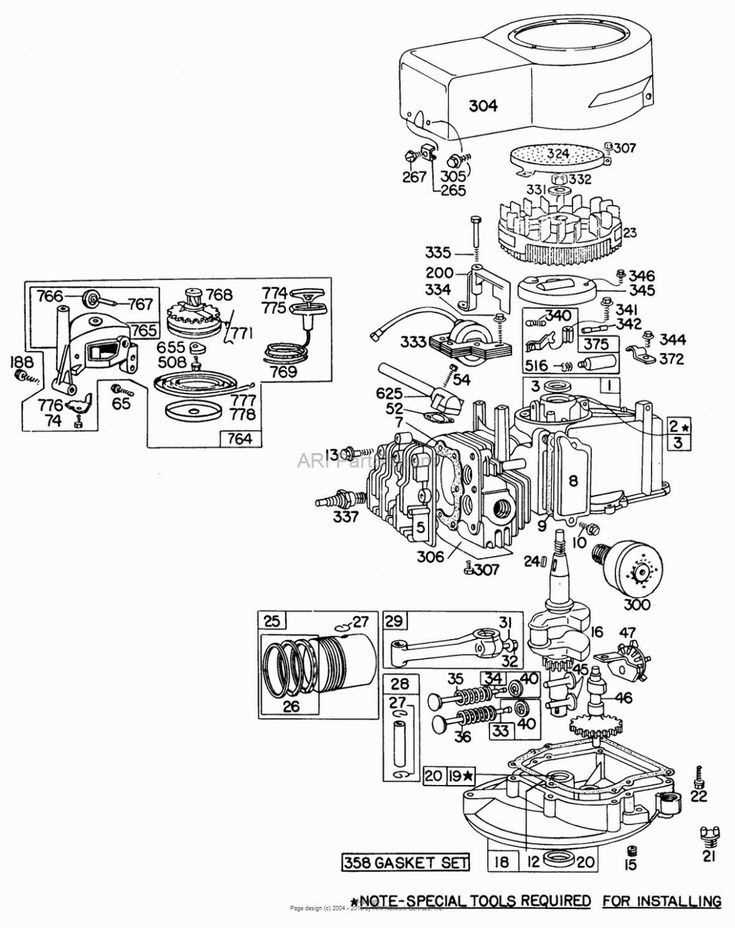

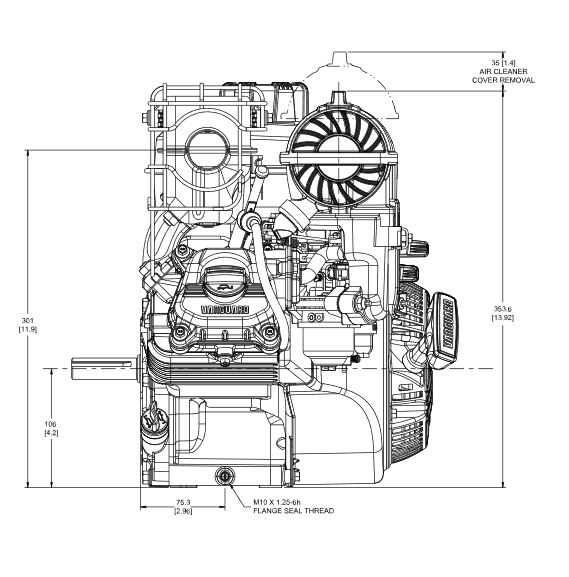

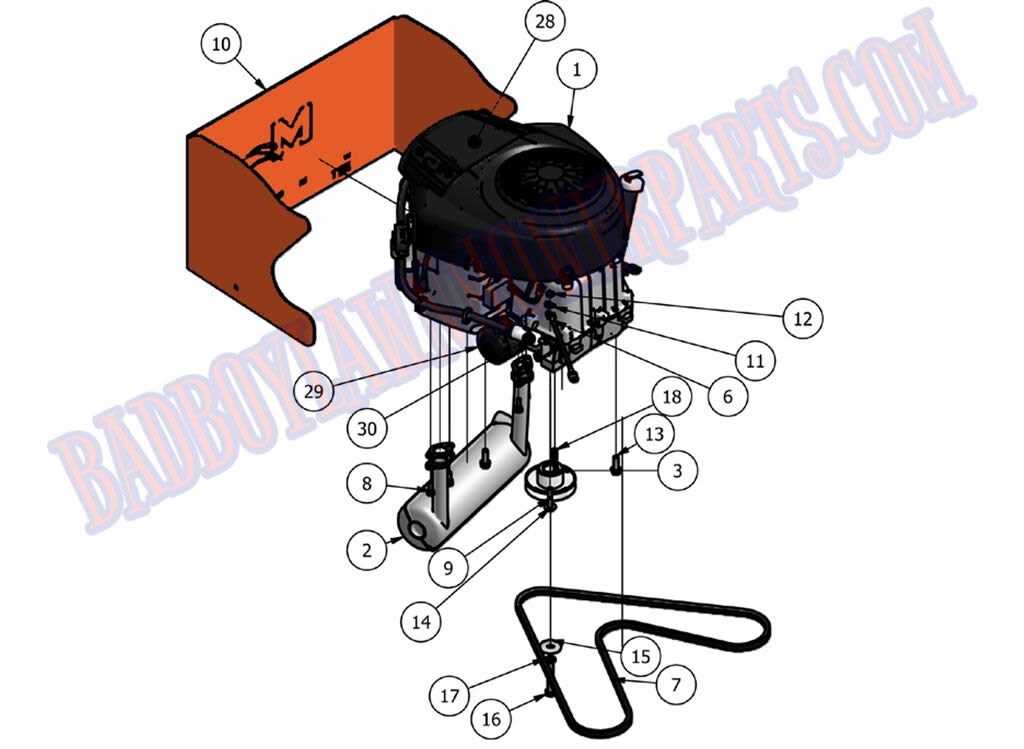

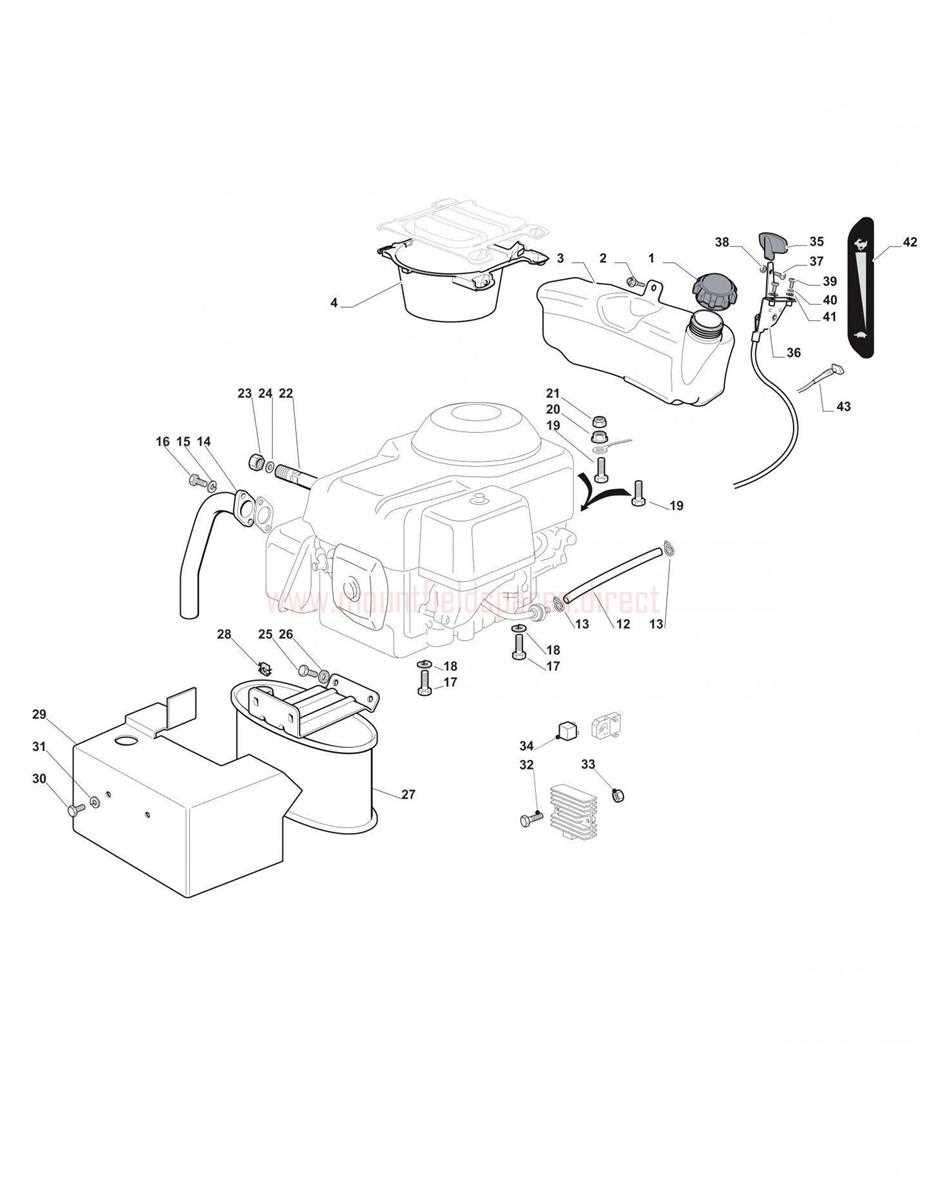

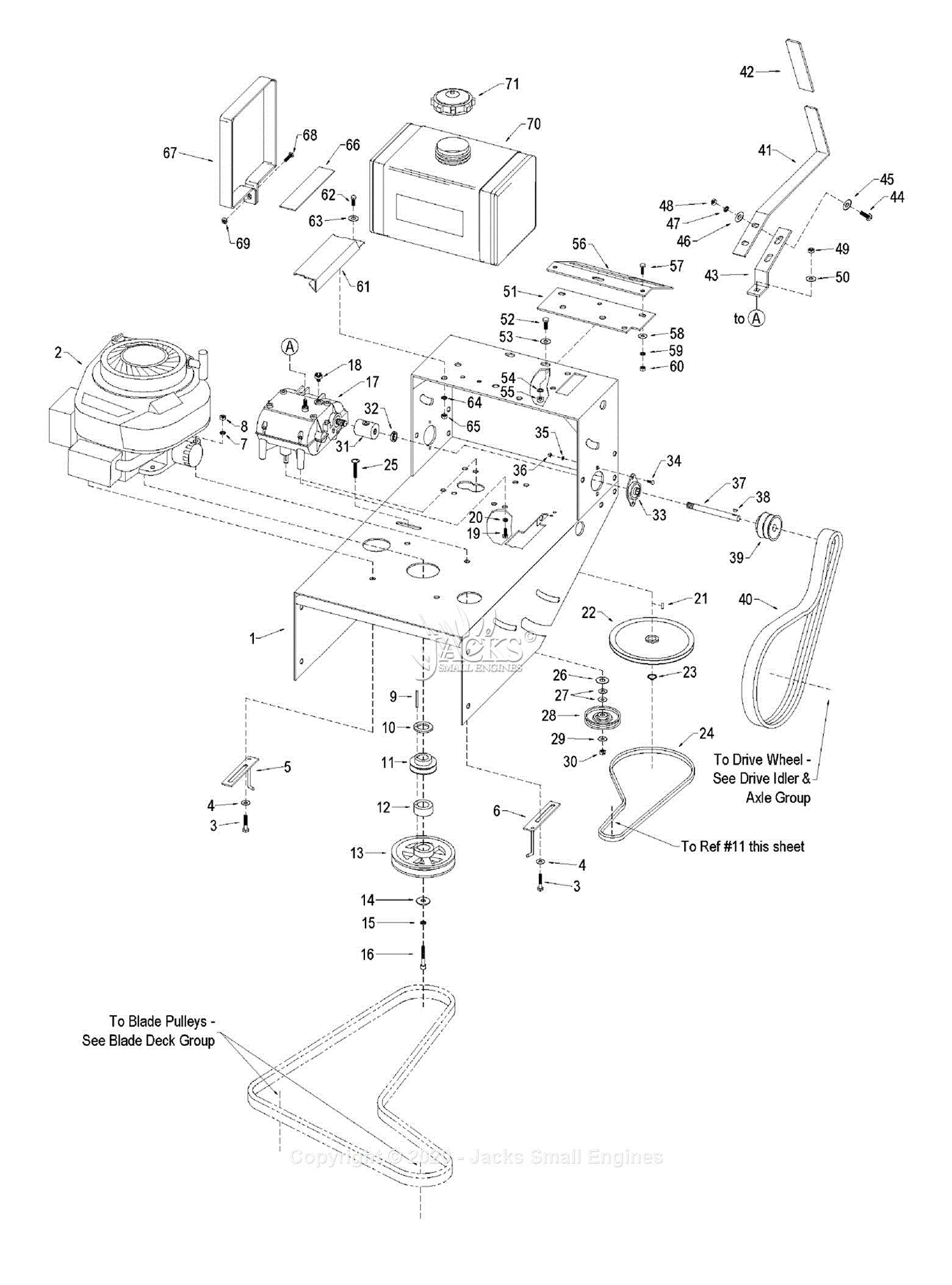

Visual Guide to Engine Diagrams

This section aims to provide a comprehensive overview of visual representations that illustrate various components of small power units. Understanding these illustrations can enhance your knowledge of how these systems function and assist in maintenance tasks.

When examining visual representations, it is essential to recognize the significance of each labeled section. These drawings can often be complex, but breaking them down can make them more accessible. Below are some key elements typically found in such representations:

- Component Identification: Labels indicate specific elements, making it easier to locate and understand their roles.

- Connection Points: Arrows and lines show how different parts interact and connect, providing insight into the system’s functionality.

