In the world of outdoor power equipment, comprehending the intricacies of machinery is essential for effective maintenance and operation. Each unit comprises various elements that work in harmony to ensure optimal performance. A thorough understanding of these components not only aids in troubleshooting but also enhances the overall longevity of the equipment.

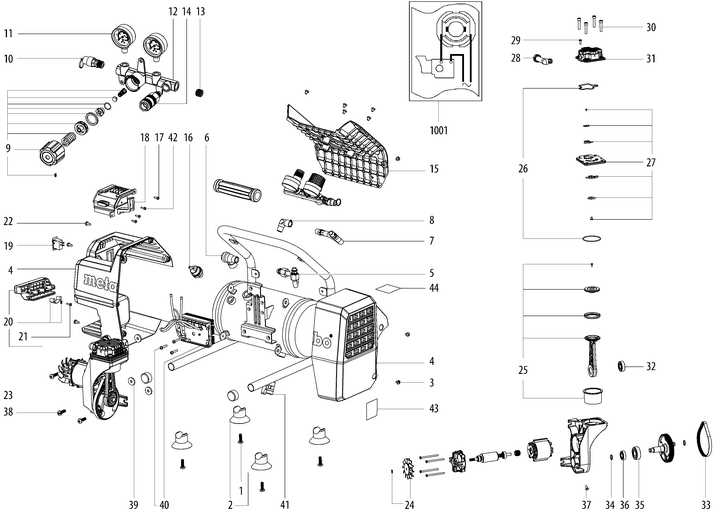

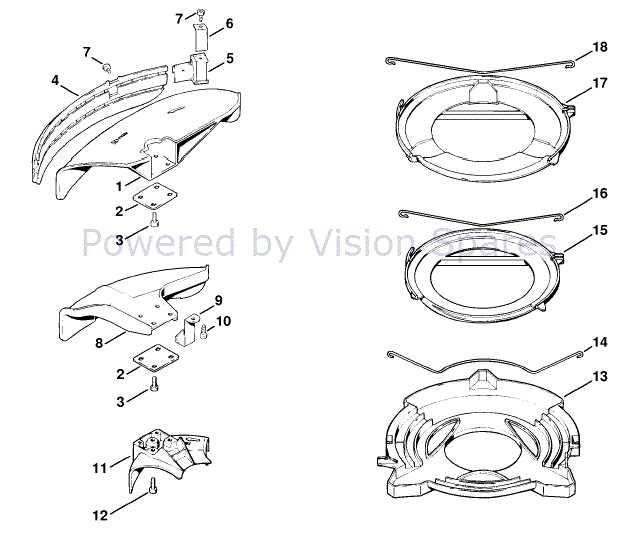

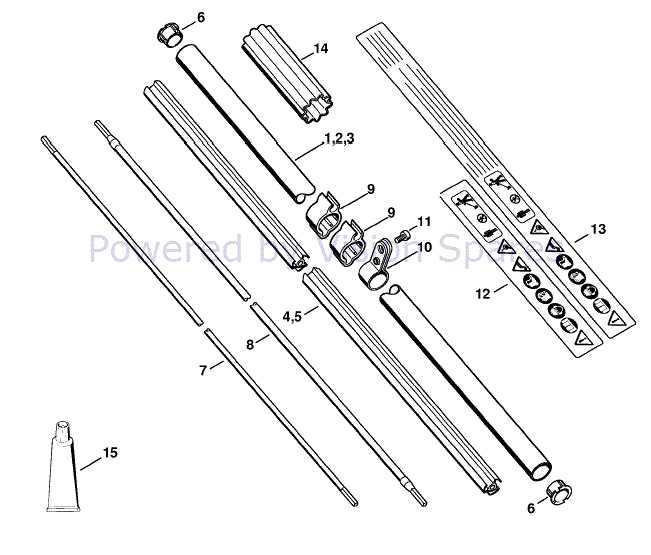

For users and technicians alike, visual representations of these elements can be invaluable. They serve as a roadmap, illustrating how each piece fits together and functions within the system. Familiarity with these layouts empowers individuals to identify specific parts and address issues more efficiently.

By delving into the intricate details of these mechanical systems, enthusiasts can develop a deeper appreciation for the engineering behind their tools. This knowledge is crucial for anyone looking to perform repairs or upgrades, ensuring that they can make informed decisions when it comes to maintenance and replacement.

