When it comes to maintaining and repairing your cutting tool, having a comprehensive overview of its internal and external components is crucial. An intricate assembly of elements ensures that the machine operates efficiently, providing the power and precision needed for various tasks. Each piece plays a vital role, and knowing their functions can greatly enhance your ability to troubleshoot issues and perform necessary upkeep.

In this guide, we will delve into the various elements that make up a high-performance chainsaw. By breaking down the structure, we aim to provide clarity on how each component interacts with others, ensuring optimal performance. Understanding these relationships can empower users to make informed decisions during maintenance and repairs.

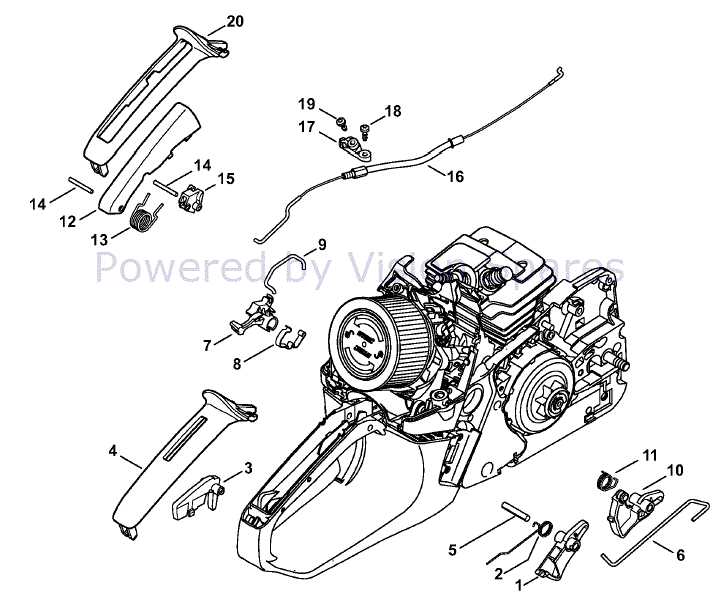

Moreover, visual representations can serve as a helpful reference for identifying parts quickly and accurately. This knowledge not only simplifies the process of locating replacements but also enhances the overall user experience by fostering a deeper connection with the tool. As we explore this topic, you’ll gain insights that will aid in extending the lifespan of your equipment.

Understanding Stihl MS661 Components

Exploring the various elements of a high-performance chainsaw reveals the intricate design and functionality that contribute to its efficiency and reliability. Each component plays a vital role in the overall operation, ensuring that the machine meets the demands of both professional and recreational users.

| Component | Description |

|---|---|

| Engine | The powerhouse that converts fuel into mechanical energy, driving the saw’s cutting performance. |

| Bar | The long metal blade that guides the chain, allowing for precise cuts through various types of wood. |

| Chain | A series of linked teeth that rotate around the bar, designed to slice through material effectively. |

| Fuel System | Includes the tank and lines that deliver fuel to the engine, crucial for operation. |

| Air Filter | Prevents debris from entering the engine, maintaining optimal performance and longevity. |

| Ignition System | Responsible for igniting the fuel-air mixture, ensuring the engine runs smoothly. |

| Clutch | Engages and disengages the chain from the engine, allowing for safe handling during operation. |

| Handle | The part that provides grip and control, essential for maneuverability and safety. |

Understanding these essential elements not only aids in maintenance but also enhances user confidence in operating the equipment effectively. Familiarity with the mechanics behind the machine is key to maximizing its potential in any cutting task.

Key Features of Stihl MS661

This high-performance tool is designed for heavy-duty applications, offering a blend of power and efficiency that meets the demands of both professionals and enthusiasts. With its advanced engineering and innovative design, it provides a reliable solution for cutting tasks in various environments.

