The intricate machinery of outdoor tools can often seem daunting, yet gaining clarity about their inner workings is essential for effective maintenance and operation. Familiarizing oneself with the various elements that constitute these devices can enhance performance and longevity.

In this section, we will explore the vital constituents of a popular model, shedding light on their functions and interconnections. By comprehensively examining each segment, users can better appreciate how these pieces contribute to the overall efficiency of the tool.

Whether you are a seasoned user or a novice, understanding these components is the ultimate key to ensuring your equipment runs smoothly. Let us delve into the specifics and unveil the details that will empower you to make informed decisions regarding care and upkeep.

Understanding the Stihl BG 50

The BG 50 is a powerful tool designed for efficient yard maintenance and landscaping tasks. It combines functionality with ease of use, making it a popular choice among homeowners and professionals alike. This equipment is engineered to provide optimal performance, ensuring that clearing leaves and debris becomes a hassle-free experience.

Key features contribute to its effectiveness. The lightweight design allows for extended use without causing fatigue, while the engine’s power ensures swift completion of tasks. Additionally, its ergonomic handle provides comfort and control, making it accessible for users of varying experience levels.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a robust engine that enhances productivity. |

| Weight | Lightweight design promotes ease of handling and reduces fatigue. |

| Ergonomics | Features an ergonomic grip for comfortable operation. |

| Fuel Efficiency | Designed for optimal fuel consumption, allowing for longer use between refuels. |

Understanding the various components and how they function together can significantly enhance the user experience. By familiarizing oneself with the tool’s mechanisms, operators can ensure it remains in peak condition, thereby extending its lifespan and improving overall performance.

Key Features of the BG 50

The BG 50 stands out for its remarkable combination of performance and user-friendly design. Engineered for efficiency, this model provides powerful air flow while remaining lightweight, making it suitable for a variety of tasks. Its features enhance usability and effectiveness in outdoor maintenance.

Performance and Efficiency

- Robust engine delivers high air velocity for quick debris clearing.

- Fuel-efficient operation minimizes downtime and running costs.

- Ergonomic design reduces fatigue during prolonged use.

User-Centric Features

- Easy-to-access controls for seamless operation.

- Adjustable air speed settings for customized performance.

- Compact design allows for easy storage and transportation.