- Maintenance Areas: Certain regions may be highlighted to indicate where regular upkeep is necessary, aiding in prolonging the unit’s lifespan.

- Assembly Instructions: Some illustrations may include steps for assembling or disassembling components, which can be invaluable for repairs.

By familiarizing yourself with these visual tools, you will enhance your ability to troubleshoot and maintain your equipment effectively. Utilize these illustrations as a reference during repairs or modifications to ensure optimal performance.

Tips for Engine Parts Installation

Installing components of a small motor can be a meticulous task that requires attention to detail and a systematic approach. Proper assembly ensures optimal performance and longevity of the machinery. Understanding the unique characteristics of each component is crucial, as is adhering to recommended procedures and practices.

Preparation and Tools

Before starting the installation, gather all necessary tools and equipment. Ensure that you have the right wrenches, screwdrivers, and any specialized tools that may be required. Review the assembly instructions thoroughly to familiarize yourself with the order of operations. A clean workspace free from debris will help avoid accidents and facilitate a smooth installation process.

Following Manufacturer Guidelines

Always adhere to the manufacturer’s specifications during assembly. Each component may have unique requirements for torque settings and alignment. Misalignment or incorrect torque can lead to premature wear or failure. Take your time to double-check that everything is seated correctly and that all fasteners are tightened according to the guidelines provided.

Resources for Further Learning

Expanding your knowledge about small machinery can greatly enhance your skills in maintenance and repair. There are numerous resources available to help deepen your understanding and provide practical insights into working with these types of equipment.

- Online Tutorials: Various websites offer step-by-step guides and video tutorials that can help you learn how to handle specific tasks effectively.

- User Manuals: Official documentation often contains valuable information on assembly, operation, and troubleshooting. Look for digital copies or download them from reputable sources.

- Community Forums: Joining forums dedicated to small machinery enthusiasts can provide you with access to a wealth of shared knowledge and experiences. Engaging with others can also help resolve specific questions you may have.

- Workshops and Courses: Local vocational schools or community colleges may offer workshops on small machinery maintenance, providing hands-on experience and expert guidance.

Utilizing these resources can significantly enhance your comprehension and skills, making you more proficient in managing various machinery tasks.