The efficiency of modern farming equipment relies on the seamless interaction of various components. Each piece of machinery is designed with precision, ensuring that every part contributes to the overall functionality and performance. Having a clear view of how these elements work together can significantly enhance the operational process, reducing downtime and increasing productivity.

Maintenance and optimization of these machines are crucial for ensuring their long-term functionality. By gaining insight into the arrangement and function of individual pieces, operators can swiftly identify any potential issues, perform timely repairs, and keep the equipment running smoothly. A detailed examination of the structure reveals the key points that require regular attention.

Proper care and regular checks are essential to maintaining the integrity of the system. Understanding the placement and interaction of the machine’s components allows for a more efficient approach to troubleshooting and ensures that the machinery operates at its peak capacity throughout its lifespan.

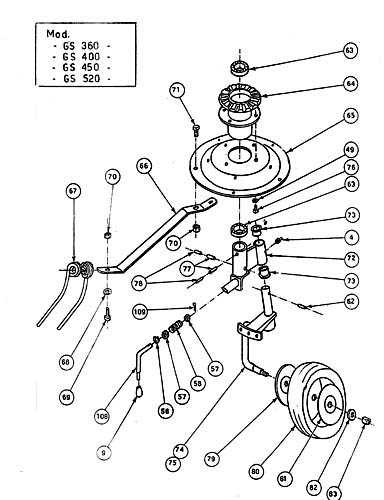

Kuhn Tedder: Key Components Overview

The efficiency and effectiveness of this equipment depend largely on the structure and functionality of its main elements. Each piece plays a crucial role in ensuring smooth operation, whether it’s distributing material evenly or maintaining stability in various working conditions. Understanding the configuration of these components helps in maintaining and optimizing performance over time.

Frame and Support System: The backbone of the machinery, the frame ensures durability and holds all other elements together, providing stability during operation.

Rotary Mechanism: This is responsible for the circular motion that handles the material, ensuring it is evenly spread across the field. Its reliability is key for consistent results.

Adjustable Settings: Customizable features allow for different operating modes depending on the conditions and material type. These adjustments help optimize output and efficiency.

Understanding the Tedder Frame Structure

The frame serves as the foundation for various agricultural machinery, ensuring stability and proper distribution of forces during operation. Its design plays a crucial role in supporting the moving components and maintaining balance, which is essential for effective performance in the field. The structure is engineered to handle stress and provide durability under different working conditions.

Key Components of the Frame

- Main support beam: This element provides the backbone of the structure, connecting various parts and distributing the load evenly.

- Cross members: These horizontal sections reinforce the frame, enhancing its strength and stability.

- Mounting points: Strategically placed areas designed for attaching additional elements or accessories, ensuring secure fit and function.

Importance of Frame Geometry

The geometry of the frame determines how well the machine handles various terrains and workloads. A well-designed structure minimizes stress points and ensures smooth operation, extending the equipment’s lifespan and efficiency.

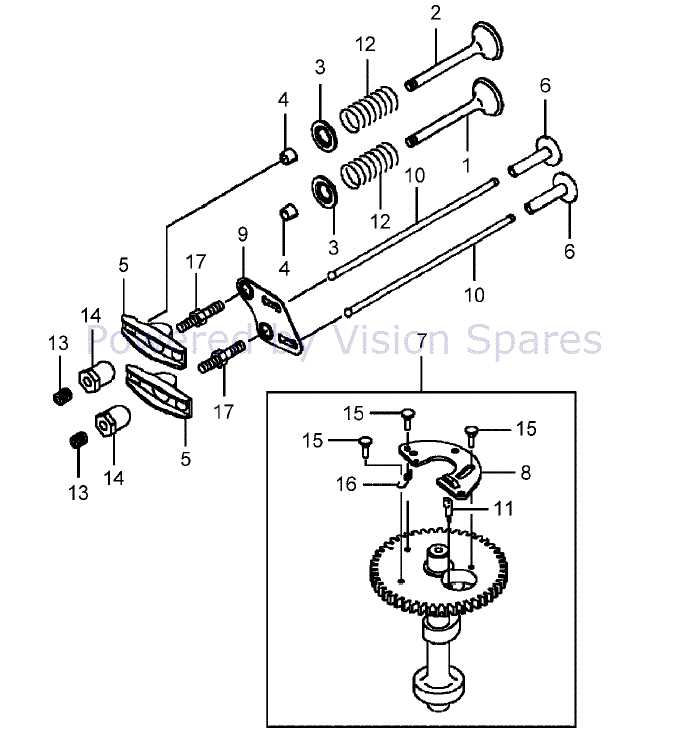

Examining the Gearbox Assembly in Detail

The gearbox assembly plays a crucial role in ensuring the smooth operation of agricultural machinery, transferring power and managing motion efficiently. Understanding its internal components and structure is key to maintaining and optimizing performance.