Understanding Stihl FS100RX Components

The intricate design of a brushcutter includes various essential elements that contribute to its efficient operation. Each component plays a significant role, ensuring the machine performs optimally in diverse tasks. Familiarity with these individual parts enhances the user’s ability to maintain and troubleshoot the equipment effectively.

Powerhead: The powerhouse of the machine, responsible for driving the cutting attachments. Its robust engine ensures reliable performance under various conditions.

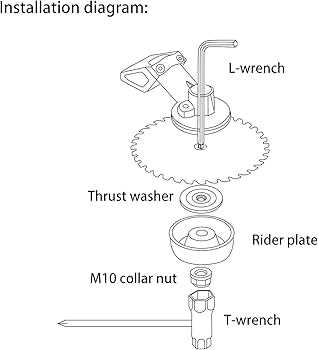

Cutting Head: This part is crucial for executing cutting tasks. Depending on the chosen attachment, it can handle different types of vegetation, from grass to thicker brush.

Shaft: Connecting the powerhead to the cutting head, this component transmits power efficiently, allowing for smooth operation.

Handle: Designed for comfort and control, the handle allows the user to maneuver the equipment easily, reducing fatigue during extended use.

Fuel System: An essential feature that supports the engine, ensuring it operates smoothly. Proper maintenance of this system can greatly affect performance.

Safety Features: Integrated into the design to protect users, these components include shields and automatic shut-off mechanisms, promoting safe operation.

Understanding the function of each part not only aids in effective usage but also in timely repairs and maintenance, ultimately extending the life of the equipment.

Importance of Parts Diagrams

Understanding the components of any machinery is essential for effective maintenance and repair. Visual representations that outline the various elements of a device offer users a clear view of how everything fits together. This clarity not only aids in troubleshooting but also ensures that users can identify specific pieces quickly when replacements or repairs are needed.

Enhanced Troubleshooting

When a machine malfunctions, having a visual reference allows users to pinpoint the source of the problem with greater accuracy. By comparing the physical components with a detailed illustration, one can systematically eliminate potential issues. This targeted approach saves time and reduces the frustration often associated with repairs.

Streamlined Maintenance

Regular upkeep is crucial for the longevity of any equipment. Visual guides provide a comprehensive overview of the various parts that require periodic inspection or servicing. By following these references, users can ensure that all necessary checks are performed, leading to improved performance and reduced downtime.

In summary, having access to accurate visual representations of a machine’s components is invaluable. It fosters a better understanding, facilitates efficient troubleshooting, and promotes effective maintenance practices.

Common Issues with FS100RX Parts

In the realm of outdoor power equipment, certain components can encounter frequent challenges that affect overall performance. Understanding these common difficulties can help users maintain their tools more effectively and ensure longevity. Various elements may require attention, from ignition systems to fuel delivery mechanisms.

Frequent Problems Encountered

Several issues tend to arise with the various components of such machines. Users should be vigilant about signs of wear and tear, as well as improper functioning. Below are some prevalent concerns:

| Component | Common Issues | Symptoms |

|---|---|---|

| Ignition Coil | Weak spark, failure to start | Engine cranks but does not ignite |

| Fuel Filter | Clogging, reduced flow | Engine sputters, loss of power |

| Trimmer Head | Line tangling, rapid wear | Uneven cutting, excessive noise |

| Carburetor | Dirty jets, air leaks | Erratic idling, stalling |

Maintenance Tips

To mitigate these issues, regular maintenance is essential. Keeping components clean, replacing worn parts promptly, and using high-quality fuel can prevent many problems. Additionally, being proactive about inspections can lead to timely interventions and enhanced performance.