Powerful Engine

- High displacement for superior cutting performance

- Efficient fuel consumption, reducing operational costs

- Robust construction ensuring longevity and reliability

User-Friendly Design

- Lightweight frame for improved maneuverability

- Ergonomic handles for enhanced comfort during extended use

- Easy-access maintenance features for convenient upkeep

Importance of Parts Diagrams

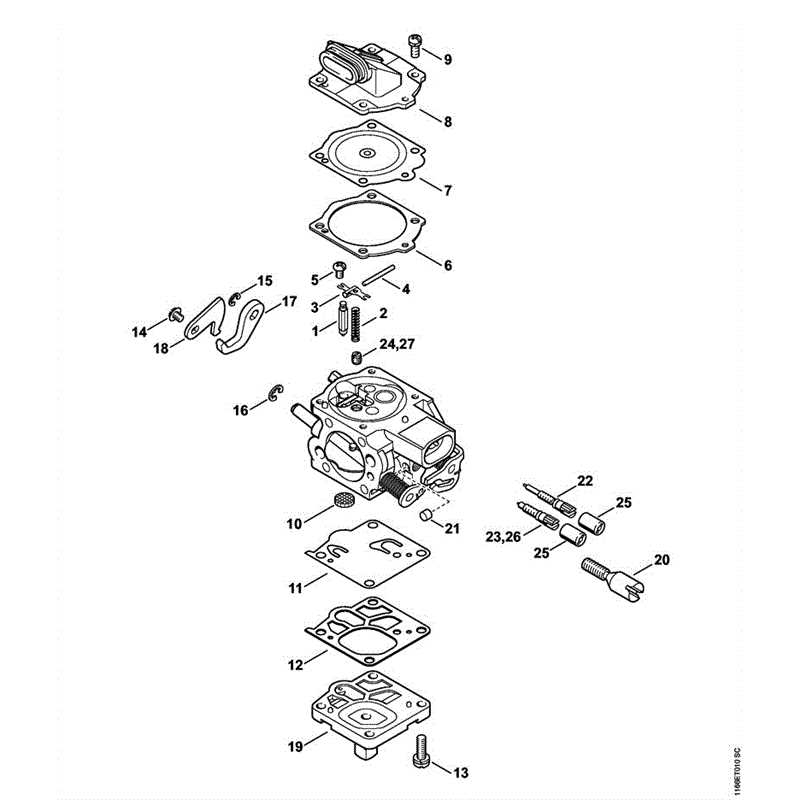

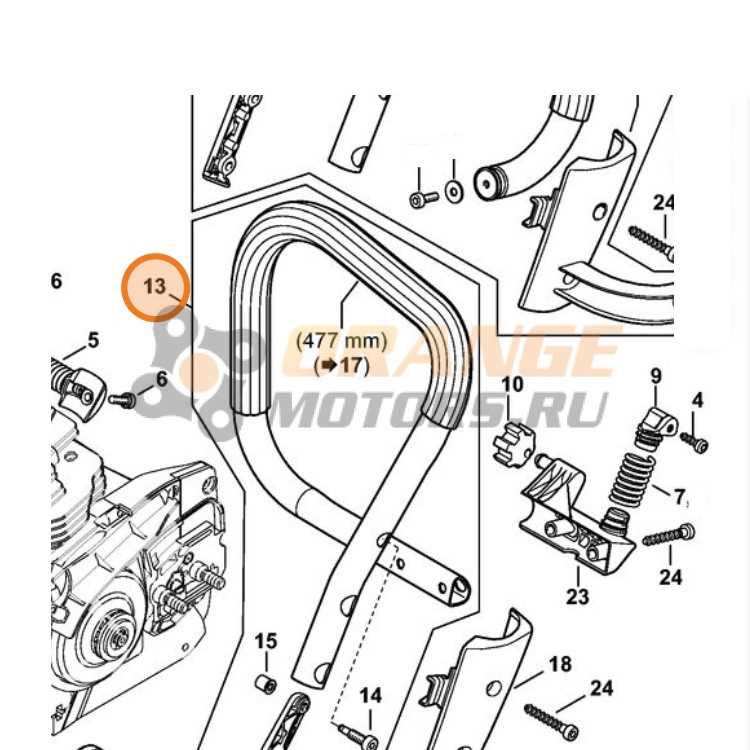

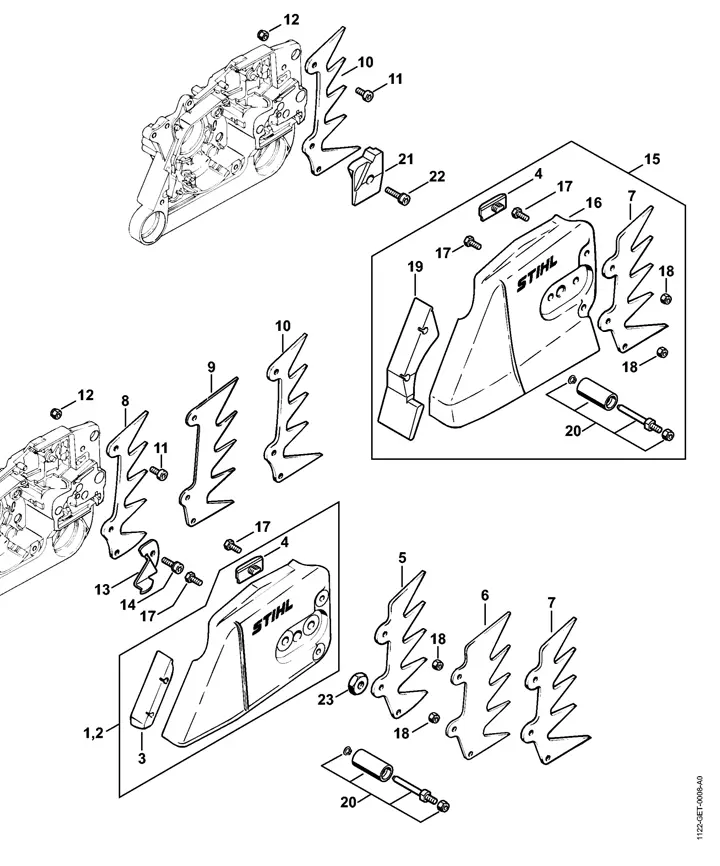

Understanding the intricate details of machinery is essential for effective maintenance and repair. Visual representations of components provide invaluable insights into how each piece interacts within the larger system. These illustrations serve as a crucial reference for both professionals and enthusiasts alike, enabling efficient troubleshooting and assembly.