- Housing and Seals: The outer casing protects the internal components from external elements. Seals are used to prevent any leakage of lubricants and keep contaminants out.

- Gears and Bearings: Inside the housing, gears of various sizes work together to convert speed and torque. Bearings support these moving parts, reducing friction and ensuring smooth rotation.

- Shafts and Couplings: Shafts connect the gearbox to other parts of the system, transmitting power effectively. Couplings ensure secure connections between shafts and other mechanical elements.

- Lubrication System: Proper lubrication is critical for minimizing wear and tear on gears and bearings, extending the lifespan of the assembly.

Regular inspection and maintenance of these components ensure that the gearbox continues to function efficiently under various working conditions.

Identifying the Role of the Tine Arms

The tine arms are essential components of agricultural machinery that contribute significantly to the overall functionality. These arms play a crucial role in the operational effectiveness, ensuring that the tasks are carried out efficiently and consistently. Understanding their role is key to optimizing performance and preventing wear over time.

Main Functions

- Ensure consistent movement during operation

- Support the distribution of materials evenly

- Maintain structural balance of the equipment

Common Issues and Maintenance

- Regular inspection for wear or damage is vital to ensure longevity.

- Replacing damaged arms promptly helps avoid disruptions in operation.

- Lubrication of moving parts can reduce friction and extend the life of the arms.

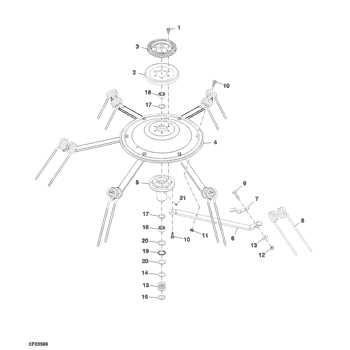

How the Rotor Assembly Functions

The rotor assembly is a vital component in the operation of agricultural equipment. It plays a key role in the overall mechanical process, ensuring smooth and efficient movement during the work cycle. By rotating at a controlled speed, the assembly enables proper airflow and material handling, contributing to the efficiency of the machine.

Main Components of the Rotor

The rotor assembly consists of several key elements that work in unison. These include blades, arms, and the central shaft, each performing a specific task. The blades move in a circular motion, driven by the power of the central shaft, to interact with the material being processed. The arms hold the blades in place and ensure stability during rotation.

Operational Process

As the machine operates, the rotor assembly starts its rotation, which is powered by an internal mechanism. The rotation speed is crucial, as it dictates how efficiently the material is handled. By carefully controlling this speed, the equipment can maintain balance and ensure optimal performance.