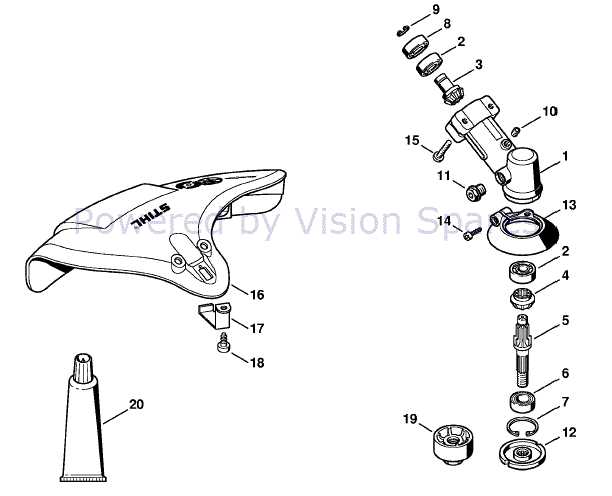

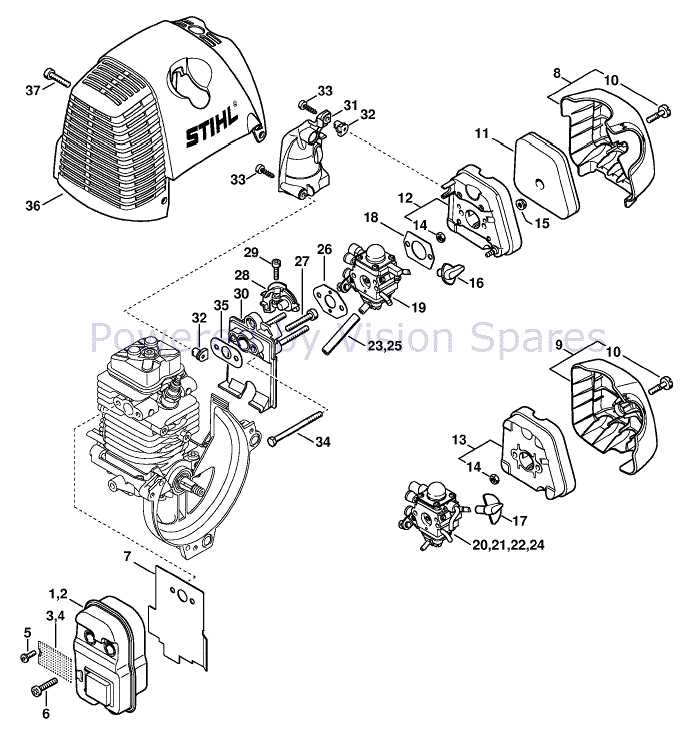

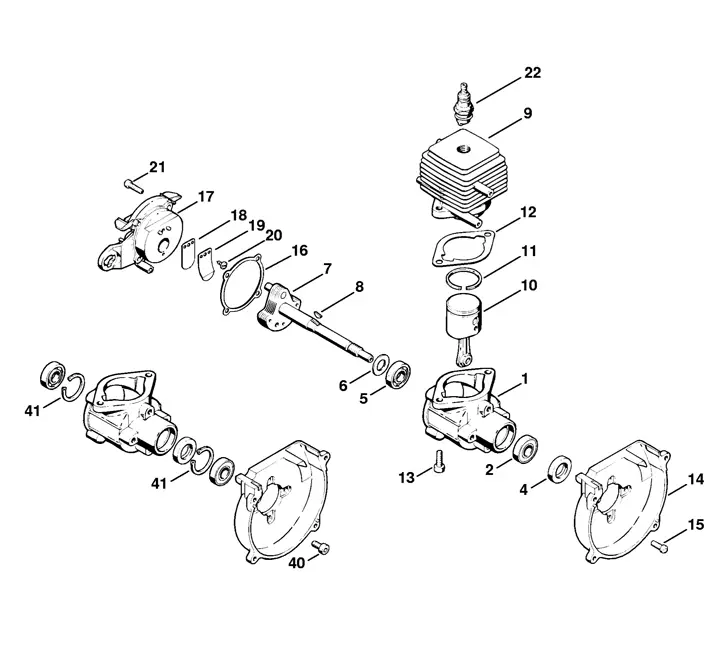

Identifying Parts by Diagram

Understanding the components of your equipment is crucial for effective maintenance and repairs. By using visual representations, you can easily locate and recognize each element, ensuring that you have a comprehensive grasp of the machine’s structure. This approach not only simplifies the identification process but also enhances your ability to troubleshoot issues efficiently.

Visual aids serve as a valuable resource, allowing users to pinpoint specific elements quickly. By studying these illustrations, one can delve into the intricate details of assembly and function, providing clarity on how each part interacts within the system. This knowledge is essential for both novice and experienced operators aiming for optimal performance.

Additionally, referencing these visuals can guide you in sourcing replacements or upgrades, ultimately leading to improved efficiency and longevity of your machinery. Familiarity with the layout equips users with the confidence to undertake repairs or modifications independently.