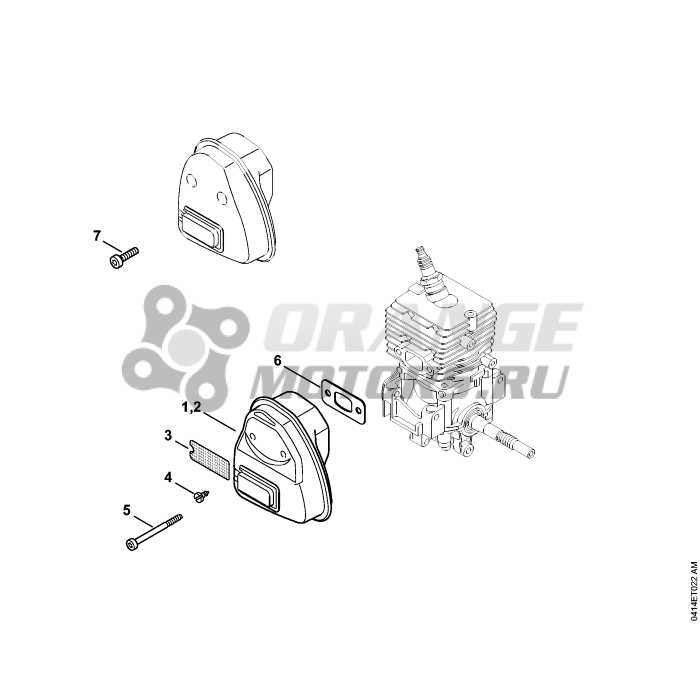

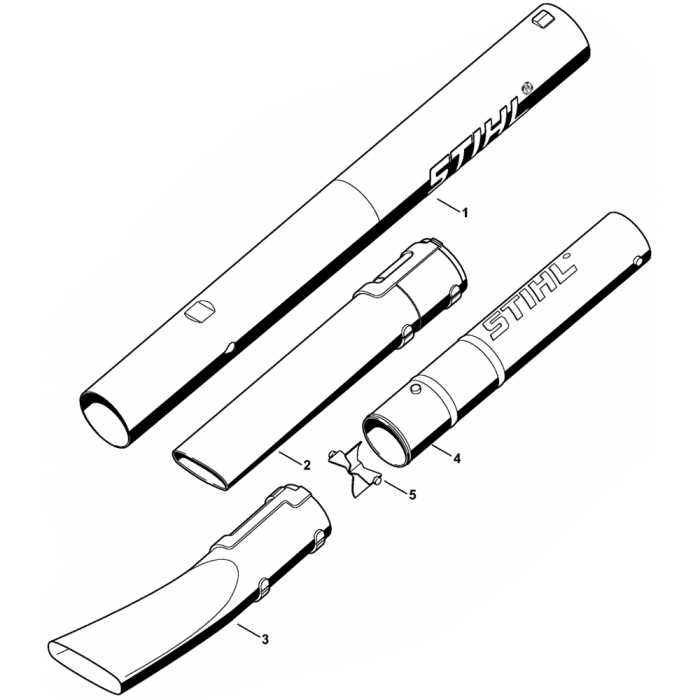

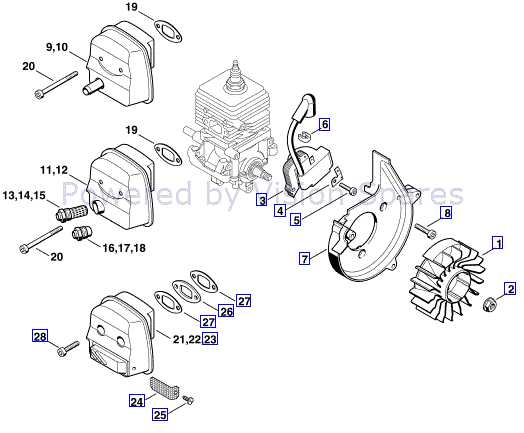

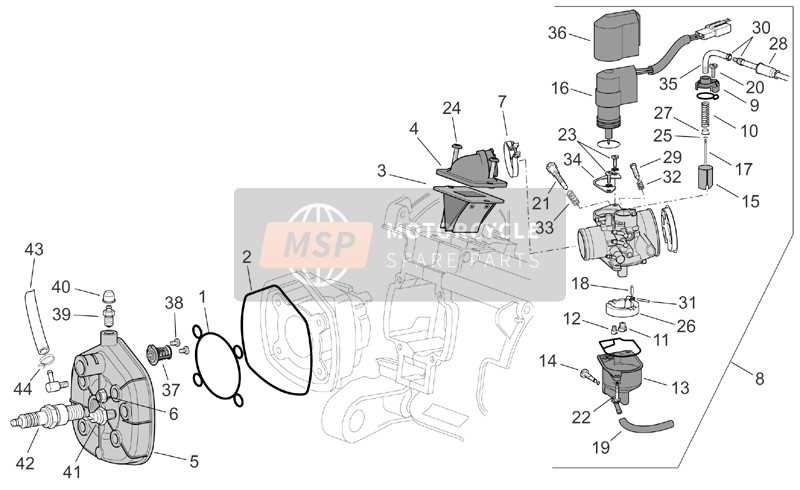

Importance of Parts Diagrams

Visual representations of components are crucial for understanding the structure and functionality of machinery. They provide an organized view that helps users identify various elements and their relationships within a system. By utilizing these illustrations, individuals can enhance their comprehension and maintenance of equipment, leading to improved performance and longevity.

Facilitating Repairs: When an issue arises, having access to detailed visuals allows technicians to quickly locate and assess the necessary components. This streamlines the repair process, saving both time and effort. Moreover, it reduces the risk of overlooking essential elements that could lead to further complications.

Enhancing Assembly: For those assembling equipment, these visuals serve as a guide to ensure correct placement and orientation of each part. This clarity prevents mistakes that could compromise the machine’s integrity and functionality.

Educational Value: For beginners or those unfamiliar with specific machinery, these illustrations provide an educational resource. They help individuals grasp the intricacies of the device, fostering a deeper understanding of how each part contributes to the overall operation.

Inventory Management: Visual guides also aid in inventory management by allowing users to identify missing or damaged components easily. This proactive approach ensures that all necessary items are available for seamless operation.

In summary, visual representations are indispensable tools that not only facilitate repair and assembly but also enhance understanding and management of machinery. Their role is vital in promoting efficiency and effectiveness in both professional and personal maintenance tasks.

Common Components in the BG 50

The efficient operation of a blower relies on several key elements working in harmony. Understanding these components not only aids in maintenance but also enhances overall performance. Each part plays a vital role in ensuring that the device operates smoothly and effectively, providing the user with a reliable tool for outdoor tasks.

Engine: The heart of the blower, the engine, converts fuel into mechanical energy, driving the airflow necessary for effective debris removal. Regular checks and maintenance of this component are crucial for optimal function.

Fan: The fan is responsible for creating the powerful air current that characterizes this equipment. Its design allows for maximum air movement, making it essential for achieving desired results in various applications.

Fuel System: This system includes the fuel tank, lines, and carburetor, working together to supply the engine with the necessary fuel mix. Ensuring these parts are clean and functional helps maintain engine efficiency.

Air Filter: The air filter plays a critical role in preventing debris from entering the engine, protecting it from damage. Regular replacement of the filter ensures that the engine receives clean air for combustion.

Ignition System: The ignition system, comprising the spark plug and coil, is vital for starting the engine and maintaining its operation. A well-functioning ignition system ensures reliable starting and consistent performance.