| Component | Function |

|---|---|

| Blades | Move material in a circular motion |

| Arms | Hold blades securely during rotation |

| Central Shaft | Powers the rotation of the blades |

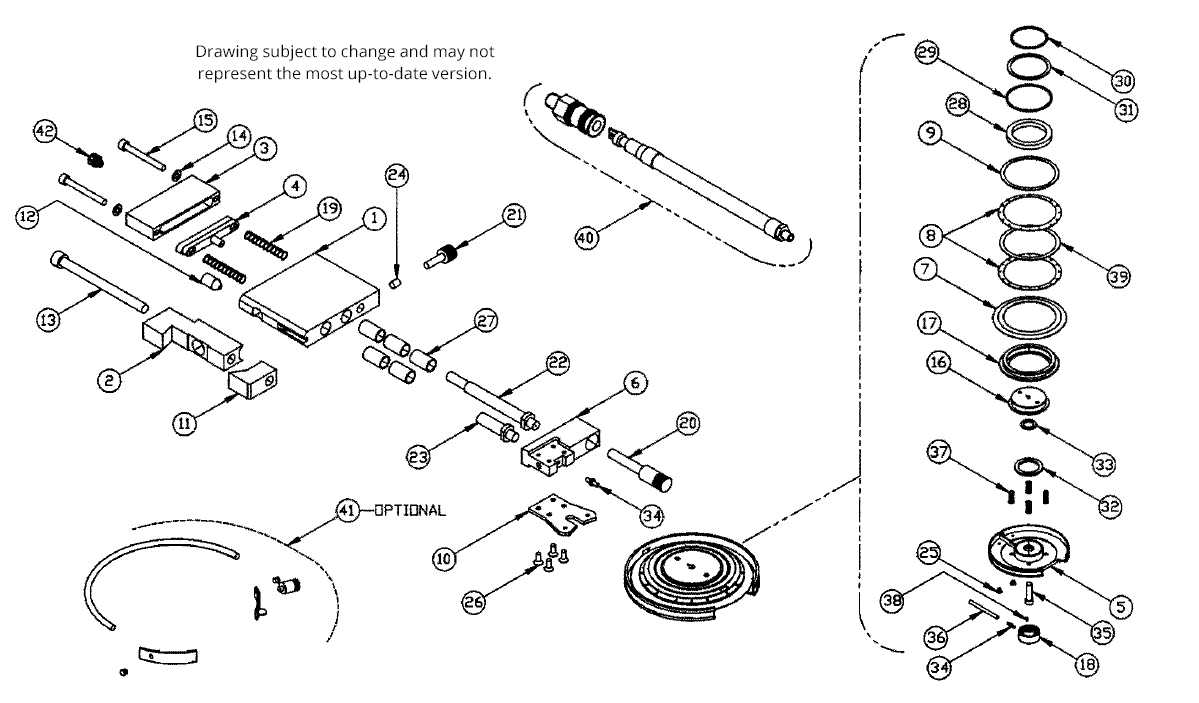

Tedder Drive System Parts Breakdown

The drive mechanism of a forage gathering machine is essential for its efficient operation. Understanding the various components involved helps in maintaining and troubleshooting the system effectively. This section provides an overview of the critical elements that contribute to the drive functionality.

Key components of the drive mechanism include:

- Transmission unit: Converts power from the engine to the working components.

- Drive shafts: Transfer rotational energy between different parts of the system.

- Belts: Facilitate smooth operation by connecting various moving parts.

- Gearbox: Adjusts the speed and torque delivered to the machine’s working elements.

- Clutch system: Engages or disengages power flow as needed for operation.

Each of these components plays a vital role in ensuring the equipment operates efficiently and reliably. Regular inspection and maintenance of these elements can significantly enhance performance and longevity.

Wheel and Axle Components for Stability

The functionality of any agricultural implement heavily relies on its wheel and axle assembly, which plays a crucial role in ensuring balance and maneuverability. These components work together to provide a stable platform that enhances operational efficiency, particularly when navigating uneven terrain. Understanding the interplay between these elements is essential for maintaining optimal performance and extending the lifespan of the equipment.

Key Features of Wheel Assembly

The wheel assembly is designed to support the weight of the implement while allowing for smooth movement. High-quality wheels are essential for reducing friction and ensuring reliable traction. Additionally, the diameter and width of the wheels can significantly affect stability and control, especially in challenging conditions. Choosing the right wheels for specific tasks can lead to improved performance and less wear on the equipment.

Importance of Axle Configuration

The axle configuration contributes greatly to the overall stability of the implement. A properly designed axle helps distribute weight evenly, reducing the risk of tipping and enhancing maneuverability. Various axle types can be employed depending on the application, with considerations for load capacity and environmental factors. Proper maintenance of the axle assembly ensures a long-lasting and reliable operation.

Exploring the Hydraulic System in a Tedder

The hydraulic system plays a crucial role in enhancing the efficiency and functionality of agricultural machinery. This system utilizes fluid power to facilitate various operations, making it an essential component in modern farming practices.

Understanding the intricacies of this system involves examining the key elements that contribute to its performance. Typically, it consists of a pump, hoses, and actuators that work together to convert hydraulic pressure into mechanical force. This conversion enables the machine to perform tasks such as lifting and lowering implements with precision and ease.

Regular maintenance of the hydraulic components is vital to ensure optimal performance and longevity. Checking for leaks, replacing worn hoses, and maintaining the correct fluid levels are essential practices for preventing system failures. Additionally, familiarizing oneself with the layout and function of these components can greatly enhance troubleshooting efforts.

In summary, the hydraulic system is a sophisticated network that significantly improves the operation of farming equipment. By delving into its structure and functionality, operators can maximize efficiency and achieve better results in their agricultural endeavors.

Common Wear Parts and Their Replacement

In any agricultural machinery, specific components are prone to wear and tear due to constant use. Regular inspection and timely replacement of these elements are crucial for maintaining optimal performance and efficiency. Understanding which components typically require attention can help ensure that equipment operates smoothly and minimizes downtime.

Identifying Worn Components

Common items that show signs of wear include those that experience friction, pressure, or contact with soil and crop material. Regularly checking these components for signs of damage or degradation is essential. Some typical indicators of wear may include cracking, excessive bending, or loss of functionality, which necessitates immediate replacement to prevent further damage.

Replacement Tips

When it comes to replacing worn components, it is vital to select high-quality replacements that match the specifications of the original parts. Utilizing appropriate tools and following manufacturer guidelines can streamline the replacement process. Additionally, maintaining a well-organized inventory of essential replacement items can significantly reduce equipment downtime and enhance operational efficiency.