Where to Find Replacement Parts

When it comes to maintaining outdoor equipment, sourcing quality components is essential for optimal performance. Whether you are looking to restore a machine to its former glory or simply replace a worn-out element, knowing where to search can save time and ensure you get the right items.

Authorized Dealers

One of the most reliable sources for obtaining high-quality components is through authorized distributors. These vendors typically offer original equipment items and can provide expert guidance to ensure compatibility with your device.

Online Marketplaces

The internet has revolutionized the way we shop for equipment components. Numerous online platforms allow you to compare prices, read reviews, and find specific items that may not be available locally. Here’s a quick comparison of some popular options:

| Platform | Pros | Cons |

|---|---|---|

| Manufacturer’s Website | Original items, warranty options | Potentially higher prices |

| eCommerce Sites | Wide selection, user reviews | Quality can vary |

| Local Hardware Stores | Immediate availability, personal service | Limited stock |

Maintenance Tips for Stihl FS100RX

Proper upkeep is essential for ensuring the longevity and efficiency of your outdoor power tool. Regular maintenance not only enhances performance but also prevents costly repairs down the line. Here are some valuable tips to keep your equipment running smoothly.

- Regular Cleaning: After each use, remove debris and grass clippings from the machine. This prevents clogging and helps maintain optimal performance.

- Inspect the Cutting Head: Check for any signs of wear or damage. Replace any worn components promptly to ensure effective cutting.

- Check Fuel and Oil Levels: Always use the recommended fuel mixture. Inspect oil levels frequently to ensure proper lubrication of the engine.

- Sharpen Blades: Dull blades can lead to inefficient cutting. Regularly sharpen or replace blades to maintain cutting efficiency.

- Air Filter Maintenance: Clean or replace the air filter as needed. A clogged filter can restrict airflow and reduce engine performance.

By following these maintenance tips, you can extend the life of your tool and enhance its performance, ensuring it remains reliable for all your outdoor tasks.

How to Use the Parts Diagram

Understanding the components of your equipment is essential for effective maintenance and repairs. A visual representation of the various elements can significantly enhance your ability to identify, locate, and order the necessary items when needed.

Here are some steps to help you effectively navigate this visual guide:

- Familiarize Yourself with the Layout:

- Take a moment to observe the overall structure.

- Identify key sections that group similar components together.

- Locate Specific Elements:

- Use the reference numbers or labels provided to find individual parts.

- Cross-reference with the user manual for descriptions and functions.

- Check Compatibility:

- Ensure that any parts you wish to order are compatible with your model.

- Consult the specifications to verify sizes and types.

- Order with Confidence:

- Once you identify the needed components, make a list.

- Contact your supplier with the list for accurate ordering.

By following these steps, you can effectively utilize the visual representation to maintain and repair your equipment, ensuring optimal performance and longevity.

Upgrading Components for Better Performance

Enhancing the efficiency of your equipment can significantly improve its overall functionality and longevity. By carefully selecting and upgrading certain elements, you can achieve superior power output and reduced operational strain. This process not only boosts performance but also contributes to a more enjoyable user experience.

First, consider replacing standard parts with high-performance alternatives. Upgraded filters and ignition systems can lead to enhanced fuel efficiency and quicker starts. Additionally, investing in lightweight materials for certain components reduces the overall weight, allowing for easier handling and maneuverability.

Furthermore, regularly inspecting and tuning your machine can reveal areas for improvement. Fine-tuning settings and replacing worn-out items can lead to noticeable gains in performance. Ultimately, these adjustments create a more reliable and powerful tool that meets your needs.

Expert Recommendations for Owners

For individuals who own and operate outdoor power equipment, maintaining peak performance is essential for longevity and efficiency. Understanding the key components and their functions can significantly enhance user experience and prolong the life of the machine. Here are some valuable insights to keep your equipment running smoothly.

Regular Maintenance is Key

Routine checks and maintenance are critical. Schedule regular inspections to identify wear and tear before they escalate into more significant issues. Pay particular attention to air filters, spark plugs, and fuel systems, as these can greatly impact performance. Clean or replace components as necessary to ensure optimal operation.

Use Quality Replacement Parts

When it comes time to replace components, always opt for high-quality alternatives. While it may be tempting to choose cheaper options, investing in reliable parts ensures better performance and durability. Quality components often come with warranties, providing peace of mind and assurance in their reliability.