Enhanced Clarity

Detailed illustrations eliminate ambiguity, ensuring that users can easily identify each element and its purpose. This clarity minimizes errors during repairs, leading to improved performance and longevity of the equipment.

Streamlined Maintenance

By consulting these visual guides, users can plan and execute maintenance tasks with greater confidence. Knowing the exact configuration allows for quicker identification of worn or damaged elements, ultimately reducing downtime and enhancing productivity.

Common Issues with MS661 Parts

Many users encounter various challenges with components of their high-performance tools. Understanding these common problems can help in maintaining optimal functionality and prolonging the lifespan of the equipment.

Frequent Wear and Tear

Over time, certain elements may experience significant deterioration due to regular use. This can lead to decreased efficiency and performance. Regular inspections can help identify wear early and mitigate potential issues.

Improper Assembly

Another prevalent issue arises from incorrect assembly during repairs or replacements. Following manufacturer guidelines is crucial to ensure that every component functions harmoniously, preventing further complications.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These illustrations provide a visual guide to the various elements of a machine, allowing users to identify, organize, and replace parts as needed. By familiarizing yourself with the structure of these graphics, you can streamline your workflow and enhance your overall proficiency.

Start by identifying the layout: Most visuals are organized in a logical manner, often grouping similar components together. Look for clusters that indicate how parts are connected or function in tandem. This can help you understand the assembly’s overall architecture.

Examine the labels: Each element is typically marked with a number or letter that corresponds to a reference list. These annotations are crucial for quickly locating specific items and can save you valuable time during repairs.

Recognize the symbols: Familiarize yourself with common icons and signs that may represent different types of components. This knowledge will aid in deciphering the illustration more efficiently, as not all schematics use the same conventions.

Use the information wisely: Once you grasp the layout, labels, and symbols, apply this knowledge to source replacement items or troubleshoot issues. A comprehensive understanding of the visual guide empowers you to tackle maintenance tasks with confidence.

By following these steps, you will gain a better grasp of how to interpret these visual aids, making your maintenance and repair efforts more effective and efficient.

Where to Find Genuine Parts

Ensuring your equipment operates at peak performance requires access to authentic components. These elements not only enhance functionality but also prolong the lifespan of your machinery. Here are the best avenues to explore when seeking genuine replacements.

Official Dealers

- Visit authorized retailers in your area for the most reliable options.

- Check their online platforms for an extensive inventory.

Manufacturer’s Website

- Browse the official website for detailed information and ordering options.

- Utilize their customer support for inquiries regarding specific components.

By choosing these avenues, you ensure that your equipment receives the ultimate care it deserves.

Maintenance Tips for Stihl MS661

Proper upkeep of your cutting tool ensures longevity and optimal performance. Regular attention to various components not only enhances efficiency but also prevents costly repairs. This guide outlines essential maintenance practices to keep your equipment in peak condition.

Routine Cleaning

After each use, remove debris from the exterior and ensure ventilation areas are clear. Use a soft brush to clean filters and other accessible parts. Neglecting this step can lead to overheating and reduced efficiency.

Regular Inspection

Periodically check key elements such as the chain, bar, and tension settings. Look for signs of wear and replace any damaged components promptly. This proactive approach will significantly enhance the lifespan of your tool and ensure safe operation.

Comparing MS661 with Other Models

This section explores the distinctions between a particular high-performance model and its peers in the industry. By analyzing various aspects such as power output, weight, and user experience, we aim to provide insight into what makes this model stand out among its competitors.

Power and Efficiency

When assessing the power capabilities, this model often excels in delivering robust performance, particularly suited for demanding tasks. In comparison, similar models may offer lower power outputs, which could affect efficiency during extensive usage.

User Experience and Handling

Ergonomics play a crucial role in user satisfaction. This model is designed with comfort in mind, providing superior handling and reduced fatigue, whereas other options may not prioritize user-friendly features to the same extent, making prolonged use less enjoyable.

Upgrades and Modifications Available

Enhancing your equipment can significantly improve its performance and efficiency. Various modifications and upgrades are available to elevate functionality, durability, and user experience. Whether you’re looking to boost power output or increase reliability, there’s an array of options to explore.

Common Enhancements

Several modifications can be implemented, including changes to the engine, exhaust, and fuel systems. These adjustments can lead to noticeable improvements in overall efficiency and effectiveness during operation.

Upgrade Options

| Type of Upgrade | Description |

|---|---|

| Performance Muffler | Reduces back pressure and enhances exhaust flow for better power. |

| Air Filter Upgrade | Increases airflow to the engine, improving combustion and performance. |

| Fuel Mixture Modification | Adjusts the fuel-to-air ratio for optimized engine performance. |

| Bar and Chain Enhancements | Improves cutting efficiency and reduces wear on components. |