Handle and Controls: These components provide the user with the ability to operate the blower comfortably and efficiently. Proper ergonomics and responsiveness of the controls enhance user experience during operation.

Understanding these essential components not only assists in troubleshooting but also promotes effective care, ensuring the longevity and efficiency of the blower.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual aids provide a detailed representation of components and their arrangement, helping users identify and source the necessary elements for their equipment. Familiarity with these representations can significantly enhance troubleshooting and assembly processes.

To effectively interpret these visuals, it’s important to recognize key features such as labels, numbering systems, and color coding. These elements guide users in pinpointing specific components and understanding their relationships within the overall structure.

| Feature | Description |

|---|---|

| Labels | Identifying markers that specify the name or function of each element. |

| Numbering | Sequential numbers that correspond to a list, providing a clear reference for ordering. |

| Color Coding | Different colors used to indicate specific categories, such as types of components or assembly stages. |

By paying attention to these aspects, one can navigate through the illustrations with ease, ensuring efficient identification and procurement of required elements. This knowledge empowers users to tackle maintenance tasks confidently, contributing to the longevity and performance of their equipment.

Maintenance Tips for Your Blower

Keeping your blower in optimal condition ensures efficiency and longevity. Regular upkeep can prevent performance issues and extend the lifespan of your equipment. Here are essential tips to help you maintain your blower effectively.

Regular Cleaning

After each use, it’s important to clean the exterior of the device. Remove any debris or dirt that may have accumulated on the casing and air intake. This prevents blockages and maintains airflow. Additionally, ensure that the air filter is free of dust and dirt. Cleaning or replacing the filter regularly enhances performance and reduces strain on the motor.

Check Fuel and Oil Levels

For models that require fuel, always use the recommended type and check the levels before operation. Running a blower on low fuel can lead to engine damage. If your device has a two-stroke engine, make sure to mix oil as specified. Regularly inspect the oil levels to ensure proper lubrication, preventing wear and tear on internal components.

By following these maintenance tips, you can ensure that your blower remains a reliable tool for all your outdoor needs.

Where to Find Replacement Parts

Locating the necessary components for your equipment can be straightforward with the right resources. Whether you are looking to restore functionality or enhance performance, knowing where to search is crucial.

Here are some effective avenues to explore:

- Official Retailers: Start with authorized dealers who offer genuine components. They often provide warranties and assurances of quality.

- Online Marketplaces: Websites like eBay, Amazon, and specialized platforms offer a wide variety of options. Be sure to check seller ratings and reviews.

- Local Hardware Stores: Many local stores stock common items or can order them for you. It’s worth checking their inventory.

- Second-Hand Shops: Consider thrift stores or salvage yards. You might find used components at a fraction of the cost.

- Manufacturer’s Website: Many manufacturers have online catalogs where you can order directly from them.

By exploring these options, you can easily find what you need to keep your equipment running smoothly.

Repairing Common Issues

Addressing frequent problems with outdoor equipment can greatly enhance its performance and longevity. Understanding the underlying causes of these issues is crucial for effective troubleshooting. Regular maintenance and prompt repairs not only improve functionality but also prevent further damage.

One common issue is difficulty starting the machine. This can often be attributed to fuel-related problems or a faulty ignition system. Checking the fuel quality, ensuring it is fresh and free from contaminants, is essential. Additionally, examining the spark plug for wear or damage can reveal whether a replacement is needed.

Another frequent concern involves inadequate power output. This may result from a clogged air filter or issues with the carburetor. Cleaning or replacing the air filter can significantly enhance airflow, while adjusting or servicing the carburetor can restore optimal fuel delivery.

Lastly, vibrations during operation can indicate loose components or worn parts. Inspecting the housing and tightening any loose screws or bolts is a good first step. If the vibrations persist, further examination of the internal components may be necessary to identify any damaged elements.

By systematically addressing these common challenges, users can ensure their equipment operates smoothly and efficiently, ultimately extending its useful life.

Upgrading Your Stihl Equipment

Enhancing your outdoor tools can significantly improve performance and efficiency. Whether for professional use or personal projects, upgrading components can lead to better results and a more enjoyable experience. Understanding the various options available and how they can impact your equipment’s functionality is essential for making informed choices.

Benefits of Upgrading

Upgrading your tools can provide numerous advantages. Improved durability, enhanced power, and increased ease of use are just a few of the benefits. Additionally, modern enhancements often lead to better fuel efficiency and lower emissions, contributing to a more environmentally friendly approach to yard work.

Common Upgrade Options

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | High-performance engines | Increased power output |

| Blades | Replacement or specialty blades | Improved cutting efficiency |

| Filters | High-flow air and fuel filters | Better air intake and fuel efficiency |

| Handles | Ergonomic grips | Enhanced comfort during use |

| Safety features | Upgraded guards and shields | Increased user safety |

Investing in upgrades can transform your tools, making them more reliable and effective for any task. Consider what enhancements align best with your needs to ensure optimal performance.